R-4A55

TEST PROCEDURES

PROCEDURE

LETTER COMPONENT TEST

F) The time must be measured with stopwatch or wristwatch.

G) After 1 minute and 51 seconds, stop the oven by opening the door.

H) Put the two (2) beakers out of the oven cavity and measure the temperature of the water by stirring

the water with thermometer and note them.

Example

Initial temperature .......................................................*........................... Tl = 23°C T2 = 24°C

Temperature after 1 min. 51 set I

. *.......................................................... Tl = 33°C T2 = 34°C

Temperature difference Cold-Warm ...................................................ATI = 10°C ?,T2 = 10°C /

Mean temperature rise AT ..............................AT /

Measured output power = (AT1 31AT2) /2 = (1O”C+1O”C) / 2 = 10°C I

The equation is P= 75 x AT I

..............................................................

P= 75 x 10°C = 750 Watts /

NOTE: The measured output power should be at least i 15 % of the rated output power.

CAUTION: 1°C CORRESPONDS TO 75 WATTS.

REPEAT MEASUREMENT IF THE POWER IS INSUFFICIENT. I

II

d

x

- -

- -

-

- -

--

(Tl “C) (Tl “C)

Heat up for mtn. 5 set

II

Eli

7

--

--

--

--

(T2 “C)

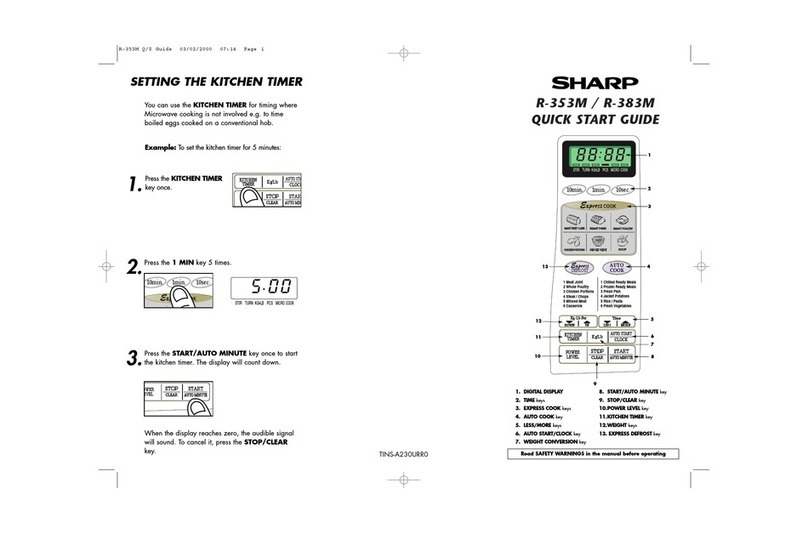

J TOUCH CONTROL PANEL ASSEMBLY TEST

The touch control panel consists of circuits including semiconductors such as LSI, ICs, etc. Therefore,

unlike conventional microwave ovens, proper maintenance cannot be performed with only a voltmeter

and ohmmeter. In this service manual, the touch control panel assembly is divided into two units,

Control Unit and Key Unit, and troubleshooting by replacement is described according to the symp-

toms indicated.

1. Key Unit

The following symptoms indicate a defective key unit. Replace the key unit.

a) When touching the pads, a certain pad produces no signal at all.

b) When touching a number pad, two figures or more are displayed.

c) When touching the pads, sometimes a pad produces no signal.

2. Control Panel

The following symptoms indicate a defective control unit. Replacing the control unit.

2-1 In connection with pads.

a) When touching the pads. a certain group of pads do not produce a signal.

b) When touching the pads, no pads produce a signal.

2-2 In connection with indicators

a) At a certain digit, all or some segments do not light up.

b) At a certain digit, brightness is low.

c) Only one indicator does not light.

d) The corresponding segments of all digits do not light up; or they continue to light up.

e) Wrong figure appears.

f) A certain group of indicators do not light up.

g) The figure of all digits flicker.

2-3 Other possible problems caused by defective control unit.

a) Buzzer does not sound or continues to sound.

7