Scan Helicopter –Manual

- iv -

Table of Contents

1Specifications...................................................................................................................................... 2

1.1 Electrical specifications ............................................................................................................... 2

1.2 Mechanical specifications............................................................................................................ 3

1.3 Range of application .................................................................................................................... 4

1.4 Scope of supply............................................................................................................................ 4

1.5 Overview...................................................................................................................................... 5

2Safety Regulations.............................................................................................................................. 6

2.1 Symbols........................................................................................................................................ 6

2.2 Safety precautions........................................................................................................................ 6

2.3 Organizational measures.............................................................................................................. 6

2.4 Personnel...................................................................................................................................... 8

2.5 Safety regarding operation of machine ........................................................................................ 8

2.6 Electrical safety............................................................................................................................ 9

2.6.1 Cables.................................................................................................................................. 10

2.7 Definition of the “Safety off position”....................................................................................... 10

2.8 Safety regarding maintenance.................................................................................................... 10

2.8.1 Lifting ................................................................................................................................. 11

2.8.2 Inside vehicles..................................................................................................................... 11

3Operation .......................................................................................................................................... 12

3.1 Precautions................................................................................................................................. 12

3.2 Control device............................................................................................................................ 13

3.3 Start up ....................................................................................................................................... 13

3.4 Stop ............................................................................................................................................ 13

3.5 Safety off position...................................................................................................................... 14

3.6 Troweling blades........................................................................................................................ 14

4Maintenance...................................................................................................................................... 15

4.1 Precautions................................................................................................................................. 15

4.2 Battery Belts............................................................................................................................... 15

4.3 Directions for Battery charger TC PHASE 5............................................................................. 15

4.4 Maintenance and inspection list................................................................................................. 16

4.5 Cleaning the machine................................................................................................................. 16

4.6 Trouble shooting ........................................................................................................................ 16

4.6.1 Common faults.................................................................................................................... 16

5Spare parts......................................................................................................................................... 17

6Warranty ........................................................................................................................................... 20

7EU Declaration ................................................................................................................................. 21

8Alphabetical reference...................................................................................................................... 22

9Contact information.......................................................................................................................... 23

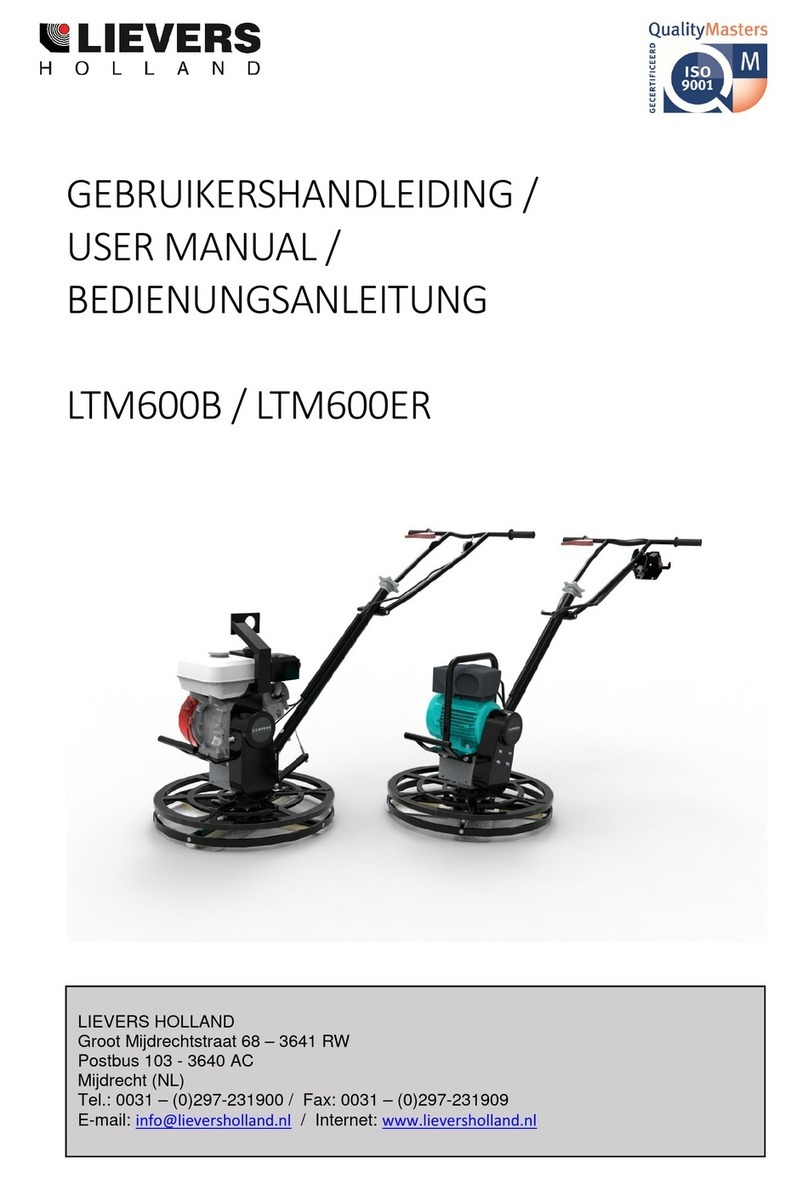

”HELICOPTER” POWER TROWEL, BATTERY OPERATED............................................................ 24

Article number: 210000........................................................................................................................ 24

Delivery supervisor (sign.)____________________________ ....................................................... 24

”HELICOPTER” POWER TROWEL, 230VOLT DRIVEN ................................................................... 25

Delivery supervisor (sign.)___________________________________ ............................................. 25