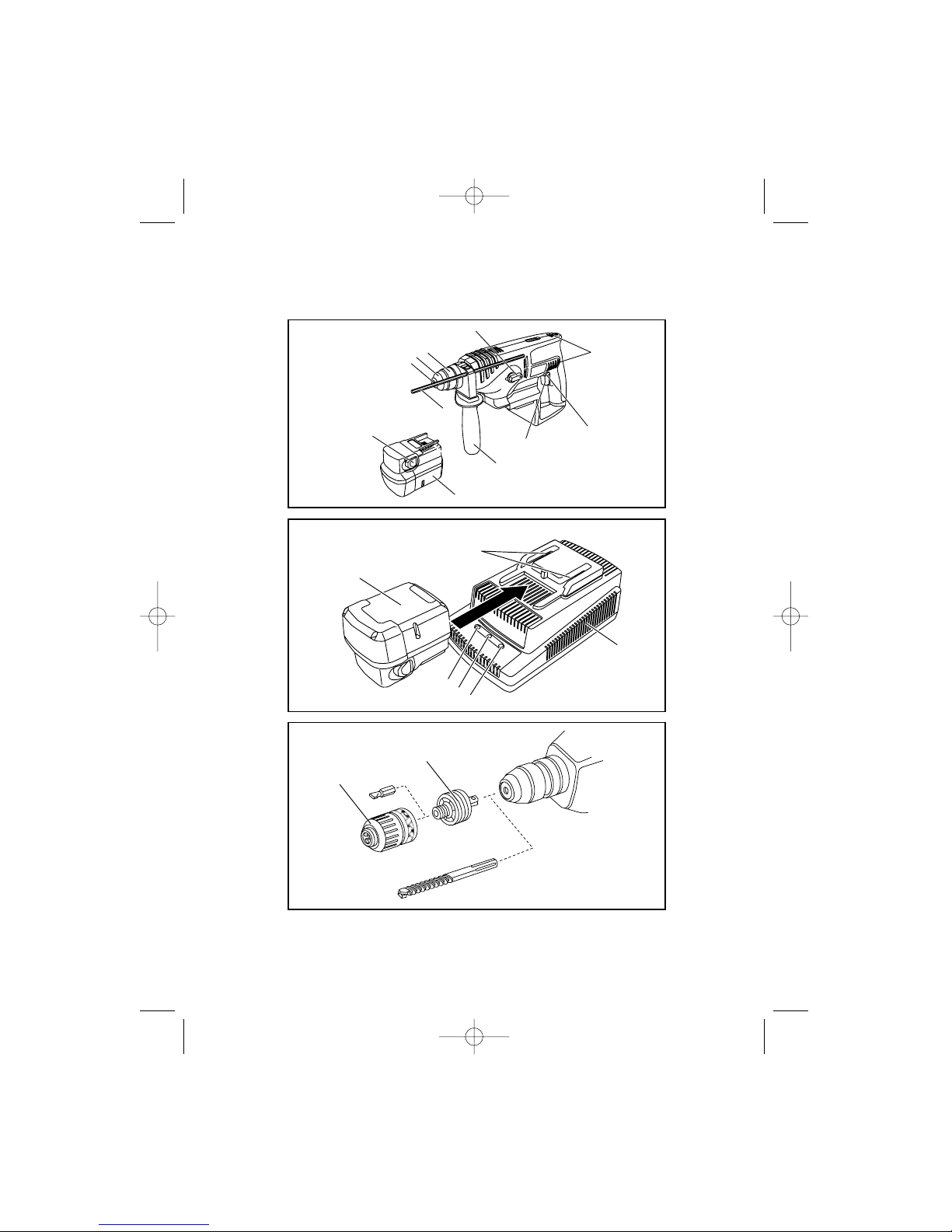

The battery-powered pneumatic hammer drill can be

used universally for hammer drilling and drilling as well

as for screwdriving in wood, metal and plastic. This

pneumatic hammer dill is not suited for chiselling work

(also not with pointed chisels).

WARNING

When using battery-driven tools basic safety

precautions are to be taken, including the

following, in order to reduce the risk of fire,

batteries leaking and persons becoming injured.

Before operating the machine, please read the operating

instructions completely, follow the Safety Instructions in

this manual as well as the general Safety Instructions for

Power Tools.

Important instructions, which should be read before

starting operation, and which we strongly

recommend observing:

Keep work area clean. Cluttered areas and benches

invite injuries.

Keep children away. Do not let visitors touch the tool.

All visitors should be kept away from area.

Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool. Do not

use tool for purposes not intended.

Dress properly. Do not wear loose clothing or

jewellery, they can be caught in moving parts. Rubber

gloves and non-skid footwear are recommended

when working outdoors. Wear protecting hair

covering to contain long hair.

Secure work. Use clamps or vice to hold the work.

It is safer than using your hand and it frees both

hands to operate the tool.

Do not overreach. Keep proper footing and balance

at all times.

Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you tired.

Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate

properly and perform its intended function. Check for

alignment breakage of parts, mounting and any other

conditions that may affect its operation. A guard or

other parts that is damaged should be properly

repaired or replaced by an authorised service centre

unless otherwise indicated in this instruction manual.

Have defective switches replaced by an authorised

service facility. Do not use the tool if the switch does

not turn it on and off.

Disposal of battery. Ensure battery is disposal of

safely as instructed by the manufacturer.

For charging the batteries, only use a charger

which is recommended by the manufacturer and

never use the recommended charger to charge other

electrical equipment.

Never carry the tool with your finger on the switch.

Before commencing any work on the machine

itself, remove the battery.

Do not use any defective or deformed batteries.

Any machines and batteries that are not being

used should be kept separately in a dry place that

is high up or locked, out of the reach of children.

For safety's sake, a battery charger connected to the

mains should also be permanently supervised.

Do not expose the machine, battery and battery

charger to rain. Do not use the machines in a wet or

damp environment.

Always keep the battery and battery charger clean

and dry.

Do not open the battery and protect from impact.

Protect the battery from heat and fire: Danger of

explosion! Do not place the battery on radiators or

expose to strong sun rays for a longer time;

temperatures over 50 °C cause damage.

In extreme conditions battery fluid can leak out.

This does not mean it is defective. If in such a case

the casing is no longer sealed and battery fluid comes

into contact with the skin, proceed as follows:

- Wash affected skin immediately with soap and water.

- Neutralise the battery fluid with vinegar or lemon juice.

- If the eyes are affected, rinse with clear water with

at least 10 minutes. Consult a doctor immediately!

Before connecting the charger to the mains,

please check that the voltage of your mains

connection corresponds to the voltage stated on

the name plate of the charger.

Always inspect the plug and cable before use.

If damaged, they must be replaced by a qualified

professionals.

Caution

High voltage: Do not open the battery charger!

2