SEATEK ROTO-SPLIT ROTO-FLEX RS-101 User manual

ROTO-SPLIT

Made in USA Patent Pending

Standard MC Small MC

www.SeatekCo.com

t

t

RS-101AC AUTOCLAMPING

RS-101 WITH THUMB NUT CLAMPING

Back-up thumb screwa& insert cable binto the channel. Hold cableb

in place with your thumb. Now turn thumb screw aclockwise until the tip

of the clampingstud efalls into the helical groove of the cablecasing

b. Secure by hand tightening thumbscrewa. Note: Do not tighten with

pliers, only hand tightening is required to clamp the cable securely.

ROTO-SPLIT

SEATEK Co.

STAMFORD, CT

PATENTED

ROTO-SPLIT

SEATEK Co.

STAMFORD, CT

PATENTED

c

c

The patented ROTO-SPLIT ® strips #14, 12, 10 & 8 gauge BX & MC cable & cuts 3/8" trade size ex. The new patent pending

ROTO-SPLIT ®RS-101AC & RS-101B have exclusive auto clamping. The RS-101AC strips new reduced diameter brands

of MC cable. The ROTO-FLEX cuts 1/2" to 3/4" trade size ex & strips large size BX & MC cable such as: AWG #2/3 & AWG

#4/3. For larger cables & ex up to 1-1/2" trade size use our ROTO-FLEX RF-170.

Remove the hex nut from the curved handle c. Put the threaded screw

into the blade shaft and push out the red plug. Screw on the hex nut

with the counterbored side against the blade. Tighten the nut with an

adjustable wrench.

RS-101A, RS-101AL & RF-120A

WITH QUICK CLAMPING

Unscrew knob aand insert cable binto the channel. Squeeze quick

clamping lever until the clamping stud ereaches the bottom of the

cable groove. The tip of the quick clamping lever 4should be

just above the bottom of the tool. Adjust the depth of the clamping

stud eby turning knob auntil the lever is in the correct position. It

is important to note that the cable should be clamped securely

but not overtightened. Adjustment is normally not required

when switching from #14 to #12 cables. The quick clamping &

release feature of the RS-101A makes it twice as fast as the original.

INSTRUCTION SHEET FOR THE ROTO-SPLIT®& ROTO-FLEX™

da

a

b

b

RS-101

RS-101A

RS-101, RS-101A, RS-101B, RS-101AC, RS-101AL AND RF-120A

View all of our products at www.SeatekCo.com

THANK YOU FOR PURCHASING A FINE U.S. MADE TOOL

PLEASE READ THESE INSTRUCTIONS TO GET YEARS OF SATISFACTION

c

b

a

RS-101AC & RS -101B

WITH EXCLUSIVE AUTO CLAMPING

Insert cable ainto the channel and squeeze auto-clamping

lever buntil the clamping stud dreaches the bottom of the

cable groove. Hold the tool near the cutting head & squeeze the

RS-101AC or RS-101B until the blade makes contact with the cable.

e

e

Hand

Tighten

d

After the MC cable has been clamped, hold the tool near the cutting

head and squeeze the ROTO-SPLIT or ROTO-FLEX. Do not apply

too much pressure while pushing the "BLUE SAPPHIRE" circular

blade against the cable. Rotate the crank handle csmoothly and

change the amount of pressure to get the most efcient cutting action.

When the force required to turn the crank suddenly decreases,

you have cut all the way through. Release pressure and turn

the crank slightly, the top should snap back to the original position.

f

DEPTH OF CUT

LEVER

STEP 2 - CABLE CLAMPING

STEP 1 - A S S E M BLY

STEP 3 - CUTTING MC CABLES

g

RS-101AC & B

RS-101AC: For small diameter MC cable lever fmust be in the

forward position and button gmust be pushed in completely

(flush with outer channel)to properly position the cable.

WARRANTY:All the ROTO-SPLITand ROTO-FLEX models have a lifetimeguaranty

except for the blade. They are warranted to be free from defects in workmanship and

material. Should any part of these tools be defective, they will be serviced or replaced

free of charge (except for replacement blade). This warranty is void if these tools

have been damaged by accident or mishandling. THIS WARRANTY IS IN

LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED, except for repair or

replacement of parts, Seatek Company assumes no liability for damage to the replacement

blade or other damages.

392 PACIFIC STREET, STAMFORD, CT 06902

PHONE 203-324-0067 P FAX 203-324-7844 Pwww.SeatekCo.com

A SMALL COMPANY WITH BIG IDEAS ®

CUTTING LARGE MC AND FLEX

For large MC, BX and Flex use the ROTO-FLEX RF-120 or

RF-170. The RF-120 cuts MC from AWG 4- 4 up to 2- 4 and Flex

from 1/2” to 3/4”. The RF-170 is our largest capacity hand tool

and cuts MC from AWG 4- 4 up to 4/0 and Flex from 1/2" to 1-1/2".

BLADE STORAGE

All our Roto-Split and Roto-Flex models (except the RS-101) have a

blade storage cartridge contained in the knob. To release the cartridge

simply pop it out with the tip of a screwdriver. Place your spare blades

inside (up to a maximum of six) and snap the cartridge back into the

knob. For best results always use genuine "BLUE SAPPHIRE" Cat.

B-102 or B-107 blades.

BLADE LUBRICATION

Use our Lubricant Stick LS-105 for longer blade life and to prevent

blade clogging (not for use on aluminum). Lubricant sticks are available

from your local distributor. NOTE: our armored cable cutters have an

opening in front to apply the lubricant stick, simply rotate the handle

with the LS-105 inserted into the tool.

All brands and product names are trademarks or registered trademarks of their respective companies

ROTO-SPLIT

SEATEKCo.

RIVERSIDECONN

PAT.PENDING

STEP 4 - REMOVING THE ARMORED CASING

With our "BLUE SAPPHIRE" blade 2 to 5 brisk turns of the handle

should be sufcient to split the BX casing. Hold the cable on each

side of the cut and twist the armored casing counter-clockwise until

it separates. If this last step fails, you have not cut all the way

through the armor. Repeat the steps above.

BLUE SAPPHIRE REPLACEMENT

BLADE. USE ON: RS-101, RS-101A,

RS-101AC, RF-120A, RF-120B & RF-170.

REPLACEMENT

BLADES

B-107

B-102

BLADE WITH OFFSET TEETH FOR

ALUMINUM OR STEEL CASING ON 1/2"

FLEX & LARGER. NOT FOR RS-101AC

FOR ALL POWER TOOLS & MACHINES.

RS-101-AP, RM-202A, B & C, RM-202M.

B-108

LUBRICANT STICK

LS-105

USE ON BLADES FOR ROTO-SPLIT &

ROTO-FLEX & ROTOMATIC MODELS.

(NOTE: DO NOT USE WHEN CUTTING

ALUMINUM ARMOR)

POWER KIT POWER CONVERSION KIT. MOTORIZE

ANY ROTO-SPLIT & ROTO-FLEX

(SAME PRINCIPLE AS POWER-SPLIT).

CONTAINS: B-108 BLADE, SHAFT, SCREW,

WASHERS, HEX NUT & HEX WRENCH.

HARDWARE

RETROFIT

SPARE PARTS KIT FOR ROTO-SPLIT &

ROTO-FLEX. CONTAINS ONE SHAFT, ONE

HEX NUT, ONE 4-40 KNURLED SCREW, ONE

RS-101 THUMBSCREW.

101-106

101-107

HANDLE ASSEMBLY FOR ALL MODELS OF

THE ROTO-SPLIT AND ROTO FLEX WITH

BLADE CARTRIDGE STORED IN KNOB.

HANDLE

101-110

WARNING!! Never attempt to cut already installed BX, MC or Flex cables on

live lines, since any contact between a live wire and ground can be lethal.

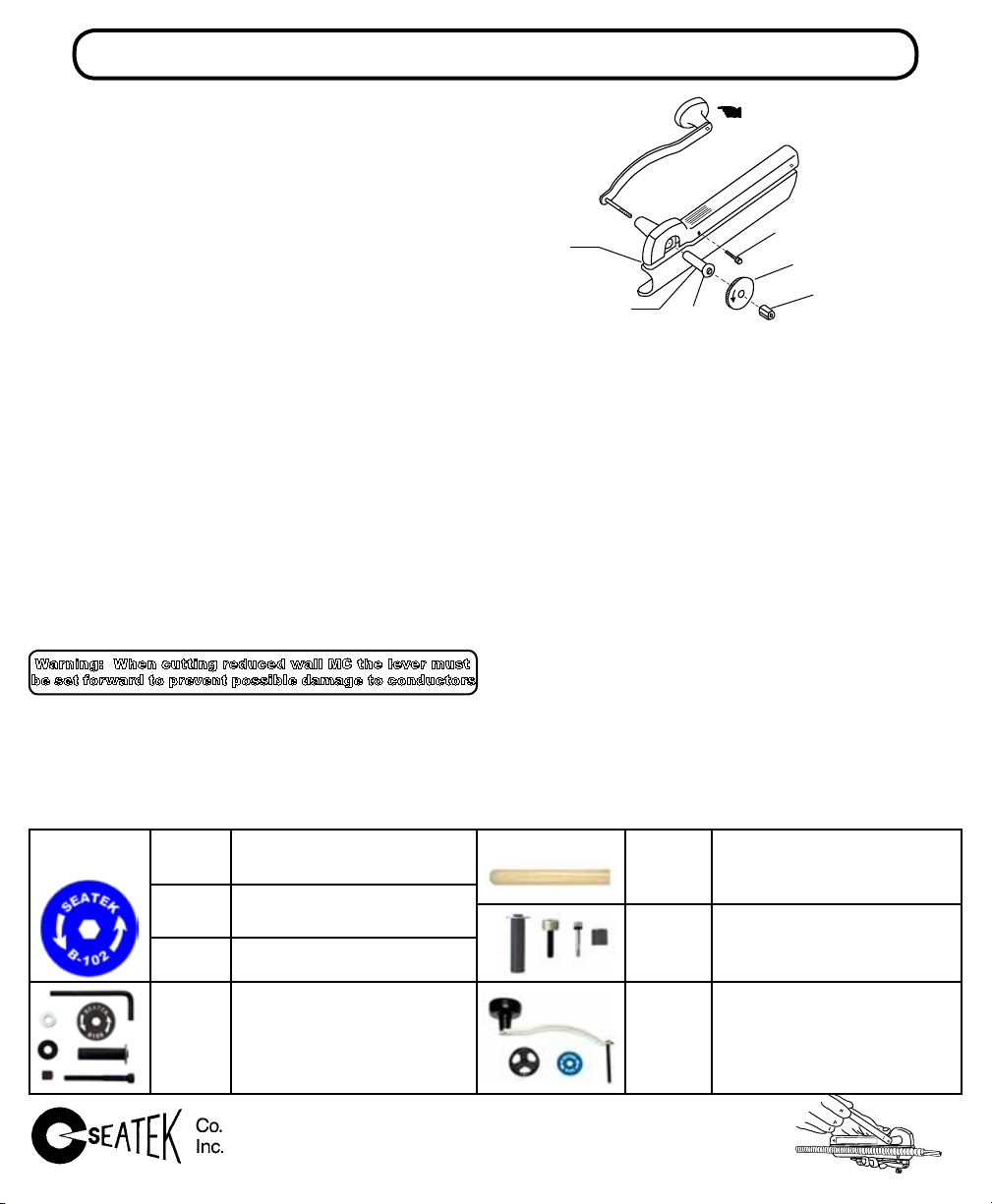

CUTTING REDUCED SIZE MC CABLE

Use the Roto-Split RS-101AC to cut reduced diameter MC cable

such as Southwire MCAP

. Since this cable requires a reduced depth

of cut slide the lever ftowards the front of the tool. Make sure

button gis pushed in completely (ush with outer channel)

to center the cable on the blade. Cut the cable armor as detailed

in Step c. To cut standard MC return lever fto the rear position.

Warning: When cutting reduced wall MC the lever must

be set forward to prevent possible damage to conductors

STEP 5 - DEPTH OF CUT ADJUSTMENT

If the Roto-Split does not completely cut through the armor it may

be required to adjust the depth of cut. Turn the set screw in

the top housing counter-clockwise a 1/4 turn (use a 3/32 Allen

wrench). Make a trial cut and adjust the set screw until the cas-

ing separates. It is critical to check that the blade does not

nick a wire after adjusting the depth of cut. Make a trial cut

to test. Casing can be separated by inserting the tip of a screw-

driver blade into the slot and twisting to crack it open, or simply

bend the cable slightly at the cut to snap the armored casing.

FOR LEFT HANDED USERS: No problem! Hold the Roto-Split upside

down in your right hand & turn the crank clockwise with your left.

BLADE STORAGE CARTRIDGE

(SNAPS IN KNOB - STORES 6 BLADES)

a

c

b

d

OUR TOOLS AND

BLADES ARE 100%

MADE IN THE USA

Oil Shaft

B-102 blades are

lubricated

DO NOT REMOVE

WAX BEFORE USE

For maximum blade

life lubricate the B-102

blade with LS-105

lubricant stick

Note: Always oil the dblade shaft & thumb screw when blade is replaced

Remove knurled screw a. Using an adjustable wrench, remove nut

cSwing up the top housing & push the handle assembly back about

1/2" inch. Lift out the blade b& replace with a new blade, making

sure that the arrow and logos are on top. Replace hex nut c&

knurled screw a. Please note that only a slight tightening of nut cis

necessary since the nut will automatically secure during the rst cut.

BLADE REPLACEMENT

Wax Stick

Opening

This manual suits for next models

5

Table of contents

Popular Tools manuals by other brands

Tüchler

Tüchler KABUKLIP operating manual

Atlas Copco

Atlas Copco PHE 20 Repair instructions

Titan

Titan TA 400 operating instructions

Victaulic

Victaulic RG3400 Operating and maintenance instruction manual

Tornador

Tornador Z-020S Original instruction manual

SAINT-GOBAIN

SAINT-GOBAIN BarbLock BLT-HHPAD Operation manual