Scorpio Miss Acro S2066 User manual

S2066 - Miss Acro

Technical data

WingSpan 1,380mm

Length 900mm

WingArea 25.6dm2

Weight 900g

WingLoading 35g/dm2

Radio 4 ch

Electric motor/Cells “400”(7/8Cells)

Introduction

CongratulationsonbuyingMissAcro,

thelatestdevelopmentofourpreviousMissMoravia.

Followingmany requests from delighted pilotsof Miss

Moravia,wehavenowaddedailerons toallow Miss

Acro to keep all of the best characteristics of Miss

Moraviaand in addition offerthemaneuverabilitythat

thesportpilot requires. The recent availability of small

brushlessmotorsoffers the ideal solution for the more

exuberantpilotswhilethe transparentfuselage

allows for easy inspection of the electronic parts at a

glanceandthe large canopy offers extraordinarily

easy access to all the equipment. Change the battery

really is a breeze on this model! Enjoy your Miss

Acro!

Before starting construction

Carefully study the building Instructions as well

as the assembly sketches: it is time well spent.

Check off each construction step as you complete it

so that if work is interrupted you’ll be able to resume

where you left off. A bracket [ ] is placed next to each

buildingstageforthispurpose.

Checking the kit

[ ] Examine the kit to ensure nothing is missing.

[ ] Removeeachdiecutpart and sand carefully

whererequired.

Equipment needed

Here’s all you need to build your Miss Acro:

[ ] Modellingknife

[ ] Scissors

[ ] Sandingblockwithcoarseand fine paper

[ ] Setsquare

[ ] Drill with a 2 and 3 mm bit

[ ] Adhesivetape

[ ] Roundfile5mmdiameter

[ ] Some black enamel paint

[ ] 5 minute Epoxy or Cyanoacrylate Glue

Wing assembly

W-1 [ ] Using a knife with a sharp blade, trim the

coveringfilmfromthewingrootrib.Leavejustavery

narrowoverlapof film. Do not allow this overlap to

come away from the root rib, if it does come loose

use a film iron to iron back into place.

W-2 [ ] Carefully cut out the aperture for the aileron

servointheright wing panel [2]. Repeat the operation

on the left wing panel [3].

W-3 [ ] Insert the wooden dowel [B3-8] into the right

wing[2],before offering this wing panel to the leftwing

[3]. Before gluing check that all the parts fit

accuratelytogether.Ifnecessary,sand the dowel or

open up the bore of the hole. Check also for the

correct alignment of the two wings. After the glue has

been applied but before it has cured, check that the

wing’s dihedral is as required (85 mm) Use a book or

block of wood under the raised panel to set the

requireddihedral,then fill any minor gaps between

them with glue.

Miss Acro S2066

W-4 [ ] Using a sharp knife cut through the covering

filmon the forward side of thedihedralbrace slot.

Peeling the film back will allow the dihedral braces

[DC3-1]to be fitted.

W-5 [ ] Glue together the dihedral braces [DC3-1].

Check that the assembled brace fits the wing slot.

Sandcarefullyif required to obtain a perfect fit.Glue

brace into position and smooth down the film flap to

coverthe brace.

Fuselage and Tailplane Assembly

F-1 [ ] Drill two 3mm holes through the bottom of the

fuselage[1],inthecorner between the main former

andthefuselagesides.

F-2 [ ] Carefully cut open the slot for the main

undercarriage[7].

F-3 [ ] Gluethe upper half-former[B3-2]onto the

mainfuselage former.

F-4 [ ] Insert the main undercarriage [7] into the

fuselageslot. Now glue the doubler [B3-1] ontothe

upperhalf-former[B3-2].Insert and glue into place the

undercarriagesecuring plate [B3-3].

F-5 [ ] Before the glue is dry, check that the

undercarriageiscorrectlyalignedwiththefuselage.

Adjust as necessary.

F-6 [ ] If necessary use a small file to clean up the

endsof the undercarriage legs[7] then fit the inner

lock washer [B2-2], the wheel [B2-1] and the other

lock washer [B2-2], ensuring that the wheel [B2-1]

runsfreely.

F-7 [ ] Glue the fuselage doublers [8] into position

insidethefuselagetogether with the spacers [DC2-4].

F-8 [ ] Glue in position the radio and servo

tray[DC2-1]andthepushrodsupport[DC2-

2] keeping the slots for the pushrods toward

the top.

F-9 [ ] Glue in position the former [DC1-2]

F-10[ ] Remove the covering film over theslot for the

tail skid [DC1-5]. Glue the tail skid [DC1-5] into

position on the fuselage. Glue the wire skid [B2-3]

overthetail skid [DC1-5].

F-11[ ] Remove the covering film over theslot for the

fin [4] in the tailplane [5].

F-12 [ ] Hold the tailplane [5] in place on the fuselage

and use a pen to mark its position. Leave a gap of

approximately2mmbetweenthefrontofthetailplane

andthefront of the tailplane mount.

F-13 [ ] Use a sharp knife and carefully cut through

thecoveringfilm along the marked line before

removing the waste film. Ensure that only the film is

cut, not the tailplane structure. Cut around 1 mm

insidethemarkedlinestoavoidbarewoodshowing

through.

F-14 [ ] Glue the fin [4] into place on the tailplane [5]

F-15 [ ] Before the glue is completely dry, check with

a square that the tailplane [5] and fin [4] are perfectly

square.Adjust as necessary.

F-16 [ ] Glue the complete tail assembly to the

fuselage.

F-17 [ ] Use a square to check the alignment of the

tail assembly to the fuselage before the glue has

completelycured.

F-18 [ ] Glue in place the fuselage brace [B3-4]

F-19 [ ] Cutaway the covering filmoverthe holes for

the wing dowels [B3-7]. Insert the dowels [B3-7]

applying some glue to the dowels inside the fuselage.

F-20 [ ] Glue in position the two canopy attachment

hooks [DC1-3]. To accurately position these hooks

usethecanopyframe [DC1-1] positioned over the

fuselage.Theframemustbefreetoslid from under

the hooks.

F-21 [ ] Gluetogether the canopy frame[DC1-1]and

the canopy catch [DC2-3] along with its spacer [DC1-

4].

F-22 [ ] With scissors cut away excess material from

thecanopymoulding[6] following the

mouldedcutline, leaving a couple of mm ofmaterial

thatwill removed later.

F-23 [ ] Paint the inside of the canopy with black

paint, as per the boxtop image. Position the canopy

frame [DC1-1] inside the canopy [6] and glue it in

position. When the glue has cured, trim the excess

canopymaterialaway carefully.The canopycatch

protrudesbehindthe canopy.

F-24 [ ] To mount the canopy [6] to the fuselage you

have first to insert the canopy catch tongue under the

S2066 Miss Acro

top of the fuselage, inside the canopy hatch. Then

slightly tilt the canopy to engage the

attachmenthooks.Theplywoodtonguewillbend

easily and allow the canopy to be slid into position.

To remove thecanopyreverse the procedure.

Radio Installation

RC-1 [ ] Position the two servos on the servo

support[DC2-2] and mark the position ofthe

mountingscrews. (notsupplied).Removetheservos

and with a 1.5 mm bit drill the holes for the mounting

screws.

RC-2 [ ] Cut out the film over the control cable slots

intherearendofthe fuselage. Insert the elevator tube

[B1-2]andthe rudder tube [B1-4] into the fuselage

slots letting them extend from the fuselage sides by

about 10 mm, then epoxy them in place.

RC-3 [ ] Punch through the film over the holes in the

rudder for the control horn [B1-7] and install it in

position on the rudder. Secure in position using nuts

[B1-8].

RC-4 [ ] Repeatthe above procedure and fit the

elevatorcontrol horn [B1-7].

RC-5 [ ] Install the servos in the servo tray [DC2-1],

connect them to the Rx and ensure they are

centered.Removethe servo arms and insert the “Z”

endofthepushrods [B1-1] and [B1-3] respectively

from above and into the central holes in the arms.

Slide the pushrods [B1-1] and [B1-3] into the tubes

[B1-2] and [1-4] until it is possible to install the servo

output arms onto the servos in the neutral position.

Gluetherudderand elevator tubes [B1-2] and [B1-4]

tothepushrodsupport[DC2-2]

RC-6 [ ] Screw the threaded adapter [B1-5] to the

snap link [B1-6]. Connect the snap link to the elevator

control horn [B1-7] in the middle hole. Fit the

threadedadapterontothe end of the pushrod and

check the length of the pushrod [B1-1] keeping the

elevatorattheneutral position and the servo

centered.Ifnecessary, shorten the pushrod [B1-1]

cutting it down to the correct length. When servo and

elevatorareaccuratelyaligned,epoxyorsolderthe

pushrod[B1-1]intotheadapter [B1-5].To improve the

joint, use pliers to slightly bend the end of the

pushrod to ensure it fits tightly inside the adapter.

RC-7 [ ] Repeat the above procedure to connectthe

ruddersurface to the rudder servo. Again carefully

checkthealignmentoftheservo arm and rudder horn.

RC-8 [ ] Mark the position of the trailing edge

doublers[DC5-1]. They must be positioned so that

the inner edge is 25 mm from the centre of the wing.

Slide the doubler back by 2mm then cut through the

coveringfilm around the edge ofthedoubler.

RC-9 [ ] Glue the doublers [DC5-1] into place,

makingsuretheedges of the film are trapped under

thedoubler.

RC-10 [ ] Usea sharpknife and remove the film

abovetheslots for the aileron torque rods [B1-9] on

boththewing and the aileron. Also removethefilm

abovethe servobay.

RC-11 [ ] Insert the aileron torque rods into the wing

slot and carefully glue the plastic tube in position.

Ensure that no glue is allowed to get into the plastic

torquetubeandensurethatthetorquerod can move

freely.

RC-12 [ ] Assemble the aileron servo tray.

RC-13 [ ] Position the aileron servo on the tray and

markfortheservo screws. Remove the servo and drill

1.5 mm holes for the servo screws.

RC-14 [ ] Glue the aileron servo tray into place.

RC-15 [ ] Screw the aileron servo into place on the

tray.

RC-16 [ ] Screw the torque rod connectors [B1-11] on

to the aileron torque rods, threading them on so that

2mmofthreadappears above the connectors. Screw

the clevis [B1-6] on to the pushrod [B1-11] and insert

the”Z”end into the servo arm. With theservocentred

ensure that the aileron is correctly aligned with the

wing section. Adjust the clevis [B1-6] as required.

Repeatforthe second aileron pushrod.

Installing the Motor

Thereare manydifferentgearboxes availablefor400

size electric motors. We have illustrated the most

common type. Below you’ll find also some information

forfittingalternativeunits.

MPJet or similar gearboxes

MPJ-1 [ ] Installation of the MP Jet gearbox requires

theuseof gearbox adapter,partnumber M-EP4MGX,

which is available separately. It is also necessary to

Miss Acro S2066

removethe unused gearbox “ears” from the gearbox.

MPJ-2[ ] Measurethedistance between the holes for

themountingscrews(not supplied) on the adapter.

Mark this dimension on the front bulkhead of the

fuselageanddrill 3mm holes for the mounting screws.

MPJ-3 [ ] Screw the motor/gearbox assembly into

place.

MPJ-4 [ ] The output shaft of the gearbox should

haveabout5°ofdownthrustand2° of sidethrust. Use

ply shims to adjust as required.

Horak and similar gearboxes

MH-1 [ ] Assemble the motor cradle gluing

together its parts.

MH-2 [ ] Put the motor cradle into the forward part

of the fuselage, add the motor and check for the

alignment of the motor shaft with the hole in the

fuselagefrontformer. When the alignment iscorrect,

epoxy the cradle into the fuselage.

MH-3 [ ] Fasten the motor to its cradle using a

plastic tie strap.

MH-4 [ ] Glue the mounting plate into place so

that the output shaft of the gearbox is central to the

hole in the nose of the fuselage.

MA-5 [ ] Screw the motor/gearbox into place, and

attachthe propeller.

Finishing

FT-1 [ ] Recommendedlayoutofradio and drive

system in Miss Acro.

FT-2 [ ] Electronic schematic of the parts installed

in Miss Acro.

FT-3 [ ] Check that the control surface movements

arecorrect. The elevator movementshouldbeabout

20°upanddown.Ruddershouldbeabout30°leftand

rightandaileronsabout 20° both directions.

FT-4 [ ] Add the supplied decals to the model as per

the box illustration.

FT-4[ ] Check the balance point. It must be between

55 and 60 mm back from the leading edge of the

wing. If necessary, move the batteries inside the

fuselageto balance.

Safety Warning!

YourMissAcro isarelatively

safe R/C model. It may be flown in fairly small areas

withoutdisturbingyour neighbours. Never forget that it

is not a toy and that it could be potentially dangerous

if common sense is not used. Avoid flying in

populatedareas or close to roads,railways, airports

and so on. Ensure that any spectators are aware of

thepotentialdangerofyourmodel.

Enjoyflying your Miss Acro!

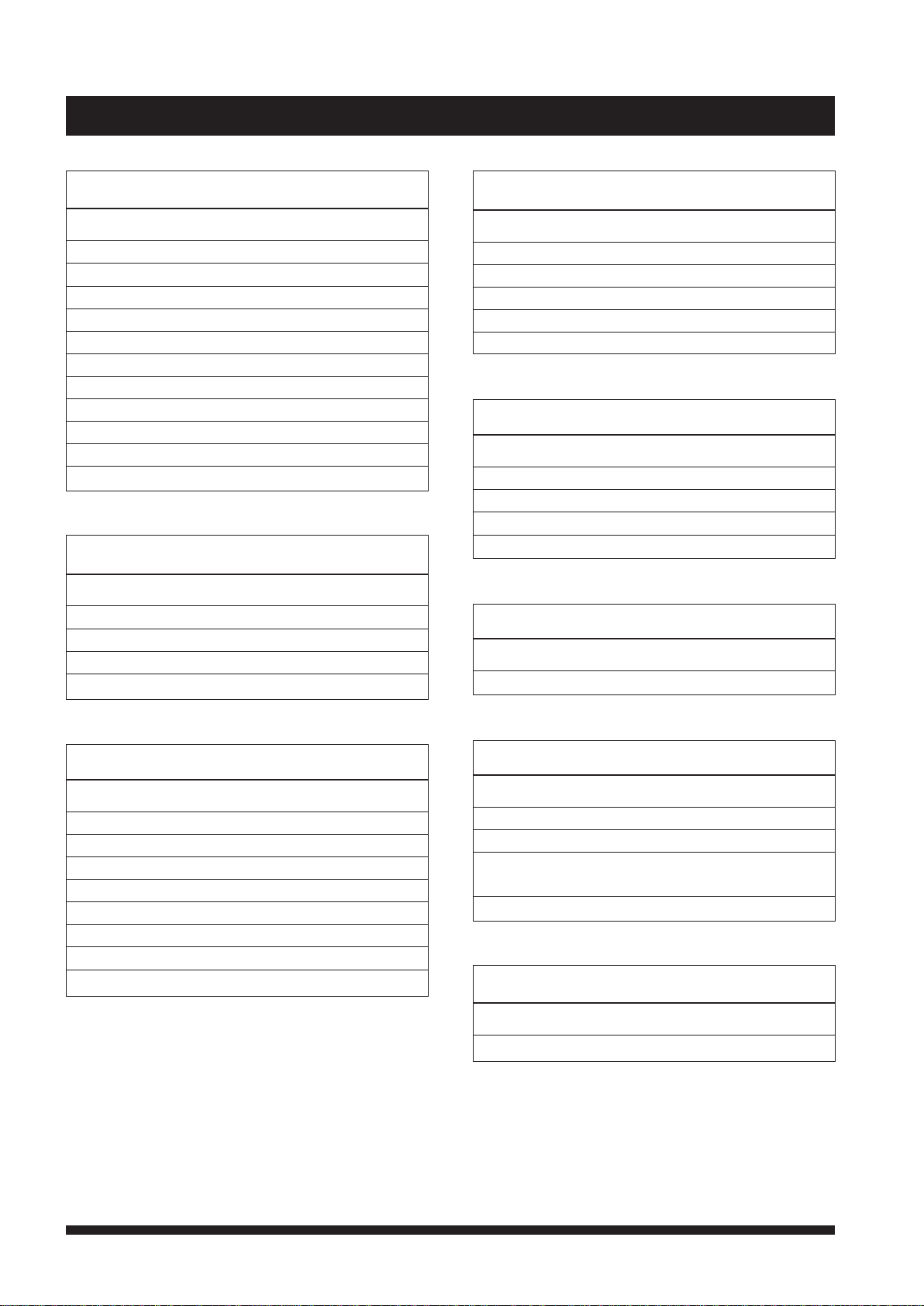

Box Parts

No. Qty. Description

[1] 1 Fuselage

[2] 1 Right Wing

[3] 1 Left Wing

[4] 1 Ruddercomplete

[5] 1 Tailplane complete

[6] 1 Canopy

[7] 1 MainLandingGear

[8] 2 Fuselage doublers

1 BagB1

1 BagB2

1 BagB3

1 DieCutDC-1

1 DieCutDC-2

1 DieCutDC-3

1 DieCutDC-4

1 DieCutDC-5

1 Decals

1 InstructionBooklet

W-1 W-2

W-3 W-4

W-5 F-1

F-2 F-3

[3]

[3]

[3]

[2]

[B3-8]

[DC3-1]

[1]

[B3-2]

[1]

[1]

F-4 F-5

F-6 F-7

F-8 F-9

F-10 F-11

[B3-3] [7]

[1]

[7]

[B2-2]

[B2-1]

[B2-2]

[8]

[DC2-4]

[DC2-2]

[DC2-1] [DC1-2]

[DC1-5]

[B2-3]

[5]

[B3-1]

F-12 F-13

F-14 F-15

F-16 F-17

F-18 F-19

[5]

[5]

[1]

[4]

[5]

[4]

[5]

[1]

[B3-4]

[1]

[B3-7]

[B3-1]

F-20 F-21

F-22 F-23

F-24 RC-1

RC-2 RC-3

[DC1-3]

[DC1-4]

[DC2-3]

[6]

[DC1-1]

[B1-2] [B1-8]

[B1-7]

[DC1-1]

RC-4 RC-5

RC-6 RC-7

RC-8 RC-9

RC-11RC-10

[B1-1]

[B1-7]

[B1-8]

[B1-5] [B1-6]

[B1-6]

[B1-5]

[B1-3] [B1-5] [B1-6]

[B1-4]

[DC5-1] [DC5-1]

[B1-9]

RC-12 RC-13

RC-14 RC-15

RC-16 MPJ-1

MPJ-2 MPJ-3

[B3-6]

[B3-5]

[B1-11]

[B1-10]

[B1-6]

MH-1 MH-2

MH-3 FT-1

FT-2 FT-3

FT-4 FT-5

[DC4-3] [DC4-4]

[DC4-1]

[DC4-2]

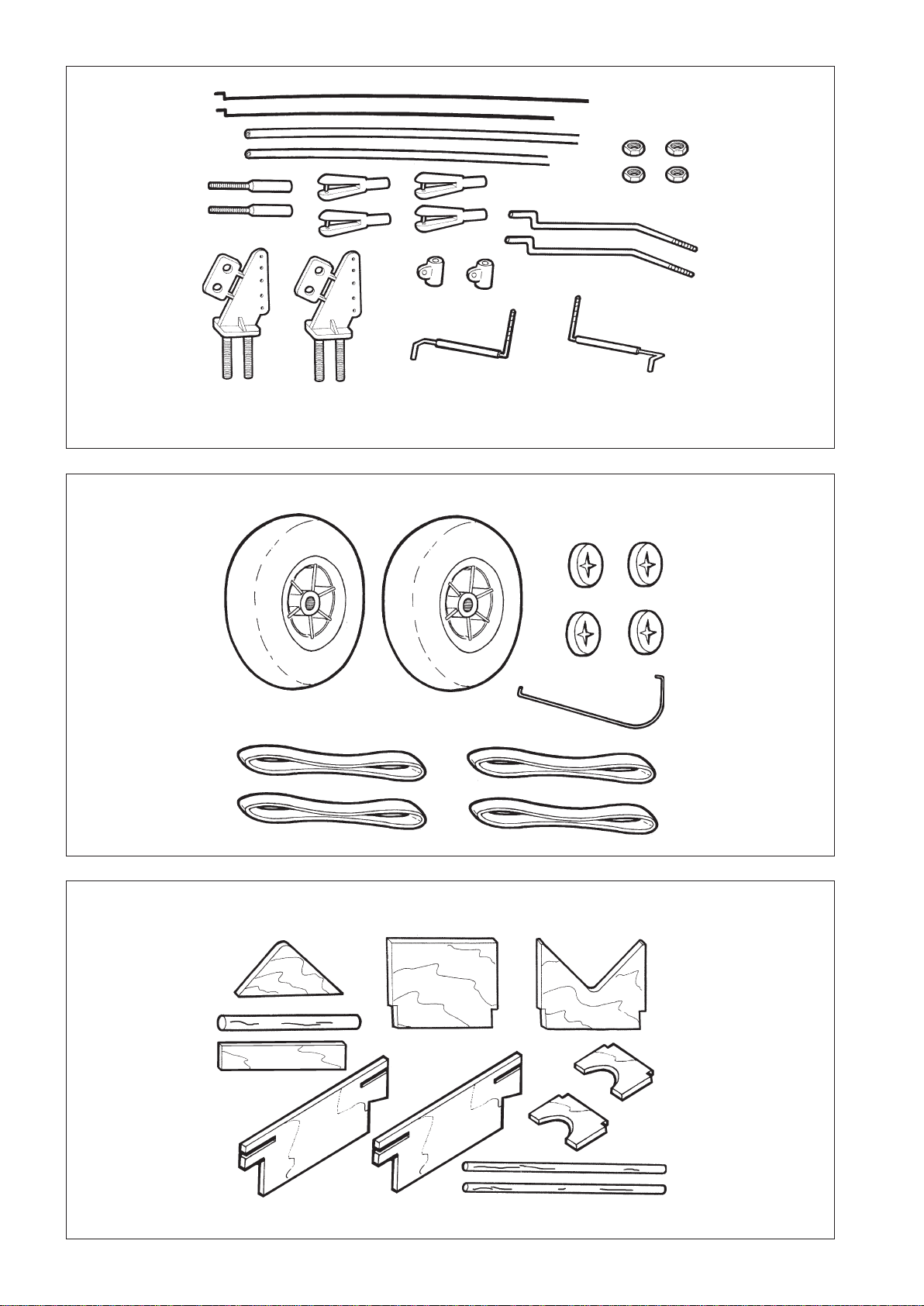

[B1]

[B3]

[B2]

[B1-1]

[B1-3]

[B1-2]

[B1-4]

[B1-8]

[B1-5] [B1-6]

[B1-11]

[B1-7] [B1-9]

[B1-10]

[B2-2]

[B3-1]

[B2-3]

[B2-4]

[B2-1]

[B3-2]

[B3-3]

[B3-6]

[B3-4]

[B3-5]

[B3-8]

[B3-7]

[DC1]

[DC2]

[DC3]

[DC5]

[DC1-5]

[DC1-1]

[DC1-2]

[DC1-3]

[DC1-4]

[DC2-3]

[DC2-1]

[DC2-2]

[DC2-4]

[DC3-1]

[DC3-1]

[DC5-1]

[DC4-2]

[DC4-1]

[DC4-3]

[DC4-4] [DC4]

Miss Acro S2066

Bag [B2]

No. Qty. Description

[B2-1] 2 Wheel

[B2-2] 4 Wheel Lock

[B2-3] 1 Tail Skid

[B3-3] 4 RubberBands

Die Cut [DC-3]

No. Qty. Description

[DC3-1] 2 Wing joiner

Die Cut [DC-4]

No. Qty. Description

[DC4-1] 1 Motor cradlerearformer

[DC4-2] 1 Motor cradle front former

[DC4-3] 1 Motor cradle front former

doubler

[DC4-4] 2 Motor cradle side

Die Cut [DC-2]

No. Qty. Description

[DC2-1] 1 Radio and servo tray

[DC2-2] 1 Pushrod support

[DC2-3] 1 Canopy catch

[DC2-4] 2 Fuselage longeronspacer

Bag [B1]

No. Qty. Description

[B1-1] 1 Pushrod

[B1-2] 1 Pushrod

[B1-3] 1 Tube

[B1-4] 1 Tube

[B1-5] 2 ThreadedAdapter

[B1-6] 4 Snap Link

[B1-7] 2 ControlHorn

[B1-8] 4 Nuts

[B1-9] 2 Torque rod

[B1-10] 2 Torque RodConnector

[B1-11] 2 Pushrod

Bag [B3]

No. Qty. Description

[B3-1] 1 Semi-former

[B3-2] 1 Doubler

[B3-3] 1 GearLock

[B3-4] 1 FuselageBrace

[B3-5] 2 WingServo Cradle Side

[B3-6] 2 WingServo Cradle Joiner

[B3-7] 2 WingDowel

[B3-8] 1 WingJoining Dowel

Die Cut [DC-1]

No. Qty. Description

[DC1-1] 1 Canopyframe

[DC1-2] 1 Fuselageformer

[DC1-3] 2 Canopy hooks

[DC1-4] 1 Spacer

[DC1-5] 1 Tail skid

Die Cut [DC-5]

No. Qty. Description

[DC5-1] 2 TrailingEdgeDoubler

S2066 Miss Acro

Notes:

Table of contents

Other Scorpio Toy manuals

Popular Toy manuals by other brands

Tyco R/C

Tyco R/C R3044-0920 instructions

Sky Master

Sky Master ARF PLUS PRO HAWK 100 Assembly and operation manual

V-tech

V-tech Go! Go! Cory Carson DJ Train Trax & the Roll... Parents' guide

Hot Wheels

Hot Wheels CONSTRUCTION ZONE CHAOS instructions

V-tech

V-tech Switch & Go Stegosaurus Buggy Parents' guide

V-tech

V-tech Kidizoom camera Connect user manual

V-tech

V-tech Hover Pup instruction manual

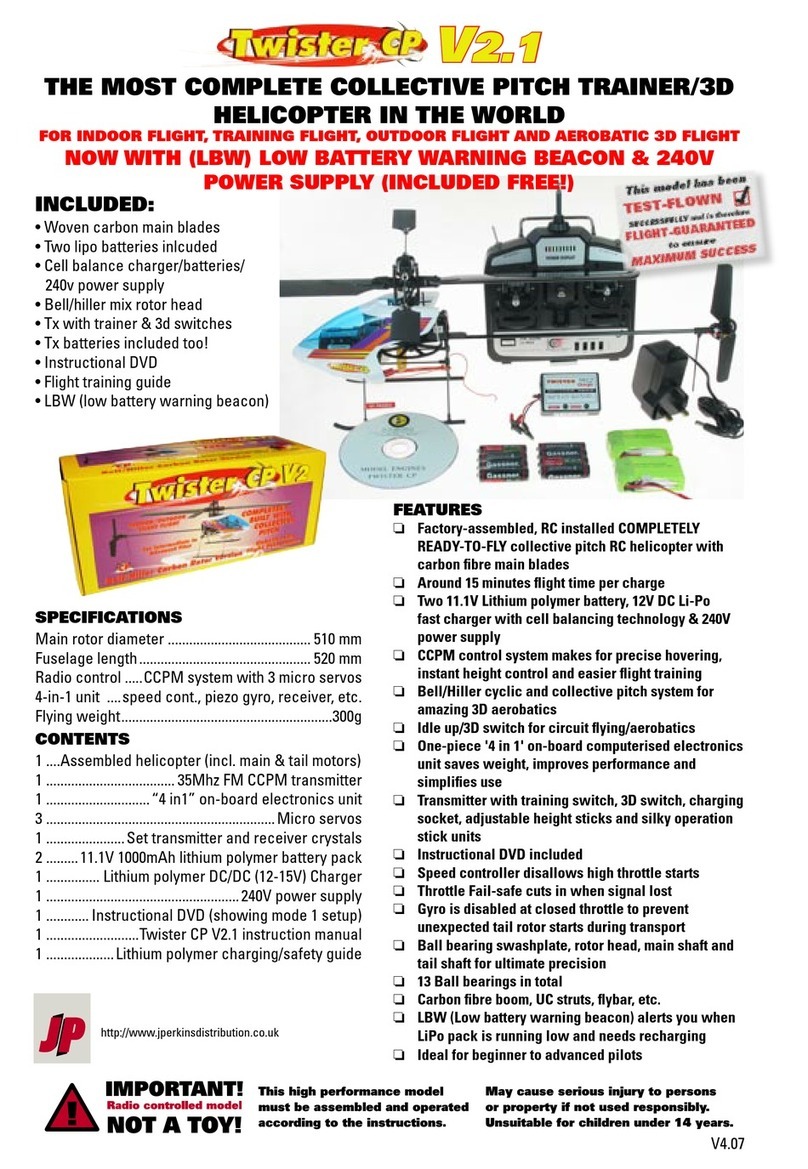

J. Perkins

J. Perkins Twister CP V2.1 manual

V-tech

V-tech SWITCH & GO DINOS Turmoil the Triceratops Parents' guide

Best Choice Products

Best Choice Products SKY3895 instruction manual

V-tech

V-tech 3-in-1 Smart Wheels user manual

Hobby King

Hobby King Electrolyte Assembly manual