NOTE: When pullingthe starter rope, OPERATING TIPS

do not use the full extent of the rope. • Check chain tendon before first use

Do not let stinter rope snap bad_ Hold and aftor,1 minute of operation. See

handle. Let rope rewind slowly. Chain Tension in the Maintenance

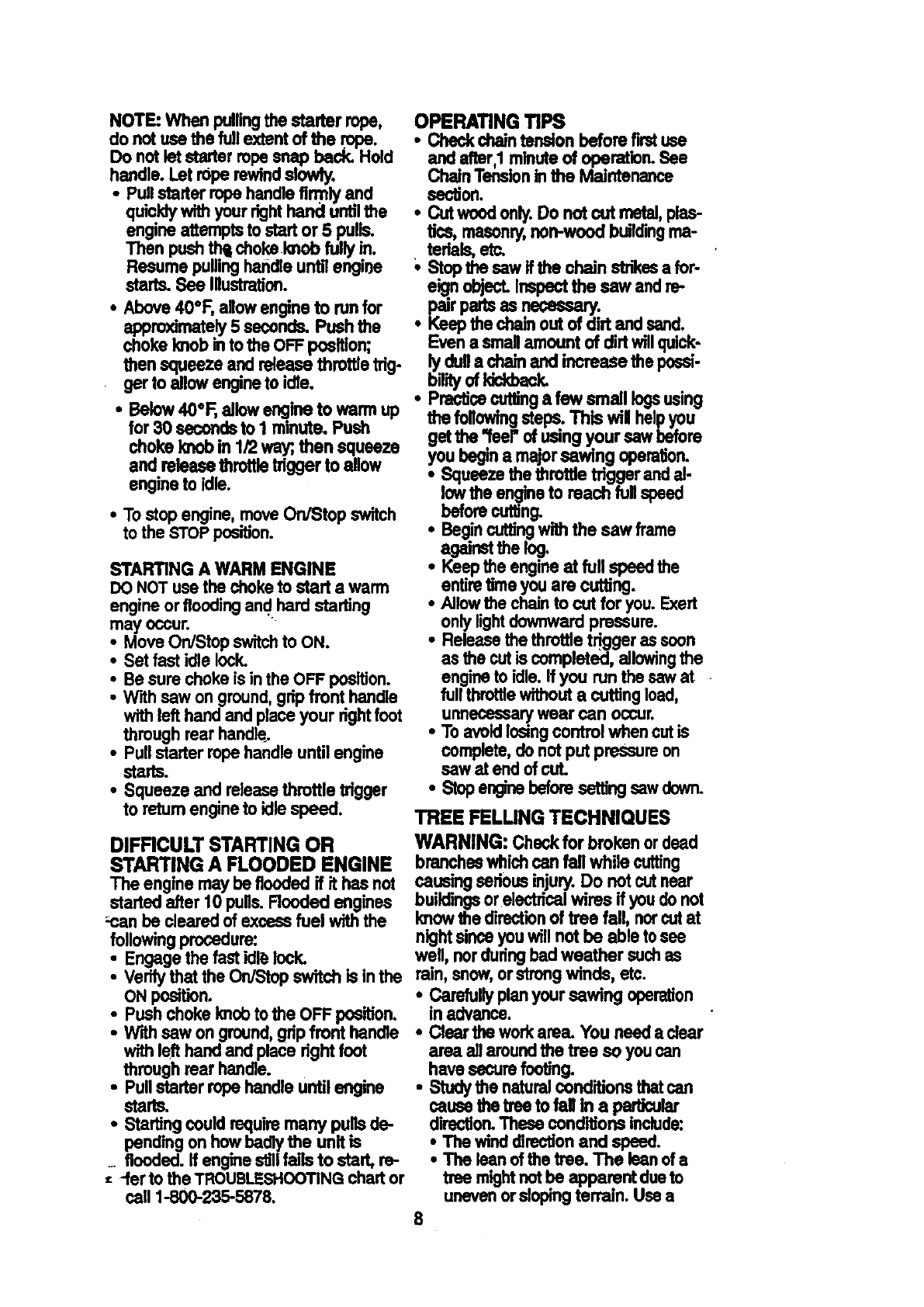

• Pullmiter rope handlefirmly and

quicklywith your righthand untl"lthe

engineattemptsto start or 5pulls.

Then pushtl_ chokeknob fully in.

Resume pullinghandleuntil engi0e

starts. See Igustration.

• Above 40°F, allow engine to runfor

approximately5 seconds. Push the

choke knob in tothe OFF position;

then squeeze and release throttle trig.

ger to allow engineto idte.

•Below 40°F, allow engine to warm up

for 30 saconds to 1 mirnJte.Push

choke knob in 1/2 way;,then squeeze

and release throffie tdgger to allow

engine to idle.

• To stopengine, move On/Stop switch

to the STOPposition.

STARTING A WARM ENGINE

DO NOT use the choke to start a warm

engine or floodingandhard starting

may occur.

•Move On/Stop switchto ON.

•Set fast idle lock.

•Be sure choke is in the OFF position.

• With saw on ground,gdp front handle

with left hand and place your dght foot

through rear handle.

•Pullstarter ropehandle untilengine

starts.

•Squeeze and releasethrottle trigger

to returnengineto idlespeed.

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

The engine may be flooded if ithas not

started after 10 pulls.Flooded engines

;can be cleared of excessfuel with the

followingprocedure:

•Engagethe fast idl_lock.

•Verifythat the On/Stop switch ls inthe

ON position.

Pushchoke knob to the OFF position.

•"With saw on ground,gnpfront handle

with left hand and place dght foot

through rear handle.

•Pull starter rope handle until engine

starts.

• Starting could require many pulls de-

pending on how badly the unit is

_ flooded, if en_ne stillfails to start, re-

-fer to the TROUBLESHOOTING chart or

call 1-800-235-5878.

8eotJon.

•Cut woed only.Do not out metsl, plas-

tics, masonry,non-wood buildingrna-

tedab, etc;

•Stop the saw ifthe chatn atnlcsea for-

eign object.Inspectthe saw and re-

pairpaits as .r.r._.:

•Keep the chain out of dirt and sand.

Even a smallamount of dirtwillquick.

blYduliachainandincreasethepossl-

llHyofidcid:)ask.

• Practicecuttingafew small logsusing

the foflowingsteps. This wil helpyou

get the "feet"of usingyour saw before

you begina majorsawing operaSon.

•Squeeze the throttle _gger andal-

lowtheenginetoreachfullspeed

beforecutting.

•Begincuttingwiththe saw frame

againstthe log

•Keep the engineat full speed the

enbretimeyou are cutting.

• AJIowthe chain to cut for you. Exert

onlylightdownward pressure.

•Release the throttletdgger as soon

as the cutis completed, allowingthe

engineto idle. Ifyou runthe saw at

full throttle withouta cuffingload,

unnecessarywear can occur.

•To avoidlosingcontrol when cut is

complete, do not put pressureon

saw at end ofcut.

•Stopenginebeforesettingsawdown.

TREE FELUNG TECHNIQUES

WARNING: Check for broken or dead

brancheswhichcan fall while cutting

ca_ing serious.injury.DO notcut near

buddingeorelectricalwires if you do not

know the directionof tree fall, norcut at

nightsinceyou will not be able tosee

well, nordudngbad weather suchas

rain, snow,or strongwinds, etc.

•Carefullyplanyour sawing operation

in advance.

•Clear the workarea. You need a dear

area allaroundthe tree so you can

have securefooting.

•Studythe naturalconditions thatcan

_usa the treeto fall in a partbular

direction.These conditions include:

•The wind directionand speed.

•The lean of the tree. The lean ofa

tree mightnotbe apparent due to

uneven or sloping terrain. Usea

8