Selkirk ULTRA-TEMP UT Instructions for use

1

SELKIRKCANADA

375 Green Road,

Stoney Creek, ON L8E 4A5

1-888-SELKIRK (735-5475)

Fax: 1-866-835-9624

www.selkirkcorp.ca

(5” to 14” dia.)

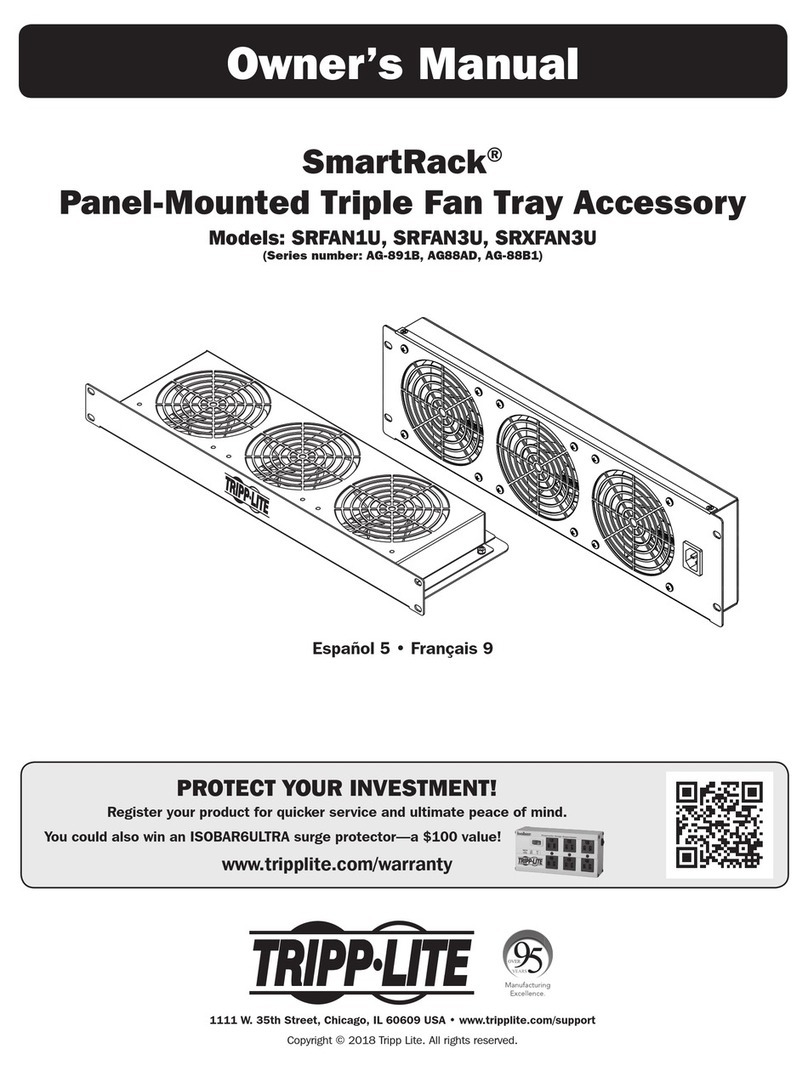

FACTORY-BUILT

INSULATED CHIMNEY

Installer: It is of the utmost importance that these UT instructions are

left with the homeowner.

Homeowner: Keep these instructions and maintenance guide in a safe place

forfuturereference.

INSTALLATION INSTRUCTIONS

&

MAINTENANCEGUIDE

(CANADAONLY)

Tested to Standard

CAN/ULC-S604

&

ULC/ORD-C959

PLEASE READ ALL INSTRUCTIONS

BEFORE BEGINNING YOUR

INSTALLATION.

FAILURE TO INSTALL THIS SYSTEM IN

ACCORDANCE WITH THESE

INSTRUCTIONS WILL VOID THE

CONDITIONS OF CERTIFICATION AND

THE MANUFACTURER'S WARRANTY.

A MAJOR CAUSE OF VENT

RELATED FIRES IS FAILURE

TO MAINTAIN REQUIRED

CLEARANCES (AIR SPACES)

TO COMBUSTIBLE

MATERIALS.

IT IS OF THE UTMOST

IMPORTANCE THAT THIS

CHIMNEY SYSTEM BE

INSTALLED ONLY IN

ACCORDANCE WITH THESE

INSTRUCTIONS.

LISTED

2

3

4

4

4

5

5

5

5, 6

6, 7

7

8

8

9, 10, 11

11

11, 12

12

12, 13

13, 14, 15

15

16

16

16

17

18

18

19

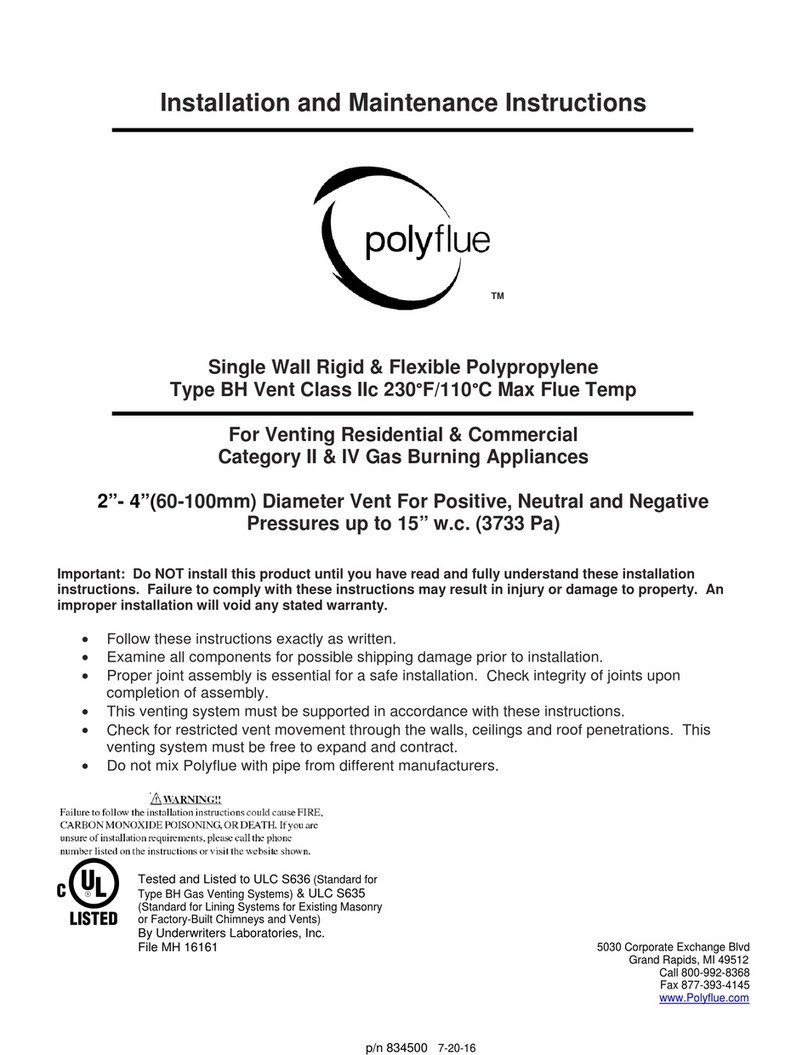

CERTIFICATIONLABELS...........................................................................................................................

.

FUELSANDAPPLIANCES...........................................................................................................................

RULESFORSAFETYDURINGINSTALLATION.........................................................................................

GENERALINSTALLATIONRULES..............................................................................................................

TOOLS..........................................................................................................................................................

CHIMNEYSIZING..........................................................................................................................................

FRAMINGDETAILS......................................................................................................................................

CEILINGSUPPORT...................................................................................................................................

ADJUSTABLELENGTH..............................................................................................................................

ATTICINSULATIONSHIELD.....................................................................................................................

FIRESTOPJOISTSHIELD.........................................................................................................................

ELBOWINSTALLATION.............................................................................................................................

ADJUSTABLEWALLSUPPORT...............................................................................................................

WALLBAND................................................................................................................................................

CATHEDRALCEILINGSUPPORT............................................................................................................

ROOFSUPPORT.......................................................................................................................................

ROOFFLASHING.......................................................................................................................................

UNIVERSALROOFBRACEKIT................................................................................................................

ROUNDTOPANDSPARKARRESTER..................................................................................................

STOVEPIPEADAPTER............................................................................................................................

ANCHORPLATE........................................................................................................................................

CHIMNEYOPERATIONANDMAINTENANCE...........................................................................................

OFFSETCHART........................................................................................................................................

CHIMNEYCHARTABOVEROOF............................................................................................................

REPLACEMENTPARTSLIST..................................................................................................................

PRODUCTANDINSTALLATIONINFORMATION....................................................................................

TABLEOFCONTENTS

3

CERTIFICATIONLABELS

4

Thechimneyshould belocatedwithinthebuildingsoas to avoidcuttingor

altering load bearing members such as joists, rafters, studs, etc. If you

require to cut or alter an existing load bearing member, special reframing

methodsarerequiredwhichoften include doubling of adjacent members.

If such a case arises, contact your local Building Code Official regarding

localregulationsandproperinstallationmethods.

Model UT chimney requires 2” (50mm) clearance to

combustible material or as established by support

assembly.

Attachflue pipepartssecurely toeachother, andto theapplianceusing

three sheet metal screws per joint.

• Be sure that ladders are in good condition and always rest on a level

firm surface.

• Be very careful around electrical wiring and be sure it is secured at

least 2 inches away from any part of the chimney. If wiring must be

relocated,hirea professional electrician.

Do not place any type of insulating materials or run any

electrical wiring within the required clearance air space

surrounding the chimney.

FUELS& APPLIANCES:

Model UT chimney has been designed as gravity venting only if the

appliance operates with neutral or negative draft at its outlet. Any

positive pressure in the chimney should use a Selkirk Model PS or

IPS system. Model UT has been designed for connection to liquid or

gas fired residential type appliances and building heating appliances,

in which normally producing flue gas temperatures of 540° C (1000° F)

or less.

All diameters (5”, 6”, 7”, 8”, 10”, 12” and 14”) comply fully with the

requirement of CAN/ULC-S604. Model UT 10” through 14” comply

also to the requirements of ULC/ORD-C959 the 540° and 760° In-

dustrial Chimney Standard.

May also be used with specific factory-built fireplaces listed to UL 127

and CAN/ULC-S610 when specified in the fireplace manufacturer’s

installation instructions.

Before commencing the installation ensure that you obtain any nec-

essary building permits, and that your installation will conform with all

federal and municipal building codes requirements affecting the fuel-

burning appliance and its chimney. This chimney is intended for use

in accordance with:

-National andProvincial Building Code ofCanada,

-CAN/CSAB-149.1-00InstallationCode for Gas Equipment,

-CAN/CSAB-139.00InstallationCode for Oil Burning Equipment;

-Applianceandventingmanufacturers’sInstallationInstructions.

Sectionsof the UTchimney whichpassthrough accessible areas ofthe

building such as closets, storage areas, occupied spaces or anyplace

wherethesurfaceofthechimneycouldbecontactedbypersons or com-

bustible materials must be enclosed in a chase to avoid personal

contact and damage to the chimney.

The chase may be fabricated using standard building materials. Dry-

wall mounted on 2” x 4” studs is typically used in this situation. Except

for installation in single and two family dwellings, factory-built chim-

neys shall be enclosed with approved walls having a fire resistance

rating equal or greater than that of the floor, wall or roof assemblies

through which they pass. and must have a fire resistance rating equal

to or greater than the floors or ceilings through which they pass. The

minimum airspace clearance between the outer wall of the chimney

and the enclosure shall be at least 2 inches.

•Besure that electricallypoweredtools are properlygrounded.

If you are knowledgeable in carpentry and mechanically inclined, you

can take on the task of installing your new venting system. It is impor-

tant that all pertaining installation instructions and local codes are

followed carefully. If you have any doubt concerning your ability or

knowledge of the appliance being connected to your chimney sys-

tem, arrange for a professional installation. Certified technicians

having installed systems many times before and have the knowledge

and experience to perform your installation in a professional and

timely manner.

YOURCHIMNEYHASBEENTESTED,ANDLISTED USINGALL

OFTHESUPPORTS,SHIELDS,ETC.,DESCRIBEDHEREIN.

DELETIONORMODIFICATIONORANYOFTHEREQUIRED

PARTSORMATERIALSMAYSERIOUSLYIMPAIR THESAFETY

OFYOURINSTALLATION,ANDVOIDTHECERTIFICATIONAND

ORWARRANTYOFTHISCHIMNEY

WEARSAFETYGLOVESWHENHANDLING

SHEETMETALPARTSWITH SHARPEDGES

The chimney pipe and fittings must be assembled with locking bands

or stainless sheet metal screws, maximum length of 1/2” (12.70mm)

on all interior joints. Locking bands must be used on all exterior

joints.

RULESFOR SAFETYDURINGINSTALLATION: The ideal location for your chimney is within the building envelope.

In cold climates, the use of external chimneys may result in opera-

tional problems such as poor draft, excessive condensation of com-

bustion products and rapid accumulation of creosote. Under these

circumstances, the installation of the chimney within the building is

strongly recommended.

If the chimney must be installed on an exterior wall it is recommended

thatthe chimney beenclosedbelow the roofline to protect thechimney

fromcoldoutdoortemperatures,thismayhelpreducecondensation, creo-

sote formation and enhance draft. Provide an access door by the Tee

Cap for chimney inspection and cleaning. The exterior enclosure

may be insulated, maintaining the required 2” (50mm) air space clear-

ance to any part of the chimney. Consult local building codes for cold

climate applications.

GENERALINSTALLATION RULES:

Support all offsets with an offset support and adequate strapping.

The minimum clearance to Model UT meansAIR SPACE ONLY. The 2

inch (50mm) clearance to pipe, and the spaces around supports must

not be filled with any type of insulation.

An Attic Insulation Shield must be installed where the chimney passes

into an attic space. It is designed to keep insulation materials or

debris from coming into contact with the chimney. It must accomodate

the amount of insulation as required by the National Building Code.

Where height restrictions will not permit the use of the Attic Insulation

Shield, it is permissible to construct an enclosure with a 2” air space

clearance to the outer pipe all the way to the underside of the roof

deck. In this application you would install a Firestop Joist Shield on

the ceiling side.

At the level where the chimney penetrates the air/vapour barrier, spe-

cial attention is required. Seal the vapour barrier to the Firstop Spacer

or Ceiling Support assembly or Wall Thimble using an appropriate

caulking compound as per the requirement of local authorities.

Do not mix and match with other manufacturer’s products. Use only

UT listed components.

5

121/4”

12 1/4”

12”

13 1/4”

N/A

13”

111/4”

121/4”

11”

16 1/4”

N/A

16”

N/A

N/A

18”

14 1/4”

N/A

14”

N/A

N/A

20”

5” 6” 7” 8” 10” 12” 14”

TOOLS:

YourUTchimneysystemisdesignedforinstallationusing standardbuild-

ing materials and procedures. The following tools/equipment may be

requiredaswellas some others dependingon the locationand structure

inwhich thechimneyis tobeinstalled:

-Safety gloves

-Safetygoggles

-Hammerand nails

-Tinsnips

-Tapemeasure

-Scewdrivers and pliers

-Plumblineand level

-Square

-Keyholesay or powerjig saw

-Caulkinggunandcaulking

CHIMNEYSIZING:

In order to achieve safe, optimum performance of the appliance, ser-

vice life of the chimney, the chimney should be sized correctly for the

connected appliance. In general, the chimney flue should be the

same size as the appliance flue outlet. Installations should be done

in accordance with the applicable installation codes (eg. CSA-B149

for natural gas and propane appliances, and CSA-B139 for fuel oil

appliances)and appliance manufacturer instructions. Plan the in-

stallation of your appliance and chimney in such a way that both

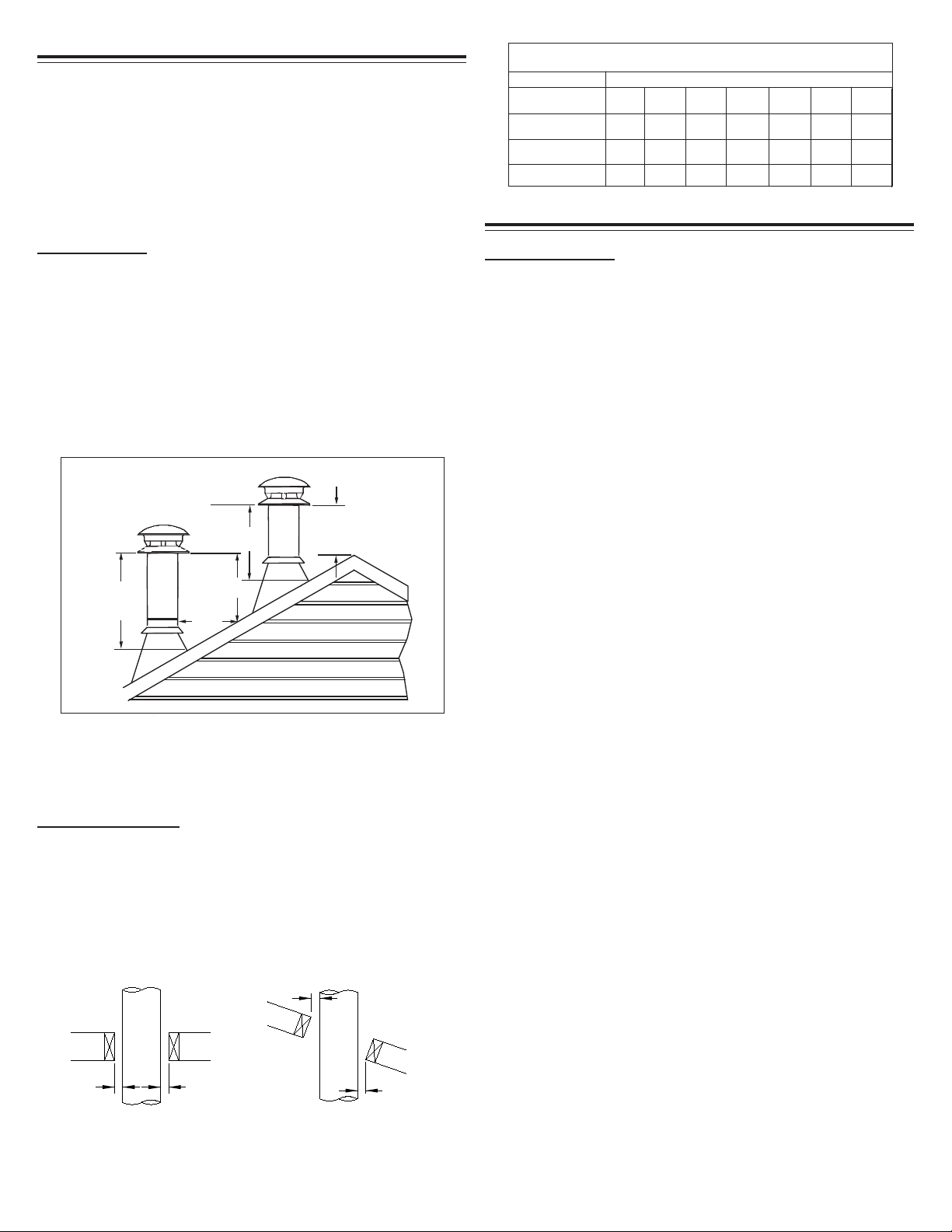

Authority require that the chimney extend not less than 3ft (900 mm )

abovethehighestpointwhereitpassesthrough the roof of a building and

not less than 2ft (600 mm)higherthananyportionof a building within 10ft

(3m) horizontally. SeeFigure1andChart2 in the back ofthese instruc-

tions.

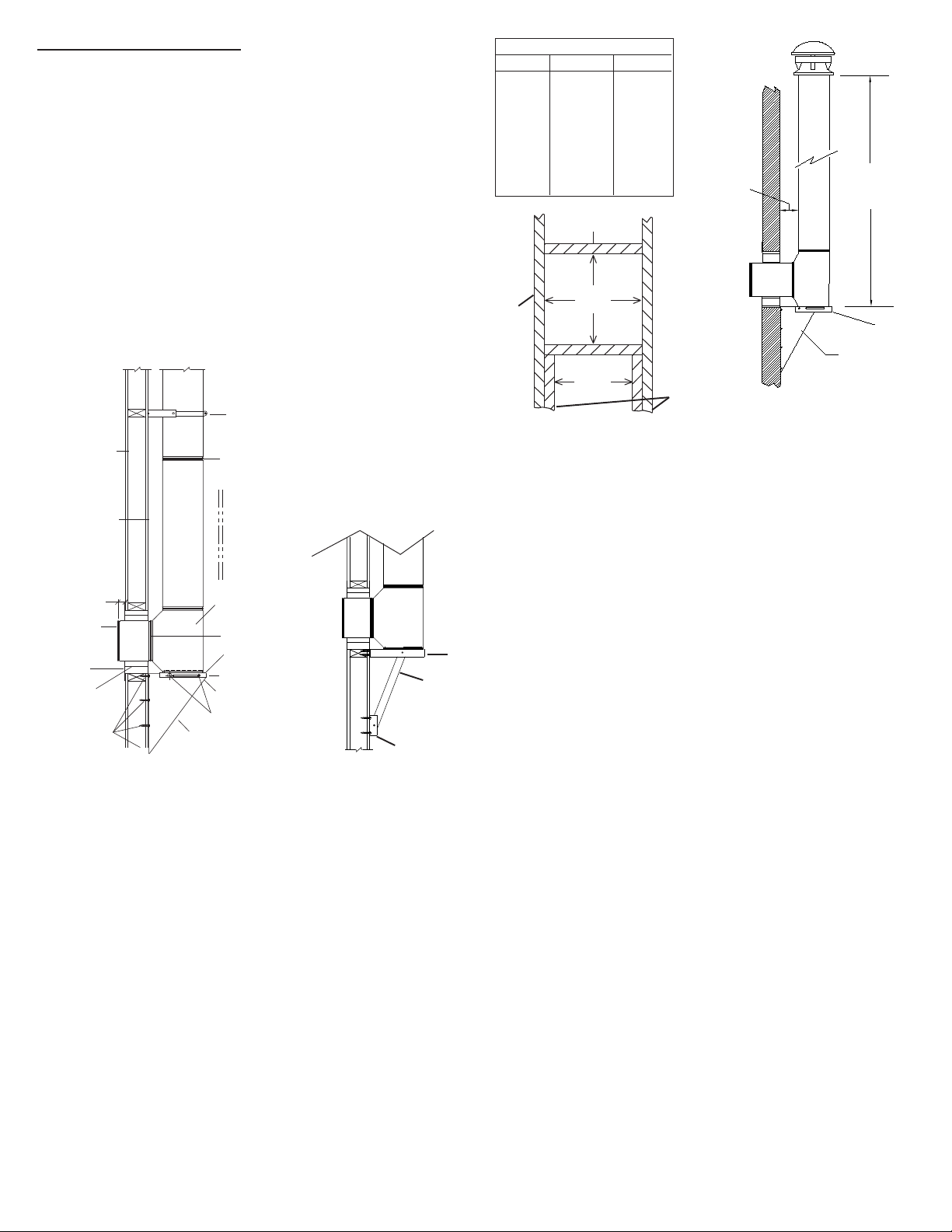

FRAMINGDETAILS:

Plan your installation carefully. If possible, position the appliance so

that the flue outlet is centered between joists, rafters or studs. Drop a

plumb line to the center of the flue outlet and mark this center point on

the ceiling. Lay out and frame all openings ensuring the specified 2”

clearance to combustibles is maintained. All openings should be

square, plumb and in perfect alignment with each other (see Figure

2). For angled roofs, ensure that the framing dimensions are mea-

sured on the horizontal plane (see Figure 3).

3 ft.

(900mm)

min.

2 ft.

(600mm)

10 ft.

(3m)

2ft.

(600mm)

3 ft. (900mm)

min.

FIGURE1

your chimney and flue pipe runs are as short and straight as pos-

sible. By having too long and/or multiple bend installations you can

reduce system draft which can affect the operation, and/or perfor-

mance of your appliance and/or chimney system.

2"

(50mm)

Min

2"

(50mm)

Min

2" (50mm)

Min

2"

(50mm)

Min

INSTALLATIONPROCEDURES:

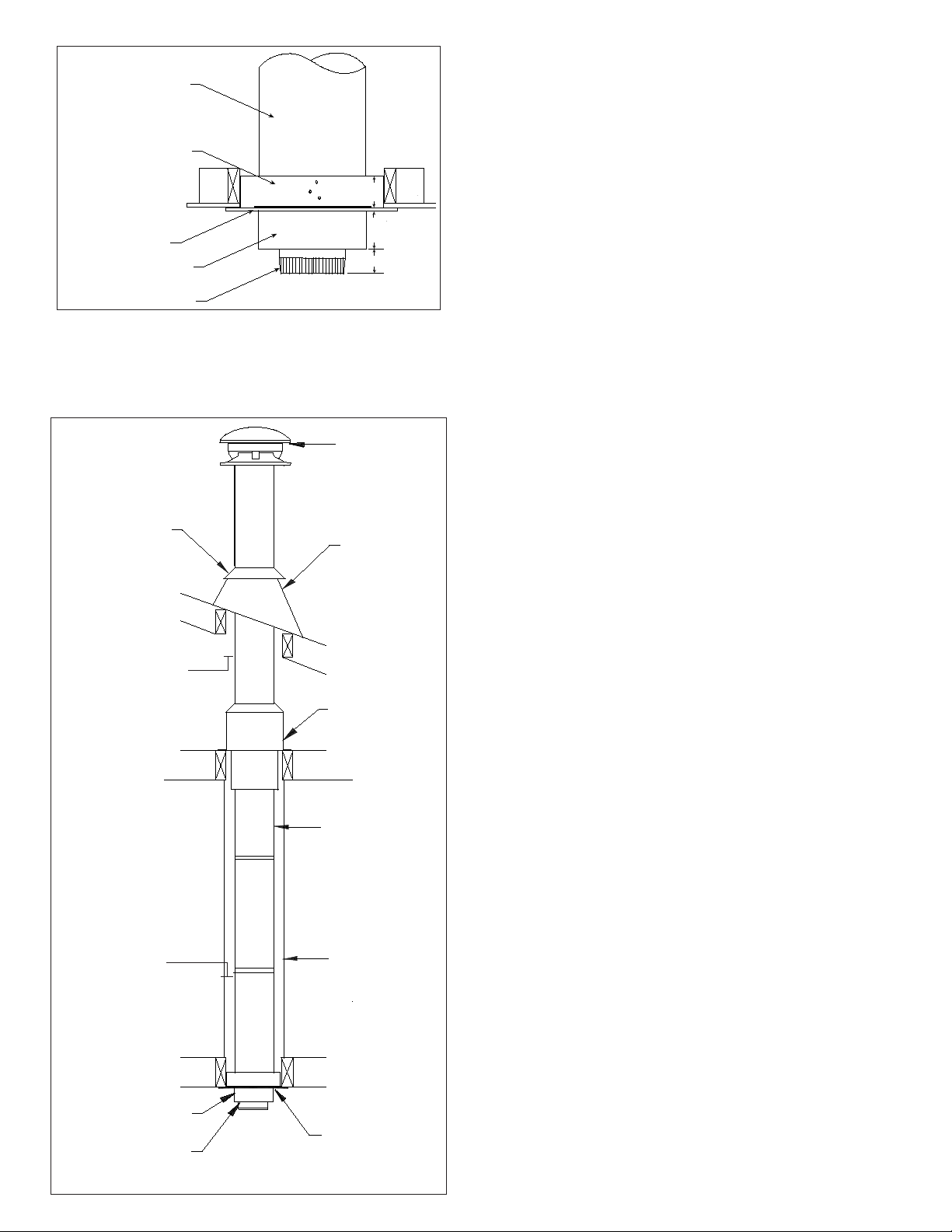

CEILING SUPPORT

TocompleteaproperCeilingSupportinstallation,the following parts may

be required. Ceiling Support available only for 5” to 10” diameters.

- Ceiling Support: For joist supported chimney system.

- Attic Insulation Shield: Where a chimney enters an open attic space.

- Firestop Joist Shield: Installed where the chimney passes from one

living space to another living space or as specified in the listed factory-

builtfireplace installation instructions.

Figure3

TypicalRoofJoist

Framing

Figure2

Typical Joist Framing

FRAMING DIMENSIONS FOR MODEL UT

TO MAINTAIN 2 INCH AIR SPACE CLEARANCE

Chimney Inside

Diameter:

All other framing*

Table 1

CathedralSupport

MODEL UT

Ceiling Support*

The following instructions will assist you in the installation of your

chimney with a Ceiling Support. This support will hold up to 15.25m

(50’) of chimney sections, all of which must be installed above the

support.

1.Frame alevelsquareopening (allfoursides). Insidedimensionsshould

conformtoTable 1.

2. With the Lower Bucket removed, place the upper bucket assembly

into the framed opening from below.

3. Ensure that the support plate is level and flush and drive one nail, 1-1/2”

commonor spiral, partway into eachofthe four (4)nailing areas ofthesup-

port. You may substitute nails with #8x1-1/2” wood screws.

4.Finishnailingthroughallprepunchedholes and fasten the finishing (sup-

port)plate to theceiling(seeFigure4).

5.ReplacetheBucketSectionfromabove. ConnectthepropersizedStove

Pipe Adapter to the first chimney section. Lower this chimney section

down into the bucket section, with the male end pointing upwards as

indicated by the arrow on the chimney label.

6.Additionalchimneylengths above thesupportare simply stacked on,

twistlockedwith a 1/8clockwise turnand securedwith alocking bandat

eachchimneyjoint. Alockingbandissuppliedwitheverychimneylength

and must be used on all chimney joints, interior or exterior. Stainless

steel sheet metal screws (maximum length of 12.70mm (1/2”) may be

substituted on interior joints.

7.Finish the chimneyto itsrequiredheight.

8. If an offset is installed in the system, an Offset Support must be in-

stalled as shown in Figure 13.

9. If the chimney extends 5 feet (1.5 m ) or more above the roof, addi-

tionallateral support isrequired,such as theUniversal RoofBrace Kit.

- Roof Flashing: Required when the chimney penetrates a roof.

- 15° , 30° or 45° Elbow Kits (2 per box with locking bands and elbow

support). NOTE: 45° Elbow kits is available in 5” to 8” only.

The Ceiling Support is for installation below a finished or unfinished

ceilings. The Support fire stop plate fits up against a ceiling, or a joist

opening framed level on all four sides.

- Suitable lengths of chimney: Available in 6”, 12”, 18”, 24” and 36”

lengths. A 48” length is available in 6”, 7” and 8” only.

- Round Top

- Stove Pipe Adapter

*All framing dimensions may be 1/2” larger, but not less than the dimensions mentioned above.

6

1-1/2”

4-1/8”

3”

FIGURE5

CeilingSupport

Bucket Section

Floor, Ceiling Joist

(Framed all 4 sides)

LIVINGSPACE

*FollowApplianceinstructions for properclearance.Ifclearance isnotgiven,use 460mm (18”)min.

*Stove Pipe Adapter

Framed

Enclosure

2” (50mm)

clearance from

chimney to

combustible wall

Chimney Lengths

50mm(2”) minimumair

space clearance to

combustible material

ATTICSPACE

Attic Insulation

Shield

50mm(2”) minimumair

space cleance to

combustible material

RoundTop

CeilingJoist

(Framed all 4 sides)

StormCollar Roof Flashing

Warning: The chimney lengths and its fittings must be assembled

with metal-to-metal joints as furnished. Do not use tape or any

sealing compound (such as tar, mastic, putty or silicone) at the outer

joints. Sealers in the joints may cause the insulation to accumulate

moisture and may cause corrosion or freezing failures.

Chimney Length

Lower Bucket

Upper Bucket

Figure 4

Support Plate

Stove Pipe Adapter

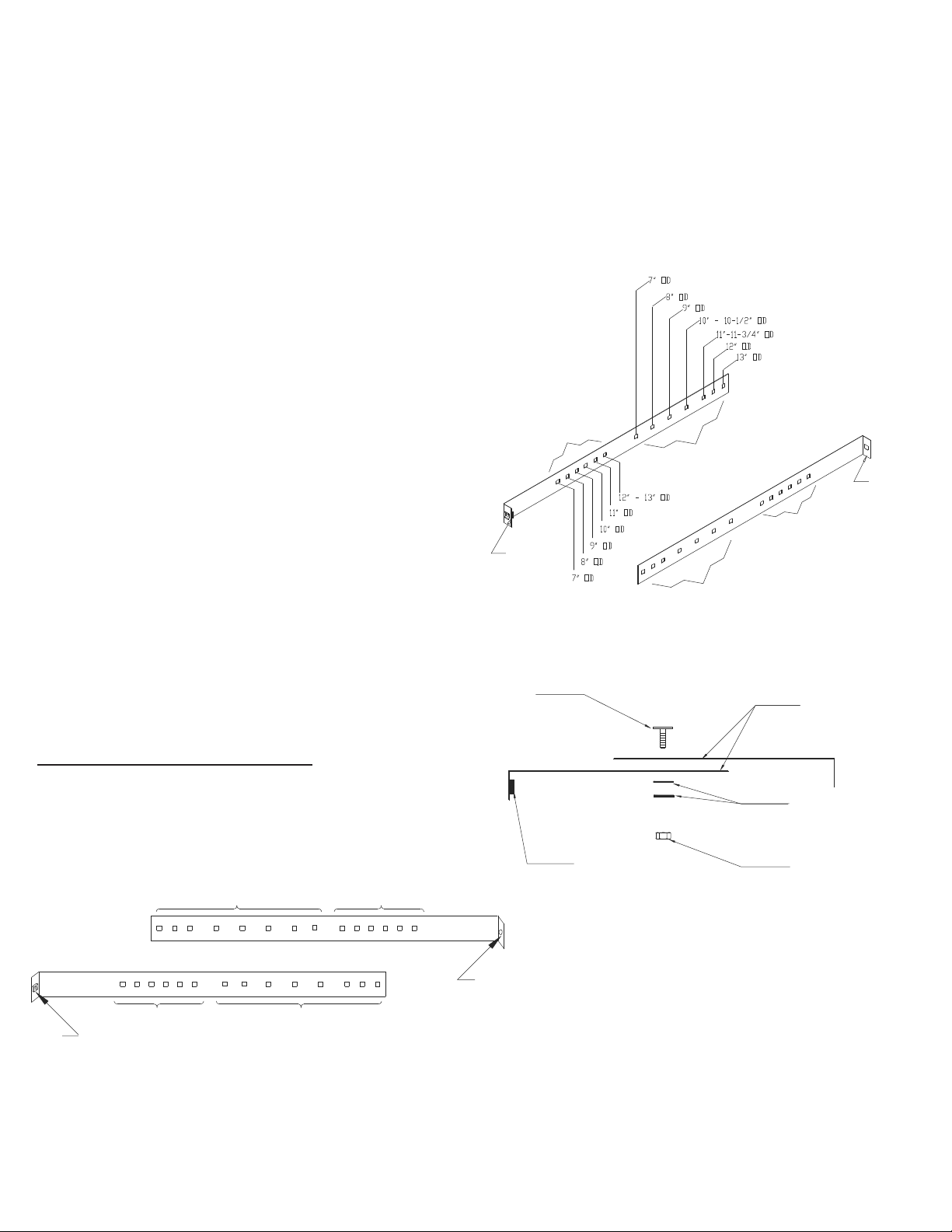

ADJUSTABLELENGTH(AL)

An Adjustable Length (AL) is installed between other components to

establish an exact finished length, where a standard length can not

be utilized. The AL has an over all length of 12” and has an installed

length that adjusts from 2” to 9-1/2”.

The Adjustable Length is available only in diameters of 5” to 8”.

The Adjustable Length must be installed above a fixed length - they

cannot be installed immediately above a support, tee or elbow.

The Adjustable Length slides over the male end of an adjoining

straight length. However, to allow engagement it is necessary to

remove some of the insulation from the inlet end of the Adjustable

Length.

To install:

1. Determine (measure) the finished (installed) length of chimney

needed (DIM “A”) and add 2.25” to the measurement (See Fig. 6).

Note: To facilitate installation, it is recommended that theAdjustable

Length be attached and secured to the lower adjoining segment

before it is installed in the system.

8. Seal the overlap seam and screws with silicone sealant (See Fig. 8b).

7. Re-orient the assembly to the upright position (Male Coupler Up)

and apply pressure to compress the adjoining segments together

until the overlapped edge of the Adjustable Length extends down to

the reference line marked on the standard length. Secure by installing

3 #8 x 1/2” stainless steel sheet metal screws through the pilot

holes in theAdjustable Length and into the outer wall of the adjoining

segment (See Fig. 8b).

6. While still positioned with the coupler end down, insert the standard

straight length into the Adjustable Length (See Fig. 8a).

5. Remove insulation from the inlet (female) end of the Adjustable

Length until the insulation is level with the line marked on the outside

of the pipe (See Fig. 7).

4. Measure the distance (Dim “B”) from that line to the edge of the

Adjustable Length and add 1”. This is the “overlap” distance. On the

adjoining standard length, measure up from the male coupler, the

“overlap” distance and mark a reference line. Make sure the location

of the reference line is measured from the standard length’s male

(coupler) end (See Fig 7).

3. From the male end, measure up the distance Dim “A” + 2.25” and

mark a line on the Adjustable Length (See Fig. 7).

2. Remove the Adjustable Length from the packaging carton and set

it with the male end (coupler end) of the Adjustable Length down to

prevent insulation from spilling out (See Fig. 7).

10. Refer to main installation instructions to continue installing the

remaining system parts.

9. Once the female end of the Adjustable Length is secured to the

adjoining segment, the assembly may be installed in the system.

NOTE: If the Adjustable Length (AL) is installed in a system where it

will be subjected to the weight of more than 4’ of chimney (either

above or below), supplementary support such as an Interior

Resupport (IR) is required.

7

A

B

C

D

E

“A” DIM.

“B” DIM.

“C” DIM.

“D” DIM.

“E” DIM.

7 -1/4”

11”

11-13/16”

13”

20”

8 -1/4”

12”

11-13/16”

14”

20”

9 -1/4”

13”

11-13/16”

15”

20”

10 -1/4”

14”

11-13/16”

16”

20”

12 -1/4”

16”

11-13/16”

18”

20”

14 -1/4”

18”

11-13/16”

20”

20”

5”

11 x 11

6”

12 x 12

7”

13 x 13

8”

14 x 14

10”

16 x 16

12”

18 x 18

16 -1/4”

20”

11-13/16”

22”

20”

14”

20 x 20

DIM “A”

(Non Standard Length)

Remove Insulation

Down to This Line

DIM “A”

+ 2.25”

Fig. 6 Fig. 7

Fig. 8a

InstallSheet Metal

Screws Through

Pilot Holes and

Into Outer Wall of

Standard Length

DIM “A” +

2.25”

Insert Standard Length While Ori-

ented as Shown to Avoid Insula-

tionSpillage

Adjustable

Length

Standard

Length

Adjustable

Length

Fig. 8b

SealOverlap Seam

and Screws With

Silicone Sealant

Standard

Length

Adjustable LengthAttached

to Standard Length

Adjustable

Length

Reference

Line

Overlap

Standard

Length

Mark an Overlap Refer-

ence Line on the Standard

Length. (The Overlap Dis-

tance is Dim “B” Plus 1”)

Standard

Length

Ensure Adjust-

ableLength Edge

isEven With Ref-

erence Line

Standard

Length

DIM“B”

MaleEnd

- It stabilizes the chimney in the framed opening and defines and

maintains the required AIR SPACE clearance to combustibles.

- It prevents heat losses from the dwelling by blocking vertical air

circulation in the space around the chimney.

- It helps provide stability for chimney extending above the roof.

FIRESTOPPING:

Firestopping is required at every joist level. Wherever a chimney

passes through a ceiling or floor, through a wall, or into an enclosure,

it must be firestopped. No firestopping is required in conjunction

with a Ceiling Support installed as shown in Figure 5, the Ceiling

Support provides the firestopping. Firestopping performs the follow-

ing essential functions for both the dwelling and the chimney.

- Together with a fully framed opening (all four sides), controls vertical

and horizontal spread of any fire external to the chimney.

ATTICINSULATIONSHIELD

The function of the Attic Insulation Shield (or a complete enclosure) is

to keep insulation from coming into contact with the chimney. The

height of the Attic Insulation Shield is to meet the insulation level

requirement of the National Building Code. Where height restrictions

will not permit the use of the Attic Insulation Shield, it is permissible to

construct an enclosure with the required air space clearance to the

outer pipe all the way to the underside of the roof deck. In this appli-

cation you would install a Firestop/Joist Shield on the ceiling side.

UT

Chimney

Pipe

Integrated

StormCollar

Attic Insulation

Shield (AIS)

Telescoping

Joist Shield

FIGURE9

- At the level where the chimney penetrates the air/vapour barrier, spe-

cial attention is required. Seal the vapour barrier to the SupportAssem-

bly orAttic Insulation Shield or Wall Thimble or Firestop using an appro-

priate caulking compound as per the requirement of local authorities.

FRAMING DIMENSION CHART

FOR ATTIC INSULATION SHIELD

DIA. OF

CHIMNEY

FRAMED

OPENING

Table 2

For proper installation, the attic opening should be fully framed at 2

inches clearance to the chimney pipe with framing material of the same

dimension as the ceiling joists as per Table 2 and Figure 10. The tabs

on the base plate of the AIS are inserted in the framed opening around

the chimney.

TheAttic Insulation Shield allows for a depth of insulation of 10 inches

plus the depth of the ceiling joists. If insulation is blown in and ad-

heres to the chimney pipe, it should be brushed off to eliminate any

possible contact of this material with the chimney surface.

Nail the AIS base to the framing dimensions with at least 2 nails per

side using 2d (1”) spiral nails or 1” x #8 wood screws. Extend the

telescoping shield down through the framing. See Figures 9 and 10.

FIGURE10

8

X X X X X X X

X X X X X X X

X X X

5” 6” 7” 8” 10” 12” 14”

and install the supplied locking band.

Installtheremaining offset elbow toreturn thechimney backto theverti-

calposition. Againsecureinplacewiththesuppliedlockingband. *Locking

bands and/or stainless steel sheet metal screws can be utilised with a

maximumlengthof12.70mm (1/2”) only onall chimney jointsforming an

offset.

Duringinstallation provide supplementarysupport for theoffsetsection

toavoid undue stressonconnected elbows.

Install an Elbow Support on the vertical length just above the highest

elbow. Securely clamp the supportbandtothechimneylengthjust above

the locking band at the joint. Attach the support straps to the support

bandassembly and nailthem totheframing using 1-1/2”nails or#8x 1-

1/2” wood screws (2 per straps) as per Figure 13.

Never install an elbow in a joist area. Chimney sections must pass

vertically through framed joist areas.

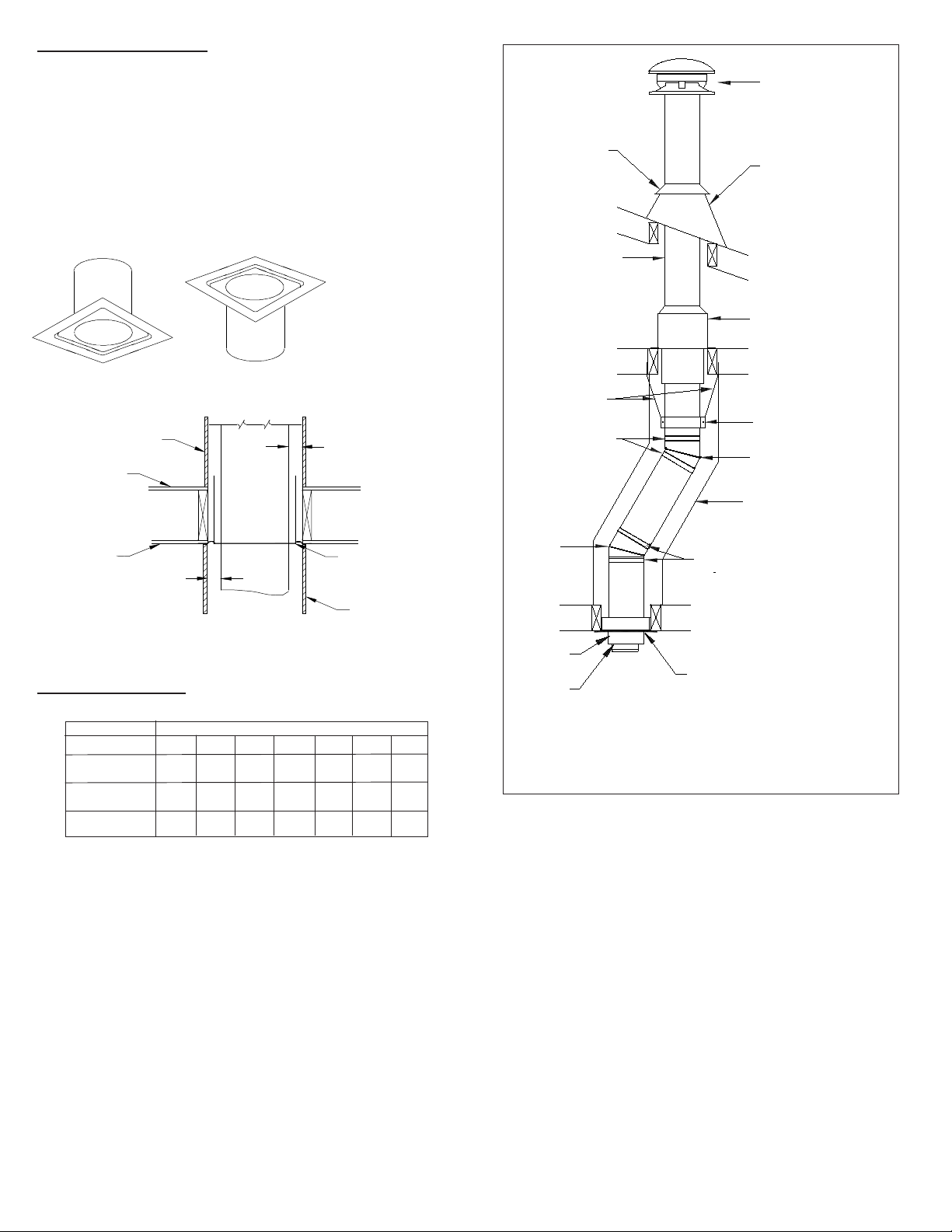

ELBOWINSTALLATION

Elbow Kits (2 elbows, 1 offset support and 4 locking bands).

FIGURE13

Attic Insulation Shield

StormCollar

Elbow Locking Bands

Intermediate/Elbow

Support Straps

Locking Bands Elbow

CeilingSupport

Roof Flashing

If the offset length is more than 1.2m (4’), an intermediate support

must be employed at 1.2m (4’) intervals. Maximum offset length

4.8 m (16’), the intermediate support must be used in conjunction

with an offset support.

Round Top

One pair only of (two) 15 or 30 or 45 degree elbows may be used to

provide an offset in order to avoid cutting of joists and to clear other

obstructions (see Table 3). The vertical run of chimney above an

offset must be supported with an elbow support. Each elbow support

will support 10m (30’) of chimney. If the offset length is more than

1.2m (4’), an intermediate support (plumbing straps not supplied)

must be installed at 1.2m (4’) intervals in conjunction with an offset

support. Maximum offset length is 4.8m (16’). See the Offset Chart for

assistance in selecting your offset. NOTE: Large diameters (10” to

14”) may combine elbow kits for a greater angle up to 45°.

15° Elbow Kit

30° Elbow Kit

45° Elbow Kit

MODEL UT

Framed Enclosure 2”

(50mm) clearance from

chimney to combustible

wall

Elbow Support Band

Roof Joist

(Framed all 4 sides)

Chimney Section

Lower

Bucket

StovePipe

Adapter

Floor, Ceiling Joist

(Framed all 4 sides)

Table 3

The female end of the elbows are not lanced in order to ensure

proper alignment of the chimney system can be maintained.

FIRESTOP JOIST SHIELD

A Firestop Joist Shield is for use in vertical enclosures where the

chimney passes through a floor / ceiling opening, from one living

space to another living space. It is installed from either above or

below the joist. Nail the Firestop Joist Shield using 1-1/2” common or

spiral nails, into the framed opening outlined in Table 1.

Firestop/Joist Shield (JS)

UsedWith UT Chimney

Enclosure

(Drywall, Plywood, etc.)

Ceiling

MinimumClearance

2” Air Space from

Combustibles

Fire Stop/Joist Shield (JS)

Used With UT Chimney

Pipe

Floor

Enclosure

(Drywall, Plywood, etc.)

MinimumClearance

2” Air Space from

Combustibles

Fire Stop/Joist Shield (JS)

Used With UT Chimney Pipe

FIG. 12

UT

Chimney

Pipe

FIG. 11

Enclose the chimney below the Fire Stop Joist Shield to prevent any

accidental contact with the chimney. To prevent blown-in attic insula-

tion from falling against the chimney, either use an Attic Insulation

Shield (AIS) or a full enclosure in the attic. See Section onAttic Insula-

tion Shield.

Install and position the insulated elbow on the vertical chimney length

in the required direction. Fasten the elbow to the chimney length with

the supplied locking band.

Place the required offset chimney length(s) (see Offset Chart for ap-

propriate length(s)) on the elbow. Turn it clockwise to lock it in place

9

A

B

9-1/4”

9-1/4”

10-1/4”

11-1/4”

13-1/4”

15-1/4”

17-1/4”

5”

6”

7”

8”

10”

12”

14”

11”

12”

13”

14”

16”

18”

20”

DIMB

DIMA

L

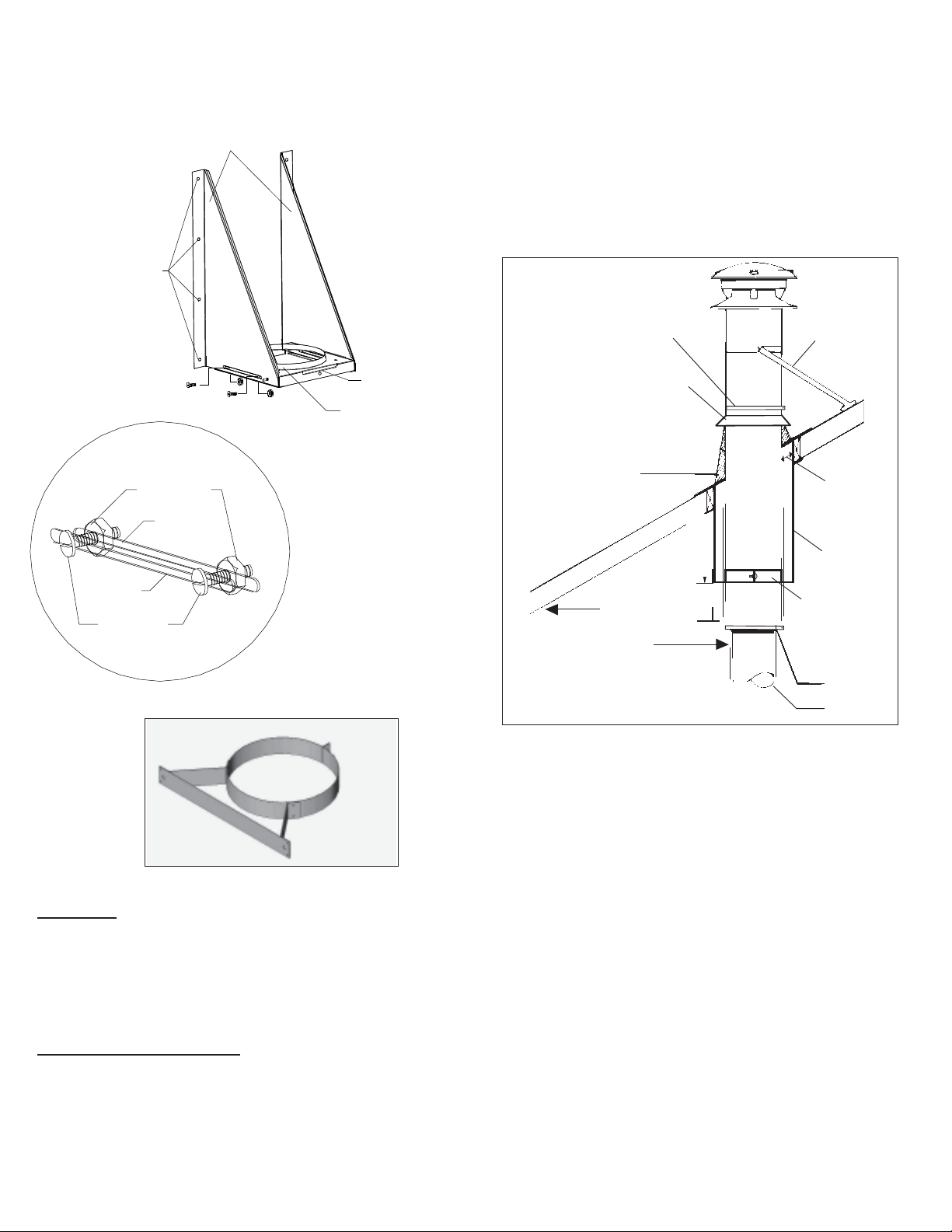

ADJUSTABLE WALLSUPPORT

As previously mentioned, the ideal location for your chimney system

is within the building envelope. An Adjustable Wall Support is re-

quired when the above mentioned location is not possible.

Theadjustable Wall Support willallowfor an adjustment of2”to 6” from

a combustible vertical wall (see Figures 14a and 16). Pem-studs are

factory installed on both side brackets and the support plate for fast

and easy assembly.

The maximum chimney height above the Wall Support wherther sup-

ported along an interior or exterior wall is indicated in Table 5 and

illustrated in Figure 16.

NOTE: If installing a 10” or larger chimney the Wall Support is a non-

adjustable version which comes with support braces and provides a 2”

clearance when properly installed. Maximum support height is 50 Feet

for 5” through 8” and 40 feet for 10” through 14” (see Figs. 14a & b).

LagScrewsInto

Structure

WallThimble

Shield

WallThimble

FacePlate

Bracket

Pem-Studs

andNuts

CappedCleanout

andRetainer Clips

SupportPlate

WallSupportKit

LockingBand(LB)

InsulatedTee

ModelUT

Chimney

Section

Min.Thru Wall3”

12”to14”

diametersrequires

4-1/2”min

Min.Clearance

To Combustible

CombustibleWall

WallBand(WB)Every

8FeetIf Not Enclosed

UseLockingBands

(LB)on AllJoints

FullEnclosure

Recommended.

BothIndoorsand

Outdoors

SupportPad

FIG. 14a - Wall

Support for 5”

to 8” Chimneys

FIG. 14b - Wall

Support for 10”

to 14” Chimneys

Support

Brace

Support

Plate

If supported along an interior wall in a non-attic area the chimney

must be fully enclosed with a minimum of 2” air space clearance. In

the attic area the chimney an Attic Insulation Shield is to be installed.

Theheight of theAttic InsulationShieldmust accommodate the amount

of insulation height as required by the National Building Code. If it is

not practical to use theAttic Insulation Shield (due to height restrction),

it is permissible to construct an enclosure with a 2” air space clear-

ance to the outer pipe all the way to the underside of the roof deck.

Install a Firestop Spacer on the ceiling side.

If supported along an exterior or interior wall, Wall Bands must be

installed every 8’ to insure chimney stability and maintenance of 2” air

space clearance. In any chimney installation, two points of stabiliza-

tion are necessary hence at least one Wall Band must be installed. It

is desirable to fully enclose an exterior chimney with minimum of 2”

air space clearance to reduce creosote buildup and to promote draft.

The framing dimensions for the Wall Support are ilustrated in Fig. 15

and Table 4.

The following steps will assist you in the installation of the Adjustable

Wall Support. Figure 16 shows a typical Wall Support installation

through a combustible wall.

-Through-The-Wall Length: Attaches to tee branch.

-InsulatedTee w/Plug

-InsulatedWallThimble:Required to passthrough acombustiblewall.

-Wall Band: Requiredtoprovidelateral support tothe chimney.

-RoundTop:To prevent rainand/ordebris from entering inthechimney.

-Stove Pipe Adapter: To connect from the chimney to appliance’s flue

pipe.

-Roof Flashing: Required when the chimney penetrates a roof or a roof

overhang.

The maximum chimney height above an Adjustable Wall Support is

indicated in Table 5 and illustrated in Figure 16, all of which must be

above the support.

“H”

Max.

Chimney

Height

“D”

Distance

from Wall to

Chimney

Support

Plate

Framed

Opening

Vertical

Wall

Studs

FIG. 16 - See Table 5 for Maximum

Chimney Heights based upon

Chimney Diameter and Distance

from Wall

StudsFor

Support

FIG. 15 - Framing for Wall Support

SIZE TABLE4

To complete a proper Wall Support installation, the following parts

may be required:

-Adjustable Wall Support: Intended for a through-the-wall installation

where the chimney has a horizontal connection.

-Suitable Lengths of chimney: Installed above the support.

2. For a non-combustible wall (concrete block or poured foundation),

cut a hole 5mm (3/16”) greater in diameter than the outside diameter

of the chimney.

1. Determine the centre line of the horizontal connection (Chimney

Length through the wall) and frame an opening to the dimensions

specified for the Wall Thimble in a combustible wall (see Table 4

Section Aand Figure 15).

3. After framing in your opening to the dimensions specified in the

Framing Dimensions in Table 1, install the outer half (with the unfin-

ished square plate) of the Insulated Wall Thimble in the outside wall

opening. Secure in place using appropriate fasteners through the

pre-punched holes.

4. Installthe inner half(with blackplate)of the Insulated wallThimblein

the inside wall opening, ensuring that the shield slides into the shield of

the outer half. Once in place and flush against the wall, fasten with ap-

propriatefastenersthrough the pre-punched holes.

5. Assemble the side Brackets (point of triangle facing down) to the

SupportPlate(flange up) by insertingthe threaded studsinto theoblong

slots. Install the supplied nuts on the threaded studs. (see Figures

17 & 18).

10

2

2.5

3

3.5

4

4.5

5

5.5

6

74

73

71

69

66

62

58

52

45

63

62

60

59

56

53

50

45

39

56

55

53

51

49

46

43

38

34

49

48

47

46

44

42

39

35

30

Insulated Wall Thimble

Telescoping adjustment

from 6” to 11”

Insulation

Blanket

Interior Inner

Half of

InsulatedWall

Thimble

Exterior Outer

Half of

InsulatedWall

Thimble

Figure 19

FIG. 20 -SECURINGOFINSULATED TEE CAP

Support

Plate

Insulated Tee Cap Screw to

Secure Tee Cap

Bracket

Tee Cap

Bracket

WARNING: The Insulated Tee Cap must be installed

and secured in place. Failure to install retaining clips

could cause fire, injury or death.

Nutsert

Insulated

Chimney

Section

9. Place the insulated Tee on the support plate ensuring that the

male coupler of the Tee is facing up and the flange on the top of the

plate slides into the female coupler. Insert and secure the Tee Cap

with the attached retainer clips (see Figure 20). In earthquake zones,

secure the Tee to the flange on the support plate by installing 2 stain-

less steel sheet metal screws as per figure 20.

10. For extension of the Tee, slide an appropriate insulated Chimney

Lengththroughthe WallThimble and attachit to the horizontalbranch of

theInsulatedTee with thesupplied lockingband. Make sure thenut and

bolt are facing down to prevent any water from collecting in the locking

band. The insulated length must protrude at least 76mm (3”) through

the wall into the room as per Figure 14a.

Stud and Nut

located to front

of Support

Bracket

Support

Brackets

Threaded Stud

and Nut

located at

rear of

Support Plate

Pre-

Punched

Holes of

Support

Bracket

Slot for Tee

Cap Bracket

Flange Up

FIG.18 - FRONTVIEW OFWALLSUPPORTASSEMBLY

Support

Plate

6. Ensurethat theWallSupport is level,and secure tothe wall through

the pre-punched holes located on the sides of each of the wall support

bracketsusing(8)#14x1-1/2”hexheadlagscrewsor #10 x 1-1/2” wood

screws. You can drill 5/32” pilot holes for the lag screws.

7. Once in its final position and all clearances have been met, tighten

each of the nuts on the threaded studs.

8. Attach the two (2) retainer clips to the bottom of the support plate

and fasten with the supplied nuts and bolts using the two (2) holes on

top of the support plate (see Figure 20).

11. Use a non-hardening high-temperature sealant (500oF) to seal

around the horizontal length where it enters the wall thimble or the

concrete wall.

12. Chimney lengths above the Insulated Tee are simply stacked on

and locked with a 1/8 clockwise turn. Locking bands must be used

on all joints.

13. For lateral stability of the chimney above the support, a Wall Band

mustbeused every 8feet, andat leastone Wall Bandmust beinstalled.

Interiorchimneysmustuse the Firestop JoistShield (JS) inplace ofWall

Bandsifextending through floor /ceiling penetrations.

Distancefrom

Wall to

Chimney 5” ID

Chimney 6” ID

Chimney 7” ID

Chimney 8” ID

Chimney

H(feet)

Max. Height H(feet)

Max. Height H(feet)

Max. Height H (feet)

Max. Height

D (inches)

Wall/Chimney

Table 5 - Wall Support Chimney Height Chart

Support Side

Brackets

Support Plate

Threaded Stud

Support Bracket

Threaded Stud

Nut

Support

Plate

Nuts

Nut

Support Bracket

Threaded Stud

Support

Plate

Threaded

Stud

FIG. 17 - UNDERSIDE VIEW OF

THREADED STUDS AND NUTS

11

76mm

(3”) min.

WALLBAND

The Wall Band is used along an outside wall at 8 ft intervals for lateral

stability. Secure the Wall Band bracket to the wall using two 6d or 2”

spiralnails. For concrete wallsusesuitable masonry fasteners.Thenut

andbolt supplied will fastenthe bandaroundthechimney.

NOTE: Inverting the brackets (brackets mounted above the support

plate) can be accomplished by inserting extra bolts through the oblong

slots of the support side brackets and the support plate as per Figures

21 and 22. Secure with nuts. In this position, the range of adjustability

is limited to 5” from the wall.

Nuts

Slot on

Support

Bracket

Support Brackets

Pre-Punched

Holes of Support

Bracket

Support Plate

w/ Flange Up

Slot for Tee Cap

Bracket

Slot on

Support

Plate

Bolts

FIG. 22- SLOTAREAS

WITH BOLTSAND NUTS

ASSEMBLYOF SUPPORT

BRACKET AND

SUPPORTPLATE

FIG. 21-FRONTVIEWOF

WALLSUPPORT

ASSEMBLYWITH

BRACKETSMOUNTED

ABOVETHE SUPPORT

PLATE

Wall Band Figure 23 - After framing in your opening to the dimensions specified above and

in Table 1, slide the Cathedral Support Box into the joist/rafter open-

ing. Once the box is at the desired location, ensure the box is level

and plumb. Nail the box to the framing using four 2” spiral nails or

equivalent per side. The excess material sticking above the roof can

either be trimmed off before attaching the box to the framing or, after it

is installed the corners can be cut and the excess material folded

down onto the roof deck.

- Install the Support Band on a chimney length at the desiredposition

by tightening the support band with the bolt and nut. Secure the band

to the chimney outer casing by screwing four stainless steel sheet

metal screws through the support band and into the outer casing.

- Lower the chimney length down through the opening in the bottom

of the support box, so that the Support Band makes contact with the

bottom of the Support Box (see Figure 24).

-Cathedral Ceiling Support /w 4 painted ceiling trim angles

-RoofFlashing w/ StormCollar

CATHEDRALCEILINGSUPPORT

A Cathedral Ceiling Support is available for 5” and 6” diameters chim-

ney only. For other diameters, a roof support can be used to suspend

the chimney below the roof. To complete a proper Cathedral Ceiling

Support installation, the folllowing parts may be required:

NOTE: The male coupler of the chimney length must be pointing

upwards as per the arrow on the chimney label.

- The bottom chimney length should protrude into the living space so that

proper clearances are maintained at the adapter (see Figure 24).

- The Cathedral Ceiling Support Box is manufactured to an overall

outer dimension of 12” x 12” (305mm x 305mm). Therefore, the sug-

gested framing to fit the box is 12-1/4” x 12-1/4” (311 x 311mm).

The following instructions will assist you in the installation of your

chimney with a Cathedral Ceiling Support. This support will hold up

to 30’ of chimney, of which 15’ can be suspended below the box.

Chimney joints made below the support must be secured with lock-

ing bands.

-Suitable lengths of chimney

-Stove PipeAdapter

-TrimCollar

-RoundTop

Flashing Minimum

50mm 2”

air space

clearance

Roof

Brace Kit

StormCollar

Locking

Band

Stove

Pipe

Adapter

Follow

Appliance

Instructions

for proper

connector

clearance

Support

Band

Cathedral

Ceiling

Support

FluePipe

RoundTop

Figure 24

12

158

7

6

4

32 910

1

26

453 78910

11

11

3”

ROOFFLASHING:

Ensure that you have the proper roof flashing by checking your roof

pitch using a level and two rulers (see Figure 27) or by using a roof

pitch card.

12”

Ruler Level

Roof

Figure 28

Figure 27

Shingles

Nails

Flashing

7.Attach the Roof Brackets to the chimney plates. Centre the assem-

bly in the roof opening, ensuring that a 2” clearance to combustible is

maintained.

8.Adjust Roof Brackets to the roof pitch and tighten nuts.Attach to the

roof with six (6) large wood screws per bracket

with the inner-most screws going into the rafters or headers (See

Figure 25 & 26).

9. Additional chimney lengths above the support are simply stacked

on and locked with a 1/8 clockwise turn.

10. Locking Bands must be used on all exterior joints.

11. Finish the chimney to its required height. If the chimney extends

1.5 m (5') or more above the roof, a Universal Roof Brace Kit is

required (see Figure 36).

Apply a bead of

silicone caulking

along the seam

where the plate

meets the cone.

Apply a bead of

silicone caulking

along the back

seam of the

cone

ROOFSUPPORT

The following instructions will assist you in the installation of your

chimney with a Roof Support. This support will hold up to 9.0 m (30')

of chimney of which 6.0 m (20') may be suspended beneath it.

1. Frame a rectangular roof opening to provide a 50mm (2") minimum

clearance from combustible materials (See Figure (25).

2.Bend both chimneyplates at thevertical slots tofitthe outside curva-

ture of the chimney length (Figure 25).

Install additional chimney sections and lock together by turning clock-

wiseuntil the twosections lock togethertightly. Locking bands mustbe

usedatalljoints. Continueinthis manner until the required height above

theroof is achieved.

Chimney sections installed below the Cathedral Support are locked

together from below by turning counter-clockwise until tightly locked

together with each joint being secured by locking bands which are

provided. Do not offset the chimney below the Cathedral Support.

Figure 25

Figure 26

Flashing

StormCollar

Roof Support

50mm (2”) min.

clearance

InsulatedChimney

Length

FramedOpening

ChimneyPlate

Carriage Bolt

50mm (2”) min.

clearance

Chimneylength

Bend to fit curve of

chimney

Roof Bracket

Large wood screws

provided

Smallsheet metal

screws (provided)

5. Using the bent chimney plate as a template, drill 3/32" holes in the

outer casing of the chimney (do not penetrate more than 12 mm (1/2'’)

into the chimney). Attach the plate with the small sheet metal screws

provided.

6. Install the second plate in a similar manner on the opposite side of

the chimney length.

3. Determine the chimney plate position on the chimney casing (See

Figure 26).

4. Install two (2) carriage bolts per chimney plate in the square holes.

Once you have marked and located the area where the chimney will

come through the roof, center, position and prepare the roof area by

removing shingles, shingle nails and cutting the roofing material.

Frame a RECTANGULAR opening to suit the pitch of the roof and

ensure that a 2” (50mm) clearance is maintained to combustibles on

all four (4) sides. This is done before extending the chimney above

the roof. Do not nail the flashing to the roof at this time as ajustments

may be required.

Roof Pitch is 3/12

13

HEAVYDUTYUNIVERSALROOFBRACEKIT

The Chimney, Flashing and Storm Collar may be painted with a heat

resistant rust proofing paint when enclosing of the chimney is not

possible or if exposed to wind driven ocean spray. Salty humid air

causes metal to corrode faster than air with normal humidity. This will

extend its life and improve the appearance and could be matched with

the roof shingles. To improve adhesion to the chimney, degrease,

clean and prime before painting. Follow the paint manufacturer’s in-

structions.

Continueaddingchimneylengthsuntiltheproperheightisachieved(see

Figure1and Chart 2). Install aRoundTop. TheRoundToppreventsentry

ofmoisturewhichmightleadtoprematuredeteriorationofthechimney.

A Rubber Boot Flashing Kit is available as an option for passing

through a corrugated or metal roof. See separate instructions pack-

aged with the Rubber Boot Flashing Kit. On metal or steep roofs, it is

recommended that an ice deflector or “cricket” fabricated from heavy-

guage galvanized steel be installed. The wedge-shaped deflector is

installed 2” from the chimney on the upper slope. Its function is to

split ice and snow as they slide down the roof, preventing damage to

the chimney.

Slide the top edge (nearest the roof peak) of the flashing under the

roofing shingles. At least half of the flashing (top and sides) should

be UNDER the shingles and the lower end OVER the shingles to

provide a watershed. Trimming off the shingles may be neccessary

around the cone of the flashing for a better fit. On existing roof appli-

cation, lower a chimney length into the flashing opening and twist

lock in place and secure with a Locking Band. Ensure that the chim-

ney is level and plumb before nailing the flashing to the roof.

Nailthe flashing totheroof deck (alsounderthe shingles) alongtheup-

per edge and down each sides with 12 nails with neoprene washers or

covertheheadswithasuitablenonhardeningwaterproof caulking. Seal

the shingles to the plate in the same manner. As a precaution, apply a

bead of caulking along all seams of the flashing as per Figure 28.

Applyanon-hardeninghightemperaturesilicone caulking just above the

top of the flashing cone where it meets the chimney casing. Slide the

Storm Collar through theapplied caulkingand place intoitsfinal position

toensure a waterproofjoint. Applyadditional caulking abovethe Storm

Collarasrequired.

The HDURBK will provide lateral support to the chimney above the roof

line. TheHDURBK isrequiredwhenthechimneyextends 5feet(1600mm)

or more above the roof penetration. The kit contains Telescoping Legs,

Support Band, Roof Angle Brackets and hardware package.

Holes used to assemble Support

Band

Holes used to attach

Telescoping Legs to

Support Band

Support Band Holes Identifier

Holes used to assemble Support

Band

Holes used to attach

Telescoping Legs to

Support Band

Cage

Nut

Tab for

2” Bolt

Figure 29

The HDURBK accommodates most models of chimneys with outer

diameters ranging from 7" through 13". For larger diameter a suitable

Bracing System would need to be constructed (guy wires).

NOTE: Different holes combination can be selected as required.

ToInstall:

A. Measure the outside (OD) diameter of your chimney.

B. From the row of holes (see Figures 29 and 30), select the hole in

each half that corresponds to the outside diameter identified with

the chimney being installed. Place the two halves together. Insert

an elevator bolt through the chosen holes (Ex - for a 10” OD

chimney, place the elevator bolt through the holes identified for 10”

OD). The elevator bolt should be oriented as shown in Figure 31.

Secure the center bolt with washers and 1/4” flanged nut (see

Figure 31). NOTE: On smaller diameter chimneys the excess

band material can be cut off.

Cage Nut

Assembly of

Universal

Support Band (2

Halves)

Tab For

2” Bolt

Holes for Telescoping Legs

to Support Band

Holes for Support Band

Holes for Support Band

Holes for Telescoping Legs

to Support Band

Figure 30

Topview assembly of Support

Band - Elevator Bolt, Washers

and Nut

Hex Nut

Flat Washers

Support Band

Halves

Elevator

Bolt

Cage Nut

Figure 31

C. Form the band into a circle (see Figure 32) and loosely connect

tabs using the supplied 2” bolt into the cage nut located on one

of the two formed tabs.

D. Select the hole in each half that corresponds to the OD of the

chimney. Insert an elevator bolt in each of the holes (1 per side).

14

Elevator

Bolt

Angled end of Leg

Wing Nut

Elevator

Bolt

Angled end of Leg

Wing Nut

Assembly of

Telescoping Legs to

Support Band

Flat Washers Flat Washers

Lock Washer Lock Washer

Smaller Diameter Leg

Roof Shingles

Rafter or

framing

structure

Securing

Angle Bracket

2” Lag Screw

K. The two telescoping legs should form an angle of about 60° to

give support to the chimney in all directions. The angle of the

telescoping legs should be approximately 45° from vertical when

fastened to the roof (see Figures 34 & 36).

NOTE: Do periodic inspections of all fasteners including the securing

screws as high winds can cause the chimney system above the roof

to vibrate and in time loosen some of the fasteners.

Figure 34

Figure 35

Universal Support

Band formed into a circle

2” Bolt

Cage Nut

One of 2 halves

of Support Band

One of 2 halves

of Support Band

Elevator

Bolt

Flat Washer

Figure 32

E. Position the Support Band approximately two thirds of the way up

the chimney height (see Figure 36). The preferred location is

next to a joint, immediately above or below a Locking Band.

Secure Support Band by tightening the 2” bolt. NOTE: Only one

chimney joint should be above a Roof Brace Kit. An additional

Roof Brace Kit may be required for taller systems.

G. Place a flat washer on the elevator bolts and attach the top portion

of each of the telescoping legs to the 2 elevator bolts on the Support

Band with washers and nut (see Figure 34). Leg can be bent at an

angle using the claw of a hammer.

H. Attach the other end of each telescoping leg assembly to anAngle

Bracket using one (1) 1/4-20 X 1” bolt and nut (see Figure 35).

Preparation of Telescoping Legs:

F. Assemble the telescoping tubes by inserting the smaller diameter

into larger one. Thread the securing nut to the securing bolt then

thread this assembly into nutsert. Tighten firmly against the

smaller tube which will lock them together (see Figure 33). Repeat

for the other telescoping leg assembly.

Smaller Diameter

Telescoping Leg

Larger Diameter

Telescoping Leg

Securing Bolt

Nutsert

Assembly of Telescoping

Legs with securing

screwand nut Securing Nut

Figure 33

I. Determine the location of the two Angle Brackets on the roof

structure. Ensure the fasteners are into rafters or framing and

not just roof sheathing. Secure the Angle Brackets to the roof

structure using two (2) 1/4 X 2” lag screws per brackets (see

Figure 35). Apply a thin layer of caulking under the angle bracket

(before securing in place) as well as over the lag screw heads.

J. Make sure the chimney is level and plumb. Check all required

dimensions and angles, adjust if necessary. For added security,

we recommend that you secure the inside and outside tubes

together using # 8” x 1/2” stainless steel self tapping screw to

permanently lock them in place.

15

RoundTop

Upper Leg

Lower Leg

Angle

Bracket

2” Lag

screws

10’

MAX

2/3rd

of HT.

Securing Screw

Placement of

Universal Roof Brace Kit

B

C

A

TYPE HT ROUND TOP - 5” to 8” only (10”, 12” and 14” have a

different design)

AttachtheType HTRoundTop tothe chimney by sliding it over the chim-

ney length. ensure that the three (3) vertical tabs are located on the

outside of the chimney length and that the RoundTop sits flush on the

top surface of the length. Wrap the band snug to the bottom of the 3

tabs and secure in place with the supplied nut and bolt.

Chimney

Dia.

5”

6”

7”

8”

FIGURE37

A

7”

8”

9”

10”

B

10”

12”

14”

16”

C

5”

5-1/2”

6-1/4”

7”

Figure 36

Some Selkirk Tops (CT) have a nominal inch diameter expanding

utility attachment adaptable to Selkirk Selkirk Chimney and other prod-

ucts of like internal diameter. To attach securely:

1. Loosen screw on top of collar and squeeze bottom to allow collar to

enter pipe.

2. Press down evenly on lower skirt until it contacts upper end of pipe.

3. Tighten screw on collar to expand lower end and clamp to inside of

pipe. Keep tightening screw until collar is expanded and fully tight.

SPARKARRESTER (Part No. SA)

For 6” to 8” diameters a pre-formed Spark Arrester is available. See

separate instructions packaged with the Spark Arrester.

Spark

Arrester

To Install:

1. Place the pre-formed SparkArrester directly over the dome and skirt

of Round Top (Figure 2).

2. Ensure that the flanged end of the SparkArrester is on top of dome

and the bottom folded edge overlaps the skirt.

Ifclogged:

If the Spark Arrester becomes clogged with creosote, it should be

cleaned or replaced. Remove Round Top by removing cinch band.

Lightly tap away (from the outside of the Spark Arrester) any creosote

residue. If necessary use a soft bristle brush for assistance. If Spark

Arrester is to be removed from the Round Top, release the bottom

edge of the SparkArrester from the skirt edge and raise SparkArrester

from Round Top.

Round Top

Cinch Band

UT

Chimney

Length

FIGURE39

FIGURE38

16

With a new chimney installation, the chimney should be inspected at

least once every 2 weeks during the heating season to determine if a

creosote or soot buildup has occured. When familiar with the appliance

and chimney characteristics, the chimney should be inspected at least

once every 2 months during the heating season.

Ifcreosote or soot hasaccumulated, itshouldberemoved to reduce the

risk of a chimney fire. Depending on the rate of buildup, as you learn

whatis going onin thechimney, you canadjustyour cleaning schedule.

If you have any doubts about your ability to clean the

chimney,orifthedepositsareveryheavyandhardtoremove,callacertified

chimneysweep. Donot try toburn themoff.

Ifchemicalcleanerisusedto assist in cleaning your chimney,makesure

it is a product which is non corrosive to the chimney liner. The optimal

methodfor cleaning a chimneyisbya mechanical brushingof thechim-

neyinconjunctionwithacompleteevaluationof the system by a certified

chimneysweep. TheNationalFireCodeof Canada states: “Every chim-

neyflueandfluepipeshallbeinspected and cleaned annually or as often

as maybe necessary, to keep the chimney and flue pipe free from dan-

gerousaccumulations of combustibledeposits”.

CHIMNEYFIRESANDWHATTODOABOUT THEM:

Your Selkirk chimney is not intended or designed for use as a combus-

tionorfirechamber. Ifthefireinyour appliance has gotten out ofcontrol,

or if you suspect a chimney fire for any reason, follow these steps:

1. Immediatelyclose all dampers and/orairentrance to your appliance.

2. Alertyourfamily to thepossible danger.

3. Inspectyourapplianceandchimneyfor possible fires, if in doubt,alert

yourFireDepartment.

4. Do not use salt or water on the fire. Salt is corrosive and water will

causeadangerous steam explosion. Youmaybe able to controlthe fire

byusingashes, sand orbaking soda,since bakingsoda isan ingredient

usedfor dry chemicalfireextinguishers.

5. Donot continue touseyour appliance untilitand your chimneyhave

beenthoroughlyinspected by acertified servicetechnician.

6. After a chimney fire, when it is safe to do so, check internal locations

such as the attic and under the roof and keep watching for two or three

hours. Theremaybe delayed smoldering andsubsequent ignitioneven

if the fire inside the chimney has been controlled.

The Anchor Plate may be used for adapting the UT chimney to a

“Listed” Factory-Built Fireplace certified for use with Model UT.

NOTE: It is of the utmost importance that theAnchor Plate be installed

in accordance with the manufacturers installation instructions sup-

plied with the “listed” Factory-Built Fireplace.

MODELUTANCHOR PLATE

CHIMNEYOPERATIONANDMAINTENANCE:

The need for chimney maintenance depends on the kind of appliance

and how it is operated. Gas and oil-burning appliances need very little,

butwood-burningappliances may need agreat dealof chimneymainte-

nance.

IMPORTANT

Burningwood produces creosote, soot,and flyashwhichtend to collect

inchimney flue and on terminationpartscausingreduced flow ofgases

through the chimney. Check top weekly for excessive accumulation of

thesenormalcombustion productsand clean as necessary. Ifthe spark

arresterbecomes cloggedwithcreosote,itshould becleanedorreplaced.

4. Always secure all single wall flue pipe joints with a minimum of 3

screws.

5. Obtain proper attachment parts for the appliance end and for the

entryto the chimney.

6. Locate or support the flue pipe to avoid contact of damage.

7. Caps or plugs for single wall tees should be secured against fall-

ingout and designedsothey can’t leak creosoteorrain.

The connection of a single wall base tee or single wall flue pipe or

double wall flue pipe to the insulated chimney must be secured with

the screws supplied in the Support carton. The use of a stove pipe

adapter is recommended with the first length, this will provide a posi-

tive connection between the insulated chimney and the appliance

connector. The Stove Pipe Adapter is inserted into the female end of

the first insulated chimney length and extends beyond the ceiling

support approximately 32mm (1-1/4”). For a Cathedral Support and

Wall Support application, the stove pipe adapter is inserted into the

female end of the exposed chimney length and extend into the room

and held in place with the finishing collar secured with 4 screws

which is used to attach the stove pipe adapter to the finishing collar.

Installinter-connecting fluepipe followingtheappliance manufacturer’s

instructions,andappropriatebuildingcode requirements keeping in mind

that the flue pipe run should be as short and straight as possible. All

joints should be secured in place with three (3) sheet metal screws.

Besidesfollowingtheapplianceinstructions for flue pipe, other rulesthat

shouldbetaken into account:

To comply with the National Building Code of Canada the single wall

base tee can be installed with a 229mm (9”) minimum airspace

clearance between connnecting single wall material and combus-

tible products provided that the flue gas temperature does not exceed

400° C (750° F) (most oil fired appliances). Otherwise, the minimum

air space clearance must be 450mm (18”). Refer to the appliance

installation instructions for the proper chimney requirements.

STOVEPIPEADAPTER:

Connectonlytolowheat(liquidfuelorgasfired)applianceswithcontinu-

ous flue gas temperatures below 540° C (1000° F). When installing a

factory-builtfireplacerefer to the fireplace installationinstructions forthe

properchimneyrequirements.

1. Never enclose single wall flue pipe, even at 18 inches clearance.

2.Neverrunit through ceilingsorfloors, or windows.

3. Don’tuse singlewall flue pipe outdoors.

PAINTINGOFTHEEXTERIORCHIMNEY

If the chimney cannot be enclosed it is highly recommended to paint

all exterior chimney, including the roof flashing and storm collar with a

heat resistant rust proofing paint when the chimney is exposed out-

doors to wind driven ocean spray. Salty humid air causes metal to

corrode faster than air with normal humidity. This will extend its life

and improve the appearance. To improve adhesion, degrease, clean,

prime before painting. Follow the paint manufacturer’s instructions.

17

AA

BBAB

AB

AABBAB

AB

AABBAB

AB

15/16

2-1/4

3-3/4

5-1/4

6-7/8

8-1/8

10

12-3/4

14-3/8

17-1/4

13-1/8

8-1/4

12-7/8

18-5/8

24-1/2

30-1/4

34-7/8

41-7/8

52-1/4

58-7/8

68-3/8

53-3/8

340

444

576

708

840

953

1104

1341

1472

1605

1841

3-1/2

5-15/16

8-15/16

11-15/16

379

517

532

669

745

821

958

15/16

2-1/4

3-3/4

5-1/4

6-7/8

8-1/8

10

12-3/4

14-3/8

17-1/4

13-1/8

9-1/8

13

19-3/8

25-5/16

31-1/8

35-3/4

42-5/8

53-1/16

58-7/8

69-1/4

54-1/4

90

150

228

303

379

517

532

669

745

821

958

394

499

630

762

894

1131

1158

1395

1527

1659

1895

15/16

2-1/4

3-3/4

5-1/4

6-7/8

8-1/8

10

12-3/4

14-3/8

13-1/2

13-1/8

8-13/16

13-7/16

19-1/4

25

30-1/2

35-7/16

42-3/8

52-7/8

58-5/8

69

54

15/16

2-1/4

3-3/4

5-1/4

6-7/8

8-1/8

10

12-3/4

14-3/8

13-1/2

13-1/8

8-5/8

13-3/16

19

24-7/8

30-3/8

35-3/16

42-1/8

52-1/2

58-3/8

68-3/4

53-3/4

105

164

241

317

395

530

545

681

758

835

972

407

511

643

775

907

1144

1171

1407

1539

1672

1908

407

524

656

788

920

1156

1184

1420

1552

1684

1921

120

205

313

421

529

722

744

937

1045

1153

955

304

389

497

605

713

906

928

1121

1229

1337

1144

120

205

313

421

529

722

744

937

1045

1153

955

305

390

498

606

713

906

929

1122

1230

1337

1144

140

225

333

441

548

742

764

958

1065

1173

980

356

441

549

657

765

958

980

1173

1281

1388

1196

140

225

333

441

548

742

764

958

1065

1173

980

384

469

577

685

793

986

1008

1201

1309

1417

1224

105

164

241

317

395

530

545

681

758

835

972

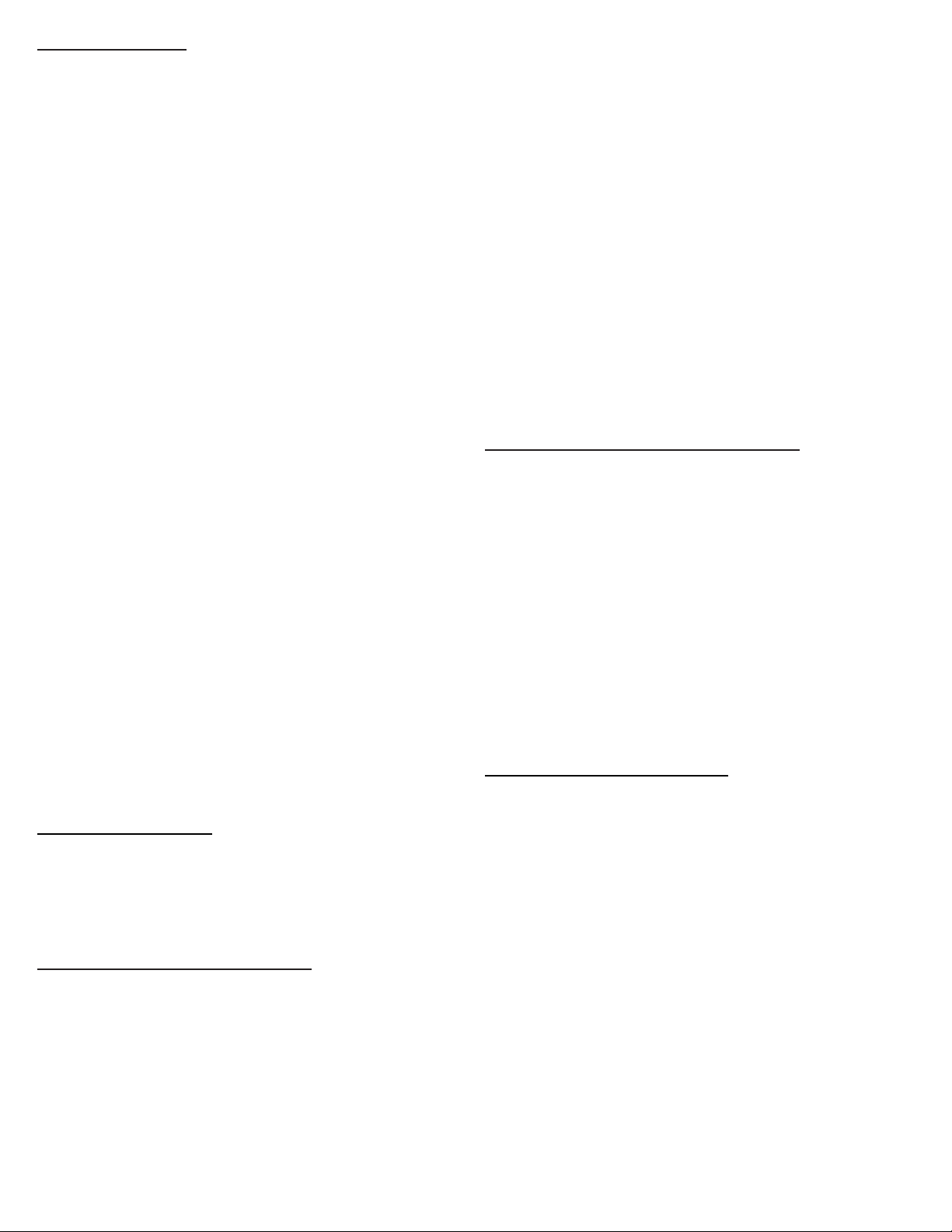

OFFSETCHARTCHIMNEYINSTALLATION(5” to8”only)

It may be necessary to offset the chimney in order to clear a joist or an obstacle. The three (3) charts below will assist you in selecting the proper combination

of elbow angle and chimney length(s) that will provide the necessary degree of offset within an available height.

1. Select the column with the proper chimney

diameter of your system.

2. Determinethedistance ofthe offset requiredby

dropping a plumb line for an accurate measure-

ment. Theoffset ismeasured atthe chimneycen-

tre line as per the "A" Offset measurement in the

diagrambelow.

3. On the chart, find the predetermined distance

(underthe "A"column) required for the 15oelbow.

Forgreater offset,use the30oor 45ooffset charts.

4. After finding the offset, look at the “B” (height)

measurement in the chart to find the specified

height. The appropiate"chimneylengths"required

in between elbows is found in the left hand side

column on the chart.

NOTE:

• UltraTemp chimney can be offsetted us-

ing 15o, 30oor 45oelbows. Combining offsets for a

greaterangleisnot permitted.

• One pair of (two) 15o, 30oor 45oelbows

may be used per interior installation.

• Never install an elbow in a joist area.

Chimney sections must pass vertically through

framedjoist areas.

• Each elbow support will support 30 feet

ofchimney.

•Anintermediate supportmust be used at

4feetintervals inconjunctionwith anelbowsupport.

•Themaximum length ofchimney allowed

betweenelbows is 16 feet.

All measurements in inches.

Construction tolerances + one inch.

Offset

“A”

"B"

Height

45o OFFSET CHART

30o OFFSET CHART

15o OFFSET CHART

none

6"

12"

18"

24"

12" & 18"

36"

12" & 36"

18" & 36"

12"&18"&36"

48"

none

6"

12"

18"

24"

12" & 24"

36"

12" & 36"

18" & 36"

24" & 36"

12"&24"&36"

none

6"

12"

18"

24"

12" & 24"

36"

12" & 36"

18" & 36"

24" & 36"

48"

Chimney

Lengths 7"Diameter

6"Diameter 8" Diameter

5"Diameter

Chimney

Lengths 7"Diameter

6"Diameter 8" Diameter

5"Diameter

Chimney

Lengths 7"Diameter

6"Diameter 8" Diameter

5"Diameter

18

44

42

40

38

36

*36

*36

*36

*36

*36

54

51

48

45

42

39

36

*36

*36

*36

64

60

56

52

48

44

40

36

*36

*36

74

69

64

59

54

49

44

39

*36

*36

84

78

72

66

60

54

48

42

36

*36

94

87

80

73

66

59

52

45

38

*36

104

96

88

80

72

64

56

48

40

*36

114

105

96

87

78

69

60

51

42

*36

124

114

104

94

84

74

64

54

44

*36

134

123

112

101

90

79

68

57

46

*36

144

132

120

108

96

84

72

60

48

36

*36

*36

*36

*36

*36

*36

*36

*36

*36

*36

1/12 2/12 3/12 4/12 5/12 6/12 7/12 8/12 9/12 10/12 11/12 12/12

*UT-36 / *U-36

*UT-24 / *U-24

*UT-18 / *U-18

*UT-12 / *U-12

*UT-06 / *U-6

*T-ITP / *S-IT

*T-EL15KIT / *U-EL15 Kit

*TEL30KIT / *U-EL30 Kit

*T-CSB / N/A

*T-AWS/ *S-AWS

*T-CCSK / N/A

URSP / *S-RSP

*T-LB / *S-LB

*T-AD / *S-CPA

DESCRIPTION

DESCRIPTION

*T-IWT / *S-IWT

*T-WB /*S-WB

URBK / N/A

*T-AP / *S-AP

*T-AIS /*S-AIS

*T-JS / *S-JS

*T-FS / *S-FS

*T-RT / *S-CT

*T-FF / *S-TF

*T-FA / *S-AF6

*T-FAA / *S-AF12

*T-SC / *S-SC

©2019 UltraTemp (Canada) All Rights Reserved 510000 08/19/2019

Requirement # 1 : The code requires that the chimney must extend at least 3 feet (900mm) above the highest point of the roof that it penetrates.

Requirement # 2 : It must also be 2 feet (609mm) above any roof, wall or other obstruction within a horizontal distance of 10 feet (3m).

The following Chart is to assist you in determining the minimum chimney height you will require above the roof. You may need to add to

this height as nearby buildings, trees and other parts of the house roof could interfere with airflow over and around the top of the

chimney and affect its performance. If you think a nearby obstacle could affect draft, you might want to install one or more additional

lengths.

CHART2 - CHIMNEY HEIGHT ABOVE THE ROOF

DISTANCE

FROM PEAK

10 Ft

9 Ft

8 Ft

7 Ft

6 Ft

5 Ft

4 Ft

3 Ft

2 Ft

1 Ft

CHIMNEY HEIGHT ABOVE ROOF (INCHES)

PITCH OF ROOF

* Defaulted to 36" to meet requirement #1. Both requirements (#1 and #2) must be met.

• If the chimney extends more than 5 feet or more above the roof, a Universal Roof Brace Kit is required.

•Alllengthsabovetheroofmusthavelockingbandsatalljoints. ThiswilleliminatetheriskofsectionsbecomingundonebelowtherooflinewhentheRoundTop

isremovedwhen inspections andcleaningofthe system isbeingdone.

All measurements are in inches with the exception of "distance from the peak" being in feet.

REPLACEMENT PARTS LIST

ULTRATEMP

PARTNO.

5” - 8” / 10” - 14”

36" Chimney Length

24" Chimney Length

18" Chimney Length

12" Chimney Length

6" Chimney Length

Tee with Insulated Plug

15o Elbow Kit

30o Elbow Kit

Ceiling Support

Adjustable Wall Support

Cathedral Ceiling Support Kit

Roof Support

LockingBand

Stove Pipe Adapter

InsulatedWallThimble

WallBand

Universal Roof Brace Kit

Anchor Plate

Attic Insulation Shield

Firestop Joist Shield

Firestop Spacer

Type HT Round Top

Flat Roof Flashing

1/12 - 7/12 Roof Flashing

8/12 - 12/12 Roof Flashing

StormCollar

* Specifies chimney diameters (5” to 14”).

ULTRATEMP

PARTNO.

5” - 8” / 10” - 14”

19

INSTALLATION INFORMATION

Leave with homeowner. Homeowner: Keep in a safe place for future reference.

PRODUCT INFO

CHIMNEYMODEL:Ultra-Temp

FLUESIZE________

TOTALHEIGHT_________

INSIDEINSTALLATION OUTSIDEINSTALLATION

CONNECTED TO (type of appliance):

BOILER

FURNACE

LISTED FACTORY-BUILT FIREPLACE

OTHER (specify) ____________________

LOCATION OFAPPLIANCE:

BASEMENT

MAIN FLOOR

OTHER (specify)___________________

INSTALLATION DATE:__________________________________________________

DEALER INFO

DEALERNAME:_______________________________________________________

Address:_____________________________________________________________

City:________________________________________________________________

Province:_____________________________________________________________

TECHNICIAN INFO

TECHNICIANNAME:___________________________________________________

Address:____________________________________________________________