10

has not yet engaged and the rotors do not yet

rotate (the clutch engages at 1500 rpm). In order

to prevent slippage which might lead to rapid wear

of the clutch, firmly push the accelerator to reach

a value of 2500 rpm.

For more specific information on starting,

consult the engine instruction manual.

5.3. Driving the Float Machine

Use the machine at reduced speed until

you have fully mastered controlling the

movements.

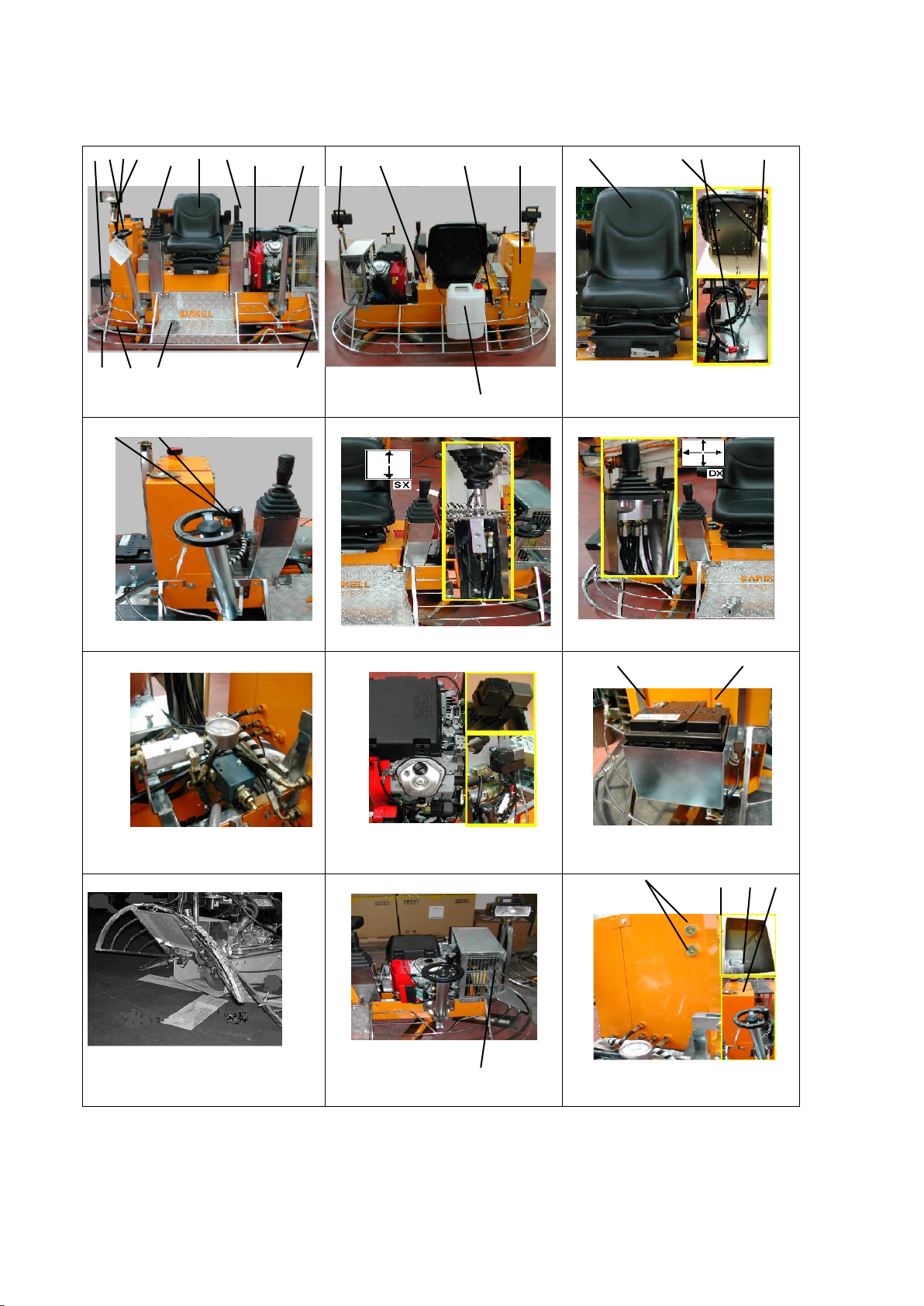

To drive the machine in the desired direction,

there are two control joysticks (Fig. 1 No. 10 &

11). Move the joysticks slowly and smoothly. To

stop the float machine movement, return the

joysticks to the rest position. The joystick control

positions and the relevant movements are

described on page 3 of this manual.

5.4. Use

For reasons of stability it is

recommended to use the machine on a

flat, stable and horizontal surface. Do

not use the machine on slopes of more

than a 4-5% gradient.

During the working phases, be

particularly careful not to lose control of

the float machine (for example, due to

too much water on the surface to be

worked).

Check that there are no obstacles or

obstructions on the working surface or

projecting parts which may hinder

rotation of the blades.

Preparing the Surface:

Use a mechanical vibrating float or manual float to

level the floor surface in order to obtain a well-

compacted concrete footing and thus prepare the

ideal surface for floating and finishing. The float

machine does not improve planarity of a badly

floated or levelled floor.

Floating Phase:

IMPORTANT: Before starting the

floating operation, check that the floats

have been mounted correctly on the

blades (Par. 7.5).

The floor is ready for the first pass when the

imprint of the shoe heel sinks into the concrete by

about 2-3 mm when walking on it.

The floating pass intervals depend on the ambient

factor, temperature and atmospheric conditions

(cold or hot season). On average about 250-300

m2of surface are floated in 10 minutes.

When the concrete is still fresh, take care not to

work continuously on the same spot since,

considering the weight of the float machine, you

might cause damage to the planarity of the floor

surface.

During the floating phase the floats must not

bounce on the surface. If this occurs it might be

caused by dirt between the blades and the floats.

If necessary, clean them after you have finished

work by following the instructions given in the

paragraph on cleaning.

Finishing Phase

When floating has been completed, detach the

floats from the blades and clean the cement that

has collected during the floating phase off the

blades, the spider and the protection rim. Turn the

blade-lifting knob clockwise (Fig. 4 No.1 & 2) until

the blades are inclined by about 1 cm for the first

pass. For the subsequent smoothing operations,

continue increasing the blade inclination until

obtaining the desired finish.

Once again, the time between one pass and the

next is determined by the atmospheric conditions

(hot or cold season) and by the amount of water in

the concrete. If the concrete has hardened too

quickly in some areas, it can be moistened by

spraying a small amount of water using the button

(Fig. 1 No. 11) located on the control bars in order

to obtain the degree of finish desired.

IMPORTANT: Turn off the engine after

each operation. Never leave the float

machine standing with the engine

running, especially during the floating

phase when the concrete is still fresh.

5.5. Stopping

For more specific information on

stopping consult the engine instruction

manual.

To stop the float machine, move the accelerator

(Fig. 1 No. 5) to idle and release the two joysticks

(10 & 11). Close the fuel cock and remove the

start key from the control panel.