User manual.

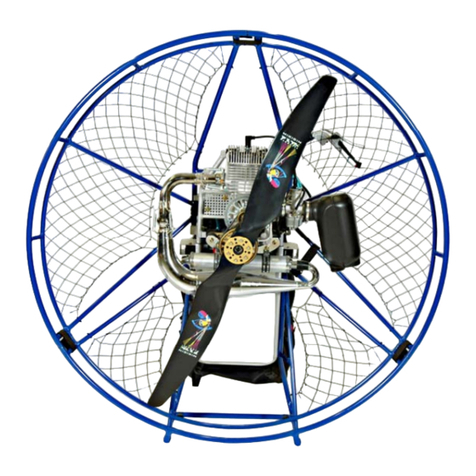

5 Paramotor assemb y

Tips for cage assembly

SCOUT paramotor comes completely assemble an pilot only nee s to install the cage an

propeller. For assembly, please follow these steps:

1. lay the paramotor own, engine facing own

2. Insert the Enduro stand by pusing the

brass pins, make sure the pins pop out.

You will regret later if you forget this now

:-)

3. Now your can flip your parmaotor in the

normal stan ing position.

4. install first Carbon DTC spar on to the main

frame. Start with the right bottom one, the

one that is near the fuel tank cap.

5. install the low ring section

6. Step on the stan , push the main frame

away from you still hol ing the stan with

your foot to make room for the ball joint to

enter in the bottom hoop CNC machine

hole.

7. install all other carbon spars like on this

picture (secon picture)

8. Take the 5 ring sections out of the bag,

keep them fol e together.

9. Keep the carabiner locke throughout the

whole process - this prevents the netting

from tangling.

10. Look at the INNER ring section an fin out

which si e it fits.

11. Approach the paramotor from front so that

the netting stays in front of the arms.

12. Place the inner ring section on to the lower

arm on respective si e whi e sti keeping

a fo ded ring sections together. .

13. Leave the other end of the first ring

section free. Leave the free end of the

section on the OUTER side.

14. While the first section is in place, "unfol " the

remaining four an place the inner section on

the next arm (3 or 9 o'clock).

15. Repeat with all other sections

16. It may be necessary to unlock t e

carabiner on t e netting to be able to put

t e last ring section in place

17. At t is point you s ould end up wit all

sections pus ed alf-way only wit one

end.

18. Now finis t e assembly of t e cage by

pus ing t e section onto t e arms until

Proudly designed and manufactured in Slovakia. (www.scoutparamotor.com)