Sensorex SD7000CD Series User manual

Page 1 of 8

Congratulations on your purchase of your Sensorex SD7000CD

pH or ORP true differential electrode. Please follow instruc-

tions and tips to get the maximum life out of your electrode.

Introduction

Electrode Care and Use Tips

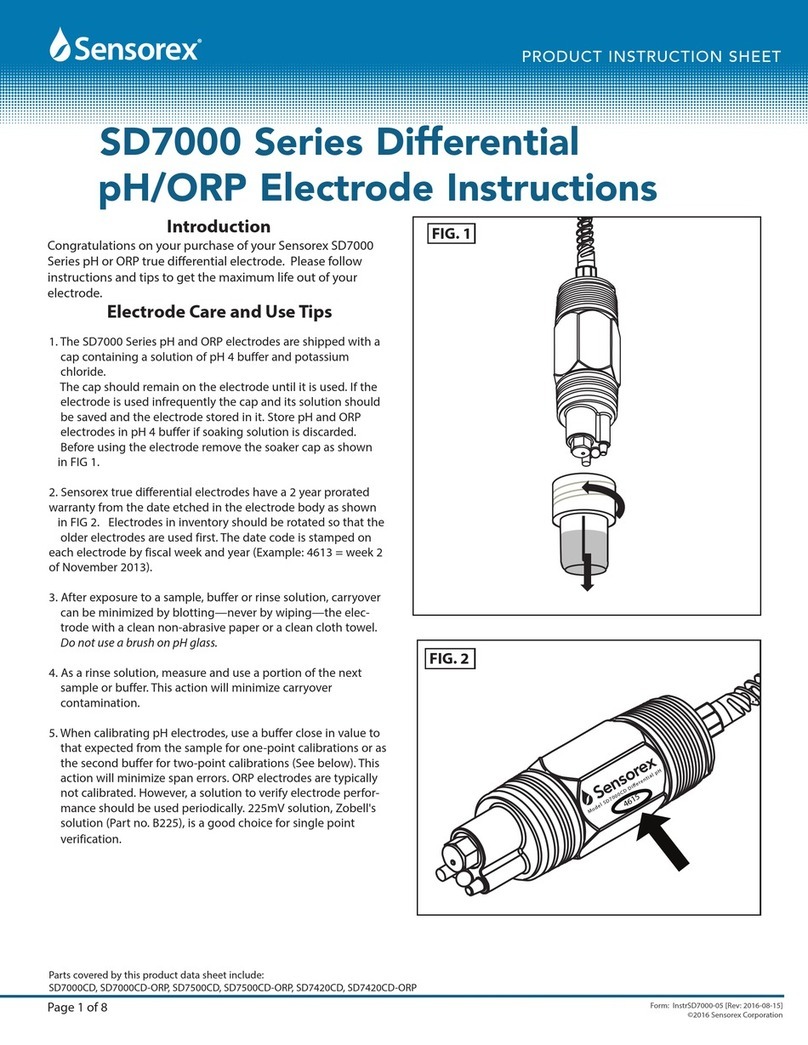

1. The SD7000CD pH and ORP electrodes are shipped with a cap

containing a solution of pH 4 buffer and potassium chloride.

The cap should remain on the electrode until it is used. If the

electrode is used infrequently the cap and its solution should

be saved and the electrode stored in it. Store pH and ORP

electrodes in pH 4 buffer if soaking solution is discarded.

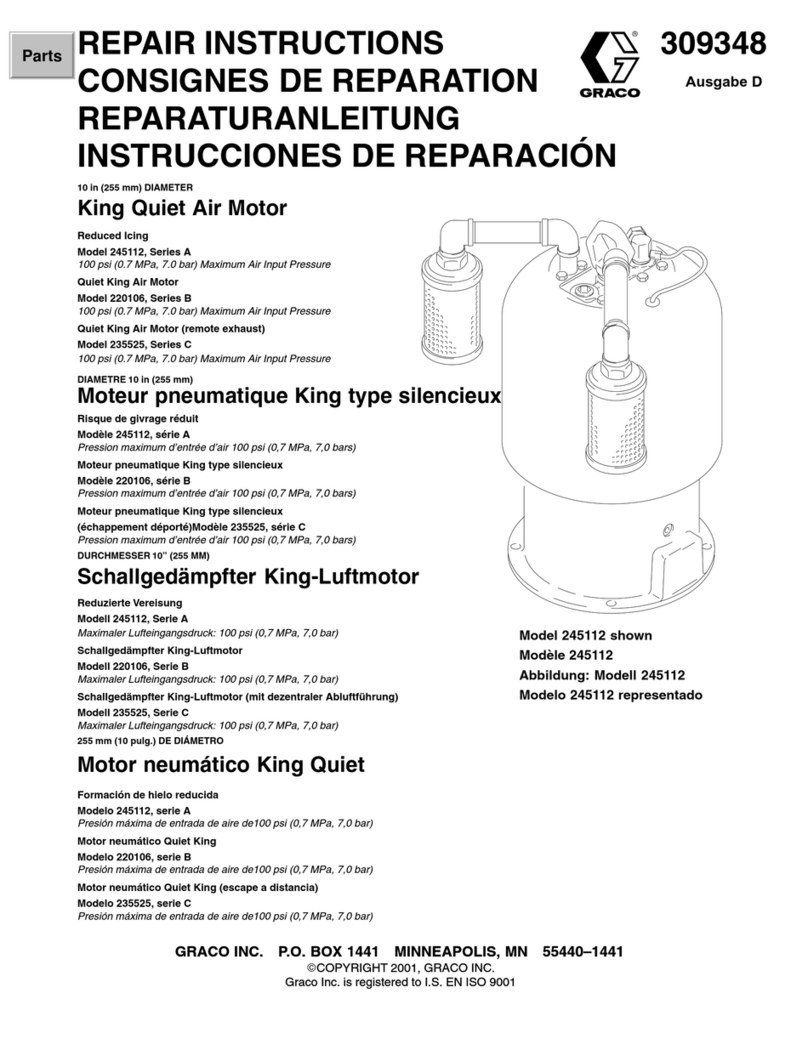

Before using the electrode remove the soaker cap as shown

in FIG 1.

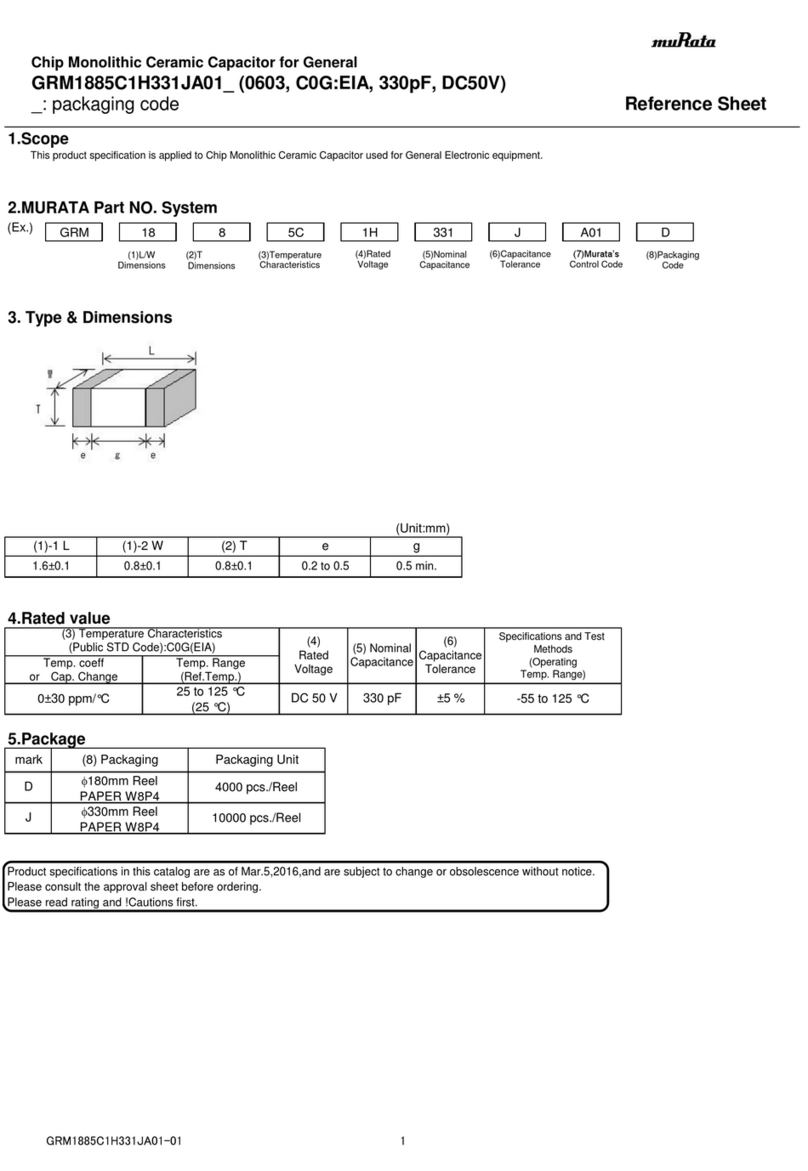

2. Sensorex true differential electrodes have a 1 year warranty

from the date etched in the electrode body as shown in FIG 2.

Electrodes in inventory should be rotated so that the older

electrodes are used first. The date code is stamped on each

electrode by fiscal week and year (Example: 4613 = week 2 of

November 2013).

3. After exposure to a sample, buffer or rinse solution, carryover

can be minimized by blotting—never by wiping—the elec-

trode with a clean non-abrasive paper or a clean cloth towel.

Do not use a brush on pH glass.

4. As a rinse solution, measure and use a portion of the next

sample or buffer. This action will minimize carryover

contamination.

5. When calibrating pH electrodes, use a buffer close in value to

that expected from the sample for one-point calibrations or as

the second buffer for two-point calibrations (See below). This

action will minimize span errors. ORP electrodes are typically

not calibrated. However, a solution to verify electrode perfor-

mance should be used periodically. 225mV solution, Zobell's

solution (Part no. B225), is a good choice for single point

verification.

PRODUCT INSTRUCTION SHEET

Parts covered by this product data sheet include:

SD7000CD, SD7000CD-ORP

SD7000CD Series Differential

pH/ORP Electrode Instructions

FIG. 1

FIG. 2

Form: InstrSD7000-04B [Rev: 2015-12-14]

©2014 Sensorex Corporation

Model SD7000CD Dierential pH

4615

PRODUCT INSTRUCTION SHEET

Page 2 of 8

Mechanical Installation

FIG. 3

Submersion Installation

Make a submersible conduit assembly using 1.5" F x 1" F

reducer and 1" pipe. On top of the pipe, mount a junction

box. with a 2-sided terminal strip. Thread the electrode onto the

reducer. Be sure to use sealing tape or paste. Attach the wires to

one side of the terminal strip and an extension cable to the other.

Match colors if using the same wires colors. See FIG 3.

In-Line Installation

Use pipe sealing tape or paste on the 1.5" threads near the

pH glass and salt bridge. Thread into user-supplied SCH80 1.5"

threaded tee. See FIG 4.

FIG. 4

6. Readings stabilize faster in some solutions than in others; allow

time for the readings to stabilize. In general, new pH electrodes

stable readings display in 10-15 seconds. ORP stability in

samples can take much longer.

7. All pH electrodes age with time. Aging is characterized by

shortened span and slower speed of response. Aging is best

detected by the two-point calibration method. If the pH meter

has manual or microprocessor slope (span) controls, the

controls can be adjusted to compensate for electrode span

errors (but will not affect the speed of response).

8. Salt bridge should be replaced when the electrode readings

cannot be corrected by the meter's controls and/or when their

speed of response is too slow for the application for which

they are being used. The frequency of electrode replacement

is a function of the application; electrodes operating in hot

liquids at very high or very low pH values will have shorter lives

than those operating at neutral pH and ambient temperature.

9. Coatings on an electrode's surface prevent new liquids from

contacting an electrode's measuring surface and can mimic the

effects of electrode aging. Before concluding that a salt bridge

needs replacing, check the pH glass surface for coatings by

removing the pH electrode cartridge and looking at the pH

glass.

10. Temperature affects electrode readings in two ways. First, the

output of an electrode varies with temperature. For pH elec-

trodes this effect can be corrected by automatic

temperature compensation (ORP/Redox readings are not

corrected for temperature effects). Secondly, the real pH or ORP

value, independent of the electrode measuring the value or use

of the temperature compensation, is temperature dependent.

Form: InstrSD7000-04B [Rev: 2015-12-14]

©2014 Sensorex Corporation

Electrode

1.5" x 1" reducer

1" pipe

Conduit box

Pipe sealing

tape

PRODUCT INSTRUCTION SHEET

Page 3 of 8

Salt Bridge Removal and Replacement

1. Remove the salt bridge using an adjustable wrench or pliers

by turning counterclockwise. SEE FIG5.

2. Pull up on salt bridge to remove. SEE FIG6.

3. Flush out chamber with fresh standard cell buffer then refill

with standard cell buffer (refill solution) to level shown in FIG 7

(below top thread).

4. Install new salt bridge by turning clockwise on hex of salt

bridge (OPPOSITE OF FIG5) DO NOT OVER-TIGHTEN. Make

sure o-ring is properly seated. The salt bridge will be slightly

below the body surface . See Fig 6A

FIG. 5 FIG. 6

Form: InstrSD7000-04B [Rev: 2015-12-14]

©2014 Sensorex Corporation

1

4

m

m

FIG. 7

Electrode Cleaning Tips:

Coating of an electrode’s measuring surface can lead to er-

roneous readings including shortened span and slow response

times. The type of coating determines the type of cleaning

technique.

Soak the sensor in a mild soap solution for 2-3 minutes. Using

a soft bristle brush, scrub the entire measuring end of the sen-

sor, taking care not to scratch the glass measuring electrode.

Rinse in clean, warm water. If the sensor is usually in a process

above 7 pH, it is advisable to soak it 4 - 5 minutes in a weak

acid solution (hydrochloric recommended). Place the sensor

back in the soap solution for 2 - 3 minutes. Rinse it in clean

warm water.

Hard Coatings should be chemically removed. The chemical

used to remove the coating should be the least harsh chemical

that dissolves the coating in one or two minutes and does not

attack the electrode’s materials of construction. For example,

a calcium carbonate coating might be removed with 5% HCl

(muriatic acid). Do not keep electrode in acid for more than 5

minutes. Rinse with clean water after acid.

Oily or Organic Coatings are best removed with detergents

or an appropriate solvent that does not attack the electrode’s

materials of construction.

NOTE: When using chemicals or solvents, care should be taken

and appropriate eye, face, hand, body and/or respiratory pro-

tection should be used.

Protein-based coatings are best removed with an enzyme-

based cleaner such as TERG-A-ZYME (www.alconox.com).

Abrading or sanding a pH electrode’s surface should never be

done.

O-ring

must be

seated in

groove

for proper

seal

install a little

below surface

FIG. 6A

O-ring

must be

lubricated

before

installa-

tion

ll to bottom

thread only

PRODUCT INSTRUCTION SHEET

Page 4 of 8 Form: InstrSD7000-04B [Rev: 2015-12-14]

©2014 Sensorex Corporation

Electrode Calibration Guidlines:

As a rule, follow the procedures shown in the pH Meter's

Instruction Manual. These procedures will vary depending on

whether the meter is a simple type with manual adjustments,

a micro-processor type or a pH transmitter.

The frequency of calibration is a function of many factors.

These factors include:

1) The accuracy required by the application.

2) The value of the off-specification product versus the cost

of calibration.

3) The coating or abrasive nature of the application.

4) The stability of the pH Electrode and pH Meter as a system.

The frequency of calibration is really determined by experi-

ence. At a new installation, calibration might initially be

checked every few hours or shift with the calibration changes

noted in a log. As a pattern of longer stability is found, the

time between calibration checks can be increased to once a

day or once a week.

System Calibration Concepts

The pH Electrode and the pH controller should always be

calibrated as a system. Electronic calibration of a pH control-

ler with a pH signal simulator checks the controller only and

does not correct for imperfections of the pH electrode. Even

if perfect when new, the performance of pH electrodes varies

with time, usually in an unpredictable way. When changing

electrodes or connecting an electrode to a different pH con-

troller, re-calibration must be performed.

Two-Point Calibrations

Two-point calibrations correct for both the pH electrode's

offset and span errors. Since both the offset and span vary

with time the two-point method is the onr preferred. Choose

buffer pH 7 for zero-point and a second buffer close to your

normal operating range (usually pH4.01 or pH 10.00). See FIG

8 A-C.

Grab Sample Calibrations

The Grab Sample Calibration method is used when it is dif-

ficult or undesirable to remove an electrode from a system.

This method involves obtaining a sample of the liquid being

measured and noting the meter's reading at that time. The

sample's reading is obtained by use of a calibrated lab or

portable meter and that reading is compared to that of the

on-line meter. The on-line meter is adjusted by the difference

between the readings. It is important to use the difference

between the readings because the system's reading may

have changed in the intervening time. It is important that the

sample being measured by the lab meter be at the process

temperature or erroneous results may occur.

pH 4.01

BUFFER

pH 4.01

BUFFER

pH Meter

7.00 pH

pH 4.01/10.00

pH 7.00

FIG. 8A FIG. 8B

FIG. 8C

PLATINUM ORP ELECTRODE IN 7 BUFFER/QUINHYDRONE MIXTURE

Temperature 20C (68F) 25C (77F) 30C (86F)

Readings (mV) 89-107 83-101 76-94

Readings (pH) 5.20-5.50 5.30-5.60 5.42-5.72

PLATINUM ORP ELECTRODE IN 4 BUFFER/QUINHYDRONE MIXTURE

Temperature 20C (68F) 25C (77F) 30C (86F)

Readings (mV) 260-287 254-281 247-274

Readings (pH) 2.15-2.60 2.25-2.70 2.37-2.82

FIG. 9

PRODUCT INSTRUCTION SHEET

Page 5 of 8 Form: InstrSD7000-04B [Rev: 2015-12-14]

©2014 Sensorex Corporation

Intermittent Operation

Some facilities are only operated part of the time. When out

of operation, electrodes must not be allowed to be exposed

to air and become dry. Electrodes should be removed from

such systems and stored in their bottles or caps or in a beaker

filled, preferably, with pH 4.0 Buffer. In some instances, power

to the meter is shut off; this condition can be harmful to elec-

trodes. Electrodes should be disconnected from un-powered

meters.

Electrode Wiring

See the figures 10 through 16 to find wiring for your particu-

lar pH or ORP controller or transmitter. If you dont't see a wir-

ing diagram for your make and model number of controller,

please contact Sensorex Technical support at techsupport@

sensorex.com or call 714-895-4344.

Product Specications

Electrode Specications:

SD7000CD , SD7000CD-ORP

pH Range: 0-14

Temp/Pressure: Min 32° F(0°C)/ Max 140° F/(60° C)

Speed of Response: 95% in 5 seconds

Wetted Materials: PPS (Body), PVDF(Salt bridge junction),

pH glass (pH), Platinum (ORP),

Titanium (ground pin), Viton (o-rings)

Cable Length: 20ft

Max ow Rate: 10ft./sec

Max transmission

distance: 3000ft (914m)

Aquametrix

Shark

Controller

Aquametrix

Shark

TX/P

Transmitter

FIG. 10

FIG. 11

PRODUCT INSTRUCTION SHEET

Page 6 of 8 Form: InstrSD7000-04B [Rev: 2015-12-14]

©2014 Sensorex Corporation

GLI PRO P3

GLI P63

GLI P33

FIG. 12

FIG. 13

FIG. 14

Troubleshooting Your SD7000CD Electrode

General Troubleshooting

Always check all electrical connections. Make sure all parts are

assembled correctly and o-rings are well greased.

Electrode Troubleshooting

1. Put the sensor in a pH 7 buer solution and wait for the

temperature of the sensor and buer to reach room tempera-

ture.

2. Disconnect the red, green, yellow and black sensor wires

from the module.

3. Measure the resistance between the yellow and black wires

to verify the operation of the temperature element. The resis-

tance should be between 250 and 350 ohms at approximately

25 ºC. If the temperature element is good, reconnect the yel-

low and black wires to the module.

4. Measure the DC mV with the multimeter (+) lead connected

to the red wire and the (–) lead connected to the green wire.

The reading should be between –50 and + 50 mV. If the read-

ing is outside of these limits, clean the sensor and change the

salt bridge and standard cell solution.

5. With the multimeter still connected the same way, rinse the

sensor with water and put it in a pH 4 or pH 10 buer solution.

Wait for the temperature of the sensor and buer to reach

room temperature.

6. Compare the mV reading in the pH 4 or 10 buer to the

reading in the pH 7 buer. The reading should dier by ap-

proximately 160 mV. If the dierence is less than 160 mV, call

technical support.

Buer reading Possible Cause Corrective Action

6.2-6.8 in all buers a) Cracked pH glass a) Replace electrode

b) Stress crack b) Contact Sensorex for

Return Authorization

7.00 in all buers a) Bad connection a) Check/x connection

b) Internal short circuit b) Contact Sensorex for

Return Authorization

Buers read close to a) Dirty electrode pH glass a) Clean electrode

expected value but and/or reference junction

speed of response* is

slow (>30 seconds)

Short span*** a) Dirty pH glass or reference a) Clean pH glass or replace

(Less than 70%) junction salt bridge

b) Aged electrode b) Replace electrode (too old)

Unstable or

drifting reading Reference dirty or plugged Clean pH glass or replace salt bridge

pH ELECTRODE TROUBLESHOOTING

SEE CONTROLLER MANUAL

PRODUCT INSTRUCTION SHEET

Page 7 of 8 Form: InstrSD7000-04B [Rev: 2015-12-14]

©2014 Sensorex Corporation

GLI P53

GLI P53

FIG. 15

FIG. 16

SENSOREX CORPORATION LIMITED WARRANTY

SENSOREX warrants all products to be free of defects

in materials and workmanship for 1 year from date

marked on the product. Sensorex will replace any

sensor that is deemed to have a workmanship defect

within 1 year of the manufacture date stamped on

the product (WWYY code). However, SENSOREX

oers no warranty, either expressed or implied, as

to the useful life of these products. There are no

implied warranties of merchantability or tness for a

particular purpose given in connection with the sale

of any goods. In no event shall SENSOREX be liable

for consequential, incidental or special damages.

The buyer’s sole and exclusive remedy and the limit

of SENSOREX’s liability for any loss whatsoever shall

not exceed the purchase price paid by the purchaser

for the product to which claim is made.

Ordering Information

Part Number Description

SD7000CD SD7000 Series differential pH sensor. Replacement

salt bridges sold separately.

SD7000CD-ORP SD7000CDSeries differential ORP sensor. Replacement

salt bridges sold separately.

SDA-7001 Refill solution for SD7000CD pH and ORP

differential sensors

SDA-7003 Replacement salt bridge quantity 3 each for SD7000CD

differential sensors

SDA-7010 Replacement salt bridge quantity 10 each for

SD7000 CD differential sensors

SDS-7025 Standard Refill solution for SD7000 Series sensors,

250mL

SDS-7050 Standard Refill solution for SD7000 Series sensors,

500mL

PRODUCT INSTRUCTION SHEET

Page 8 of 8 Form: InstrSD7000-04B [Rev: 2015-12-14]

©2014 Sensorex Corporation

NOTES:

1 2 1 2 3 4 5 6 7 8

J4 J5

HACH SC200 pH/ORP/DO Module

RED GRN CLR WHT YEL BLK

FIG. 17

This manual suits for next models

2

Table of contents

Other Sensorex Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

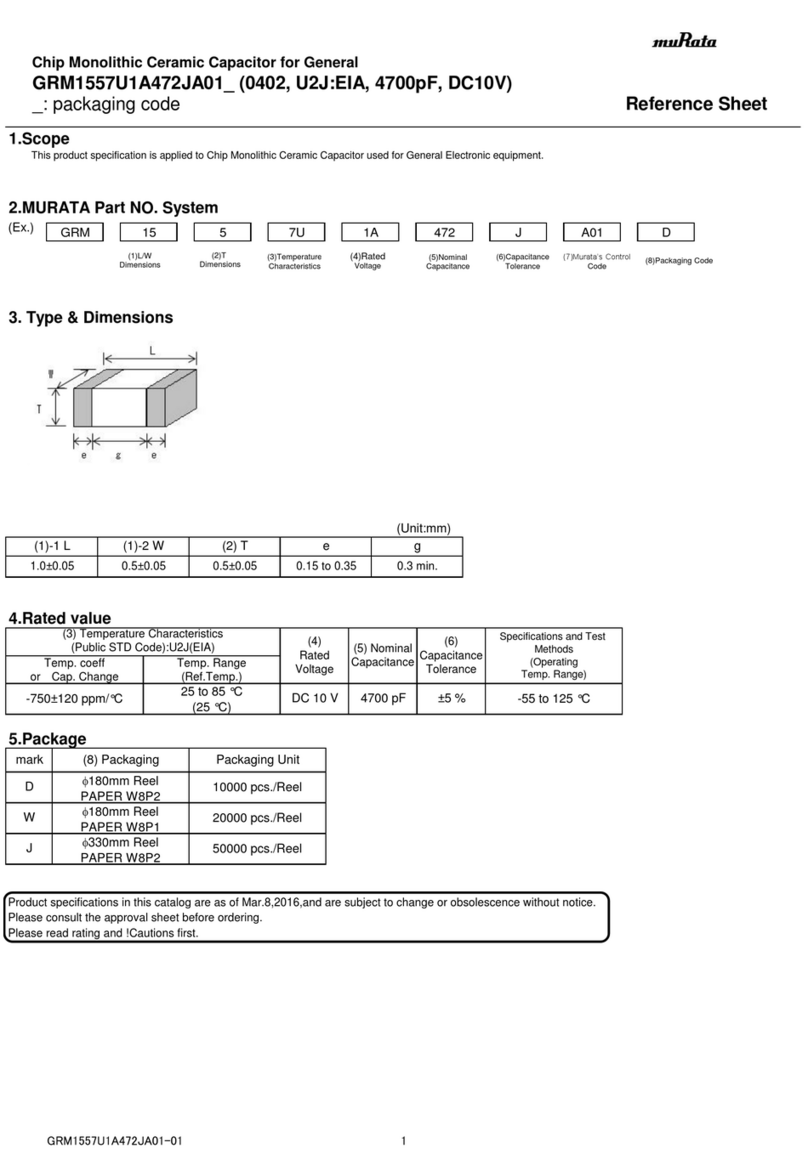

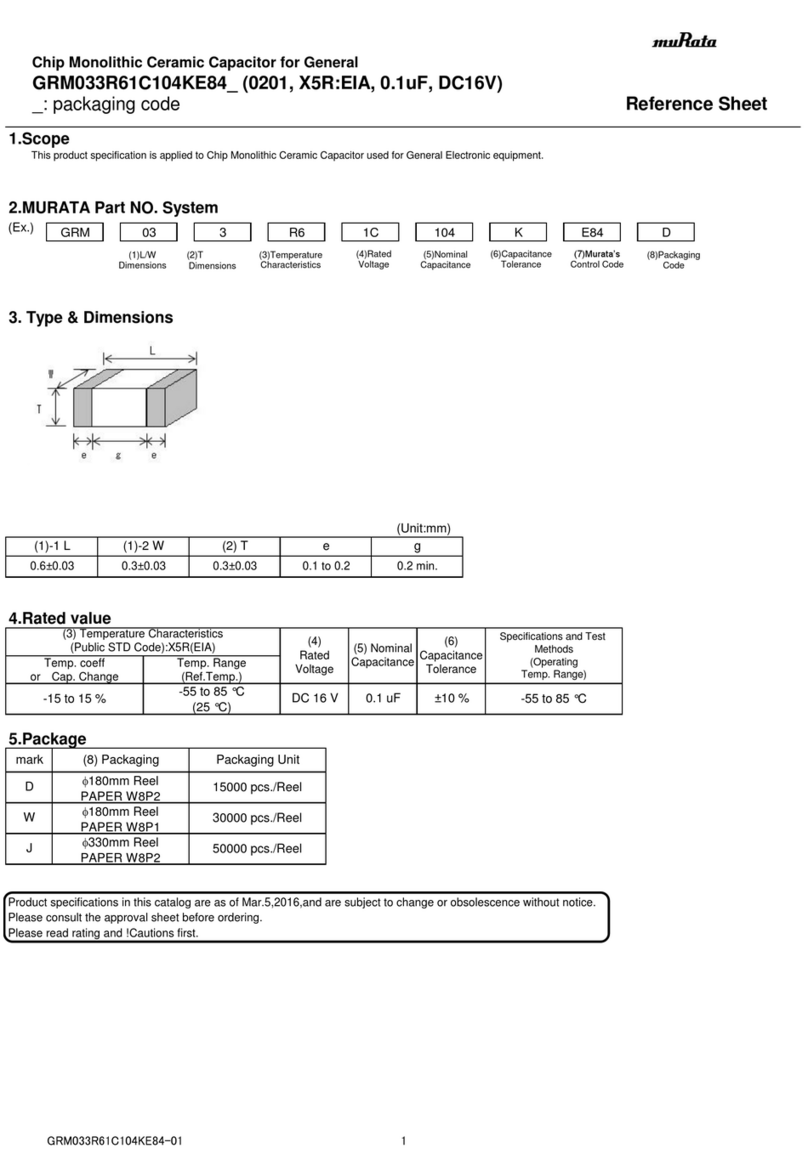

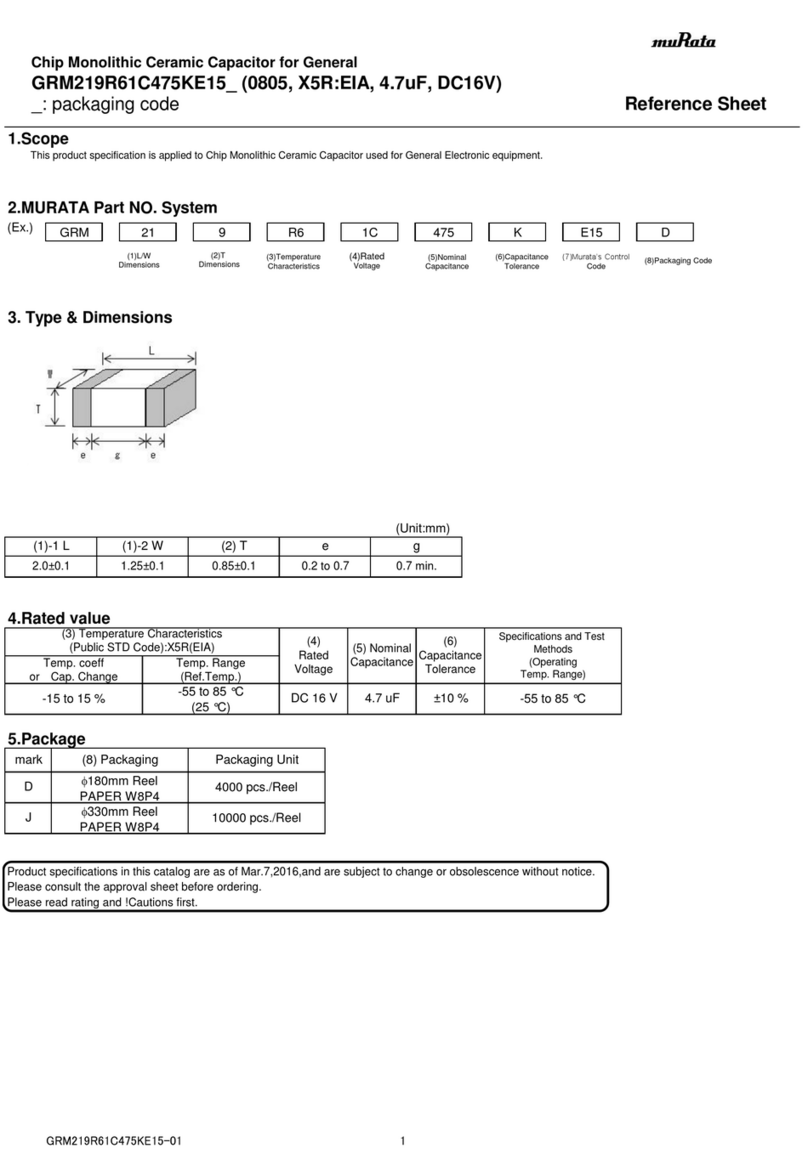

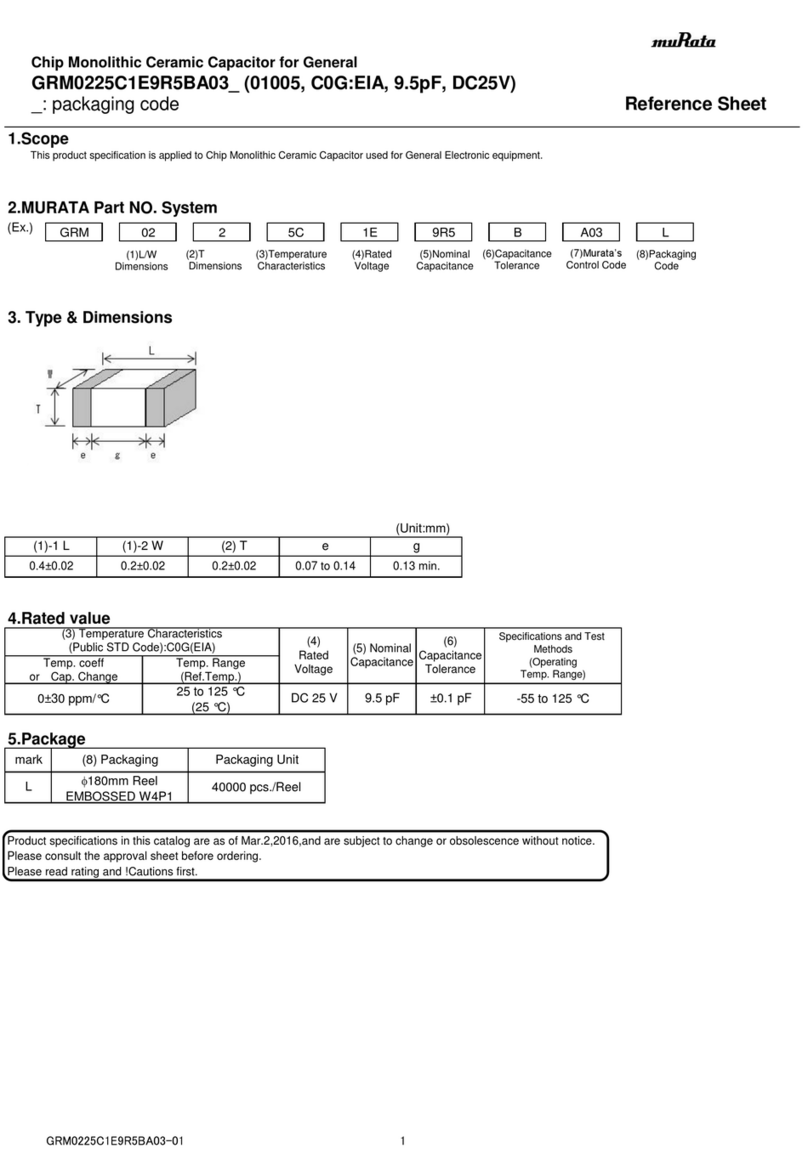

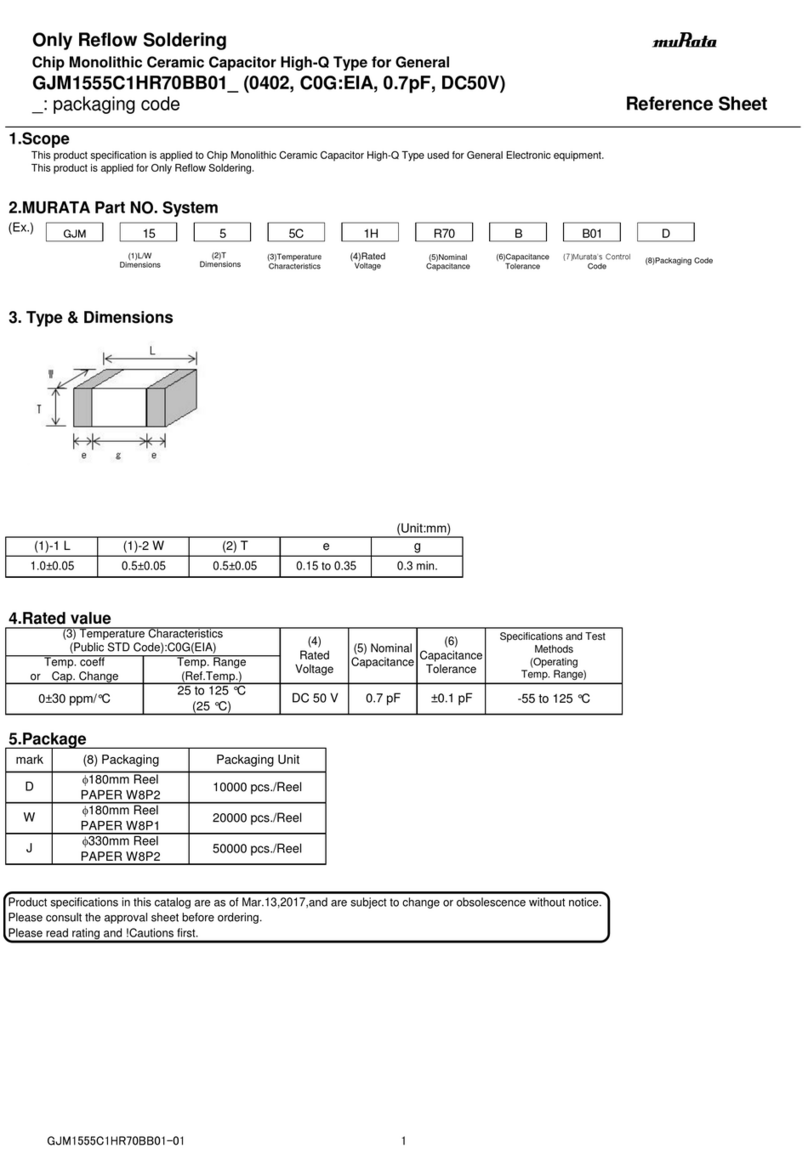

Murata

Murata GRM0225C1E9R5BA03 Series Reference sheet

Murata

Murata GRM188R71H683KA93 Series Reference sheet

Cleveland

Cleveland HCDH Series Operating and maintenance instructions

Murata

Murata GJM1555C1HR70BB01 Series Reference sheet

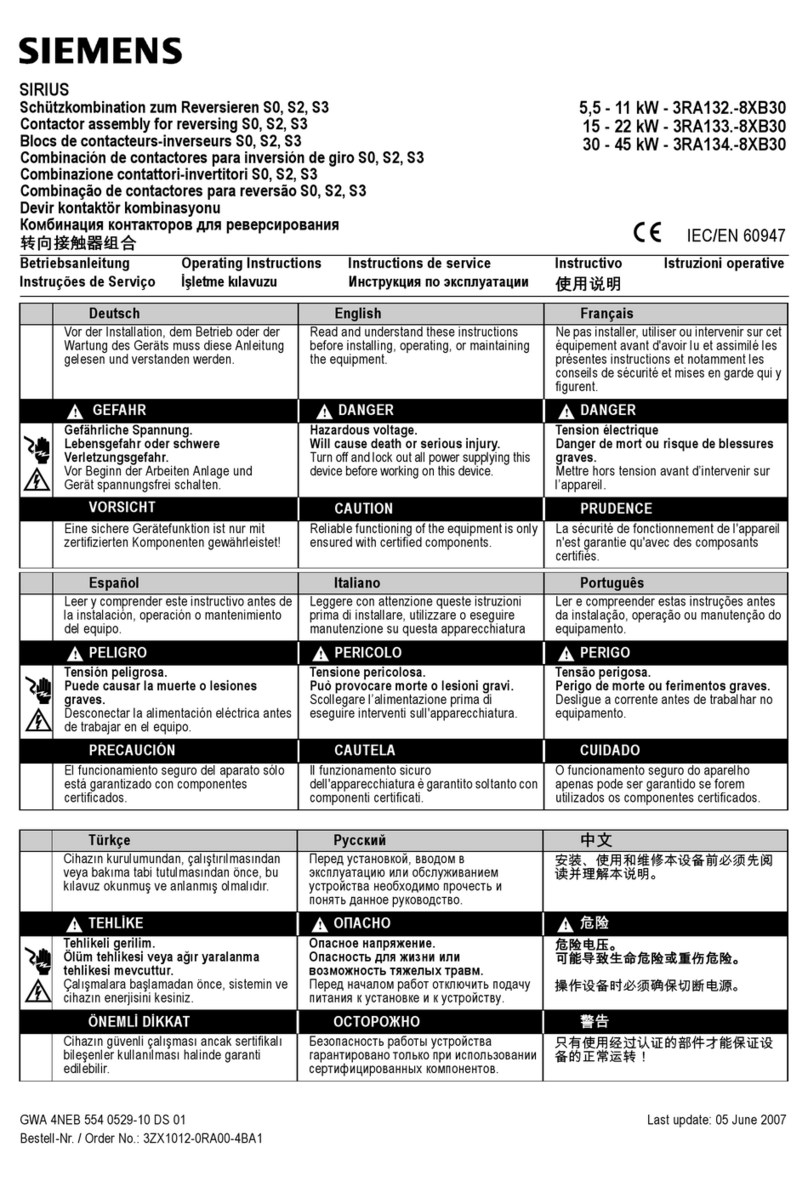

Klockner Moeller

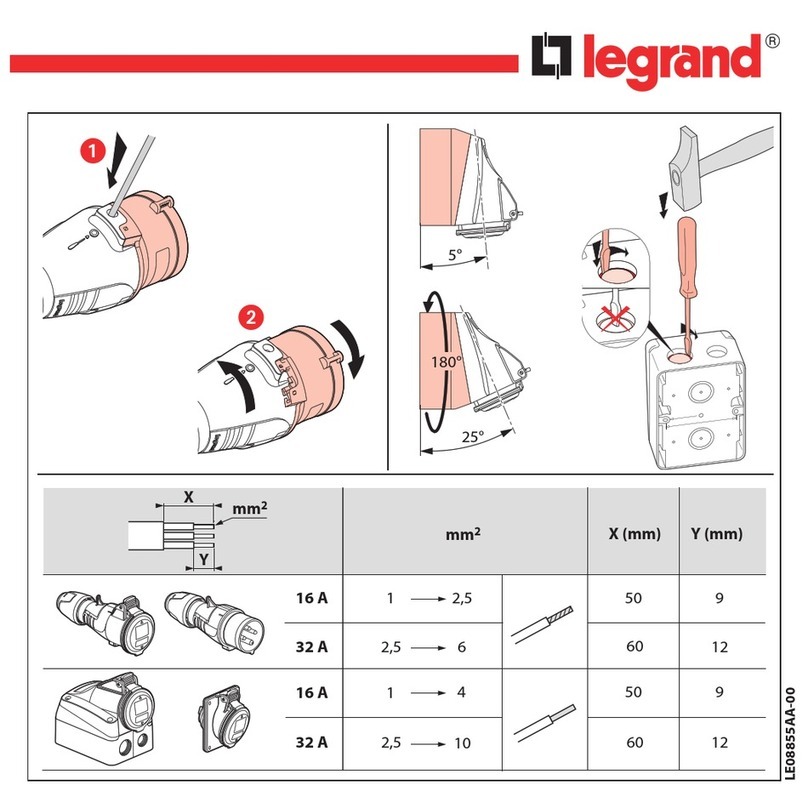

Klockner Moeller FIP30-NZM 74 installation instructions

hager

hager univers IP44 Mounting instructions