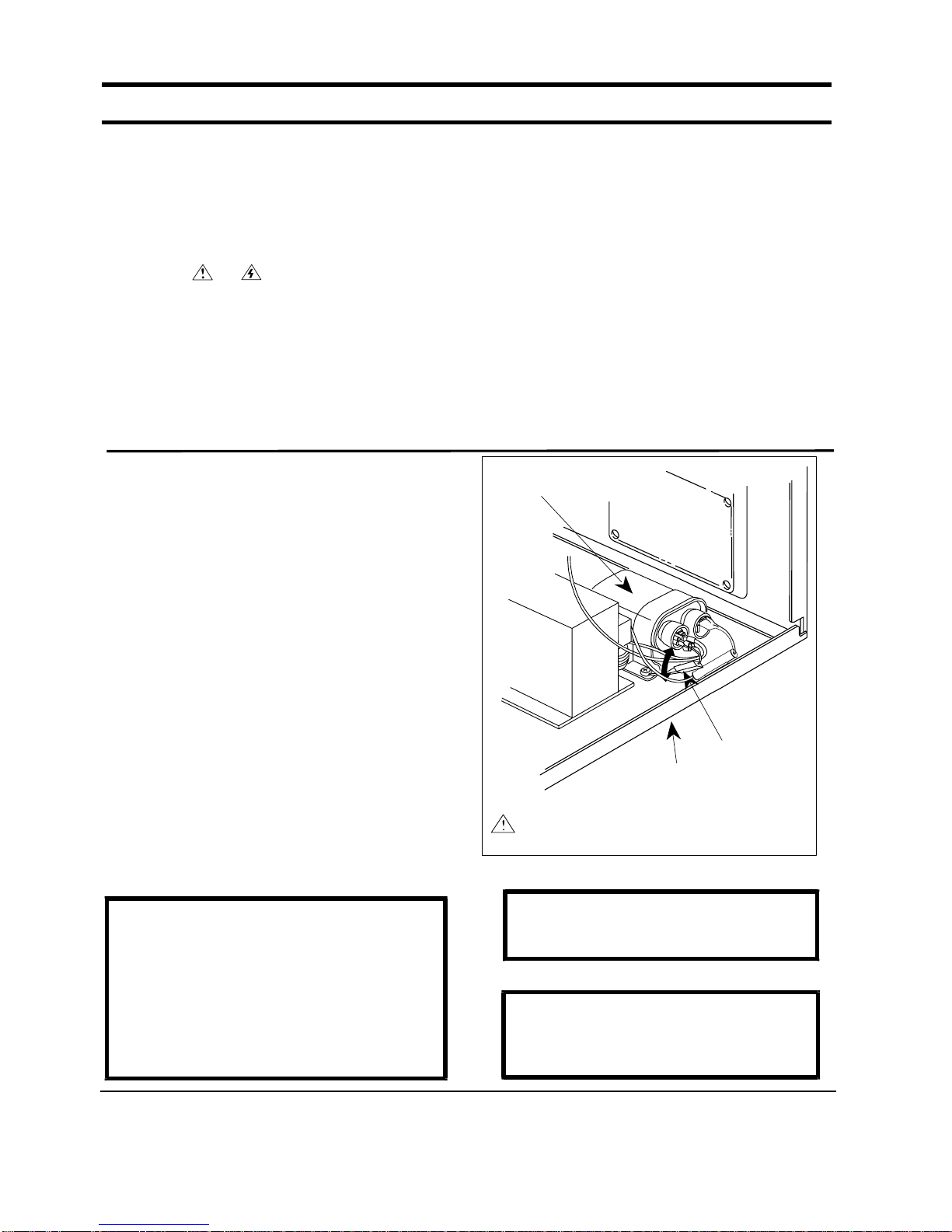

1. Precaution

Follow these special safety precautions. Although the microwave oven is completely safe during ordinary use,

repair work can be extremely hazardous due to possible exposure to microwave radiation, as well as potentially

lethal high voltages and currents.

1-1 Safety precautions ( )

1. All repairs should be done in accordance

with the procedures described in this

manual. This product complies with

Federal Performance Standard 21 CFR

Subchapter J(DHHS).

2. Microwave emission check should be

performed to prior to servicing if the oven is

operative.

3. If the oven operates with the door open :

Instruct the user not to operate the oven and

contact the manufacturer and the center for

devices and radiological health immediately.

4. Notify the Central Service Center if the

microwave leakage exceeds 5 mW/cm2.

5. Check all grounds.

6. Do not power the MWO from a "2-prong"

AC cord. Be sure that all of the built-in

protective devices are replaced. Restore any

missing protective shields.

7. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control

knobs and compartment covers.

8. Make sure that there are no cabinet openings

through which people --particularly

children --might insert objects and contact

dangerous voltages. Examples: Lamp hole,

ventilation slots.

9. Inform the manufacturer of any oven found

to have emission in excess of 5 mW/cm2,

Make repairs to bring the unit into

compliance at no cost to owner and try to

determine cause.

Instruct owner not to use oven until it has

been brought into compliance.

CENTRAL SERVICE CENTER

10. Service technicians should remove their

watches while repairing an MWO.

11. To avoid any possible radiation hazard,

replace parts in accordance with the wiring

diagram. Also, use only the exact

replacements for the following parts:

Primary and secondary interlock switches,

interlock monitor switch.

12. If the fuse is blown by the Interlock Monitor

Switch: Replace all of the following at the

same time: Primary, door sensing switch

and power relay, as well as the Interlock

Monitor Switch. The correct adjustment of

these switches is described elsewhere in

this manual. Make sure that the fuse has the

correct rating for the particular model being

repaired.

13. Design Alteration Warning:

Use exact replacement parts only, i.e.,

only those that are specified in the

drawings and parts lists of this manual.

This is especially important for the

Interlock switches, described above.

Never alter or add to the mechanical or

electrical design of the MWO. Any design

changes or additions will void the

manufacturer’s warranty. Always unplug

the unit’s AC power cord from the AC

power source before attempting to

remove or reinstall any component or

assembly.

14. Never defeat any of the B+ voltage

interlocks. Do not apply AC power to the

unit (or any of its assemblies) unless all

solid-state heat sinks are correctly installed.

15. Some semiconductor ("solid state") devices

are easily damaged by static electricity.

Such

components are called Electrostatically

Sensitive Devices (ESDs). Examples include

integrated circuits and field-effect

transistors.

Immediately before handling any

semiconductor components or assemblies,

drain the electrostatic charge from your

body by touching a known earth ground.

16. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.