Selwood Spate PD75 Manual

4

1 GENERAL INFORMATION

1.1 Installation

1. The pump unit and its associated baseplate or

trolley mounting should be positioned on a firm

horizontal platform, and in the case of portable

units restrained from accidental movement.

2. If the pump is fitted with push-on type suction and

delivery spigots the hoses must be firmly secured

on these spigots with heavy duty clamps or clips

capable of withstanding the system operating

pressure. The integrity of the hose clamping

arrangements should be checked at regular daily

intervals in the case of static installations or

whenever the pump is repositioned in the case of

portable units. Similar precautions should be

taken with clamps securing multiple lengths of

hose on installation where long delivery and

suction lines are involved.

3. Delivery hose and any associated pipework

should be capable of withstanding the maximum

system operating pressure. Suction hose should

be of non-collapsible variety.

1.2 Operation

1. CAUTION The pump should only be

operated within the speed and pressure limits

detailed in the operating handbook for the model

in question.

2. If there is a danger of freezing, the fluid normally

retained within the pump between operating

cycles should be drained off through the drain taps

provided.

3. WARNING Positive displacement pumps

of the PD75 type should not be run against a

closed valve on the delivery side. If there is a

danger of high system pressures developing

because of closed delivery valves or some other

reasons the pump should be fitted with a full flow

relief valve adjusted to a lift at a safe working

pressure for the pump and pipework system.

4. Where protective caps are used to prevent

damage to the suction and delivery spigots during

storage or in transit they must be removed before

the pump is started up.

1.3 Maintenance

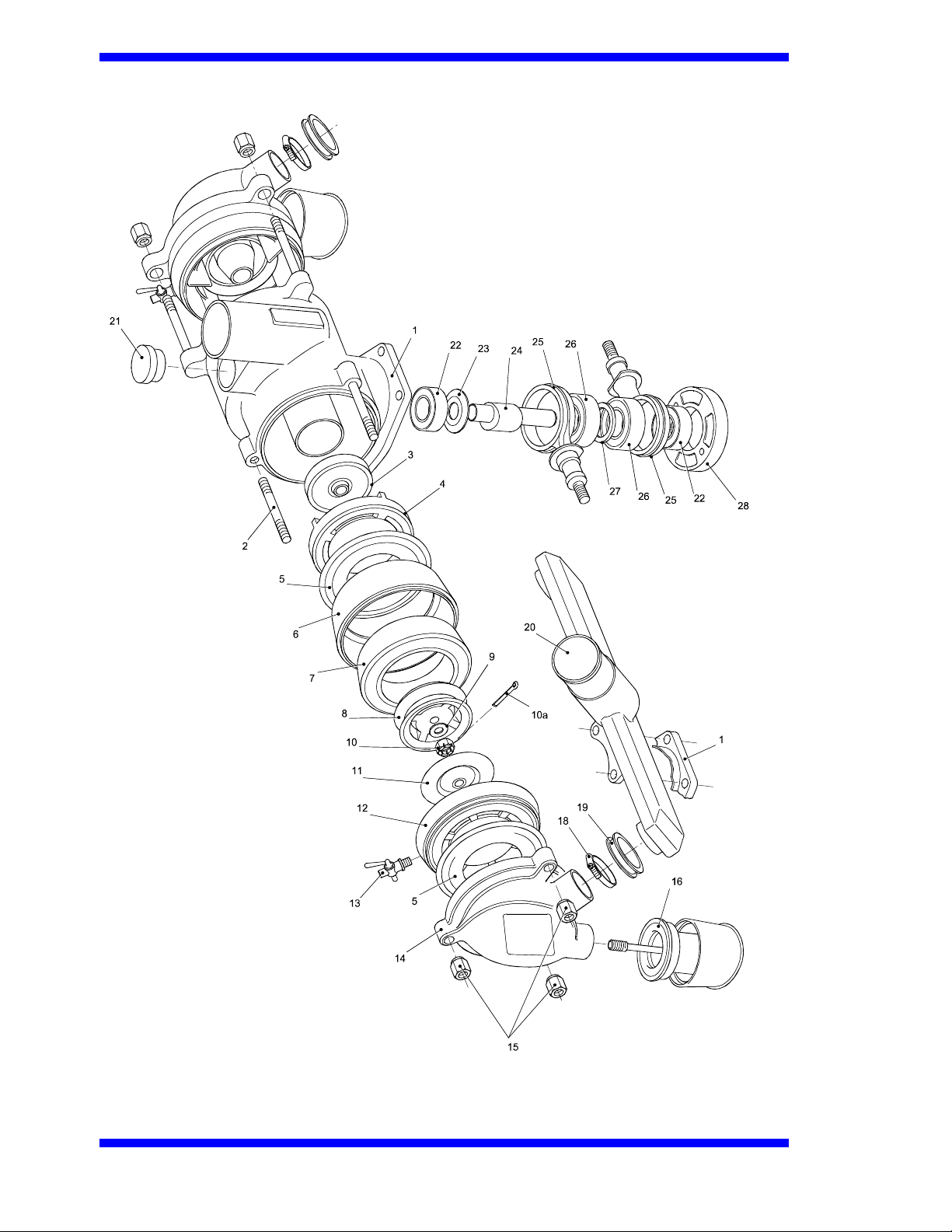

1. Inspection and maintenance. Regular flushing

after use and periodic stripping and inspection of

the cylinders will help maintain the PD75 in best

condition. All bearings are sealed for life so

lubrication is only necessary when re assembly of

the pistons to the connecting rods occurs. See

lubrication section for advice on products and

brands. Appropriate flushing with clean water after

use will further aid long service life. The engine or

driver should be maintained in accordance with

the manufacturer’s instructions.

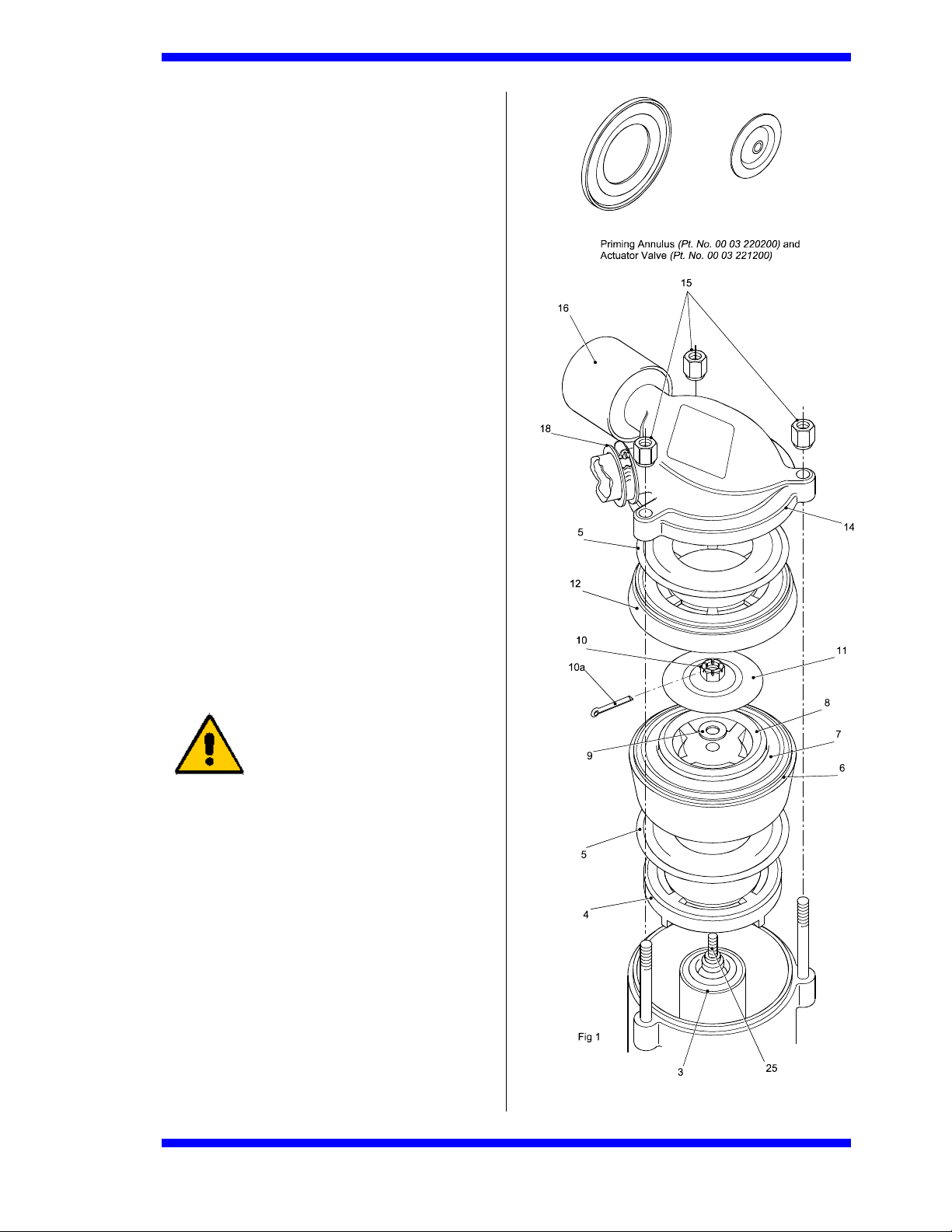

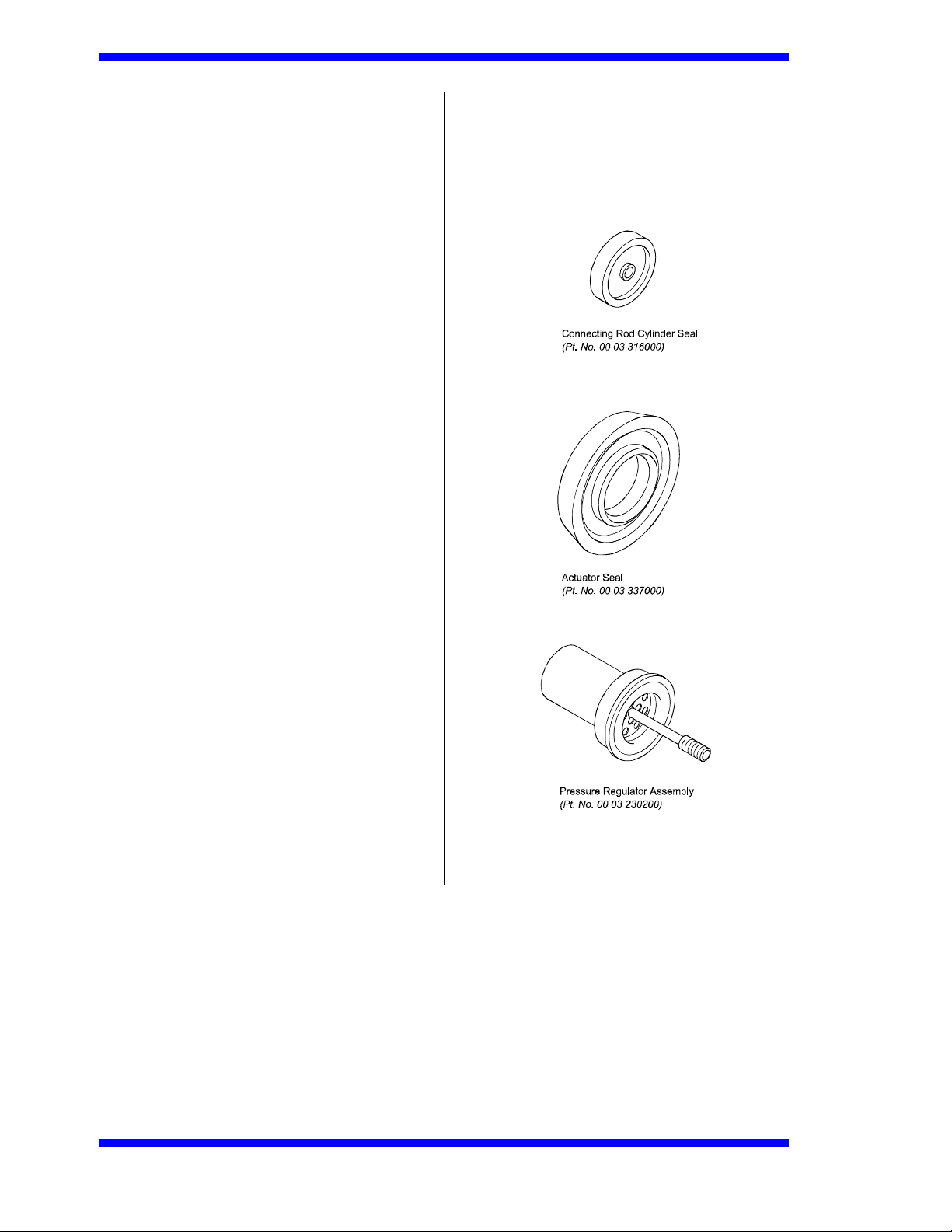

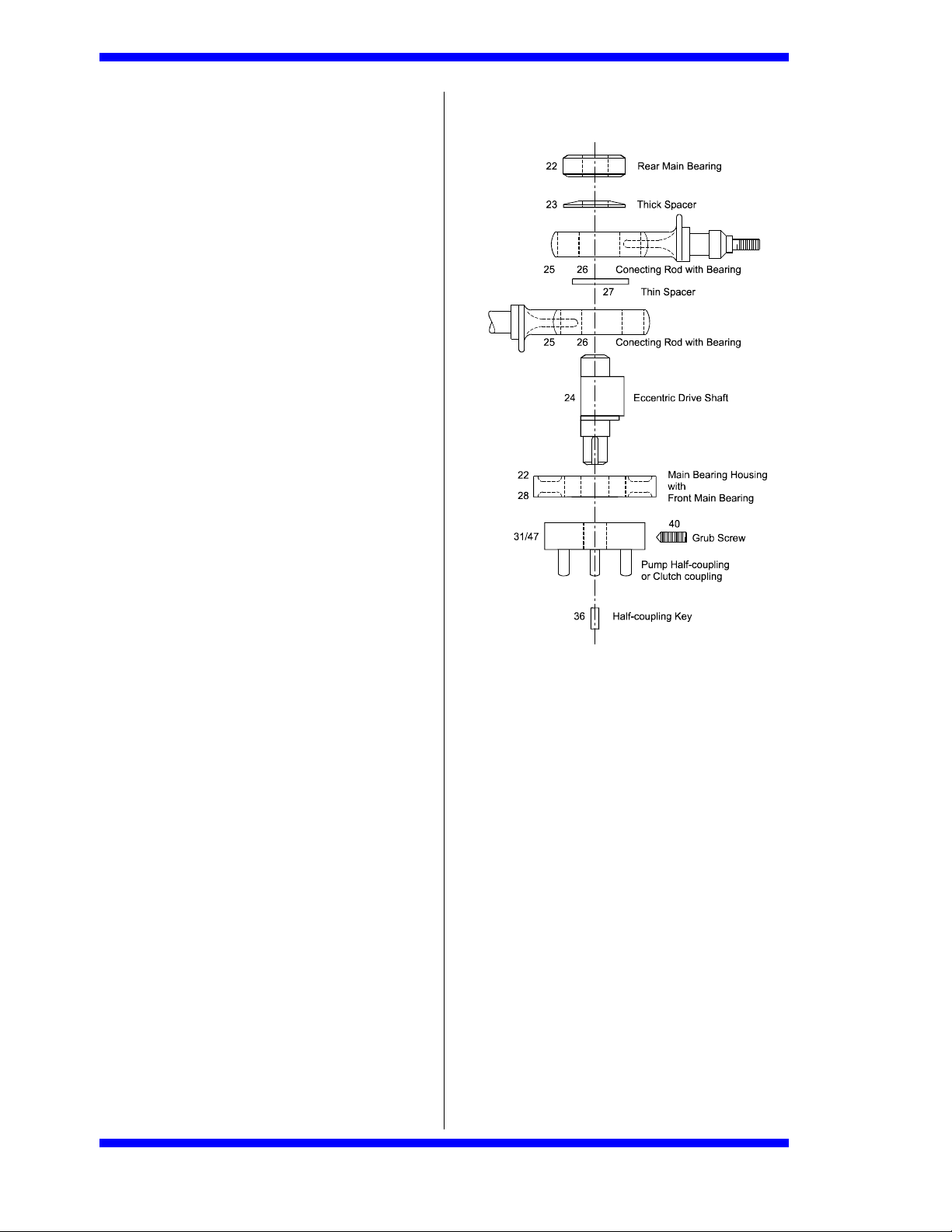

2. Replacement parts. Only the manufacturers or

factory approved components should be used as

replacement parts and where necessary they

should be fitted with the assistance of the special

purpose tools indicated in the operating and

servicing manual.

3. All maintenance work must be carried out with the

pump and engine/motor stationary.

1.4 I.C. Engines

1. Where I.C. engines are used to power the pump

they have been mounted in accordance with the

engine manufacturers recommendations and

adequate guarding provided between the pump

and engine.

2. Exhaust and Exhaust Pipes. If there is a risk of

accidental contact by operators, the exhaust

system should be lagged or screened and the

outlet directed away from operators or other

persons likely to be nearby. Direct contact with

flammable materials of all types must be avoided.

The importance of adequate ventilation to ensure

removal of exhaust fumes when engines are

operated in enclosed or covered accommodation

cannot be overstressed. Engines should not be

run in hazardous explosive atmospheres.

3. Access and Operation. Ensure that the operator

can start, control and stop the engine easily by

making all controls readily accessible. Fit remote

controls if access is difficult. Follow the

instructions laid down in the engine

manufacturer's Operators Handbook for starting,

operating and stopping procedures.

4. Fuel. In addition to the fire hazard associated with

fuel and lubricating oils, preventative action is

necessary with respect to leakage, contamination

and bodily contact.

5. WARNING Electrical Connections. It is

essential that earth terminals are connected with

an absolutely sound earth point and care should

be taken to ensure that the correct sized

conductors are selected to suit the current and

distance it is to be carried.

1.5 Electric Motors

1. All electrical connections should be made with

adequately rated conductors and starters.

Isolators and other associated switchgear should

be of adequate capacity for the imposed power

loadings. All electrical equipment should be

adequately earthed. All connections to be made

by a qualified electrician to BS7671 latest revision.

2. WARNING Isolate the power supply

before carrying out any commissioning, servicing

or maintenance work on the pump or electric

motor.