EN

Operating instructions

Solenoid interlock AZM 170

EN Operating instructions...................... pages 1 to 6

Translation of the original operating instructions

FR

Vous trouverez la version

actuelle du mode d’emploi dans

votre langue nationale ofcielle

sur l’Internet, www.schmersal.

net.

ES

Encontrará el manual de

instrucciones actual en su

idioma ocial de la UE en nu-

estra página de Internet www.

schmersal.net.

NL

U vindt de huidige versie van

de gebruikshandleiding in uw

ofciële landstaal op het Inter-

net, www.schmersal.net.

IT

Il manuale d‘istruzioni aggior-

nato nella vostra lingua (lingua

ufciale UE) è scaricabile in

Internet all‘indirizzo www.

schmersal.net.

JP

EU公用語で書かれた最新の

取扱説明書は、インターネッ

(www.schmersal.net)からダウ

ンロードできます。

1

1 About this document

1.1 Function

This operating instructions manual provides all the information you

need for the mounting, set-up and commissioning to ensure the safe

operation and disassembly of the safety switchgear. The operating inst-

ructions must be available in a legible condition and a complete version

in the vicinity of the device.

1.2 Target group: authorised qualied personnel

All operations described in this operating instructions manual must

be carried out by trained specialist personnel, authorised by the plant

operator only.

Please make sure that you have read and understood these operating

instructions and that you know all applicable legislations regarding

occupational safety and accident prevention prior to installation and

putting the component into operation.

The machine builder must carefully select the harmonised standards to

be complied with as well as other technical specications for the selec-

tion, mounting and integration of the components.

1.3 Explanation of the symbols used

Information, hint, note:

This symbol is used for identifying useful additional information.

Caution: Failure to comply with this warning notice could

lead to failures or malfunctions.

Warning: Failure to comply with this warning notice could

lead to physical injury and/or damage to the machine.

1.4 Appropriate use

The products described in these operating instructions are developed to

execute safety-related functions as part of an entire plant or machine. It

is the responsibility of the manufacturer of a machine or plant to ensure

the proper functionality of the entire machinery or plant.

The safety switchgear must be exclusively used in accordance with the

versions listed below or for the applications authorised by the manufac-

turer. Detailed information regarding the range of applications can be

found in the chapter "Product description".

1.5 General safety instructions

The user must observe the safety instructions in this operating instruc-

tions manual, the country-specic installation standards as well as all

prevailing safety regulations and accident prevention rules.

Further technical information can be found in the Schmersal

catalogues or in the online catalogue on the Internet: www.

schmersal.net.

The information contained in this operating instructions manual is provi-

ded without liability and is subject to technical modications.

If multiple safety components are wired in series, the Perfor-

mance Level to EN ISO 13849-1 will be reduced due to the re-

stricted error detection under certain circumstances. The entire

concept of the control system, in which the safety component

is integrated, must be validated to EN ISO 13849-2.

There are no residual risks, provided that the safety instructions as well

as the instructions regarding mounting, commissioning, operation and

maintenance are observed.

Content

1 About this document

1.1 Function..............................................1

1.2 Target group: authorised qualied personnel..................1

1.3 Explanation of the symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.4 Appropriateuse........................................1

1.5 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.6 Warningaboutmisuse...................................2

1.7 Exclusionofliability.....................................2

2 Product description

2.1 Orderingcode .........................................2

2.2 Specialversions........................................2

2.3 Destinationanduse.....................................2

2.4 Technicaldata.........................................2

2.5 Safety classication .....................................3

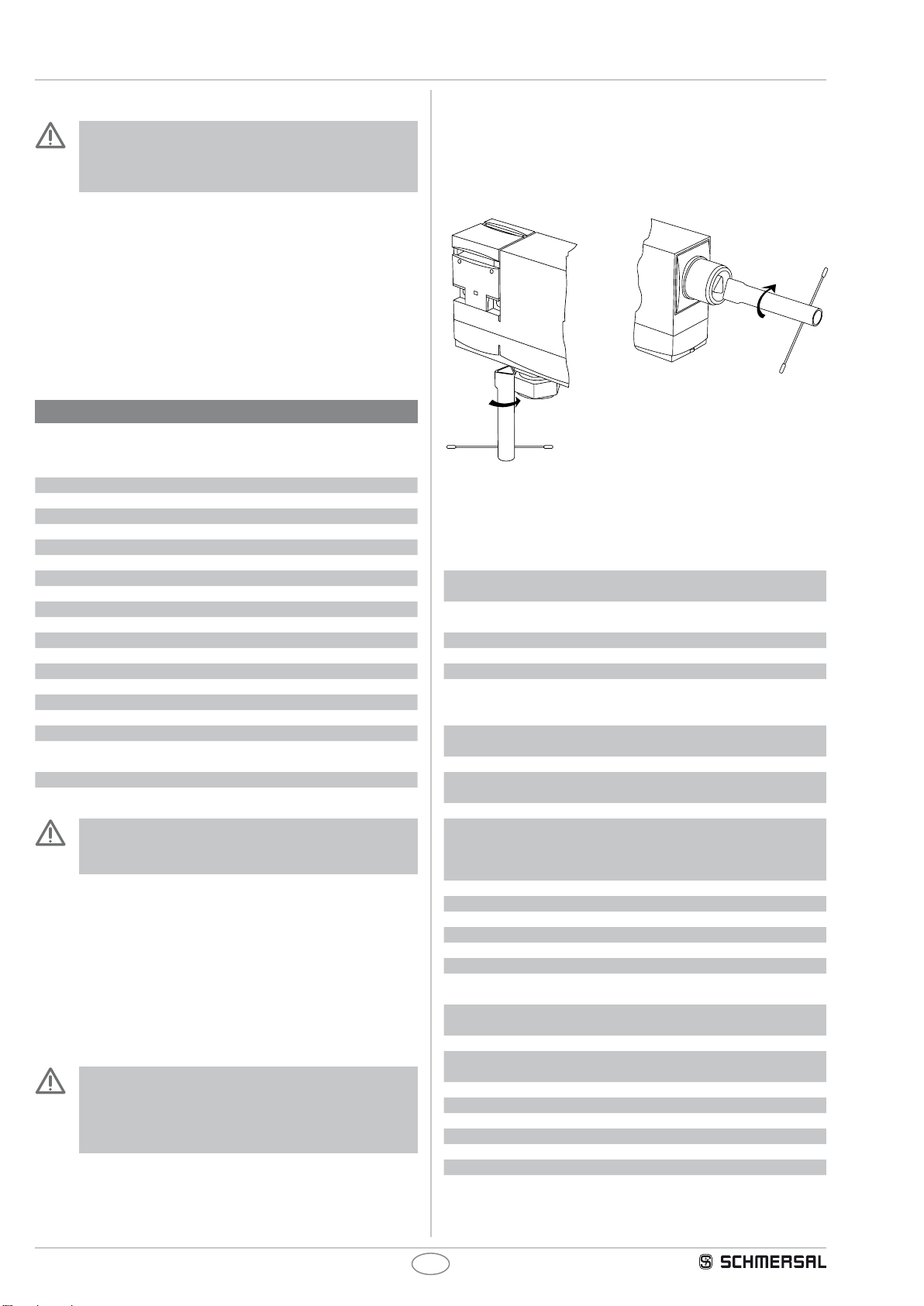

3 Mounting

3.1 General mounting instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

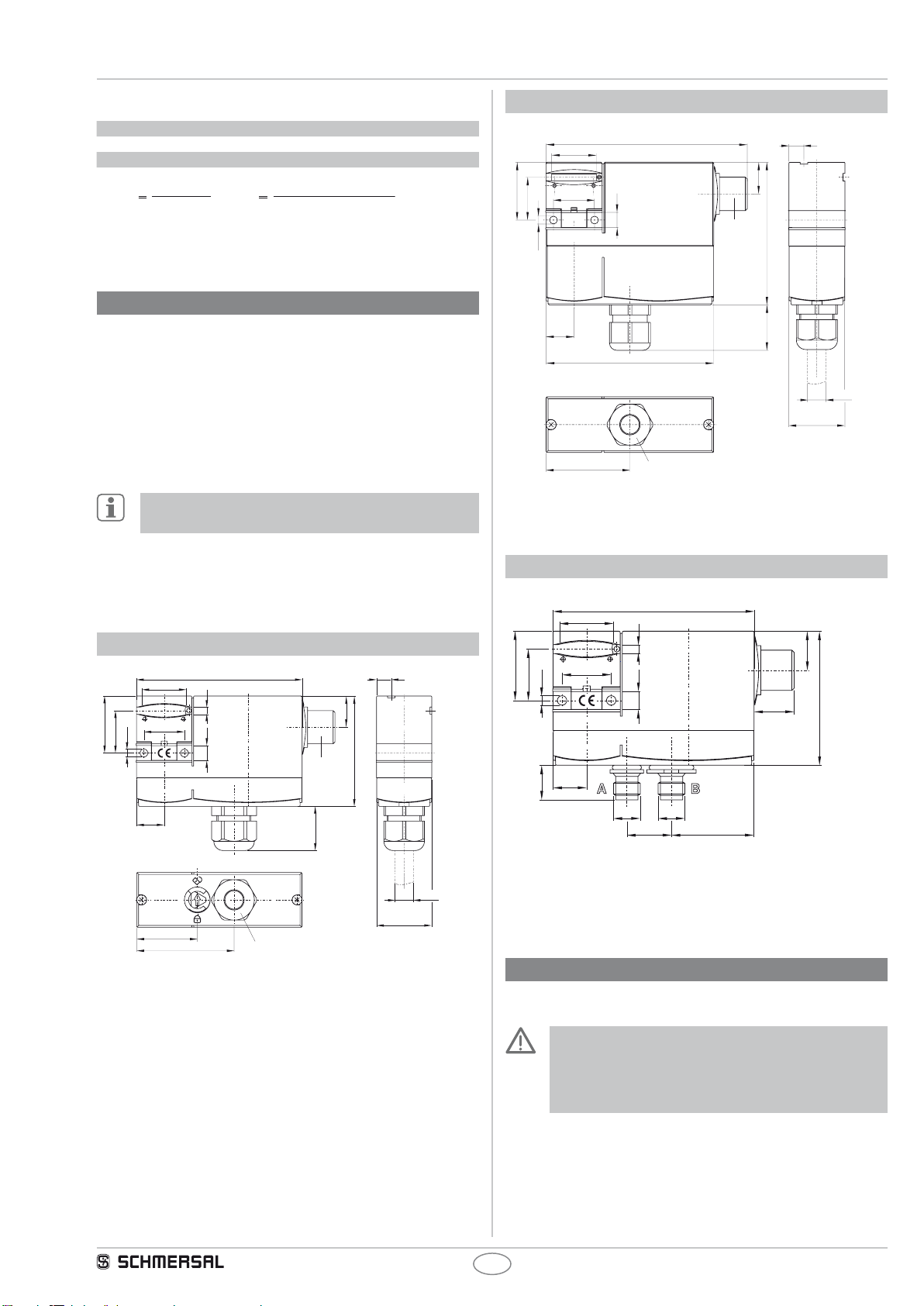

3.2 Dimensions ...........................................3

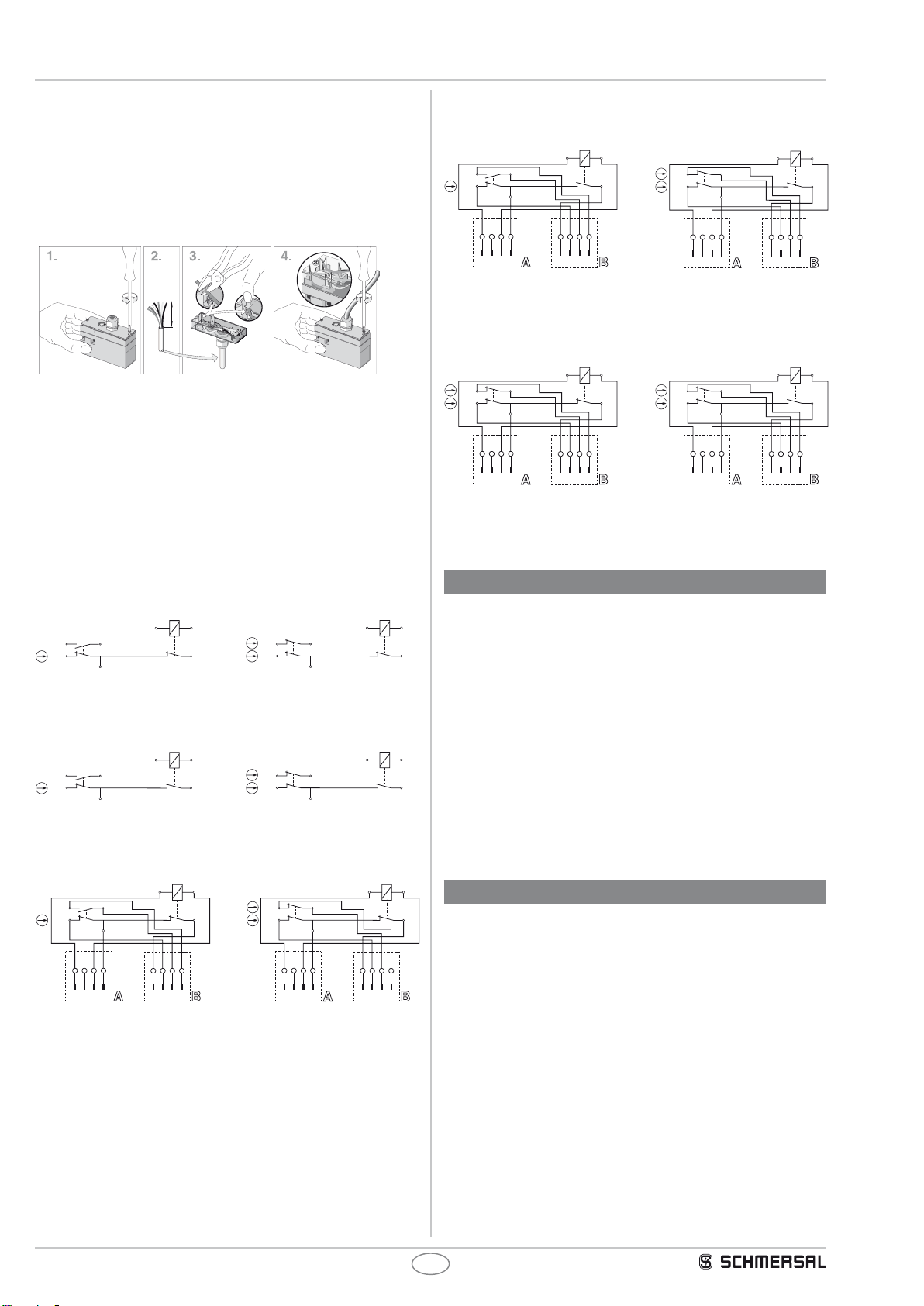

4 Electrical connection

4.1 General information for electrical connection. . . . . . . . . . . . . . . . . .3

4.2 Contactvariants........................................4

5 Set-up and maintenance

5.1 Functionaltesting.......................................4

5.2 Maintenance ..........................................4

6 Disassembly and disposal

6.1 Disassembly...........................................4

6.2 Disposal..............................................4

7 Appendix

7.1 ECDeclarationofconformity..............................5

x.500 / v.A. / 08.2009 / BZ-Nr. 50122-20V900 / Teile-Nr. 1122371-EN / Ausgabe Q