MAINTENANCE AND LUBRICATION 0B-1

SECTION 0B

MAINTENANCE AND LUBRICATION

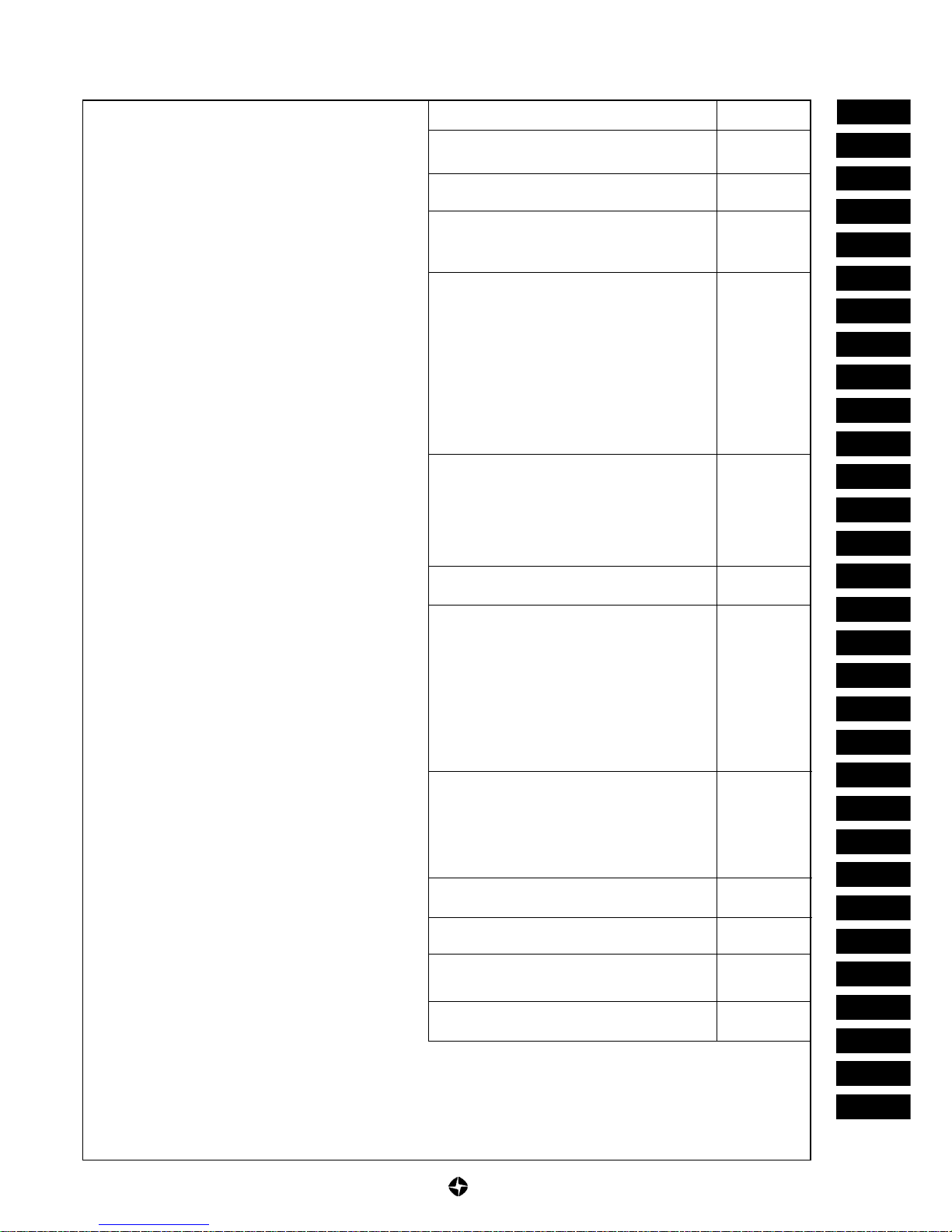

CONTENTS

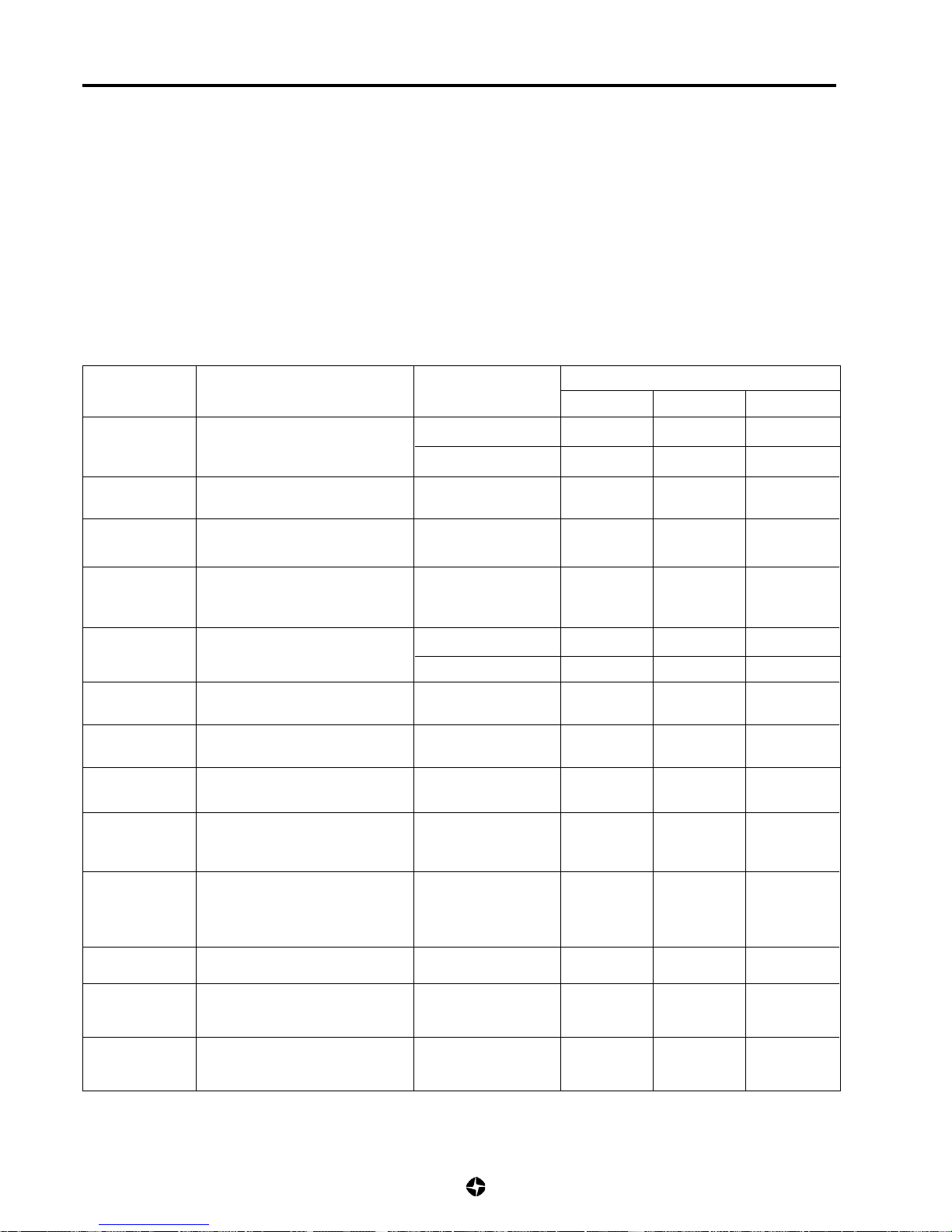

MAINTENANCE SCHEDULE ................................................................................................................................. 0B- 2

- Maintenance under normal driving conditions ................................................................................... 0B- 2

- Maintenance under severe driving conditions .................................................................................... 0B- 3

MAINTENANCE SERVICES .................................................................................................................................. 0B- 4

- Engine (Item 1) ....................................................................................................................................... 0B- 4

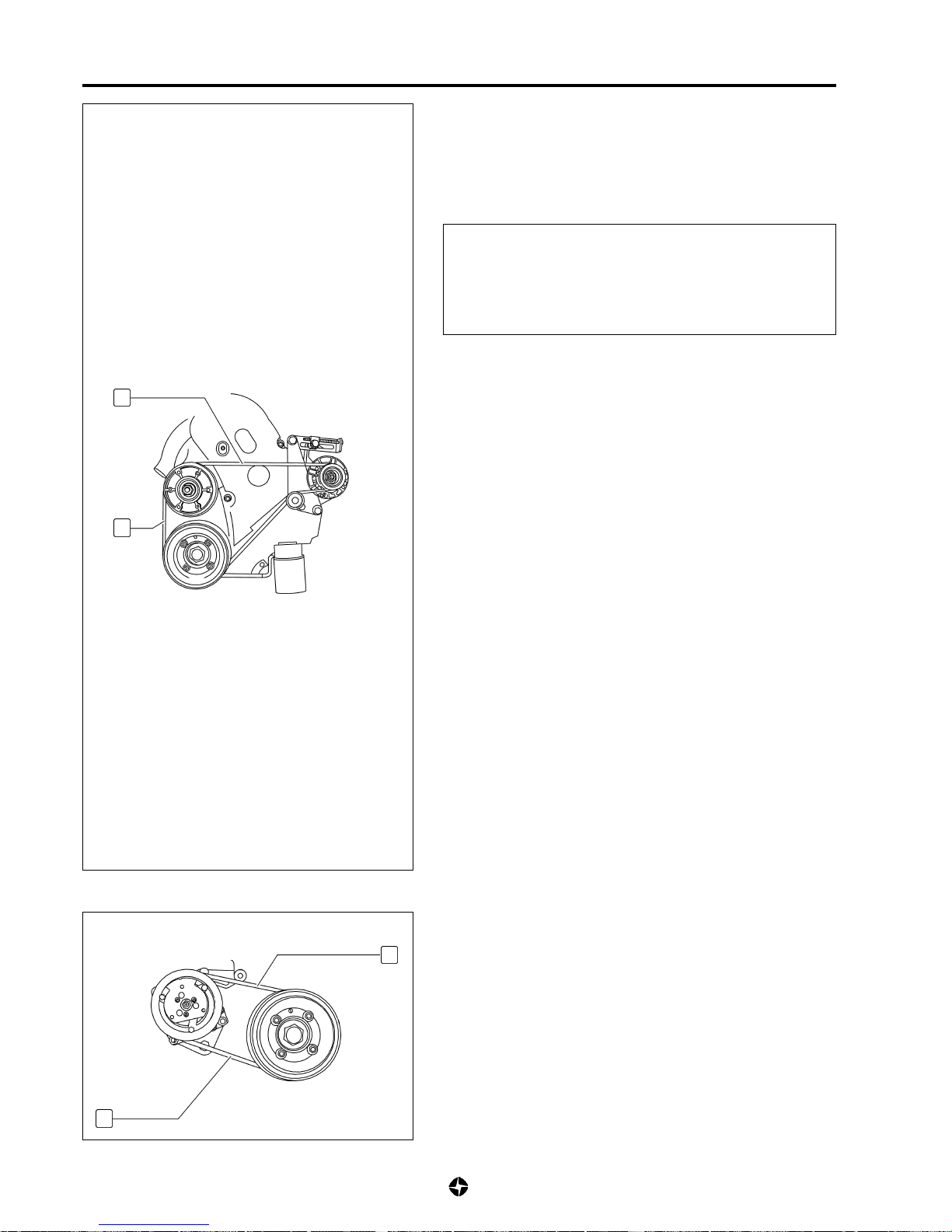

• Accesory driving belt (Item 1.1)....................................................................................................... 0B- 4

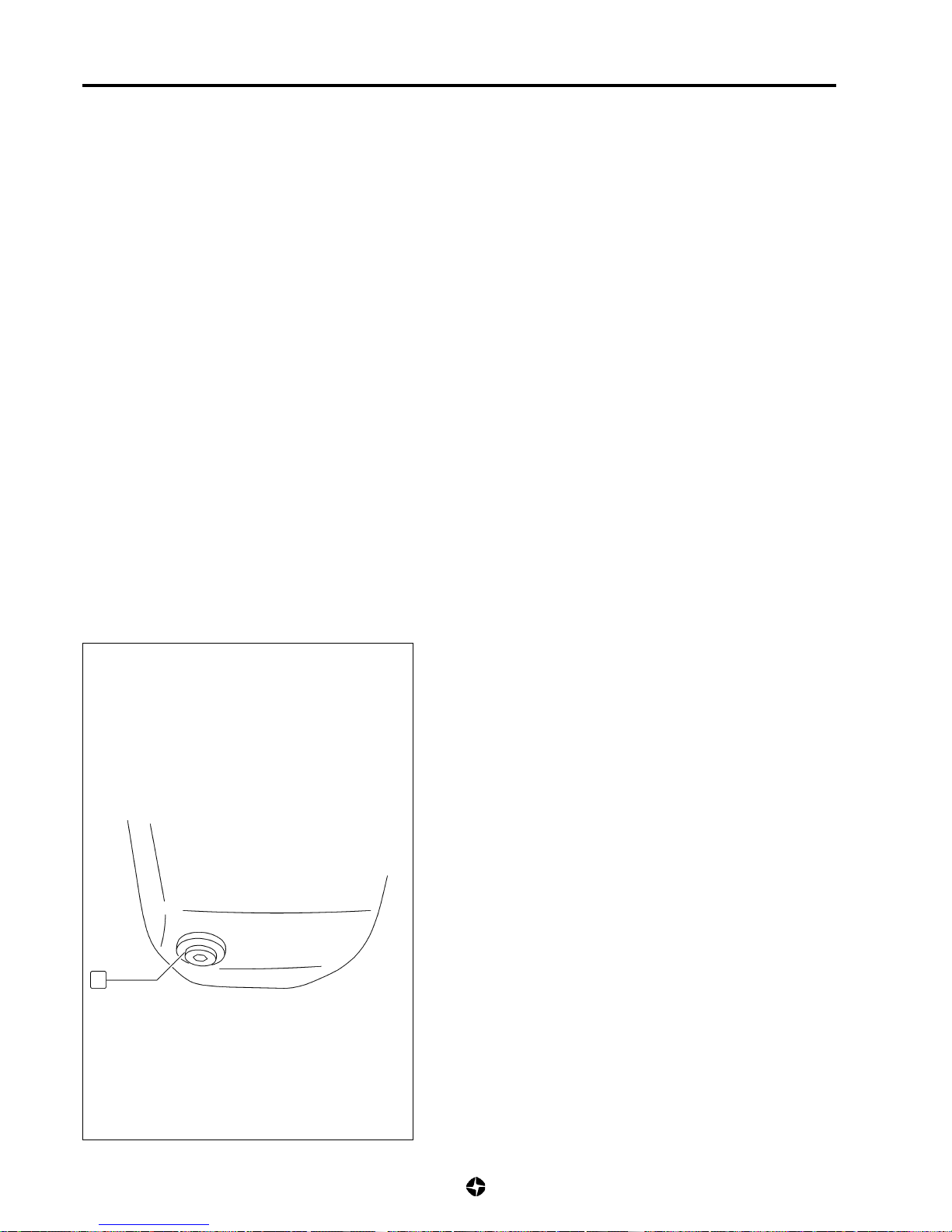

• Camshaft timing belt (Item 1.2) ....................................................................................................... 0B- 5

• Engine oil and filter (Item 1.3) ......................................................................................................... 0B- 5

• Injectors gauging (Item 1.4) (ONLY MECHANICAL INJECTION) .................................................... 0B- 8

• Engine coolant (Item 1.5) ................................................................................................................ 0B- 8

• Water radiator (Item 1.6) ..................................................................................................................0B-11

• Intercooler (Item 1.7) ........................................................................................................................ 0B-11

• Air filter (Item 1.8) ............................................................................................................................ 0B-11

• Exhaust system (Item 1.9) ............................................................................................................. 0B-12

• Visual control (Item 1.10) ................................................................................................................ 0B-12

- Fuel system (Item 2) ............................................................................................................................... 0B-13

• Fuel filter and air purging (Item 2.1) ................................................................................................. 0B-13

• Purging water and residues of the fuel filter (Item 2.2) ..................................................................... 0B-13

• Fuel lines and connections (Item 2.3) ............................................................................................. 0B-13

• Fuel tank (Item 2.4) ........................................................................................................................ 0B-13

• Fuel prefilter (Item 2.5) (ONLY COMMON RAIL ENGINE) .............................................................. 0B-14

- Transmission (Item 3) ............................................................................................................................. 0B-15

• Gear-box oil (Item 3.1) .................................................................................................................... 0B-15

• Transfer box oil (Item 3.2) ............................................................................................................... 0B-16

• Differential groups oil (Item 3.3)....................................................................................................... 0B-17

• Transmission Shafts (Item 3.4) ....................................................................................................... 0B-18

• Clutch Liquid (Item 3.5)................................................................................................................... 0B-19

• Clutch pedal (Item 3.6) ................................................................................................................... 0B-20

• Visual Control and running (Item 3.7) .............................................................................................. 0B-21

- Brakes, steering, suspension and wheels (Item 4) .............................................................................. 0B-22

• Brake Discs and Brake Blocks (Item 4.1) ....................................................................................... 0B-22

• Brake Liquid (Item 4.2) ................................................................................................................... 0B-22

• Parking brake (transmission brake) (Item 4.3)................................................................................. 0B-23

• Steering Mechanical System (Item 4.4) .......................................................................................... 0B-24

• Servo-Steering Hydraulic Oil Filter (Item 4.6) .................................................................................. 0B-25

• Servo-Steering Hydraulic Oil (Item 4.7) ........................................................................................... 0B-26

• Dampers, silent-blocks and springs (Item 4.8) ................................................................................ 0B-26

• Tyres (Item 4.9) .............................................................................................................................. 0B-27

• Wheels and Wheel Nuts (Item 4.10) ............................................................................................... 0B-28

• Visual Control (Item 4.11) ............................................................................................................... 0B-29

-Chassis, body and electrical system (Item 5) ....................................................................................... 0B-30

• Locks and hinges (Item 5.1) ........................................................................................................... 0B-30

• Chassis and body silent-blocks supports (Item 5.2) ........................................................................ 0B-30

• Optical and acoustic equipments and wiring (Item 5.3) ................................................................... 0B-30

FINAL INSPECTION ............................................................................................................................................. 0B-31

RECOMMENDED LUBRICANTS AND FLUIDS ..................................................................................................... 0B-33

TIGHTENING TORQUES ...................................................................................................................................... 0B-33

REQUIRED SERVICE MATERIAL ......................................................................................................................... 0B-33

0B