Sherbourn C-12 User manual

Owner’s Manual

C-12

COOLING UNIT

Important Safety Precautions and Explanation of Symbols

The exclamation point within an equilateral triangle is intended to alert the user to the presence of

important installation, operation, and service instructions in this manual.

The lightning ash with arrowhead symbol within an equilateral triangle is intended to alert the user

to the presence of uninsulated dangerous voltages within the enclosure that may be of sufcient

magnitude to constitute a risk of electrical shock to the user.

Please read this Installation and Operation Manual thoroughly before attempting to install, congure,

or operate the Sherbourn C-12. After successful installation and conguration of the C-12, be sure to

retain this manual in a safe place for future reference.

Safety is a key component to a long lasting and trouble free installation. Please read and follow all

instructions and heed all warnings on the C-12 and in this manual. The vast majority of the subsequent

safety precautions are common sense. If you are not comfortable with the installation of audio/video

entertainment equipment, you should seek the services of a qualied installation professional or call us

for help.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT USE THE

C-12 NEAR WATER OR IN WET LOCATIONS, DO NOT EXPOSE IT TO RAIN OR MOISTURE, DO

NOT EXPOSE IT TO DRIPPING OR SPLASHING FROM OTHER SOURCES, AND ENSURE THAT

NO OBJECTS FILLED WITH LIQUIDS (SUCH AS VASES) ARE PLACED ON IT. DOING SO MAY

RESULT IN DAMAGE TO THE C-12 AND THE RISK OF ELECTRIC SHOCK, WHICH MAY RESULT

IN BODILY INJURY OR DEATH.

WARNING: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE THE COVER

FROM THE C-12 EXCEPT TO MAKE CONFIGURATION CHANGES AS DIRECTED IN THIS

MANUAL.

The Sherbourn C-12 is a cooling device and, as such, is intended to be installed in locations above

equipment that generates heat. The C-12 may be congured to exhaust hot air in several different

directions (depending on the conguration chosen), and to operate in several different modes. Do not

install the C-12 in locations where the ow of air, as congured per the instructions in the manual, is

impeded or blocked. Do not block vents or exhaust openings in the C-12 except as directed in this

manual to implement the chosen conguration. Improper conguration of the C-12, or blocking of the

vents or air-ow openings of the C-12, may result in improper or insufcient operation of the C-12.

Doing so may result in causing either the C-12 or the equipment it services to overheat, which may

result in the risk of re, personal injury, or equipment damage.

Always install your C-12 according to the manufacturer’s instructions and only use attachments or

accessories specied by the manufacturer.

The C-12 is available in both 115 VAC and 230 VAC versions (both are marked on the exterior).

Ensure that the version you have is the correct one for your local AC line voltage, and only connect

your C-12 to outlets of the correct voltage. Only connect the C-12 to an electrical outlet or extension

cord of appropriate type and rating.

Protect the AC power cable from being pinched, walked on, or otherwise damaged. Be especially

careful where the power cable exits the C-12 unit.

DO NOT defeat the safety purpose of a grounding or polarized plug by removing ground pins or using

unsafe adapters. A polarized plug has two blades - one wider than the other. A grounding plug has a

third ground prong in addition to the two main conductors. The wide blade or third groundling prong is

provided for your safety. If the provided plug does not t your outlet, consult an electrician to replace

your obsolete outlet.

!

!

!

The C-12 should be unplugged from the outlet during severe electrical storms, or when unused for a

long period of time.

The C-12 should only be cleaned as directed in the Installation and Operation Manual. Avoid spraying

liquids directly onto the C-12 and NEVER spray liquids into the vents. Care should be taken so that

small objects do not fall into the inside of the C-12.

You should seek service for your C-12 by qualied service personnel if any of the following occur:

1. Objects or liquid have fallen or spilled into the vents.

2. The C-12 has been exposed to rain.

3. The C-12 exhibits a marked change in performance.

4. The C-12 has been dropped, or its enclosure or chassis is damaged.

NOTE: TO COMPLETELY DISCONNECT THE C-12 FROM THE AC POWER MAINS, DISCONNECT

THE AC POWER CABLE FROM THE AC RECEPTACLE.

NOTE: THE C-12’s AC POWER CABLE MUST REMAIN READILY ACCESSIBLE AT ALL TIMES.

!

CAUTION

CAUTION: TO REDUCE THE RISK

OF ELECTRICAL SHOCK, DO

NOT REMOVE COVER. NO USER

SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

Page 1

Contents

Important Safety Precautions and Explanation of Symbols

Introduction.................................................................................................2

The Sherbourn C-12...................................................................................2

About This Manual......................................................................................2

Mechanical and Environmental ..................................................................3

Installation and Conguration.....................................................................4

Mechanical Conguration...........................................................................6

Performance Specications........................................................................9

Features ...................................................................................................10

Operation..................................................................................................11

Periodic Maintenance...............................................................................12

Troubleshooting........................................................................................13

Sherbourn Technologies, LLC Ten Year Limited Warranty .......................14

Notes ........................................................................................................15

C-12

Cooling System

Page 2

Introduction

Thank you for choosing the Sherbourn C-12 Cooling System.

Sherbourn’s innovative C-12 Cooling System is an efcient and exible solution to the problem of

excessive heat in a rack or built-in system. Heat is a major threat to the reliability and performance

of modern home theater hardware. All equipment generates heat, and many racks and other

installations have little or no ventilation, so the C-12 is all that stands between your equipment and

poor performance or an early death.

The Sherbourn Team

About This Manual

This manual will provide you with all the information you need to install and congure the Sherbourn

C-12 Cooling System to achieve its optimum potential. The manual also includes a brief summary

of the features offered by the C-12 and a short description of how the controls work and how to

perform common operations.

You may wish to record serial numbers or other purchase information on the Notes page at the back

of this manual.

The Sherbourn C-12

The C-12’s three whisper quiet variable speed fans can move over 100 cubic feet of air per minute,

and it offers a wide variety of options enabling you to customize the air ow to your needs (including

an external exhaust duct). Some of the features that make the C-12 so exible include a low voltage

trigger, a built-in thermal and/or external pigtail sensor, a user-selectable temperature activation

threshold, and the ability to synchronize two or more units to run at the same speed.

Page 3

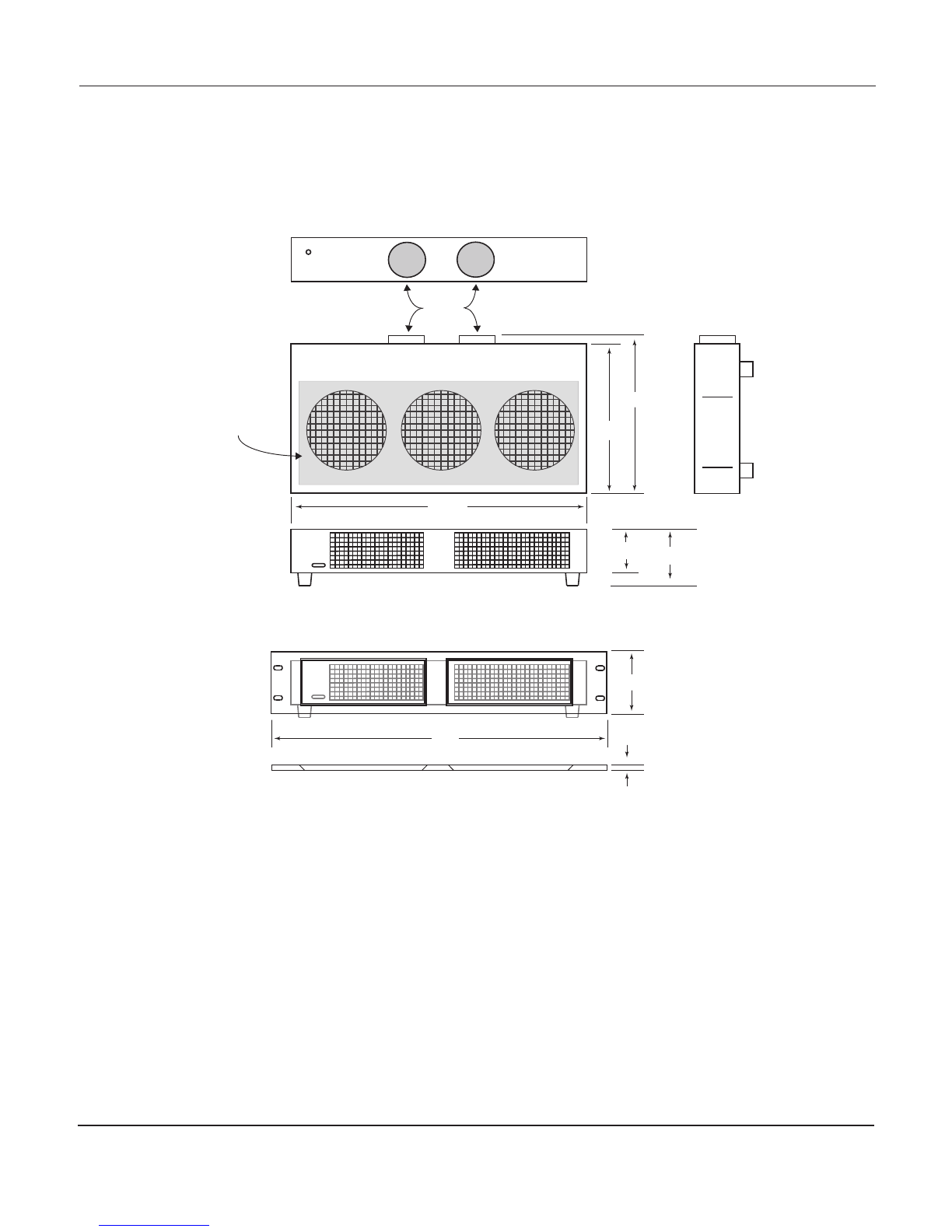

Mechanical and Environmental

16.7”

9”

8.5”

2.5”

TOP

3.25”

SHERBOURN

C-12

19”

3.5”

REAR

IN-ON

OUT-AUTO

0.1825”

FOAM

PLUGS SIDE

cover plate

TOP & BOTTOM

(external)

C12 body

FRONT

(front panel removed)

front panel

FRONT

(external)

Dimensions: 19” wide x 3.25” high x 9” deep (includes feet, foam plugs

Weight: 11 lbs / 5 kg (unboxed); 12 lbs / 5.5 kg (boxed)

Rack mountable: Yes.

Power requirements:

115 VAC or 230 VAC +/- 10% @ 50 / 60 Hz (operating voltage is factory-congured)

Power consumption: approximately 10 watts (at high speed)

Page 4

Installation and Conguration

How the Sherbourn C-12 operates is determined both by switch settings and by mechanical

reconguration of parts of the device. Read and follow the instructions carefully. Improper or

incomplete conguration may result in unusual or unexpected behavior.

In general, the electrical conguration and switch settings determine when and if the C-12 fans will

operate (and at what speed), while the mechanical conguration determines the direction of air ow

through the unit when the fans are active.

Note: The Trigger In connector on the C-12 is a switched connector. Connecting a cable to

this input operates a switch inside the C-12, so plugging in a cable that is not connected

to an appropriate device at the other end may result in improper operation of the C-12. The

Trigger In connection also serves different purposes depending on how the Trigger Mode

switch is set.

Note: The Trigger Out connector carries different signal levels depending on how the Trigger

Mode switch is set. Specically, when the Trigger Mode switch is in the Sync position, the

Trigger Out should NOT be used to trigger “ordinary” 12 V triggered devices.

Front panel Power Switch (On/Auto; on the left side of the front panel)

This is a mechanical push button switch, which toggles between settings each time it is pressed, so

it retains its setting when the C-12 is powered off.

When the front panel switch is in the On position (in), the C-12 fans will run at full speed whenever

mains power is applied to the C-12, regardless of the temperature or other settings or connections.

When the front panel switch is in the Auto position (out), the operation of the C-12 is controlled by

the Trigger Mode switch, trigger connections, and temperature sensors.

Front panel LED (blue)

The front panel LED is located just above the front panel Power switch. This LED will light blue when

power is applied to the fans (it is not a “power LED” and will not be lit if mains power is present, but

the C-12 fans are off because their temperature trigger threshold has not been exceeded).

Fan Auto-On Switch (rear panel)

This switch sets the temperature at which the C-12 fans switch on when in Auto mode. The

temperature range is from approximately 95 degrees (low) to 104 degrees (high) Fahrenheit

(about 35 and 40 degrees Celsius, respectively). The C-12’s fans will start running at a slow speed

(and very quietly) when this temperature is exceeded, and will run faster as the temperature

increases. Once the temperature exceeds this threshold by about fteen degrees, the fans will be

running at full speed and maximum air ow capacity. The fans will run only as fast as needed to

maintain the desired temperature.

Temperature Sensor connector (1/8” jack on rear panel)

The C-12 has an internal temperature sensor mounted on the bottom of the chassis. The

Temperature Sensor jack on the rear panel allows for connection of an optional magnetically

mounted remote sensor. When the external sensor is plugged in, the internal sensor is completely

overridden. To ensure proper operation, use only the appropriate Sherbourn supplied external

sensor.

Page 5

Basic Auto operation

In this mode the front panel Power switch is set to the Auto position, the Trigger Mode switch is set

to the 12VDC position, and nothing is plugged into the Trigger In connector.

The C-12 is controlled by the temperature at the temperature sensor. (If the remote sensor is

attached, then this is the temperature at that location; if no remote sensor is attached, then it is the

temperature at the bottom panel of the C-12 unit. When the remote sensor is attached, the internal

sensor is disabled and ignored.) When the temperature at the sensor reaches the value set by the

Fan Auto-On Temperature switch, the fans will start at slow speed. If the temperature continues

to rise, the fans will speed up until they reach maximum speed. (The end result is that the fans

will run just fast enough to keep your cabinet at or slightly above the set temperature. When the

temperature is below the set temperature, the fans will not run.)

Triggered Auto operation

In this mode the front panel Power switch is set to the Auto position, the Trigger Mode switch is set

to the 12VDC position, and a trigger cable (from some other device) is plugged into the Trigger In

connector.

Note: The Trigger In connector on the C-12 is a switched connector. If you plug a cable into

the Trigger In connector and don’t connect it to anything, the C-12 will NOT operate in Auto

mode at all.

When the trigger input is high (+12 VDC), the C-12 operates exactly as it does in Basic Auto mode

(the fans start running when the temperature at the sensor exceeds the threshold temperature

set by the Fan Auto-On Temperature control). When the trigger input is low, the C-12 fans do not

operate.

Sync mode

Sync mode allows the operation of multiple C-12 units to be controlled by a single “master unit”.

One unit is designated as the “master” and a second (or more) units as “slaves”. The fans in all

slave units will switch on at the same time and run at the same speed as those in the master unit. All

activity will be controlled by the temperature sensor and temperature threshold setting of the master

unit. (All sensors in slave units will be ignored.)

In this mode, the front panel Power switches in all master and slave units are set to the Auto

position, and the Trigger Mode switches are set to the Sync position. A trigger cable is connected

from the Trigger Out of the master unit to the Trigger In of the slave (or rst slave). If there are

additional slave units, then a trigger cable is connected from the Trigger Out of the rst slave to the

Trigger In of the second slave, and so on; this is repeated until all slaves are connected. (All slaves

must be set to Auto and to Sync mode).

Note: In Sync mode there should NOT be anything plugged into the Trigger In connector of

the master unit.

In this mode, ALL C-12 units are controlled by the temperature at the temperature sensor of the

master unit. (If the remote sensor is attached, then this is the temperature at that location; if no

remote sensor is attached, then it is the temperature at the bottom panel of the C-12 unit.) When the

temperature at the sensor reaches the value set by the Fan Auto-On Temperature knob, the fans

will start at slow speed. If the temperature continues to rise, the fans will speed up until they reach

maximum speed.

Page 6

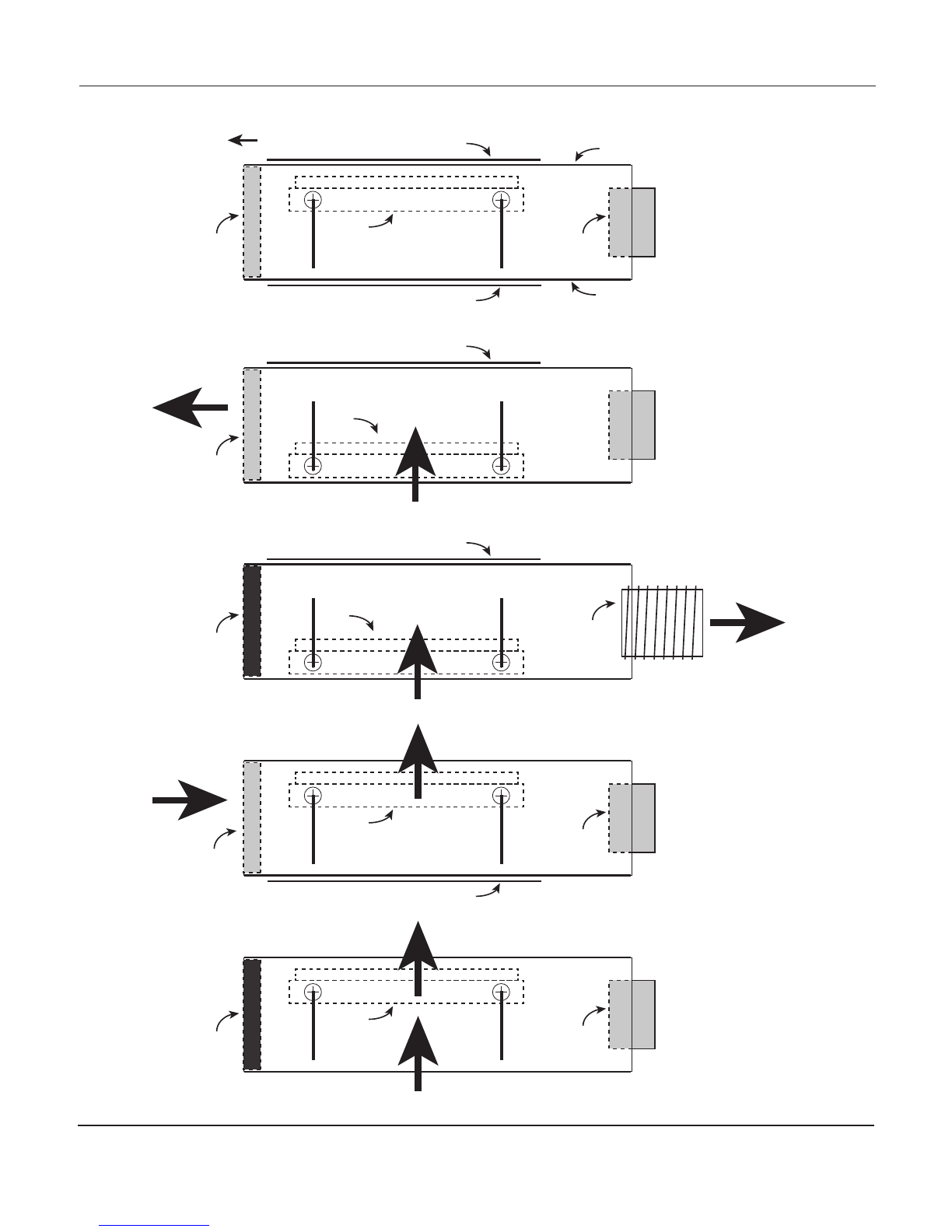

Mechanical Conguration

The direction of air ow in the C-12 is determined by the mechanical conguration of the unit itself.

The parts involved in the mechanical conguration of the C-12 are:

• Top and bottom plates - The C-12 is always operated with both top and bottom plates in place.

The top plate is removed to facilitate installing the foam block or air lter behind the front panel.

• Cover plate - The cover plate (metal) is used to cover the top or bottom vents to force air

ow in the proper direction. One cover plate is supplied with the C-12, and it is not used in all

congurations (be sure to retain the cover plate and screws in a safe place when not in use).

• Fan assembly - The fans inside the C-12 are mounted on a movable carriage which allows them

to be positioned against either the top or bottom of the case. Fans are moved by loosening the

four large screws on the sides (two on each side), repositioning the fan assembly, and

re-tightening the screws.

• Filter and Foam Block - The C-12 is supplied with both a foam lter and a dense foam block,

both of which t behind the front panel vents. The lter is used when air ow through the front

panel is desired; the foam block is used to prevent air ow through the front panel when it is

not desired. Only one is used at once (be sure to retain the other in a safe place). To congure

these, remove the top plate and insert whichever one is required, against the front panel,

sliding it behind the long screws protruding from the bottom plate. Then replace the top plate

by inserting the front edge rst (tilt the plate and insert it so the long protruding screws “pin” the

lter or foam block against the front panel rather than impaling it).

• Rear plugs - The rear plugs are foam cylinders used to block the rear vents (2) when air ow

from the rear is not congured. These plugs are dense foam cylinders, and are inserted by

squeezing them and pressing them approximately halfway into the two holes in the rear panel

(a slight twisting motion will help).

• Rear exhaust hose - When air ow from the rear exhaust vents is congured, lengths of

“standard 1-1/2” pool skimmer hose” are inserted into the rear vents (after removing and

retaining the plugs). The hose should not include end ttings of any sort; the spiral hose should

be “screwed” directly into the rear panel about two turns.

Front Exhaust (bottom entry)

• Ensure that the lter (not the foam block) is installed behind the front grill

• Ensure that the cover plate covers the vents in the top plate

• Ensure that both rear plugs are rmly inserted

• Ensure that the fan assembly is in the lower position (against the bottom plate of the C-12)

Rear Exhaust (bottom entry)

• Ensure that the foam block (not the lter) is installed behind the front grill

• Ensure that the cover plate covers the vents in the top plate

• Ensure that both rear plugs are removed

• Ensure that exhaust hose is rmly inserted into the rear vents

• Ensure that the fan assembly is in the lower position (against the bottom plate of the C-12)

Note: The maximum air ow rate of the C-12 will be somewhat reduced with this option,

and will depend on the overall length of vent hose used. Using short hose runs, with as few

bends as possible, will help to maximize air ow and so maximize cooling.

Page 7

FRONT

REAR

PLUGS

FAN

ASSEMBLY

FILTER

or

FOAM

BLOCK

COVER PLATE (bottom position)

COVER PLATE (top position) TOP PLATE

BOTTOM PLATE

AIR

HOSE

x 2

FAN

ASSEMBLY

FILTER

COVER PLATE (top position)

COVER PLATE (top position)

REAR

PLUGS

FAN

ASSEMBLY

COVER PLATE (bottom position)

REAR

PLUGS

FAN

ASSEMBLY

FRONT EXHAUST

REAR EXHAUST

TOP EXHAUST

(front entry)

TOP EXHAUST

(bottom entry)

FAN

ASSEMBLY

FOAM

BLOCK

FILTER

FOAM

BLOCK

Page 8

Top Exhaust (front entry)

• Ensure that the lter (not the foam block) is installed behind the front grill

• Ensure that the cover plate covers the vents in the bottom plate

• Ensure that both rear plugs are rmly inserted

• Ensure that the fan assembly is in the upper position (against the top plate of the C-12)

Top Exhaust (bottom entry)

• Ensure that the foam block (not the lter) is installed behind the front grill

• Ensure that the cover plate is completely removed

• Ensure that both rear plugs are rmly inserted

• Ensure that the fan assembly is in the upper position (against the top plate of the C-12)

Page 9

Performance Specications

Air-ow capacity:

>100 cfm; direct outlet; variable

(maximum airow will be reduced if long exhaust ducts are used)

Cooling modes (manually selected):

• Bottom Entry - Front Exhaust

• Bottom Entry - Rear Exhaust (can optionally be ducted using 1-1/2” hose x 2)

• Front Entry - Top Exhaust

• Bottom Entry - Top Exhaust

Auto-On temperature:

• Switchable; from approximately 95 degrees Fahrenheit to 104 degrees Fahrenheit

(about 35 to 40 degrees Celsius)

Power modes:

• Always on

• Auto-on (by temperature)

• Auto-on (by temperature) when triggered

• Sync mode (slave to another unit)

Page 10

Features

The Sherbourn C-12 Cooling System offers an effective and exible cooling solution for rack

mounted equipment. Some of the features of the C-12 include:

• Uses three high-capacity whisper-quiet 4.75 inch fans

• Front panel Power switch and blue LED indicator light

• Can be mechanically congured for front exhaust with bottom entry, top exhaust with front entry,

top exhaust with bottom entry, or rear exhaust with bottom entry

• Front panel intake includes air lter

• Offers two exhaust ports and (optional) exhaust hose for maximum exibility

• Includes embedded thermal sensor and (optional) remote sensor

• Rear panel input for remote sensor

• Optional synchronization of fan speeds between multiple units

• 12-volt trigger input

• Selectable starting temperature (95 or 104 degrees Fahrenheit; 35 or 40 degrees Celsius))

• Rack mount front panel included (removable)

You can nd more information about the Sherbourn C-12 Cooling System on our Web site at http://

www.sherbourn.com

Page 11

Operation

The Sherbourn C-12 is normally congured to operate automatically.

In normal operation, the C-12 fans will not operate until the congured Starting Temperature has

been exceeded (at the sensor). At this point, the C-12’s fans will start operating at minimum speed;

fan speed will gradually increase as the temperature rises above the starting temperature.

(In situations where little air ow is needed, the fans will operate at the minimum speed necessary to

maintain temperature, ensuring minimum noise.)

The front panel switch allows the C-12 to be manually run with the fans at full. This mode is typically

used only for testing purposes.

Page 12

Periodic Maintenance

The Sherbourn C-12 requires very little periodic maintenance.

Cleaning the C-12 air lter

The interior of the C-12 (and especially the air lter) may become dusty (or accumulate lint and

other debris) with normal operation. If this occurs, periodically disconnect the power, remove the

top cover, and vacuum out any loose debris and dust that has accumulated (be careful to avoid

damaging the interior circuit boards and wiring). The lter should be vacuumed periodically, and may

be carefully washed and rinsed if necessary.

Page 13

Troubleshooting

If problems occur, the rst step should be to verify that the Sherbourn C-12 is attached to the correct

line voltage. (The C-12 is factory congured to operate at either 115 VAC or 230 VAC.)

Note: If a cable is connected to the Trigger Input of the C-12, but not connected to a

triggering device, the C-12 will not act as expected with the Trigger switch in either position.

DO NOT insert a cable into the Trigger In connector unless the other end is connected to an

active device.

Problem: No air ow (fans sound like they are running)

• Verify that the C-12 is congured correctly (mechanical conguration)

Problem: Fans never come on - even at high temperatures

• Verify that, if a remote temperature sensor is used, it is in the warmest spot in the cabinet

• Verify that the Fan Auto-On temperature control is set to the desired temperature.

• Verify that ONLY a remote temperature sensor is plugged into the Temp Sensor connector

(plugging a trigger cable or other cable into this connector will result unpredictable behavior and

possible damage to the C-12)

• Verify that, if a remote device is expected to trigger the C-12, the trigger signal is active and the

Trigger Mode switch in in the 12VDC position.

Problem: Fans run when they shouldn’t

• Verify that the Fan Auto-On temperature control is set to the desired temperature.

• Verify that ONLY a remote temperature sensor is plugged into the Temp Sensor connector

(plugging a trigger cable or other cable into this connector will result unpredictable behavior and

possible damage to the C-12)

• Verify that, if a remote device is expected to trigger the C-12, the trigger signal is active and the

Trigger Mode switch in in the 12VDC position.

• Verify that, if the C-12 is being run in Sync mode, the C-12 unit connected to its Trigger In is

also in Sync mode (and that ONLY another Sherbourn C-12 unit in Sync mode is connected to

its Trigger In.)

Problem: Fans come on, but air ow seems weak

• Verify that the C-12 is congured correctly (mechanical conguration)

• Check if the lter needs cleaning

• If exhaust hoses are used, verify that they are clear of obstruction (and not too long)

Problem: Fans ONLY run at full speed

• Verify that, if a trigger input is used, and the C-12 is not a slave unit to another C-12, the Trigger

Mode switch is not in the Sync position

Page 14

Sherbourn Technologies, LLC Ten Year Limited Warranty

What does this warranty cover? Sherbourn Technologies, LLC (“Sherbourn”) warrants its

products against defects in materials and workmanship. This warranty is subject to revision at any

time.

How long does this coverage last? This warranty commences on the date of retail purchase

by the original retail purchaser and runs for a period of ten (10) years thereafter, with the following

exceptions: (1) receivers (including the SR-8100, SR-8200, and SR-120), preamp/processors

(including the PT-7030, PT-720C4, and PT-7020), preampliers (including the PRE-1), and the

CD-1 CD Player (with the exception of the slot load CD engine) are covered by this warranty for

ve (5) years from the date of retail purchase by the original purchaser; and (2) electromechanical

components, including the slot load CD engine on the CD-1 CD Player, and all fans (including

the C-12 Cooling Unit), are covered by this warranty for three (3) years from the date of retail

purchase by the original retail purchaser. This warranty is transferrable, upon written notication

to Sherbourn, to any person that owns the warranted product, however, if ownership is transferred,

the Term shall be no longer than ve (5) years from the date of purchase by the original purchaser.

Sherbourn warrants any replacement product or part furnished hereunder against defects in

materials and workmanship for the longer of the following: (i) the amount of time remaining under

the original warranty, or (ii) 120 days from your receipt of the repaired or replaced product. The

duration described in the previous 3 sentences is hereinafter referred to as the “Term”. TO THE

FULLEST EXTENT PERMITTED BY LAW, ALL IMPLIED WARRANTIES RELATED TO THE

ORIGINAL PRODUCT AND ANY REPLACEMENT PRODUCT OR PARTS (INCLUDING IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE) ARE

EXPRESSLY LIMITED TO THE TERM OF THIS LIMITED WARRANTY. SOME STATES DO

NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU. A claim under this warranty must be made by you within

the Term. A claim shall not be valid (and Sherbourn has no obligation related to the claim) if it is not

made within the Term and if it is not made in strict compliance with the requirements of the “How do

you get service?” section.

What will Sherbourn do? Sherbourn will, at its option, either: (i) repair the product, or (ii) replace

the product with a new consumer product which is identical or reasonably equivalent to the product.

Sherbourn may provide you with a refund of the actual purchase price of the product in the event

(i) Sherbourn is unable to provide replacement and repair is not commercially practicable or cannot

be timely made, or (ii) you agree to accept a refund in lieu of other remedies hereunder. When

a product or part is repaired or replaced, any replacement item becomes your property and the

replaced item becomes Sherbourn’s property. When a refund is given, the product for which the

refund is provided must be returned to Sherbourn and becomes Sherbourn’s property.

What is not covered by this warranty? This warranty does not apply: (i) to damage caused by

use with non-Sherbourn products, where the non-Sherbourn product is the cause of the damage;

(ii) to damage caused by service or maintenance performed by anyone who is not a representative

of Sherbourn; (iii) to damage caused by accident, abuse, misuse, ood, re, earthquake or other

external causes; (iv) to a product or part that has been modied after its retail purchase, where

the modication caused or contributed to the damage; (v) to consumable parts, such as batteries;

(vi) normal wear tear; or (vii) if any Sherbourn serial number has been removed or defaced and

Sherbourn cannot otherwise conrm that you are the original retail purchaser or authorized

transferee. SHERBOURN SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

Page 15

Notes

DAMAGES ARISING FROM OR RELATED TO ANY DEFECTS IN OR DAMAGES TO ITS

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION

MAY NOT APPLY.

How do you get service? In order to make a claim under the warranty, you must:

1. Call a customer service representative (“CSR”) of Sherbourn at (1-877-EMO-TECH /

1-877-366-8324). Provide the CSR with a description of your problem and the serial number of the

product for which the warranty claim is being made.

2. The CSR will provide you with a returned material authorization number (“RMA”).

3. Ship the product to Sherbourn at the following address, with the RMA written in large,

bold letters on the outside of the box, and with the letters “RMA” written before the number. Parcels

arriving without a RMA number on the outside of the box will be refused.

Sherbourn Technologies, LLC

Attn: Repair Department

131 Southeast Parkway Court

Franklin, TN 37064

How does state law apply? This warranty gives you specic legal rights, and you may also

have other rights which vary from state to state. CERTAIN STATES HAVE ENACTED LAWS

WHICH PRECLUDE THE WAIVER OF CONSEQUENTIAL AND INCIDENTAL DAMAGES AND/

OR PRECLUDE THE WAIVER/LIMITATION OF IMPLIED WARRANTIES. TO THE EXTENT

YOUR STATE HAS ENACTED A LAW WHICH PROHIBITS SUCH A WAIVER/LIMITATION, ALL

SUCH WAIVERS/LIMITATIONS CONTAINED IN THIS WARRANTY ARE INAPPLICABLE TO YOU.

CERTAIN STATES HAVE ENACTED LAWS WHICH REQUIRE THE DURATION OF A WARRANTY

TO BE EXTENDED (INCLUDING BUT NOT LIMITED TO DURING PERIODS OF REPAIR). TO

THE EXTENT YOUR STATE HAS ENACTED A LAW OF THIS NATURE, THEN THE DURATION

OF THIS WARRANTY WILL BE EXTENDED AS REQUIRED BY APPLICABLE LAW.

All information contained in this manual is accurate to the best of our knowledge at the

time of publication. In keeping with our policy of ongoing product improvement, we reserve the right to

make changes to the design and features of our products without prior notice.

User Manual Revision 1.0 February 2013

Table of contents

Popular Wine Cooler manuals by other brands

Twin-Star International

Twin-Star International CW-52A-TS instruction manual

Kadeka

Kadeka KA143T instruction manual

Avintage

Avintage AVI24PREMIUM use instructions

Dunavox

Dunavox DAUF-9.22B instruction manual

Diamond

Diamond SC85-I BLACK user manual

Wine Guardian

Wine Guardian WG25 Installation, operation and maintenance guide