TABLE

OF

CONTENTS

.... ....

" u

"'

0

"' "'

"'

"'

"'

N

:!.

...

"'

IDENTIFICATION

.....................................

2 o"'

"'

"'

u

co

(')

(')

"'

0

"'

... -

"'

(')

co

"'

"'

0 0

UJ

"'

PRE·OPERATING

TIPS

.................................

4 ... -" " N -:

"'

0

(')

"'

...

"'

<(

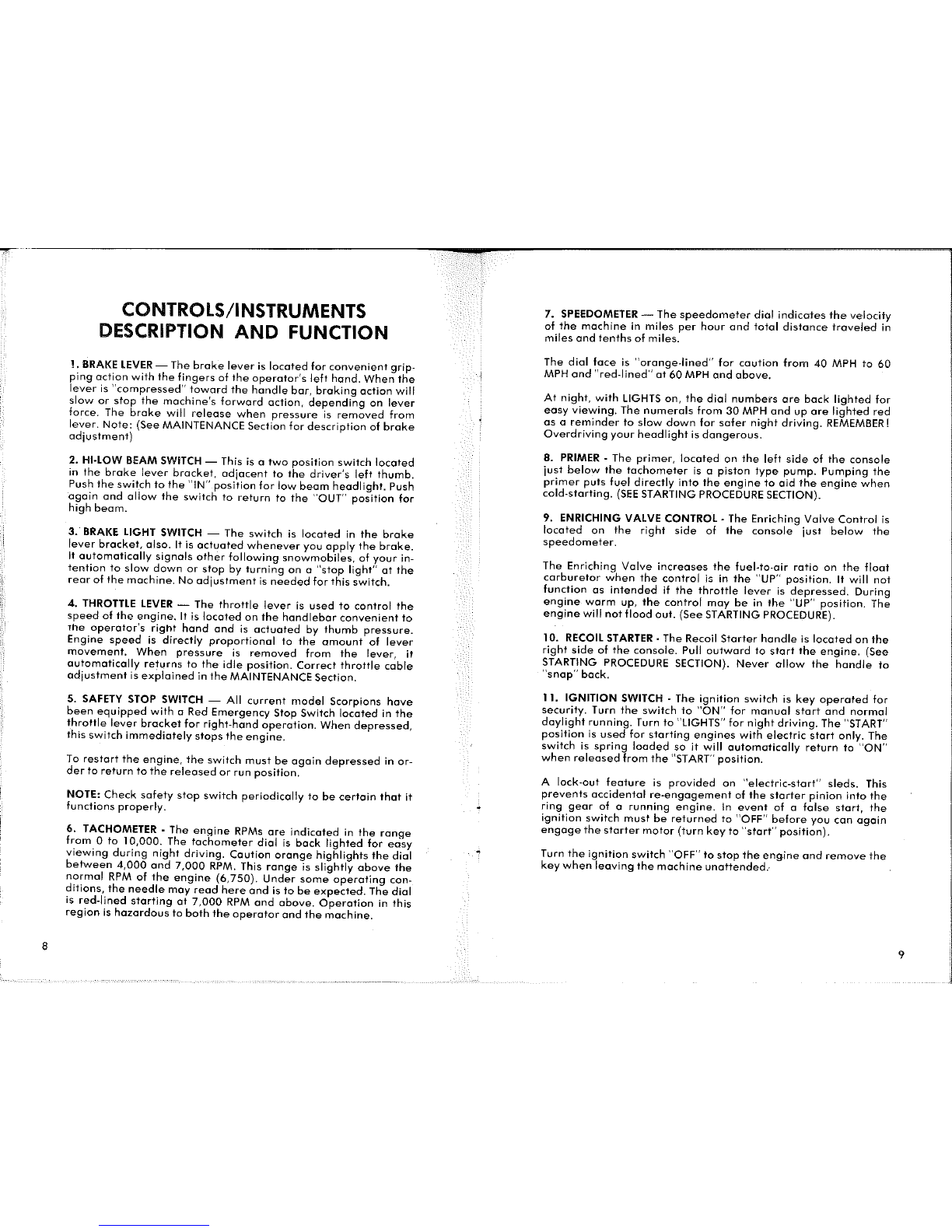

CONTROLS/INSTRUMENTS

.............................

? 0

UJ

~

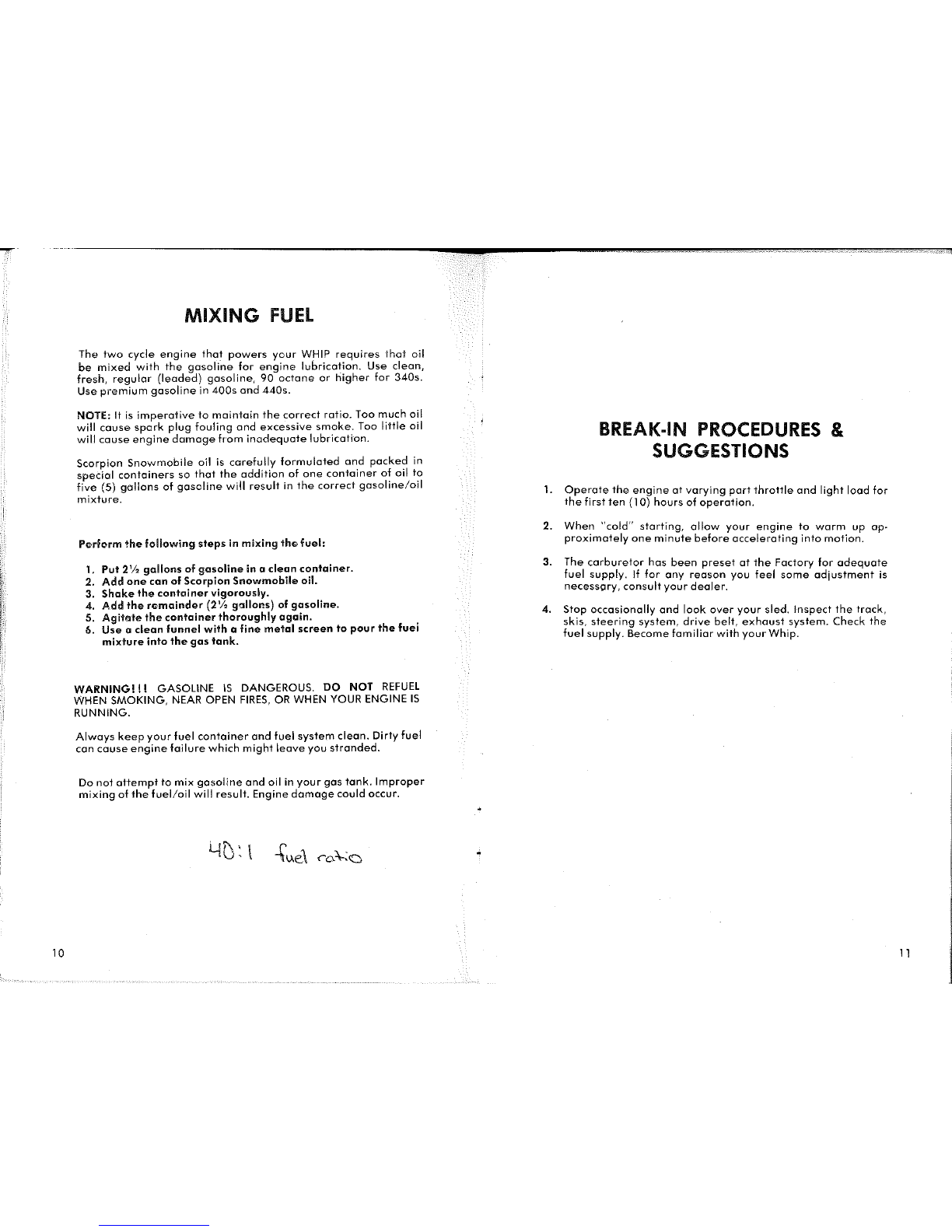

MIXING

FUEL

.......................................

10

<(

UJ

BREAK·IN PROCEDURE

...................

"

...........

11

Cl

z

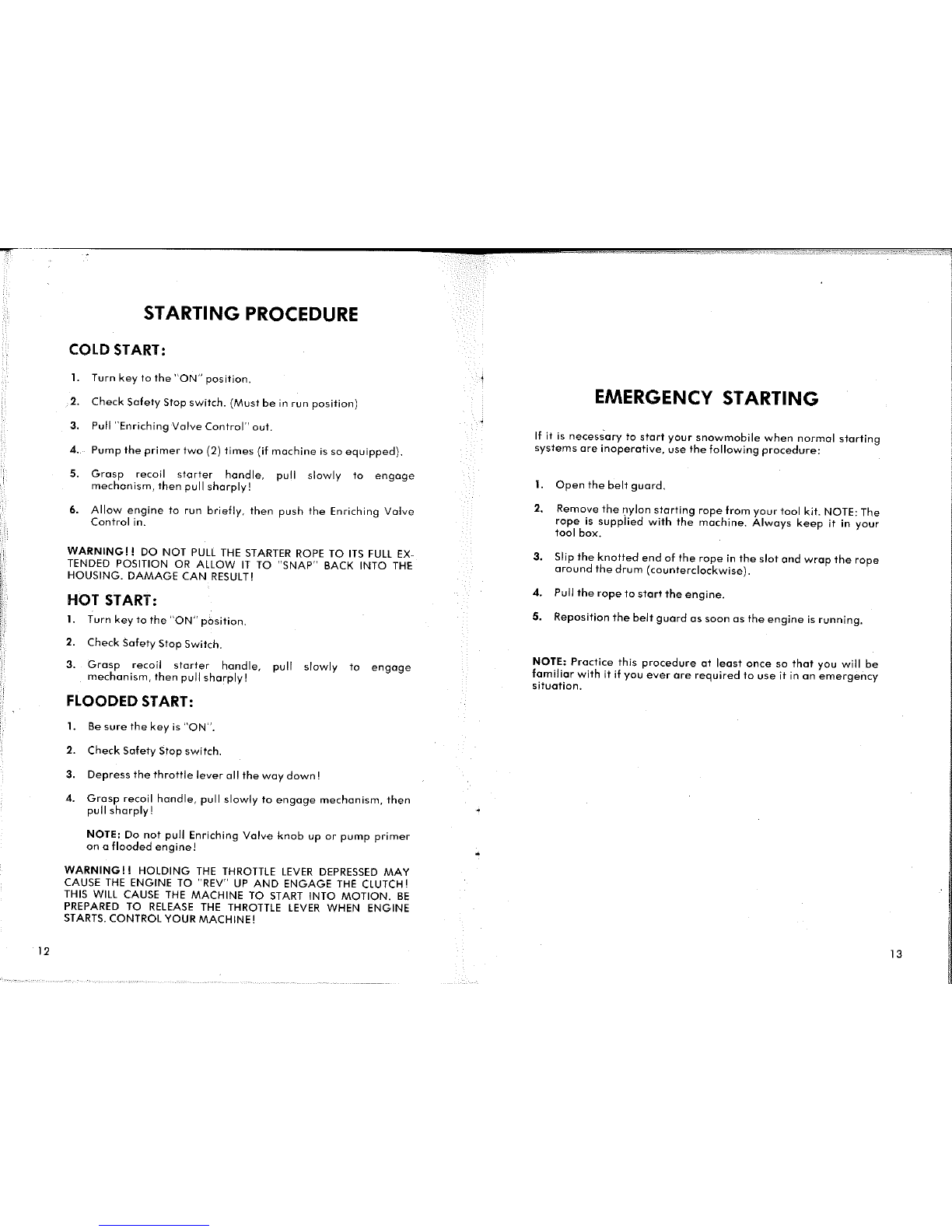

STARTING PROCEDURES.

..

"

..

"

.......................

12 Q

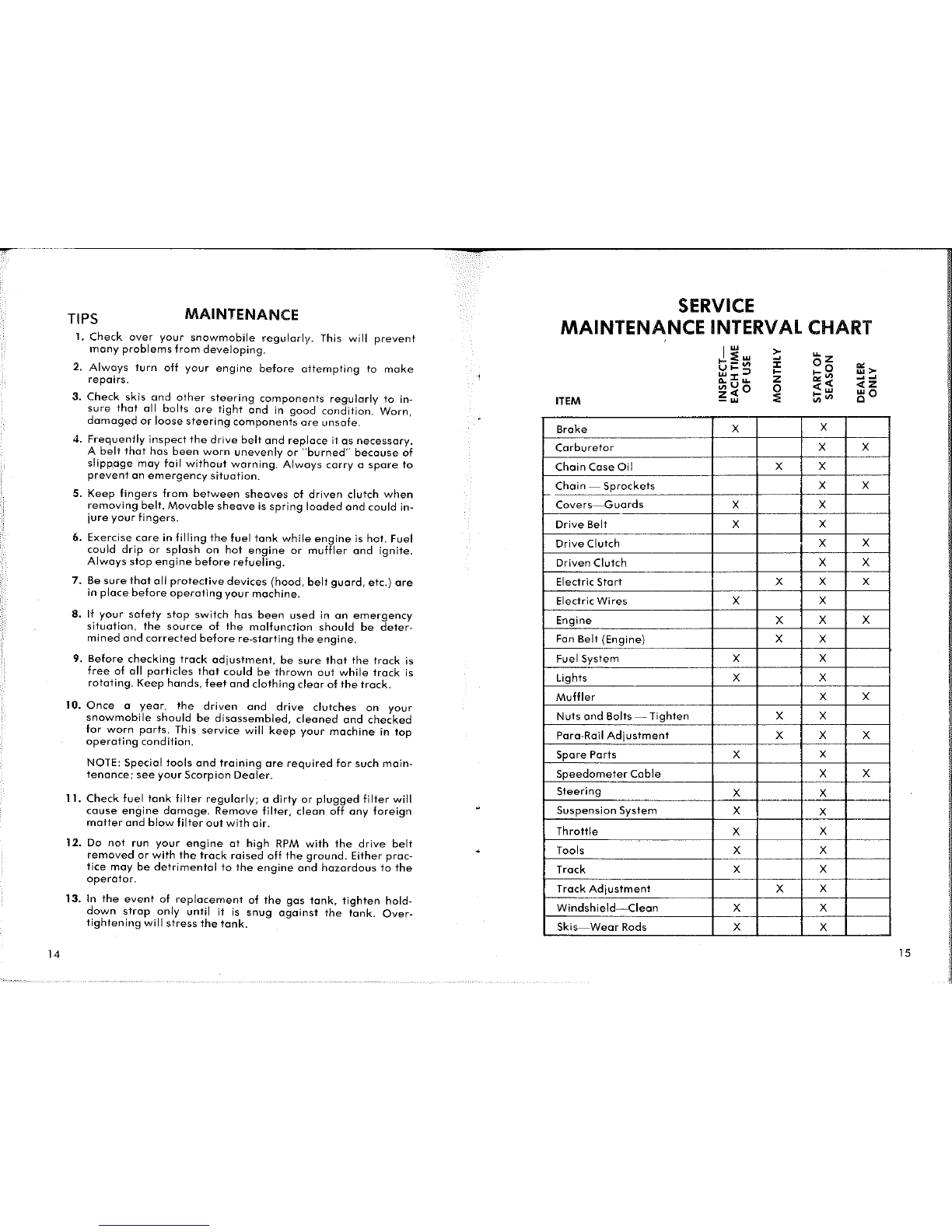

MAINTENANCE

TIPS

...

.

".

"

.......................

14

"-

"'

SERVICE

INTERVAL CHART 15

(')

0

........

'

.......

u

o-

"'

" u

"'

0

"'

"' "' "'

(')

"

:!.

...

"'

SPARK PLUG REPLACEMENT

.............

"".""

.........

16

o-

"'

"'

u <J)

co

(')

(')

"'

0

(')

""'

"'

(')

"'

"'

"' "'

0 0

UJ

"'

HEADLIGHT ADJUSTMENT

....

"

.......................

18 " "

"'

-:

::J

"'

0

(')

0

(')

BRAKE ADJUSTMENT.

................................

20 0 <(

>-

SKI

ALIGNMENT

....................

21

t-

. . . . . . . . . -. . . . . .

~

CARBURETOR ADJUSTMENT

...........................

23 ::J

<J)

THROTTLE CABLE ADJUSTMENT

........................

24

z

"'

"'

0

z " " u

"'

0

"'

"'

"'

"'

(')

"

:!.

...

"'

BELT

REPLACEMENT

........

. "

..................

25

o"'

"'

"'

u u

co

(') (')

"'

0

(')

co

0 ... -

(')

(')

(')

"'

-:

"'

0 0

UJ

"'

TRACK ADJUSTMENT "

.....

"

.........................

28

(')-

"

"'

0

(')

i=

"'

"

(')

<(

SUSPENSION ADJUSTMENT

........................

·

....

30

0

c(

BULB REPLACEMENT

.................................

31

~

TROUBLE

SHOOTING

.................................

33

II.

SUMMER STORAGE

..................................

37

0

PREPARATION

FOR

WINTER

...........................

38 w

a..

"'

IDENTIFICATION

a..

J:

The

model

and

serial

numbers

on your

machine

are

very

im- ;: "'0

portant

and

the

identification

plate

should

not

be

removed.

It

is

a;

.<:

suggested

that

you

record

them

in

the

space

provided

below.

"'

The

serial

number

is

also

embossed

in

the

frame

of

the

"'0

c

machine.

It

is

the

same

serial

number

as

appears

on

the

iden-

3:

tification

plate.

0

"

3:

"'

•

Machine

Serial

Number

c 0

"

.2

z £

u 0

c 0 0

"'

c c

0 0 z 0 "

> z

~

•

Model

Number

"'0

..c

z

"'

.<:

~

i

~

<(

>-

..c ..c

~

.<: ..c

c

~

~ .<:

Ol

"C

.S!'

"

·u

"'

~ u c .<:

E

~

Ol

~

"'

a "

3:

"

~

a.

u..

~ 0

1:

"'

t-

~

:c

"'0

Engine Serial

Number

" 0 a.

1:

1:

"

3:

u 0

"-

0

.S!'

0 =

"

.2

Ol

u

Ol Ol

"'0 0 0 0

IMPORTANT:

BE

SURE

YOUR SCORPION

DEALER

HAS

REGISTERED

-"

1:

c -" "'0

~ ~ ~

-"'

" 0 a.

~

a; 0 a. " " " " u

YOUR

MACHINE

BY

SENDING

THE

WARRANTY CARD TO

THE

~

~

"'

E 0 0 " > > > 0

0

~

0 0 a. ~ " 0

~

a.

~

FACTORY.

"'

<J)

"-

;.=

<J)

u..

:c

t-

<J) <J) 0 0 0

t-

2 3