4

PUMP

l

content of 50 grams in 1000 ml of water. For higher sand content, the pump

hydraulics will wear out at a faster rate.

lThe impeller is dynamically balanced.

lBoth suction and delivery flanges with rubber gaskets are assembled on the

volute casing.

lStrainer assembly, fitted on the pump suction flange, prevents entrance of

large-sized debris into the pump.

ELECTRICAL CONNECTION

lOWS to be connected to a DOL starter are provided with a single 3-core PVC flat

cable.

lOWS to be connected to a Star-Delta starter are provided with two separate 3-

core PVC flat cables.

7. PRE-INSTALLATION REQUIREMENTS

ARRANGEMENT FOR INSTALLATION

lUse services of a professional and trained mechanic with experience in erecting

OWS.

lEnsure proper safety during installation.

lEnsure that the bottom of the well/water source is fairly level before erection of

the OWS.

GENERAL INSTALLATION PRECAUTIONS

lOpen packaging and note down Serial number and Model for future reference.

lEnsure all fasteners are tightened properly.

lUse prescribed pipe sizes as mentioned on the product name plate.

lTo prevent motor from getting exposed during pumping, ensure suction

strainer is fitted above the level of the motor. This is done by fitting one end of

the bend to the pump suction flange and the strainer to the other end of the

bend, thereby ensuring that the level does not fall below the strainer.

lUse an NRV fitted on the delivery line when the OWS has high static delivery

heads.

lUse a power cable without joints from OWS to Control Panel. It is not

recommended to use a power cable with large number of joints as this can result

in a significant voltage drop.

The pump is designed for pumping clear, cold water with a maximum sand

5

l

lCheck availability of three-phase power.

lEnsure availability of Control Panel with inbuilt single-phase preventer, overload

protection, and High-Voltage and Low-Voltage protection.

lFill motor with pure drinking water before installation.

lIn case of rapid rise of water levels during rainy season, provide a throttle valve in

the delivery pipeline.

lWhile installing the OWS, ensure that it is not subject to shock loads which can

damage OWS parts.

Check for level of silt at the bottom of well. De-silt if necessary.

*If you detect damage or discrepancy in the product,

contact the dealer from whom the pump was purchased.

*Do not use this pump for oil or toxic, acetic, corrosive and

flammable liquids. Pumping flammable liquids could

cause explosion.

*Use eye bolts for lifting / lowering the OWS. Ensure

suitable precautions are taken while lifting and lowering

the product.

*Use trained professionals to install the OWS

*Use a power supply cable that has sufficient rating. Factor

in low-voltage operation.

*Provide proper Earthing. Improper Earthing can cause

electrical shock

*Use a Megger to verify insulation of the motor. Insulation

resistance should be 20 MÙ minimum.

*Do not run OWS dry as it contains water lubricated

bearings and oilseals.

*Mount the pump with its axis horizontal.

*It is recommended to use a starter.

*Check the bottom of the well. In case there is mud

accumulated at the bottom, de-silt the well.

*Periodically de-silt the bottom of the well so that the

OWS rests on the rocky bottom.

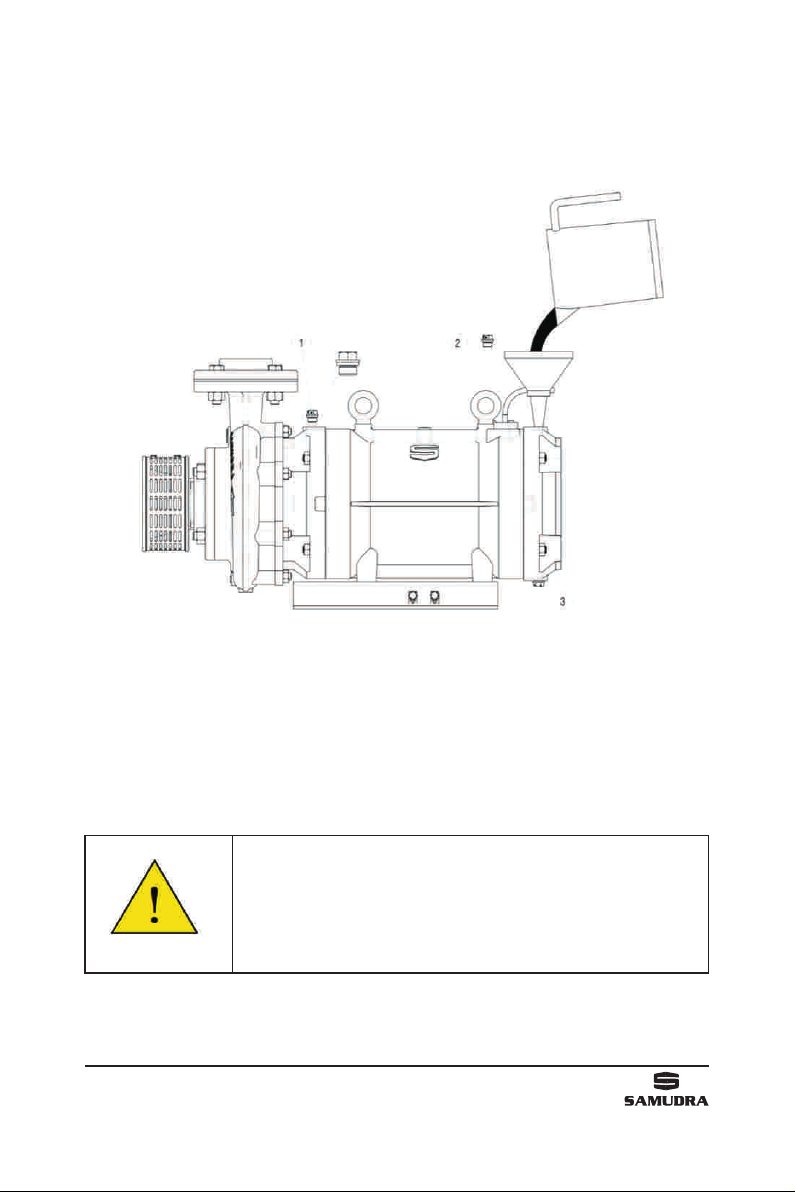

CAUTION