Select Air Systems EC Instruction Manual

Installation, Operation and Maintenance Data Kitchen Hoods

Models EC, EC-RS, EC-FP1, EC-FB, FSP, FSR, SCS, SCR, SCP, ACR, EC-I, EC-I-RS,

EC-I-FP1, FSP-I, FSR-I, SCS-I, SCR-I, SCP-I, ACR-I, ZERO CLEARANCE

Select Air Systems, Inc.

-Unpacking and Inspection of Hood

1. Upon receiving of hood, carefully inspect hood for damage. If visible damage is noted upon

unpacking, this should be indicated on shipping bill in the event that a damage claim is required

to be filed.

2. Carefully remove unit packaging to prevent damage to hood.

3. Remove hood grease filters and hood grease cup and store in a safe location until after hood is

installed.

-Installation of Hood (See Figure 1)

Note: Hood installation should be done in accordance latest requirements of NFPA-96, Removal

of Smoke and Grease-Laden Vapors from Commercial Cooking Equipment.

1. Notice location of hanger brackets on top of hood. Assure that building structure has been

prepared to allow for hanger rods at each required hanger bracket location. Hood hanger

brackets are provided for 1/2” threaded rods.

2. Carefully locate hood into position on floor underneath where it will be suspended. For hood

model EC-RS (hood with rear supply plenum), refer to step 3 below.

3. For hood model EC-RS, hang rear supply plenum at wall prior to installation of hood. Hang

plenum using hanger rods at top and securing bottom to wall using sheet metal screws. Locate

lower edge of rear plenum at a point of 32” above finished floor (This is based on a 24” high hood

mounted at 78” above finished floor).

4. Lift hood up using hi-jack device. Keep hood level during this process. Locate lower front edge

of hood at height that will be at a point of 78” above finished floor (verify this dimension with any

existing building plans that may be available).

5. Attach hanger rods with rod couplings to structure above and to each hood hanger bracket

coupling.

6. After all hanger rods are securely in place, lower hi-jack stands from underneath hood and

remove.

7. Level and plumb hood by adjusting hanger rod couplings as necessary.

8. For hood model EC-FP or EC-FR, hang front supply plenum at ceiling in front of hood. Use 1/2”

threaded rods as described above for hood.

9. Any additional sealants required after installation of hood will be based on local code

requirements and local AHJ (Zero Clearance models once installed, require joint between wall

and hood to be sealed with fire rated caulking or other approved methods by the local AHJ).

-Duct Connections (See Figure 2)

1. Connect exhaust ductwork (and supply ductwork if applicable) to duct collar(s) located on top

of hood.

2. Exhaust duct should be continuously welded to collar(s) at top of hood.

3. Supply duct should be attached to hood collar(s) using sheet metal screws. Note: If supply

duct collar includes fire damper, access should be provided to fire damper. Be sure supply

balancing damper is completely open and that sheet metal screws used do not interfere with

opening and closing of balancing damper.

-Electrical Connections

Note: Any electrical work done on unit should be performed only by a licensed electrician. All

wiring should be done in accordance with the National Electric Code.

1. Locate hood electrical wiring diagram located on top of hood.

2. If hood is provided with optional control switch panel, make field wiring connections to electrical

junction box as indicated on wiring diagram for operation of hood light switch and/or hood fan

switches.

3. If hood is provided with optional Motor Control Center unit, make field wiring connections to

unit as indicated on the provided electrical wiring diagram.

Installation, Operation and Maintenance Data Kitchen Hoods

Models EC, EC-RS, EC-FP1, EC-FB, FSP, FSR, SCS, SCR, SCP, ACR, EC-I, EC-I-RS,

EC-I-FP1, FSP-I, FSR-I, SCS-I, SCR-I, SCP-I, ACR-I, ZERO CLEARANCE

Select Air Systems, Inc.

(Continued)

-Start-up of Hood

1. After all power connections are completed and with hood light and fans switches in ‘Off’

position, turn on power at breaker.

2. Re-install hood grease filters and grease containers in hood.

3. Turn on hood light switch to ensure that hood lights are operating correctly.

4. Turn on fans switch to ensure that fans are operating correctly. (This should only be performed

after hood fans are completely installed and wired per the fan instructions).

-Hood Airflow Ratings

1. Hood System fans should be balanced to provide Exhaust CFM (and Supply CFM) rating as

indicated on plans and hood submittal drawing.

Notes:

a.) The exhaust and supply (when provided) air flow rates were established under controlled

laboratory conditions.

b.) Greater exhaust and/or lesser supply air is required for complete vapor and smoke removal in

specific installations.

-Hood Troubleshooting

Guide to common hood problems:

1. Hood Lights not operating-

a. Bulb(s) not installed or burned out.

b. Dead short in light power wiring.

c. Defective light switch.

2. Hood not properly capturing smoke-

a. Exhaust fan belt broken.

b. Exhaust fan running backwards.

c. Excessive grease buildup on hood grease filters, in grease duct, or in exhaust fan.

d. Kitchen air balance not correct.

e. Exhaust fan motor, starter overload, or breaker tripped.

3. Excessive grease in duct and on roof-

a. Dirty hood grease filters.

b. Improper exhaust air balance resulting in excessive velocity through grease filters.

Installation, Operation and Maintenance Data Kitchen Hoods

Models EC, EC-RS, EC-FP1, EC-FB, FSP, FSR, SCS, SCR, SCP, ACR, EC-I, EC-I-RS,

EC-I-FP1, FSP-I, FSR-I, SCS-I, SCR-I, SCP-I, ACR-I, ZERO CLEARANCE

Select Air Systems, Inc.

(Continued)

-Hood Maintenance

Note: Disconnect all sources of electrical power to unit prior to performing any maintenance.

Frequency of maintenance is determined by the severity of the application and amount of grease

generated.

During regular hood maintenance:

1. Remove grease filters and clean by placing in dishwasher and washing with mild detergent.

2. Check hood grease container and empty as necessary.

3. Wipe clean the hood interior to remove any deposits of grease.

4. Clean the exhaust duct and exhaust fan wheel (This should be performed by a professional

duct cleaning service).

Note: Never use harsh abrasive cleaners on stainless steel surfaces.

Product Warranty

Select Air Systems, Inc. warrants all of its products for one year from the date of shipping.

Products are warranted to be free from defects under normal use and service. If any product

should be determined to be defective or should fail within the one year period, Select Air must be

contacted immediately.

Select Air Systems, Inc. reserves the right to either replace or repair the item in question as

required.

Back charges for unauthorized work done to any product in need of repair or replacement within

the warranty period will not be accepted.

This warranty does not apply to any product that has been modified or altered in any way.

Questions regarding information contained within these instructions should be addressed to:

Select Air Systems USA, Inc.

DBA: Select Air Systems, Inc.

2716 Chamber Drive

Monroe, NC 28110

Phone (704) 289-1122

Fax (704) 289-1227

This manual suits for next models

18

Table of contents

Popular Ventilation Hood manuals by other brands

Vissani

Vissani U5H300A15 owner's manual

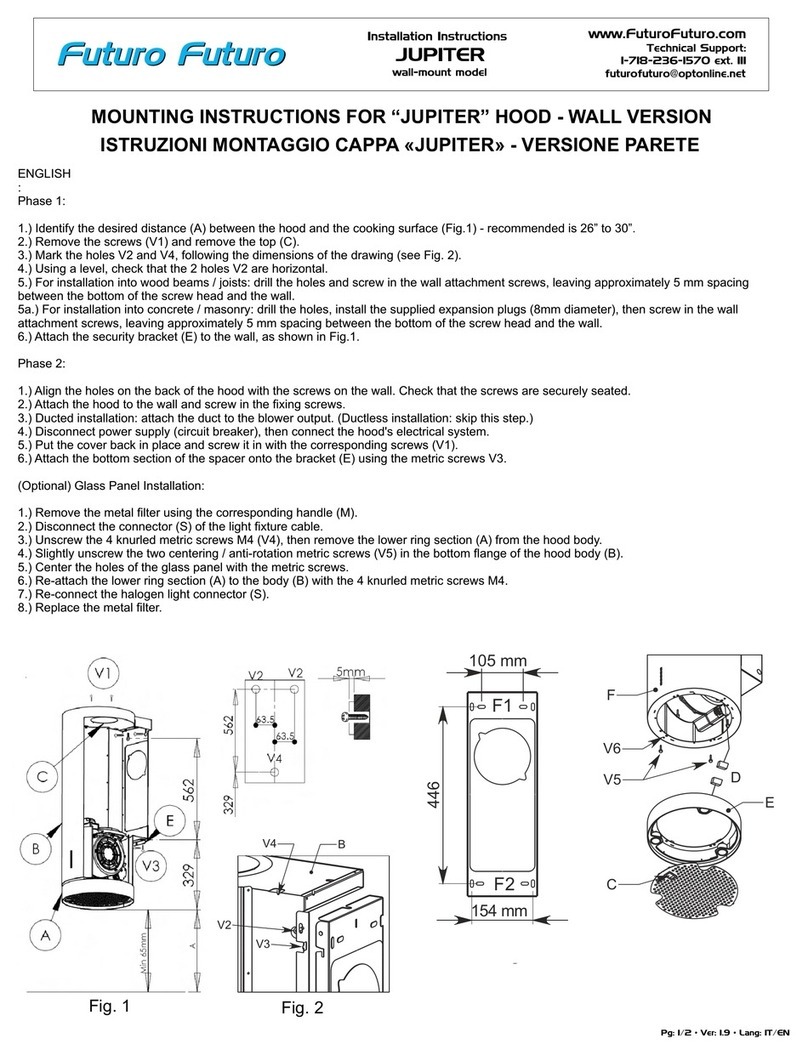

Futuro Futuro

Futuro Futuro JUPITER installation instructions

AEG

AEG X99384MDO user manual

Zephyr

Zephyr Titan Island AK7736BS Use, care and installation guide

ElectrIQ

ElectrIQ eiQCURVISL90SS Installation and user manual

Whirlpool

Whirlpool WMH78519L Quick reference guide

Dacor

Dacor HWHE30 installation instructions

Miele

Miele DA 6296 W EXT Operating and installation instructions

Franke

Franke FDF 9274 I XS-CH Instructions for use and installation

KOBE

KOBE CH0030SQB Installation instructions and operation manual

Faber

Faber Levante I installation instructions

XO Appliance

XO Appliance XOI21SC manual