SAFETY INSTRUCTIONS

When using air compressors and compressed air accesso-

ries, basic safety rules and precautions should always be

followed including the following:

1. Read all instructions fully before operating this

compressor.

2. Never use a compressor that is defective, operating

abnormally, making strange noises, or otherwise

appears defective. Stop using compressor immediately

and arrange for repairs by an authorized service center.

3. Do not modify compressor. Always contact the autho-

rized service center for any repairs.

4. Use only the manufacturer’s replacement parts.

Replacement parts not manufactured by Schrader

Bridgeport may void your warranty and can lead to

compressor malfunction and personal injuries.

Replacement parts are available from the manufac-

turer.

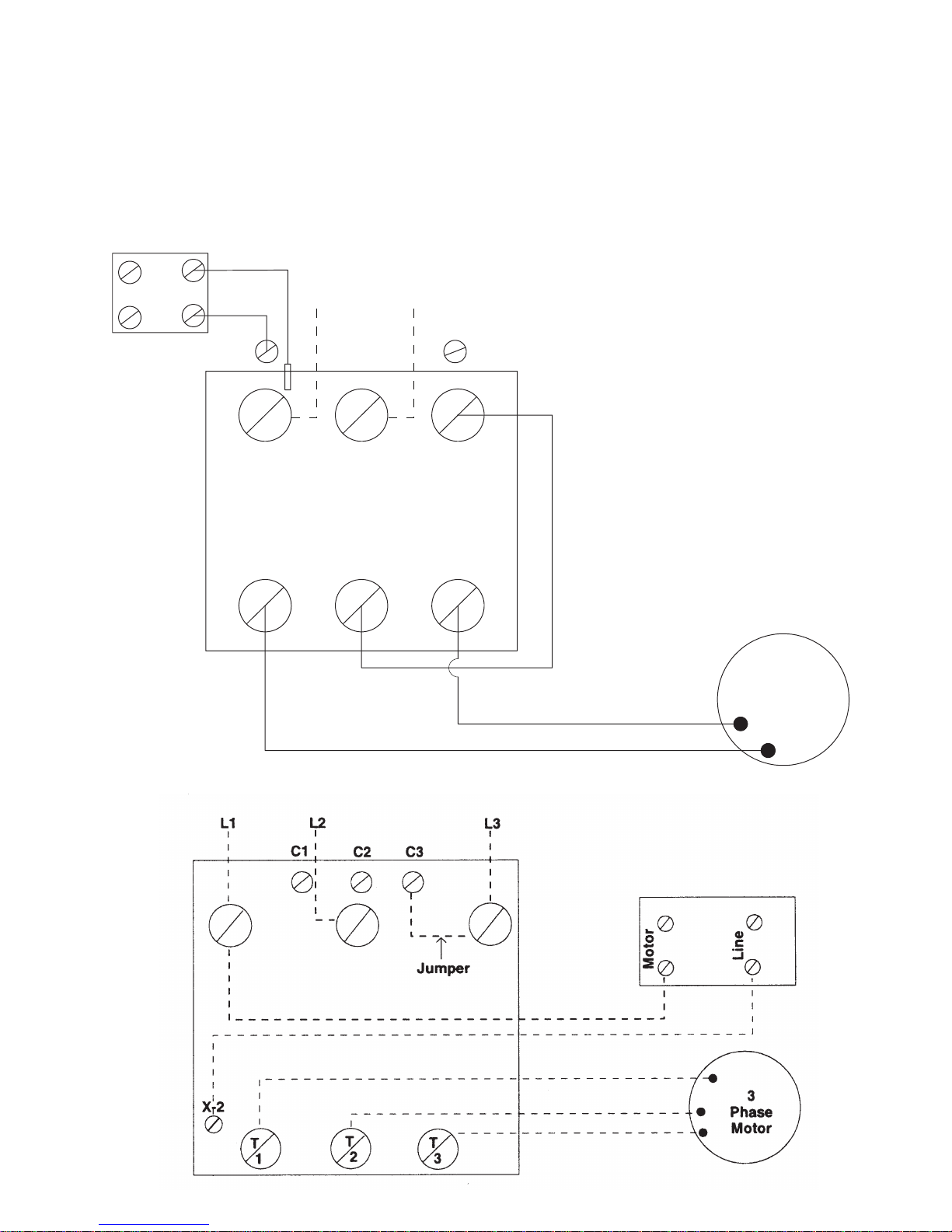

5. Wiring, starters, breakers and other related electrical

equipment should conform to electrical codes when

operating any electric air compressors. Electrical con-

nections should be made by a licensed electrician.

6. Always disconnect compressor from its power source

and remove the compressed air from the tank before

servicing, inspecting, cleaning, replacing, or checking

any parts.

7. Do not operate compressor without belt guard. If main-

tenance or servicing requires the removal of a guard or

safety feature, be sure to replace the guard or safety

feature before resuming operation of the compressor.

8. Do not use gasoline compressor if Load Genie does

not operate properly. Have defective Load Genie

replaced by an authorized service center.

9. Avoid unintentional starting. Do not move the compres-

sor while connected to its power source or when the air

tank is filled with compressed air.

10.Turn off the compressor when not in use. Then open

the drain cock to discharge the compressed air from

the air tank.

11. Do not expose compressor to rain. The compressor

should be stored in a dry clean environment.

12.Do not use compressor in the presence of flammable

liquids or gases. Compressor can produce sparks dur-

ing operation. Never use compressor in sites containing

lacquer, paint, benzine, thinner, gasoline, gases, adhe-

sive agents and other materials, which are combustible

or explosive.

13.Use only recommended air handling parts acceptable

for minimum pressure. Never use pressurized air

accessories or parts in the air system that are not suit-

able for the maximum air pressure involved. The risk

of bursting exists with use of unsuitable equipment.

Always maintain maximum pressure specified by the

manufacturer.

14.If your compressor is used for spraying, do not spray

in vicinity of open flame or other sources of ignition.

Always direct paint or sprayed material away from

compressor and locate compressor to minimize over

spray accumulation on compressor or sprayer parts.

15.Do not wipe plastic parts with solvent. Solvents such

as gasoline, thinner, benzine, carbon tetrachloride

and alcohol may damage and crack plastic parts.

Wipe plastic parts with a soft cloth, lightly dampened

with soapy water and dry thoroughly. When using

cleaning solvent, follow the instructions provided by

the solvent manufacturer.

16.Keep pressure relief devices free from paint or other

accumulation. The motor air vent must be kept clean

so that air can freely flow at all times. Check for dust

build-up frequently.

17.Do not install Shutoff valves in the discharge line

between the compressor and the receiver unless

a safety valve, with adequate flow capacity and

pressure setting, is located between shutoff valve and

the compressor. Never operate a compressor without

all guards or safety features in place and in proper

working order.

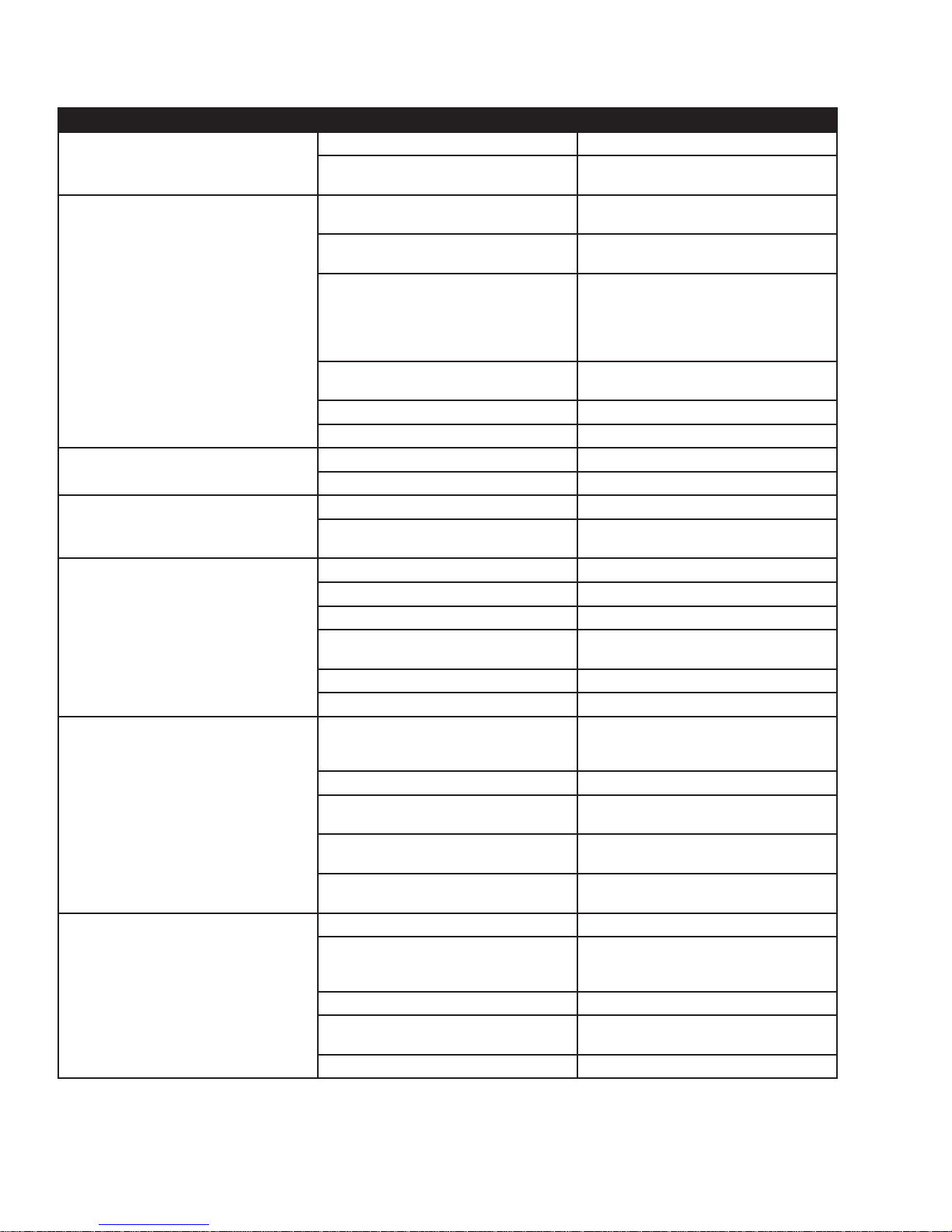

18.Proper maintenance and care is necessary to ensure

safe operation of air compressor. Check compressor

according to the maintenance schedule provided in

this manual. Maintain compressor with care. Follow

instructions for lubrication. Keep all screws, bolts, and

plates tightly mounted. Check for damaged parts and

air leaks, daily. Check for alignment of moving parts,

binding of moving parts, guard, breakage of parts, and

any other conditions that may affect the operation of

compressor. Drain tank daily to prevent rust formation

and damage.

19.Do not operate any compressor with damaged wir-

ing or hosing, or after the compressor or air handling

parts have been dropped, damaged or show signs of

deterioration, weakness or leakage. Do not use them

if a deficiency is found. A unit that is damaged should

be properly repaired or replaced by an authorized ser-

vice center unless otherwise indicated elsewhere in

this Instruction Manual.

20.Keep clear of compressor while operating It may

become extremely hot during operation. To reduce

the risk of burns, do not touch tubes, heads, cyl-

inders or motors.

21.Never touch moving parts. Always wear safety gog-

gles or equivalent eye protection. Dress properly. Do

not wear loose clothing or jewelry. These can be

caught in moving parts. Wear protective hair covering

to contain long hair.

22.Never aim compressed air at anyone or any part of

the body.

23.Never operate a compressor in damp or wet location.

Protect yourself against electric shock. Prevent body

contact with grounded surfaces such as pipes, radia-

tors, ranges and refrigeration enclosures.

4