BarbLock® Tabletop Pneumatic Assembly Tool: Operations Manual

www.biopharm.saint-gobain.com 3

FLS-5278C-CLWR-Rev 01

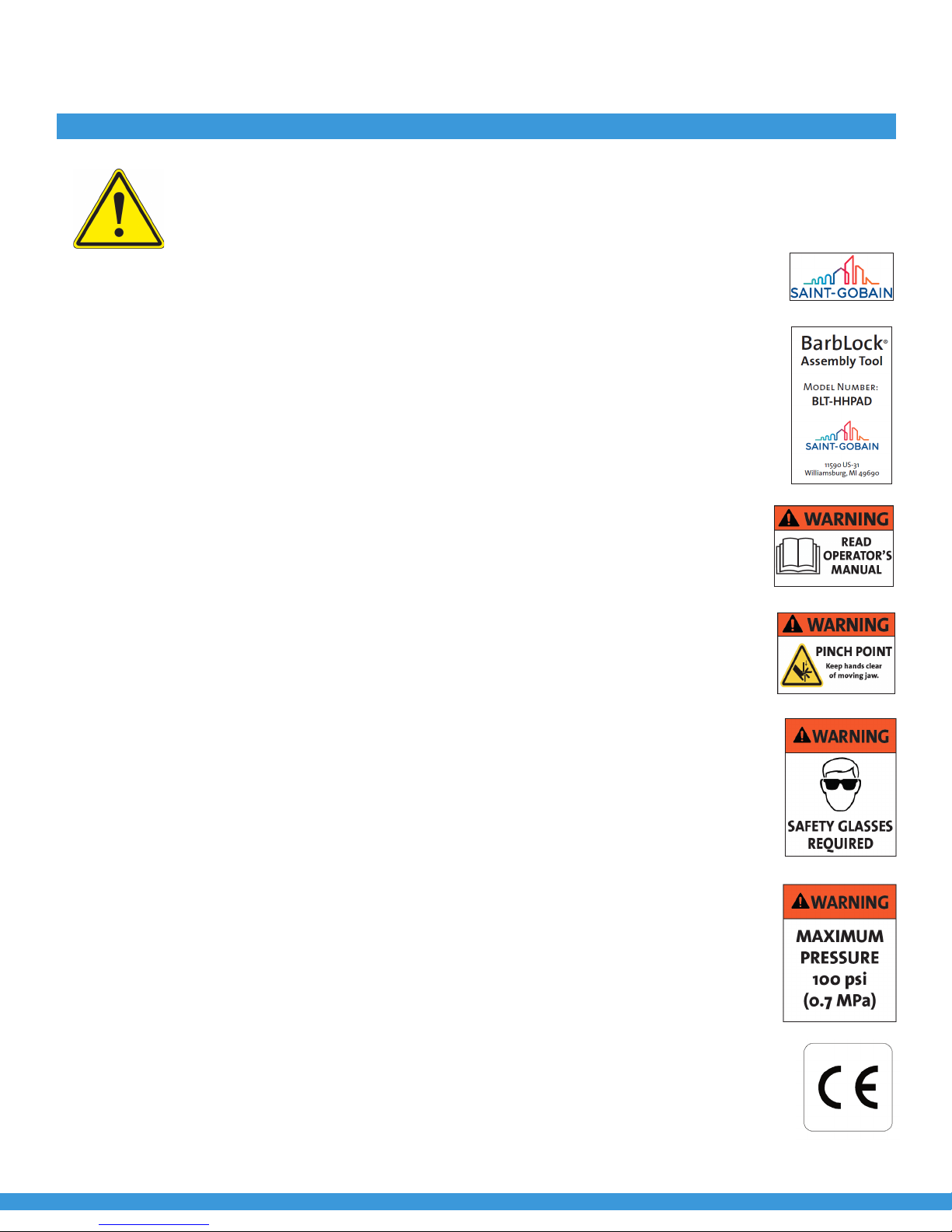

Read this before using the Saint-Gobain Performance Plastics BarbLock® Assembly Tool

We, as an authorized representative of Saint-Gobain of Williamsburg Michigan, USA certify and declare that the

following BarbLock® Pneumatic Assembly Tool:

All users must read the entire BarbLock® Assembly Tool Operating Instructions before installing, using or main-

taining the tool. Always keep the Operating Instructions at hand when using the BarbLock® Assembly Tool.

IMPORTANT: It is the user’s responsibility to ensure the suitability and safety of Saint-Gobain products for all

intended uses and that the materials to be used comply with all applicable medical regulatory requirements.

Saint-Gobain assumes no responsibility for any product failures that occur due to misuse arising out of the

design, fabrication or application of the products into which the materials are incorporated. Saint-Gobain

cannot assume liability if the BarbLock® Assembly Tool is subjected to improper use or operation. Saint-Gobain

is not liable for any damages resulting therefrom. The operator bears the sole risk. Proper use also includes

compliance with operating, inspection, and maintenance conditions prescribed by the manufacturer. Non-com-

pliance with the warnings in the operating instructions and installation instructions, in particular, constitutes

improper use of the equipment.

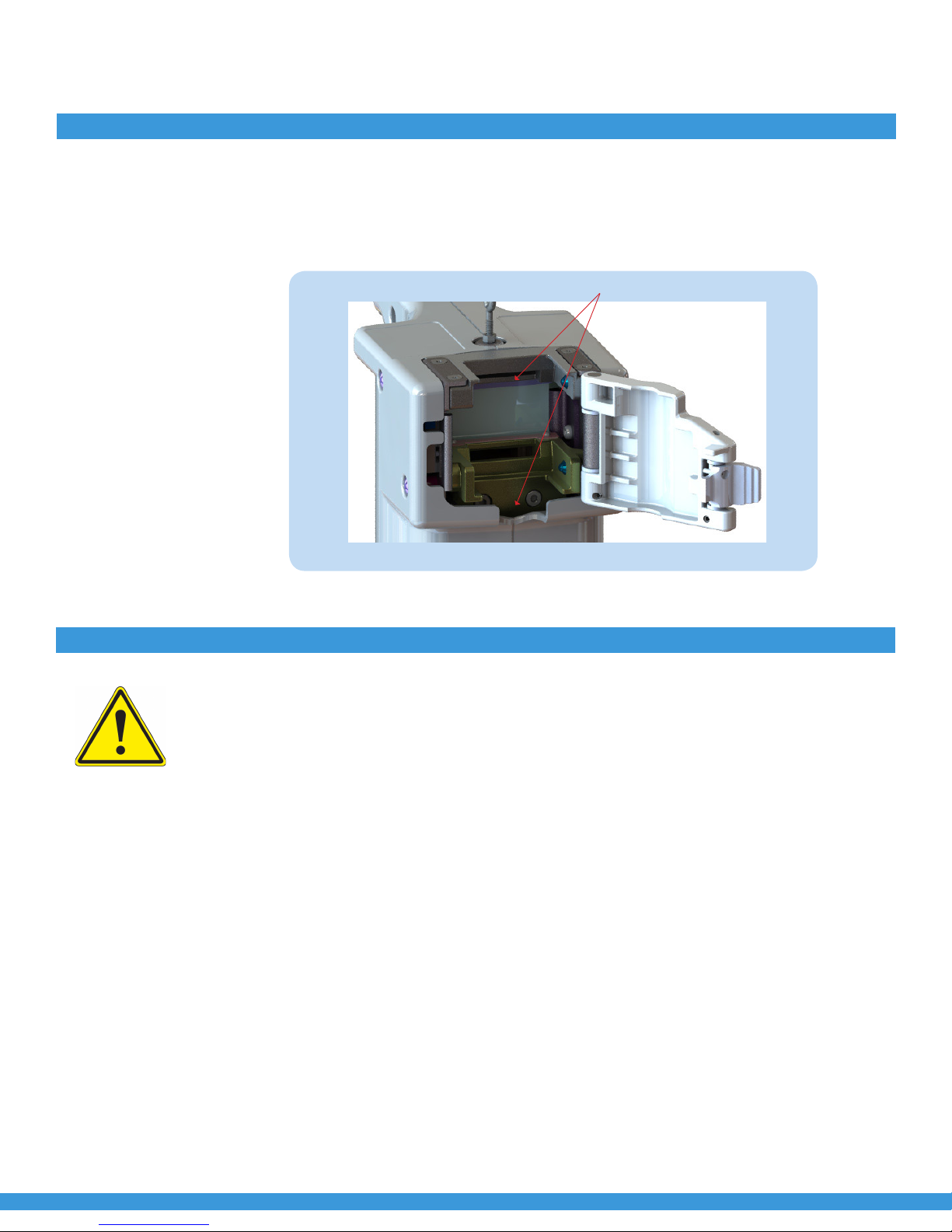

There is only one user serviceable parts inside the Tool, described in the section beginning on page 19.

Accessing the inside of the tool for any other reason may void the warranty. Contact Saint-Gobain Performance

Plastics if the product fails to operate correctly. Do not continue to use a product that is not operating correctly,

as this could result in injury to the operator or others, or damage to the product.

Intended Use

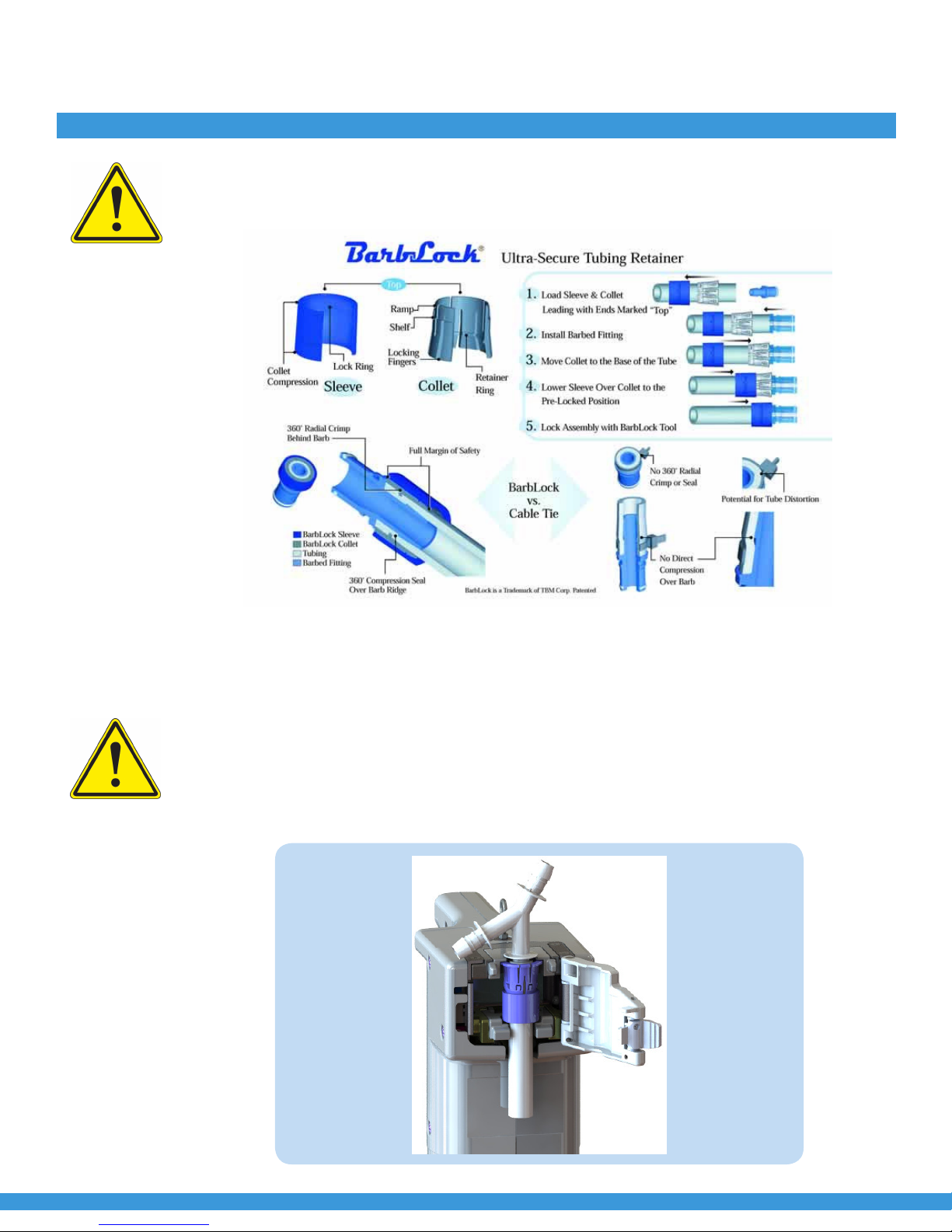

The BarbLock® Assembly Tool was exclusively developed, constructed, and built for the industrial and com-

mercial purpose of closing/locking the BarbLock® and Pure-Fit® SIB® retainers on a barbed fitting and flexible

tubing connection using pneumatic power. The BarbLock® Assembly Tool shall not be used in any clinical proce-

dures, or for diagnostic purposes. The system is exclusively designed for the purpose stated above. Any other

application above or beyond this, or any modifications to the unit without the written permission of the manu-

facturer, is considered as improper use of the device, which could result in injury to the user or damage to the

tool.

1.0 Important Notice