SENTRONIC M-SYSTEM Mini-M Series User manual

MODEL: M2CEC

Super-mini Signal Conditioners Mini-M Series

AC CURRENT TRANSMITTER

(clamp-on current sensor)

Functions & Features

• Converts an alternating current into a standard

process signal

• Easy-to-install clamp-on type current sensor with no need

of a current transformer

• Clamp-on current sensor included

• Wide input range from 10A up to 600A

• Input frequency 50 / 60 / 400 Hz

• Over-voltage clamp element for safety in open circuit

• True RMS sensing

• Universal power input

• High-density mounting

Typical Applications

• Centralized monitoring and control of motors at a

supervisory panel

• Monitoring abnormal load current at motors to detect

pump malfunctions

Model

SPAN

ZERO

23 (.91)

76

(2.99)

124

(4.88)

mm (inch)

MODEL: M2CEC-[1][2][3]-[4][5]

ORDERING INFORMATION

• Code number: M2CEC-[1][2][3]-[4][5]

Specify a code from below for each [1] through [5].

(e.g. M2CEC-150A-M/Q)

• Special output ranges (For codes Z&0)

• Specify the specification for option code /Q

(e.g. /C01/S01)

[1] SENSOR

1: Leadwire type CLSA

2: Screw terminal type CLSB

[2] INPUT

10: 0 – 10 A AC

15: 0 – 15 A AC

20: 0 – 20 A AC

30: 0 – 30 A AC

40: 0 – 40 A AC

50: 0 – 50 A AC

60: 0 – 60 A AC

75: 0 – 75 A AC

100: 0 – 100 A AC

125: 0 – 125 A AC

150: 0 – 150 A AC

175: 0 – 175 A AC

200: 0 – 200 A AC

225: 0 – 225 A AC

250: 0 – 250 A AC

300: 0 – 300 A AC

350: 0 – 350 A AC

400: 0 – 400 A AC

500: 0 – 500 A AC

600: 0 – 600 A AC

(Not selectable with the sensor type code 1.)

[3] OUTPUT

Current

A: 4 – 20 mA DC (Load resistance 750 Ω max.)

B: 2 – 10 mA DC (Load resistance 1500 Ω max.)

C: 1 – 5 mA DC (Load resistance 3000 Ω max.)

D: 0 – 20 mA DC (Load resistance 750 Ω max.)

E: 0 – 16 mA DC (Load resistance 900 Ω max.)

F: 0 – 10 mA DC (Load resistance 1500 Ω max.)

G: 0 – 1 mA DC (Load resistance 15 kΩ max.)

Z: Specify current (See OUTPUT SPECIFICATIONS)

Voltage

1: 0 – 10 mV DC (Load resistance 10 kΩ min.)

2: 0 – 100 mV DC (Load resistance 100 kΩ min.)

3: 0 – 1 V DC (Load resistance 1000 Ω min.)

4: 0 – 10 V DC (Load resistance 10 kΩ min.)

5: 0 – 5 V DC (Load resistance 5000 Ω min.)

6: 1 – 5 V DC (Load resistance 5000 Ω min.)

4W: -10 – +10 V DC (Load resistance 10 kΩ min.)

5W: -5 – +5 V DC (Load resistance 5000 Ω min.)

0: Specify voltage (See OUTPUT SPECIFICATIONS)

[4] POWER INPUT

AC Power

M: 85 – 264 V AC (Operational voltage range 85 – 264 V,

47 – 66 Hz)

DC Power

R: 24 V DC

(Operational voltage range 24 V ±10 %, ripple 10 %p-p max.)

R2: 11 – 27 V DC

(Operational voltage range 11 – 27 V, ripple 10 %p-p max.)

P: 110 V DC

(Operational voltage range 85 – 150 V, ripple 10 %p-p max.)

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

MODEL: M2CEC

[5] OPTIONS

OTHER OPTIONS

blank: none

/Q: Option other than the above (specify the specification)

SPECIFICATIONS OF OPTION: Q (multiple selections)

COATING (For the detail, refer to M-System's web site.)

/C01: Silicone coating

/C02: Polyurethane coating

/C03: Rubber coating

TERMINAL SCREW MATERIAL

/S01: Stainless steel

ACCESSORIES

The clamp-on current sensor is included in the product

package.

■ CLAMP-ON CURRENT SENSOR (leadwire type CLSA)

• 0 – 10 A through 0 – 75 A Use

Sensor model No.: CLSA-08

Sensor cable model No.: CLSA-08C-30

Applicable cable diameter: Max. 10.0

Sensor leadwire: AWG 22

Weight: 45 g (1.6 oz)

• 0 – 100 A Use

Sensor model No.: CLSA-12

Sensor cable model No.: CLSA-08C-30

Applicable cable diameter: Max. 16.0

Sensor leadwire: AWG 22

Weight: 70 g (2.5 oz)

• 0 – 125 A through 0 – 300 A Use

Sensor model No.: CLSA-30

Applicable cable diameter: Max. 24.0

Sensor leadwire: AWG 18, 200 mm

Weight: 200 g (7.1 oz)

• 0 – 350 A through 0 – 500 A Use

Sensor model No.: CLSA-50

Applicable cable diameter: Max. 36.0

Sensor leadwire: AWG 18, 200 mm

Weight: 300 g (10.6 oz)

■ CLAMP-ON CURRENT SENSOR (screw terminal type CLSB)

Connection: M3 screw terminal (torque 0.5 N·m)

Screw terminal: Nickel-plated steel

Output wiring: Use AWG22 or thicker wires for the output.

Twist the paired wires, extendable up to 30 meters.

• 0 – 10 A through 0 – 50 A Use

Sensor model No.: CLSB-05

Applicable cable diameter: Max. 10.0

Weight: 45 g (1.6 oz)

• 0 – 60 A through 0 – 100 A Use

Sensor model No.: CLSB-10

Applicable cable diameter: Max. 16.0

Weight: 80 g (2.8 oz)

• 0 – 125 A through 0 – 200 A Use

Sensor model No.: CLSB-20

Applicable cable diameter: Max. 24.0

Weight: 200 g (7.1 oz)

• 0 – 225 A through 0 – 400 A Use

Sensor model No.: CLSB-40

Applicable cable diameter: Max. 35.0

Weight: 300 g (10.6 oz)

• 0 – 500 A through 0 – 600 A Use

Sensor model No.: CLSB-60

Applicable cable diameter: Max. 35.0

Weight: 360 g (12.7 oz)

Note 1: The output values may vary depending on the

accuracy of engagement at the clamp connection.

Note 2: The sensor is detachable up to 100 times (approx.).

Note 3: The sensor’s mechanical construction may cause it

to generate resonance sound. However, it does not affect

the performance of the sensor.

GENERAL SPECIFICATIONS

Construction: Plug-in

Connection: M3 screw terminals (torque 0.8 N·m)

Housing material: Flame-resistant resin (black)

Isolation: Sensor core to input to output to power

Input waveform

RMS sensing: Up to 15 % of 3rd harmonic content

Overrange output: 0 to 120 % at 1 – 5 V

Zero adjustment: -5 to +5 % (front)

Span adjustment: 95 to 105 % (front)

INPUT SPECIFICATIONS

Frequency: 50 / 60 / 400 Hz

Overload capacity

CLSA - 08: 120 A continuous

CLSA - 12: 300 A continuous

CLSA - 30: 360 A continuous

CLSA - 50: 600 A continuous

CLSB - 05: 100 A continuous

CLSB - 10: 200 A continuous

CLSB - 20: 300 A continuous

CLSB - 40: 600 A continuous

CLSB - 60: 720 A continuous

Operational range: 0 – 120 % of rating

Be sure that the input voltage is of 440 V or less.

OUTPUT SPECIFICATIONS

• DC Current: 0 – 20 mA DC

Minimum span: 1 mA

Zero suppression/elevation: Max. 1.5 times span

Load resistance: Output drive 15V maximum

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

MODEL: M2CEC

• DC Voltage: -10 – +12 V DC

Minimum span: 5mV

Zero suppression/elevation: Max. 1.5 times span

Load resistance: Output drive 1 mA max. at≥0.5 V

INSTALLATION

Power Consumption

•AC Power input:

Approx. 3 VA at 100 V

Approx. 4 VA at 200 V

Approx. 5 VA at 264 V

•DC Power input: Approx. 3 W

Operating temperature: -5 to +55°C (23 to 131°F)

Operating humidity: 30 to 90 %RH (non-condensing)

Mounting: Surface or DIN rail

Weight: 150 g (0.33 lbs)

PERFORMANCE in percentage of span

Accuracy: ±0.5 % (±1.0 % at 400 Hz)

Temp. coefficient: ±0.05 %/°C (±0.03 %/°F)

Response time: ≤ 0.7 sec. (0 – 90 %)

Ripple: 0.5 %p-p max. (50/60 Hz)

Line voltage effect: ±0.1 % over voltage range

Insulation resistance: ≥ 100 MΩ with 500 V DC

Dielectric strength: 2000 V AC @1 minute

(input to output to power to ground)

1000 V AC @1 minute

(sensor core to sensor output)

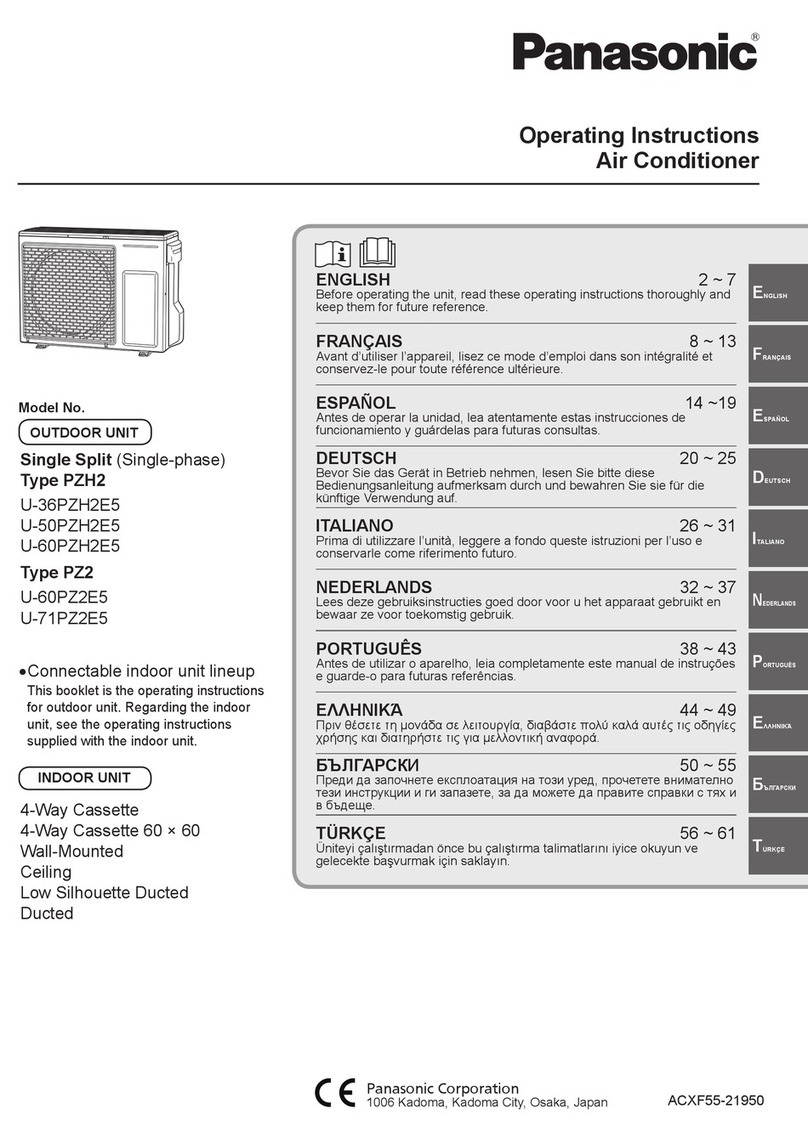

EXTERNAL DIMENSIONS & TERMINAL ASSIGNMENTS unit: mm (inch)

5

9

21.5 (.85)

70.5 (2.78)

84 (3.31)10 (.39) 15 (.59)

6 (.23)

59 (2.32)

DIN RAIL

35mm wide

[4 (.16)]

8–M3

SCREW

72 (2.83)

23 (.91)

2–4.2x5

(.17x.20)

MTG HOLE

6 (.24) deep

114 (4.49)

• When mounting, no extra space is needed between units.

4

8

12

14 13

1

4 (.16)

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

MODEL: M2CEC

■ Sensor model No.: CLSA-08

L K

10 (.39)

dia.

41 (1.61)

23 (.91)

27 (1.05)26 (1.02) 150 (5.91) 3000 (118)

l

k

■ Sensor model No.: CLSA-12

16 (.63)

dia.

44.5 (1.75)

29 (1.14)

30 (1.18)

31 (1.22)

150 (5.91)

l

k

L K

3000 (118)

■ Sensor model No.: CLSA-30

24 (.94)

dia.

64 (2.52)

47.5 (1.87)

40 (1.57)34 (1.34)

200 (7.87)

4

(.16)

4

(.16)

l

k

K L

■ Sensor model No.: CLSA-50

36 (1.41)

dia.

80 (3.15)

59.5 (2.34)

50 (1.97)38 (1.50) 4

(.16)

4

(.16)

200 (7.87)

l

k

K L

■ Sensor model No.: CLSB-05

k

k

l

l

28.9 (1.14)

26.3 (1.04)8.6

(.34) 8.6

(.34) 48 (1.89)

10 dia. (.39) 2–M3 SCREW

TERMINAL COVER

(detachable)

K L

■ Sensor model No.: CLSB-10

37.4 (1.47)

30.5 (1.20)7.5

(.30) 7.5

(.30)

53.7 (2.11)

16 dia. (.63) 2–M3 SCREW

k

k

l

l

TERMINAL COVER

(detachable)

K L

■ Sensor model No.: CLSB-20

k

k

l

l

2–M3 SCREW

55.9 (2.20)

35.9

(1.41)

8.3

(.33) 8.3

(.33) 75.7 (2.98)

24 dia. (.94)

TERMINAL COVER

(detachable)

K L

■ Sensor model No.: CLSB-40

35 dia. (1.38)

k

k

l

l

2–M3 SCREW

K L

73.5 (2.89)

35.5

(1.40)

8.8

(.35) 8.8

(.35)

93 (3.66)

TERMINAL COVER

(detachable)

■ Sensor model No.: CLSB-60

73.5 (2.89)

35.5

(1.40)

8.8

(.35) 8.8

(.35) 93 (3.66)

TERMINAL COVER

(detachable)

35 dia. (1.38)

k

k

l

l

2–M3 SCREW

K L

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

MODEL: M2CEC

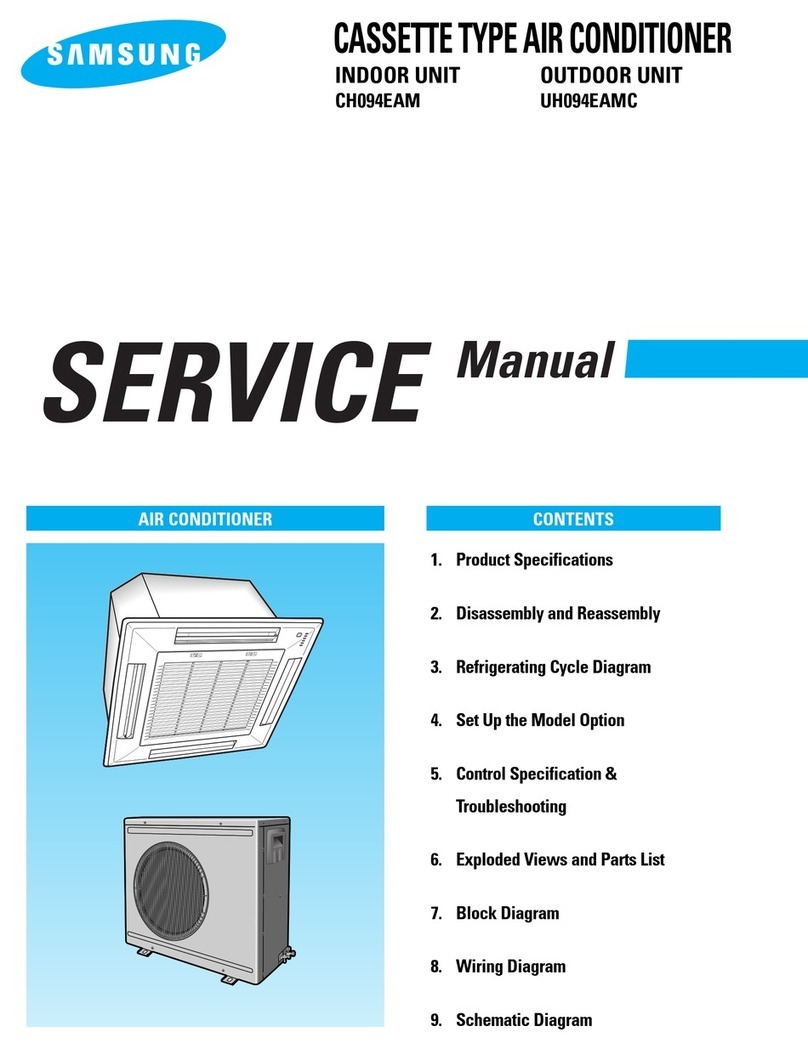

SCHEMATIC CIRCUITRY & CONNECTION DIAGRAM

+

–

Isolation

Base Socket

1R.M.S.

Operation Output

Driver OUTPUT

4

5

8

9

12

SZ

AC

Amplifier

U(+)

V(–) POWER

13

14

LOAD

SOURCE

CONNECTOR*

k

l

CLAMP-ON SENSOR

*Connector provided only for the CLSA-08 and CLSA-12.

Specifications are subject to change without notice.

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

M2CEC

P. 1 / 4EM-5062 Rev.2

AC CURRENT TRANSMITTER

(clamp-on current sensor) MODEL M2CEC

INSTRUCTION MANUAL

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■ PACKAGE INCLUDES:

Signal conditioner (body + base socket) ...................... (1)

Sensor............................................................................ (1)

Cable (CLSA-08, -12 only)............................................ (1)

■ MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■ POWER INPUT RATING & OPERATIONAL RANGE

• Locate the power input rating marked on the product and

confirm its operational range as indicated below:

85 – 264V AC rating: 85 – 264V, 47 – 66 Hz, approx. 3 – 5VA

24V DC rating: 24V ±10%, approx. 3W

11 – 27V DC rating: 11 – 27V, approx. 3W

110V DC rating: 85 – 150V (110V ±10% for UL), approx. 3W

■ GENERAL PRECAUTIONS

• Before you remove the unit from its base socket or mount

it, turn off the power supply and input signal for safety.

■ ENVIRONMENT

• Indoor use

• When heavy dust or metal particles are present in the air,

install the unit inside proper housing with sufficient ven-

tilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -5 to +55°C

(23 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

• Be sure that the ventilation slits are not covered with ca-

bles, etc.

■ WIRING

• Do not install cables (power supply, input and output)

close to noise sources (relay drive cable, high frequency

line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■ AND ....

• The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

• With voltage output, do not leave the output terminals

shortcircuited for a long time. The unit is designed to en-

dure it without breakdown, however, it may shorten ap-

propriate life duration.

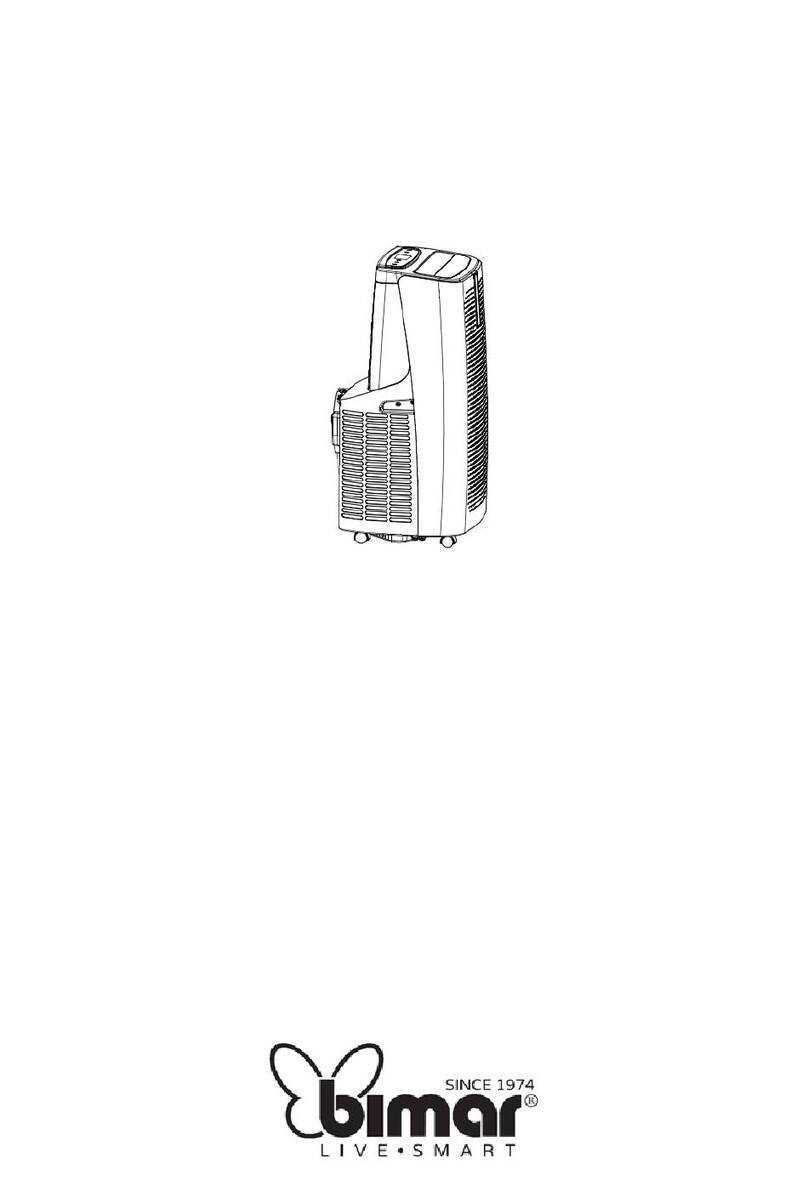

COMPONENT IDENTIFICATION

INSTALLATION

Loosen the fixing screw at the front of the unit in order to

separate the body from the base socket.

■ DIN RAIL MOUNTING

Set the base socket so that

its DIN rail adaptor is at

the bottom. Position the

upper hook at the rear side

of base socket on the DIN

rail and push in the lower.

When removing the socket,

push down the DIN rail

adaptor utilizing a minus

screwdriver and pull.

■ WALL MOUNTING

Refer to “EXTERNAL DI-

MENSIONS.”

TERMINAL CONNECTIONS

Connect the unit as in the diagram below or refer to the con-

nection diagram on the side of the unit.

Model

SPAN

ZERO

Zero Adj.

Span Adj.

Body Base Socket

Connection

Diagram

Specifications

Fixing Screw

DIN Rail

35mm wide

Spring Loaded

DIN Rail Adaptor

+

–OUTPUT

9

12

1

4

LOAD

SOURCE

CONNECTOR*

k

l

CLAMP-ON SENSOR

U(+)

V(–)

13

14

POWER

*Connector provided only for the CLSA-08 and CLSA-12.

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

M2CEC

P. 2 / 4EM-5062 Rev.2

CHECKING

1) Terminal wiring: Check that all cables are correctly con-

nected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal

13 – 14 with a multimeter.

3) Input: Check that the input signal is within 0 – 100% of

the full-scale.

4) Output: Check that the load resistance meets the de-

scribed specifications.

ADJUSTMENT PROCEDURE

This unit is calibrated at the factory to meet the ordered

specifications, therefore you usually do not need any cali-

bration.

For matching the signal to a receiving instrument or in case

of regular calibration, adjust the output as explained in the

following.

■ HOW TO CALIBRATE THE OUTPUT SIGNAL

Use a signal source and measuring instruments of sufficient

accuracy level. Turn the power supply on and warm up for

more than 10 minutes.

1) ZERO: Apply 0% input and adjust output to 0%.

2) SPAN: Apply 100% input and adjust output to 100%.

3) Check ZERO adjustment again with 0% input.

4) When ZERO value is changed, repeat the above proce-

dure 1) – 3).

MAINTENANCE

Regular calibration procedure is explained below:

■ CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accu-

racy described in the data sheet. When the output is out of

tolerance, recalibrate the unit according to the “ADJUST-

MENT PROCEDURE” explained earlier.

EXTERNAL DIMENSIONS unit: mm (inch)

5

9

21.5(.85)

70.5 (2.78)

84 (3.31)10 (.39) 15(.59)

6(.23)

59 (2.32)

DIN RAIL

35mm wide

[4 (.16)]

8–M3

SCREW

72 (2.83)

23 (.91)

2–4.2x5

(.17x.20)

MTG HOLE

6 (.24) deep

114 (4.49)

• When mounting, no extra space is needed between units.

4

8

12

14 13

1

4 (.16)

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

M2CEC

P. 3 / 4EM-5062 Rev.2

CLAMP-ON CURRENT SENSOR

The clamp-on current sensor is included in the product package.

• 0 – 350A through 0 – 500A Use

Sensor model No.: CLSA-50

Applicable cable diameter: Max. 36.0

Sensor leadwire: AWG 18, 200 mm

Weight: 300 g (10.6 oz)

■ CLAMP-ON CURRENT SENSOR (leadwire type CLSA)

• 0 – 10A through 0 – 75A Use

Sensor model No.: CLSA-08

Sensor cable model No.: CLSA-08C-30

Applicable cable diameter: Max. 10.0

Sensor leadwire: AWG 22

Weight: 45 g (1.6 oz)

• 0 – 100A Use

Sensor model No.:CLSA-12

Sensor cable model No.: CLSA-08C-30

Applicable cable diameter: Max. 16.0

Sensor leadwire: AWG 22

Weight:70 g (2.5 oz)

• 0 – 125A through 0 – 300A Use

Sensor model No.:CLSA-30

Applicable cable diameter: Max. 24.0

Sensor leadwire: AWG 18, 200 mm

Weight:200 g (7.1 oz)

L K

10 (.39)

dia.

41 (1.61)

23 (.91)

27 (1.05)26 (1.02) 150 (5.91) 3000 (118)

l

k

16 (.63)

dia.

44.5 (1.75)

29 (1.14)

30 (1.18)

30 (1.18)

150 (5.91)

l

k

L K

3000 (118)

24 (.94)

dia.

64 (2.52)

47.5 (1.87)

40 (1.57)34 (1.34)

200 (7.87)

4

(.16)

4

(.16)

l

k

K L

36 (1.41)

dia.

80 (3.15)

59.5 (2.34)

50 (1.97)38 (1.50) 4

(.16)

4

(.16)

200 (7.87)

l

k

K L

■

CLAMP-ON CURRENT SENSOR (screw terminal type CLSB)

Connection: M3 screw terminal

(nickel-plated steel; torque 0.5 N·m)

• 0 – 10A through 0 – 50A Use

Sensor model No.: CLSB-05

Applicable cable diameter: Max. 10.0

Weight:45 g (1.6 oz)

• 0 – 60A through 0 – 100A Use

Sensor model No.:CLSB-10

Applicable cable diameter: Max. 16.0

Weight:80 g (2.8 oz)

k

k

l

l

28.9 (1.14)

26.3 (1.04)8.6

(.34) 8.6

(.34) 48 (1.89)

10 dia. (.39) 2–M3 SCREW

TERMINAL COVER

(detachable)

K L

37.4 (1.47)

30.5 (1.20)7.5

(.30) 7.5

(.30) 53.7 (2.11)

16 dia. (.63) 2–M3 SCREW

k

k

l

l

TERMINAL COVER

(detachable)

K L

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

M2CEC

P. 4 / 4EM-5062 Rev.2

M-SYSTEM WARRANTY

M-System warrants such new M-System product which it manufactures to be free from defects in materials and workmanship during the 36-month period following the date that such

product was originally purchased if such product has been used under normal operating conditions and properly maintained, M-System’s sole liability, and purchaser’s exclusive

remedies, under this warranty are, at M-System’s option, the repair, replacement or refund of the purchase price of any M-System product which is defective under the terms of this

warranty. To submit a claim under this warranty, the purchaser must return, at its expense, the defective M-System product to the below address together with a copy of its original

sales invoice.

THIS IS THE ONLY WARRANTY APPLICABLE TO M-SYSTEM PRODUCT AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. M-SYSTEM SHALL HAVE NO LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR

SPECIAL DAMAGES OF ANY KIND WHATSOEVER.

M-System Co., Ltd., 5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN, Phone: (06) 6659-8201, Fax: (06) 6659-8510, E-mail: [email protected]

• 0 – 125A through 0 – 200A Use

Sensor model No.: CLSB-20

Applicable cable diameter: Max. 24.0

Weight: 200 g (7.1 oz)

• 0 – 225A through 0 – 400A Use

Sensor model No.:CLSB-40

Applicable cable diameter: Max. 35.0

Weight:300 g (10.6 oz)

• 0 – 500A through 0 – 600A Use

Sensor model No.:CLSB-60

Applicable cable diameter: Max. 35.0

Weight:360 g (12.7 oz)

Note 1: The output values may vary depending on the ac-

curacy of engagement at the clamp connection.

Note 2: The sensor is detachable up to 100 times (approx.).

Note 3: The sensor’s mechanical construction may cause it

to generate resonance sound. However, it does not

affect the performance of the sensor.

35 dia. (1.38)

k

k

l

l

2–M3 SCREW

K L

73.5 (2.89)

35.5

(1.40)

8.8

(.35) 8.8

(.35) 93 (3.66)

TERMINAL COVER

(detachable)

73.5 (2.89)

35.5

(1.40)

8.8

(.35) 8.8

(.35) 93 (3.66)

TERMINAL COVER

(detachable)

35 dia. (1.38)

k

k

l

l

2–M3 SCREW

K L

k

k

l

l

2–M3 SCREW

55.9 (2.20)

35.9

(1.41)

8.3

(.33) 8.3

(.33) 75.7 (2.98)

24 dia. (.94)

TERMINAL COVER

(detachable)

K L

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

Other manuals for M-SYSTEM Mini-M Series

2

This manual suits for next models

1

Table of contents

Other SENTRONIC Air Conditioner manuals