MAINTENANCE:

----WARNING----

Do not attempt to perform

maintenance on valves in

pressurized lines.

Stem Seal Adjustment:

If leakage is evident from the stempackingarea,

tighten the packing gland (below the handle) 1/8

turn. If the leakage persists, repeat tightening.

If leakage cannot be corrected by tightening the

gland, replacement of the stem seals will be

necessary.

Seal Replacement:

Turn valve to the open position and remove

handle nut, lockwasher, and handle. Loosen

and remove packing gland from valve body.

Loosen and remove body bolts, and remove

body center section assembly, placing it on a

suitable work surface. Remove seats and body

seals.

Using the handle if necessary, turn ball to the

closed position, and remove ball from body with

a rolling motion away from the stem. Handle

ball with care to avoid damaging the surface.

Push downwards on the top of the stem to slide

it through the stem seals, and remove stem from

inside body bore. Remove thrust washer from

stem, or from body bore if retained in body.

Remove stem seals using a packing hook or

sharp object.

Sharpe recommends that all soft parts, including

seats be replaced with new parts, which can be

ordered in kit form.

REASSEMBLY:

Make sure all valve components are clean and

undamaged before assembly.

Install thrust washer on stem, and slide down to

shoulder. Insert stem into body and upwards

through the stem bore until the shoulder is

seated in the bore.

Slide stem seal over stem top, and into stem

bore in body. Take care not to damage seal on

stem threads. Install packing gland, and tighten

finger tight.

Place stem in the “closed” position, and install

the ball carefully by rolling the stem tang into the

ball slot.

Install seats in the body at both ends, making

sure the concave face fits against the ball, and

press the body seals into the grooves in the

body faces.

Turn ball to the “open” position, and replace

between the end caps in line. Slide body hex

bolts through end caps and body guide holes,

and secure with lockwashers and hex nuts.

Tighten snugly.

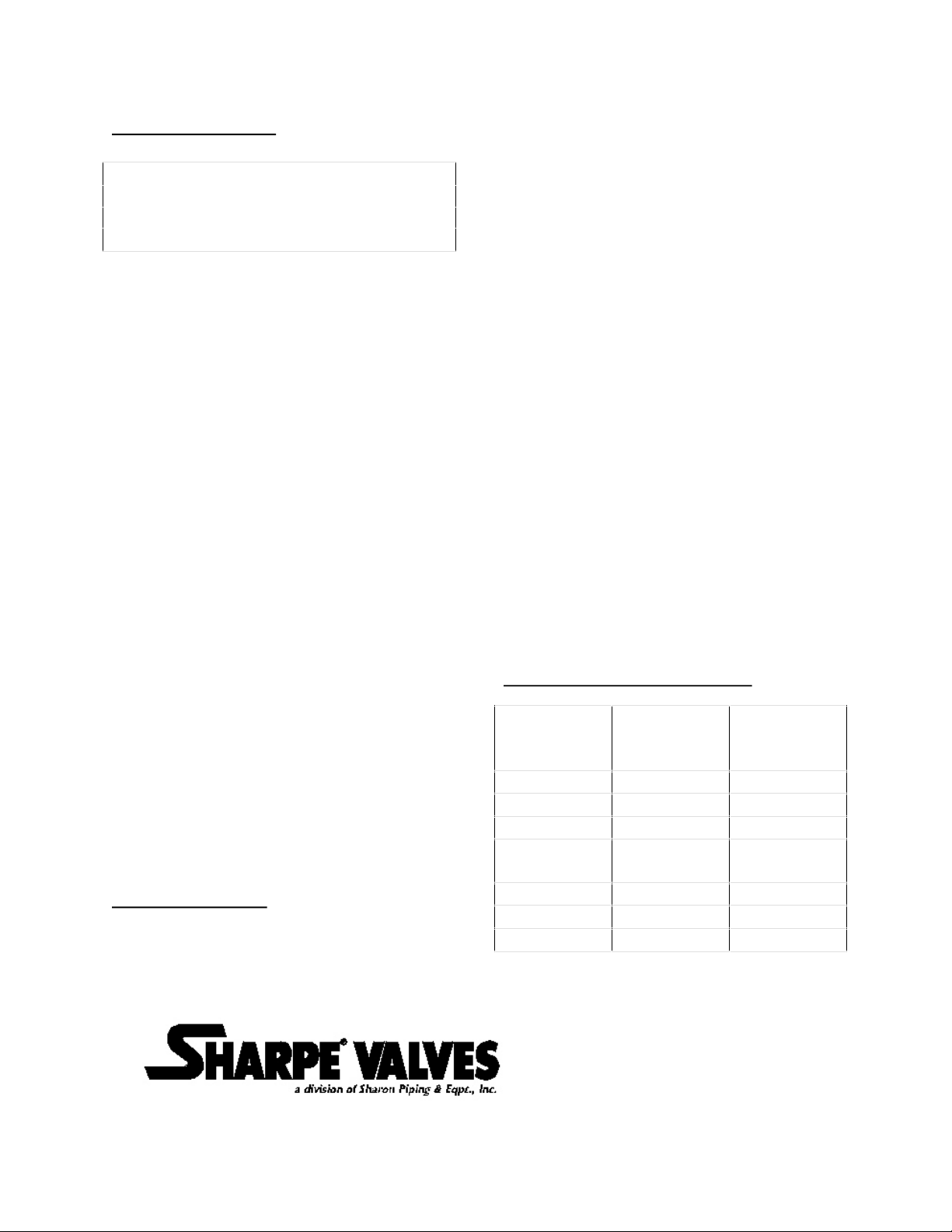

Tighten packing gland to the torque value givn in

the table below, and replace the handle,

lockwasher, and handle nut.

Tighten the body bolting to the torque values

given in the table below, using a cross or star

pattern to tighten evenly.

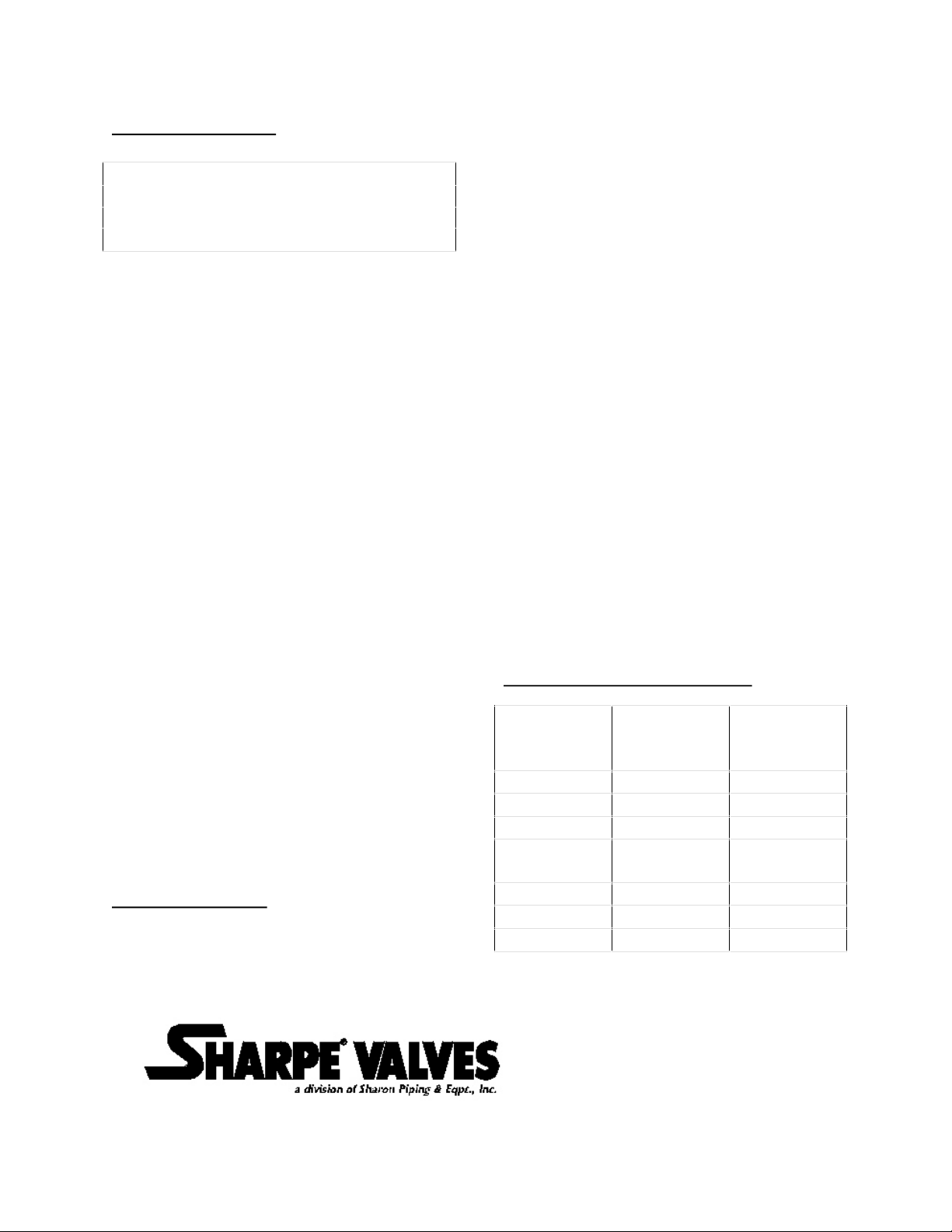

Table 1 –Assembly Torques

Valve Size Gland

Torque

(in-lb)

Body Bolt

Torque (in-

lb)

¼” – 3/8” 35 50

½” 35 110

¾” – 1” 80 115

1-1/4” –

1-1/2” 115 120

2” 115 125

2-1/2” 250 350

3” – 4” 350 460

1260 Garnet Drive, Northlake, Illinois 60164-1028 Phone (630) 883-8020 Fax:(630) 833-2661 www.sharpevalves.com