SHIRE CONTROLS SDX-15 User manual

issue 11

02-06-2021

The SDX-15 Alarm

System

for

Piped Medical Gases

WOULD BE THIS SUPPLY

ON THIS REPEATER

SYSTEM FAULT No 2

THESE CABLES.

WOULD BE ON ANY OF

SYSTEM FAULT No 1

THESE CABLES.

WOULD BE ON ONE OF

ON THIS REPEATER

SYSTEM FAULT No 4

5 CORES

VACUUM PLANT

WITH EMS

AIR PLANT

EMS

MANIFOLD WITH

NITROUS OXIDE

INTERNAL TRANSMITTER

WITH 2 GAS

2 GAS REPEATER

ROOM

ALARM IN TELEPHONE

5 GAS CENTRAL

LODGE

ALARM IN PORTERS

5 GAS REPEATER

COMPUTER INTERFACE

S

D

X

P

I

C

4 CORES

5 CORES

5 CORES

2 CORES

2 CORES

2 CORES

2 CORES

2 CORES

2 CORES

2 CORES

TYPICAL PLANT ALARM SYSTEM

TO BMS SYSTEM

INTERFACE

PLANT TO ALARM

WITH EMS

OXYGEN VIE

SUPPLY

240 Vac

MEDICAL GA S ALARM

PLANT TO ALARM

INTERFACE

SUPPLY

240 Vac

SUPPLY

240 Vac

SUPPLY

240 Vac

SDX-15

MEDICAL GAS ALARM

SDX-15

MEDICAL GAS ALARM

SUPPLY

240 Vac

SUPPLY

240 Vac

SDX-15

MEDICAL GAS ALARM

TRANSMITTER

REMOTE

ESM

AUTO-MANIFOLD

2

INTRODUCTION

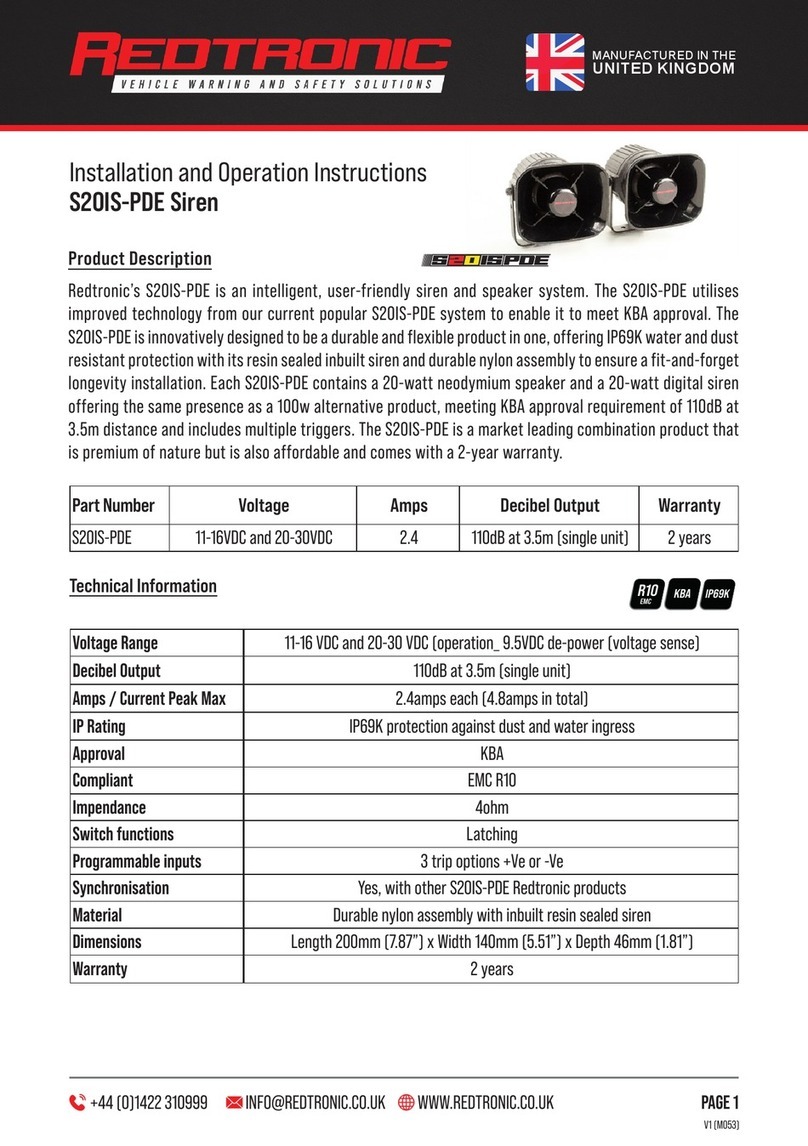

The SDX-15 Medical Gas Alarm system has been

developed to meet the requirements of Medical Gas

Plant Alarms as de

ned in DHSS HTM02-01 and C11

model standard, fully meeting the requirements of these

documents.

Emphasis is placed on reliability and

exibility,

enabling an economical system to be installed and

expanded as required. The manufacturers guarantee the

availability of electrically compatible equipment for

system expansion for a minimum of 10 years from the

date of supply of the original system. The SDX-15 is fully

back compatible with earlier SDX-15 alarms and indeed

SD-15 alarm systems.

A full range of accessories are available allowing

the system to be shaped to the requirements of each

project.

OPERATOR

The SDX-15 Plant Alarm is designed for manual

operation via the Test/Mute push-button. Hence it is

envisaged that the operator is able to visually monitor

from within 900mm.

The inherent design includes Red/Yellow/Green

indicator LED's and the use of gas colour recognition

within the title bar of each gas window, which ensures

that the alarm can be monitored comfortably from 3-4

metres away.

Consideration should be made for

nal location, in

accordance with the latest HTM guidelines, prior to

installation.

About this manual

When you see this symbol, the associated text in

bold type refers to something which may cause

danger or damage.

Section 2

SYSTEM DESCRIPTION

The SDX-15 Medical Gas Alarm system is a

multiplexed system using the MEDCON data

transmission standard, a pulse width modulated signal,

on 2 core inter-panel wiring, capable of displaying up to

15 services, each consisting of up to 4 fault conditions

(plus normal). Any service may be split into four

individual displays to be used to bring signals, such as

the common alarm output from Area alarms, to a central

point or to any point where this information is required.

Signals from plant or other monitored equipment

are fed into the system via transmitters located adjacent

to the equipment (See Section 4). A complete service

can be transmitted from one transmitter or, if required,

the service can be transmitted from several transmitters

(i.e. EMS for plant located remotely to the plant). The

services are displayed at each panel as required, the

service being selected by a rotary switch for each

service within the panel.

Five long-life, block LEDs per service show the

conditions of the service through a replaceable lens

mounted behind a wipe-clean membrane. As an alarm

condition occurs, the appropriate alarm condition will

ash and the audible alarm will sound if selected by a 4

way DIL switch for that service within the panel (these

will always be set as ON upon dispatch).

Operating the Mute switch on a repeater panel

will silence the audible on that panel. Operating the

Mute switch on the central panel will silence the audible

on the central panel and convert the

ashing condition

LED to steady on all panels. (The audible on repeaters is

not a

ected). If the condition remains, the audible will

re-trigger, on all Alarms requiring re-muting every 15

minutes.

If a condition is to be in an alarm condition for a

prolonged period (e.g. for pipeline maintenance) the re-

trigger can be prevented by silencing the audible with

the Lockout button within the panel (large

at white

push-button on the rear of the LED board. The audible

will not then sound for that condition of that service until

it has returned to normal and then back to alarm

condition.

A volume control is

tted within the panel.

Typically volume is set at half level but can be adjust by

inserting a 3mm terminal screwdriver and rotating.

A loud speaker is used for the audible rather

than a buzzer, to give a mellow sound which, whilst

drawing attention to the alarm condition, can be

tolerated by sta

otherwise occupied.

Operation of the test button on the front of the

panel will cause the normal lamps to illuminate, the

alarm conditions to

ash, the system fault lamp to

ash

and the audible to sound. Any fault condition which is

locked out will not

ash, showing at a glance if a

condition has returned to normal operation. A seven

segment display below the system fault lamp will also

illuminate, showing which system fault, if any, is present

(Power failure, data transmission failure,

ashing circuit

failure or contact line fault – see Appendix B).

The alarm is housed in a steel enclosure (

ush or

surface mount) with a bezel which houses an aluminium

front plate covered by a PVC membrane. Within the

enclosure are mounted the power supply with battery

reserve, control board with lamps, selector switches etc.

and ITX type transmitter (optional). The front plate with

control board is mounted on a hinge which allows the

front to swing clear for connection or servicing, or

reversed for access to the rear of the board.

The battery reserve enables the system to

remain in operation for up to 8 hours with only the lamps

on the panel a

ected by the power failure out of

operation, or for 4 hours if the panel is set for full

backup.

Computer interfaces are available to decode the

multiplexed signals to volt-free contacts for connection

to BMS systems or other alarm systems.

Section 3

MOUNTING

Mount the surface or

ush mounting boxes as

required, following the mounting instructions as per this

manual. Fit bezel using countersunk screws and earth

lead supplied. Do not over tighten these screws.

IMPORTANT. Ensure that the M4 screw

below and to the left of these terminals is

secure. This is the earth connection to box.

CABLING

Install cable, observing cable entry areas as

shown on the mounting instructions in this manual.

Before connecting cabling on any panels, check

continuity of cores and earth or screen, and insulation

between cores and to earth.

WARNING. Do not use high voltage testers

such as Meggers for these tests.

A 230Vac 50/60 Hertz supply, fused at 3 amps,

from an essential supply, is required for each alarm

panel, remote transmitter, plant to alarm interface and

computer interface.

Connect Live, Neutral & Earth to terminals under

the cover marked ``ISOLATE MAINS BEFORE REMOVING

COVER'', making a cut-out in the cover to suit the cable

being used.

WARNING. This equipment is not suitable

for connection to an IT power system. A

readily accessible means of disconnecting

must be provided. The max. prospective

fault current must not exceed 1500 amps.

Replace the protective cover after connection.

3

Connect the inter-panel signal wiring to terminals 1 & 2

on the power supply board, observing polarity.

WARNING. Ensure that cable screen,

armouring or conduit is connected to earth

at both ends of each run. Termination

boards must be connected to cable screens

or earth. Failure to carry out these instructions

WILL result in intermittent faults invalidate the

Declaration Of Conformity.

Two core cable as speci

ed in appendix A, must

be run between all alarm panels, remote transmitters,

plant to alarm interfaces and computer interfaces.

WARNING. A minimum of 20mm clearance

must be maintained between the alarm

system cabling and any other cables

(including the mains supply to the alarms).

Cabling as speci

ed in appendix A must be run

between alarm condition source (plant, manifold etc.)

and the transmitter from which the service is to be

transmitted. (One core per condition + common for each

service).

Connect alarm condition cabling between

transmitter & plant, terminating at the plant with a

termination board.

WARNING. Where over 5 Gases are

displayed at the Central location (i.e. more

that one panel is present). Connect the

remote 'common', 'mute' & 'test' terminals

on power supply, to similar terminals in the

adjacent alarm(s).

Section 4

TRANSMITTERS

Transmitters introduce signals from plant etc.

onto the multiplexed signal wiring. They also monitor the

wiring between the between the plant contacts and the

transmitter terminals via termination boards mounted in

or near the plant, checking for short or open circuits of

the cable.

INTERNAL TRANSMITTERS (ITX)

Internal transmitters are available as 1, 2, 3

or 4 service units and are mounted, 1 per 1-5 service

alarm, in the alarm panel enclosure. If a fault is detected

on the contact lines, an alarm condition is transmitted

for the condition relating to the faulty line, and a system

fault visual and audible alarm will appear on this panel.

Each service on the system is allocated a

channel when the system is initially set up, this being

entered on the log sheet. The alarm contacts on the

plant or manifold are connected via the termination

board to a service on the transmitter as follows:-

C Common

1 First condition

2 Second condition

3 Third condition

4 Pressure fault

and this service is then set to the channel for this service

with the rotary switch. For example, if Oxygen is

allocated channel 1, this plant could be connected to

service A terminals on the transmitter, which would then

be set to channel 1.

Any condition not transmitted from this

transmitter must be terminated with a 56k resistor to set

the condition to normal if the condition is not to be used,

or with a 1k8 resistor if the condition is to be transmitted

from another transmitter. The resistors are used to

prevent a system fault due to short or open circuit. Note

that if a resistor is

tted, the condition must NOT be

connected to the termination board.

Resistor codes:-

1k8 brown grey red silver, gold or red

56k green blue orange silver, gold or red

Important. Ensure that each condition is

only transmitted from one location although

other conditions on the service may be

transmitted from other transmitters.

Any service can be displayed on any alarm panel

by selecting the channel on which the service is

transmitted (by reference to log sheet) using the rotary

switch for the appropriate column on the alarm.

Internal transmitters are powered by the alarm

panel power supply or the reserve battery in the event of

a power failure. Should the power remain o

for long

enough to discharge the battery, all conditions

transmitted from this transmitter will show on other

alarm panels as gas fault conditions (i.e. not system

fault).

REMOTE TRANSMITTERS (RTX).

The Remote transmitter is a self contained unit,

used where indication of the alarm condition is not

required locally, e.g. when a manifold or plant has an

integral plant to alarm interface, and are available as 1,

2, 3 or 4 service units. The services are selected, as in

the alarm panel, with a rotary switch. However, the

remote transmitter has only one switch for up to 4

services. This switch is set to the

rst service required

and the other services will follow in sequence. e.g. if the

switch on a 3 service transmitter is set to channel 2 then

the services transmitted will be channels 2, 3 & 4.

Connection to the plant (or manifold) is identical

to the internal transmitter above.

A 230Vac, 50/60 Hertz supply is required, which

is connected under the mains terminal cover.

The 2 core inter-panel wiring is connected to

signal terminals 1 & 2. The cable screen must be

connected to the ``S'' terminal. Refer to the instruction

sheet supplied with the transmitter.

RTX1 TRANSMITTER

Again, the RTX1 is a self contained transmitter,

used where indication of the alarm condition is not

required locally and is available as a single channel

variation only.

These transmitters are often factory

tted by

Plant or Manifold Controller manufacturers within the

same housing as the contact sources, hence the board

C1 2 3 4

SERVICE A

C 1

SER

C

C

1

1

2

2

3

3

4

4

TO ALARM

TO PLANT

CABLING BETWEEN

TRANSMITTER AND

TERMINATION BOARD

TERMINATION BOARD.

TO BE MOUNTED IN

CONTROL PANEL ON

PLANT OR MANIFOLD.

WIRING TO PLANT

A

L

A

R

M

C

O

N

T

A

C

T

S

SDXPIC3

T

RANSMITTER

TYPICAL TRANSMITTER

C

ONNECTIONS SHOWING

ONE UN-USED ALARM

C

ONDITION LINKED OUT

WITH A RESISTOR

TERMINALS

4

is design to be used WITHOUT termination boards.

Again the service channel is selected with a

rotary switch and the connection to the plant (or

manifold) is similar to the internal transmitter, only there

is no requirement for the Termination Board.

A 230Vac, 50/60 Hertz supply is required.

Note. This is the only item on the SDX-15

system which does not include a mains

termination cover. Note the warning label

on the outside of the box.

The 2 core inter-panel wiring is connected to

signal terminals 1 & 2. The cable screen must be

connected to and earth point or to the circuit earth.

COMPUTER INTERFACES.

Computer Interfaces are available which will give

volt-free contacts which are closed when a condition is

at normal. The relays are grouped in blocks of four,

giving four conditions plus normal, which is closed only

when all four conditions on that service are at normal.

The services are selected, as in the alarm panel, with a

rotary switch. However, the computer interface has only

one switch for up to 5 services. This switch is set to the

rst service required and the other services will follow in

sequence. e.g. if the switch on a 3 service interface is

set to channel 2 then the services detected will be

channels 2, 3,4 &5.

The computer interface is a self contained unit,

supplied as a 1, 2, 3, 4 or 5 service unit. A 230Vac, 50/60

Hertz supply is required, which is connected to terminals

under the mains terminal cover. The 2 core inter-panel

wiring is connected to signal terminals 1 & 2. The cable

screen must be connected to the ``S'' terminal.

The rating of the relay contacts is 0.5amp, 24V

dc resistive.

NOTE. Each SDX-15 central or repeater alarm

has an integral common alarm relay

tted as standard.

This relay opens when any alarm condition or fault

occurs on the panel and is similarly rated.

PLANT TO ALARM INTERFACE.

The plant to alarm interface is a low cost means

of complying with the C11 & HTM02-01 requirements for

indication of alarm status in plant or manifold room. It is

mounted in a clear fronted polycarbonate enclosure

protected to IP65, making it weatherproof and suitable

for use in VIE compound etc. with no further protection.

It consists of the following.

Four alarm conditions plus normal Power On &

system fault lamps. A one gas transmitter, connected to

the plant & set to the required channel in the same way

as a standard transmitter. Four relays, giving volt-free

contacts, closed under normal conditions, for connection

to other alarm systems, BMS systems etc. A battery

reserve to power the system failure lamp and the

transmitter in the event of power failure.

The plant to alarm interface requires a 230Vac,

50/60 Hertz supply and connection to the two core inter-

panel wiring.

Note. Being a basic indicator, the plant to alarm

interface has no audible alarm or test facility. Refer to

the instruction sheet supplied with the plant to alarm

interface for further details.

Section 5

SYSTEM DESIGN

If in doubt, please contact the

manufacturers. Errors can easily be recti

ed at

this stage.

The system must consist of a single central

panel, which should be mounted in a area which is

manned 24 hours a day. Select the number, location and

size (number of services to be displayed) of alarm panel

as required by C11/HTM02-01.

Select the location and size of transmitters. Use

internal transmitters if an alarm panel is in the same

room as the plant, or a remote transmitter if no

additional local indication is required.

Remember that a plant to alarm interface is

cheaper than a one service repeater with internal

transmitter for locations where local indication is

required.

With more than one service, a repeater with

transmitter is more economical. The distance between

the plant and the transmitter should be kept to a

minimum, and in any case should not exceed 100

metres.

See section 4 if conditions of a service are to be

transmitted from more than one location.

Transmitters are supplied with termination

boards, which must be mounted in or adjacent to the

plant.

Select Computer interfaces as required.

Section 6

SETTING UP

WARNING. STATIC SENSITIVE DEVICES.

OBSERVE HANDLING PRECAUTIONS.

Set the alarm panel at the central location as a

central by placing the jumper between the centre & right

hand pins on the central selector. Ensure that all other

panels have the jumper between centre & left hand pin.

Set the power failure mode as required using the

jumper adjacent to the ribbon cable connector. If the

any alarm panel is to have full battery operation under

power failure conditions, place the jumper between the

centre and lower pins on the power selector.

Allocate a channel for each service and enter the

name of the service on the log sheet in the “Gas

Service'' column. It may be useful to allocate the

services in the order in which they appear on the central

panel, although this is not necessary. Go to each

internal transmitter and set the rotary switch for each

service to the channel allocated to that service on the

log sheet. Set the rotary switch on each remote

transmitter to the channel allocated to the

rst service

on this transmitter. Set the channel for each computer

interface as for remote transmitters.

Set the rotary switch on each plant to alarm

interface to the appropriate channel. For each alarm

panel, set the rotary switch for each service displayed on

the panel to the channel allocated to that service.

If a column is not required e.g. if a spare service

has been installed for future use, set the rotary switch to

``F'' which switches o

that column.

Set the four audible switches for each service as

required (switch number 1 is condition 1, the

rst lamp

below normal. If a switch is on, the audible for that

condition will operate, otherwise it will never sound).

Mount the front plate & PCB onto the hinge by

springing the ends of the hinge apart &

tting into the

clips on the PCB.

Plug the ribbon cable on the power supply into

the control PCB. (it is keyed to prevent incorrect

connection).

Switch on the power to all panels, transmitters

etc. and connect the battery cables, observing polarity.

The system should now be operational.

No panels will operate if the central panel is not

functioning. In this case, all repeater panels will show an

Incoming Signal (number 1) on the system fault display

when the test button is pushed.

This will also happen if the inter-panel wiring is

reversed at any panel or the wiring is short circuited.

Disconnect each panel in turn until the fault

clears. If it does not, check for short circuits.

5

If a Contact Line fault (number 4) is indicated,

check that resistors are

tted in all unused conditions on

the internal transmitter, that the termination boards are

tted and the cabling between termination board and

transmitter is not short or open circuit.

If a Power Failure (number 2) is indicated, check

the 230Vac supply to the panel and the two fuses on the

power supply board.

When all panels are on, each condition in turn

should be created at the plant to con

rm the operation

and setting of the system. When it is not possible to

create a condition e.g. from a pressure switch on a

pipeline which is in use, disconnect the condition on the

plant side of the termination board to simulate condition

faults.

When satis

ed that all conditions operate

correctly, anti confusion tests must be

carried out by creating alarm conditions on

each service in turn and con

rming that

each panel on which the service is displayed

operates correctly.

Section 7

OPERATION

All that is required for routine operation is for

sta

to mute the audible alarm on alarm panels in their

areas as required, taking any action required by the

nature of the service fault. The audible will resound

periodically as long as the service fault remains,

requiring re-muting.

When a condition is to be at alarm condition for a

long time, the audible can be continuously muted as

follows. Open the panel and, while the alarm condition is

present, press the white push button on the rear of the

control board.

Note that any other conditions present at the

time will also be locked out. Close the panel and con

rm

that the condition has been successfully locked out by

pressing the test button. All other lamps should

ash,

the locked out condition(s) being steady. The lockout will

cancel as soon as the condition returns to normal.

NOTE. This operation should only be carried

out by service personnel.

TESTING

Periodically operate the test button and

ensure that all lamps illuminate and the audible

sounds. Periodically disconnect the mains sup ply

to each panel and ensure that the system fault

lamp

ashes and the audible sounds. Provided

that the battery in the panel under test is sound

and fully charged, no other panel will be a

ected

by this test. Any remote audible connected to the

alarm panel under test will sound.

6

<R C>

B

M

ON

12 3 4

3

<R C>

A

UDIBLE SELECTOR SWITCH

C

H

A

N

N

E

L

S

E

L

E

C

T

O

R

S

W

I

T

C

H

LOCKOUT BUTTON

CENTRAL/REPEATER SELECTOR JUMPER

POWER FAILURE SELECTOR

JUMPER SHOWN SET FOR

SYSTEM FAILURE LAMP

ONLY

HINGE CLIP

ON

1 2 3 4

4

ON

1 2 3 4

2

ON

1 2 3 4

3

ON

1 2 3 4

1

ON

1 2 3 4 0

CONTROL

BOARD

BM

S

D

X

P

I

C

2

VOLUME CONTROL

SHOWN AS CENTRAL

SECTION 8

FAULT FINDING

Properly installed, the SDX-15 alarm system will

give many years of trouble-free service. Experience

shows that the majority of problems are due to incorrect

connection or poor workmanship during installation.

Problems with intermittent faults are usually due to

screens not connected to earth, badly made connections

or water-

lled junction boxes.

Most problems will be identi

ed by the system

fault indicator below the system fault lamp, which will

illuminate when the test button is pressed. See appendix

B to decode these numbers.

If no lamps show when the test button is

pressed, check that the power supply is present at the

panel and that the battery is not discharged. (a

discharged battery will take about 72 hours to fully

recharge)

.

Flashing circuit has failed.

Fit a service exchange or replacement SDX-15

control PCB

Incoming Signal fault.

If this fault is present on all panels on the

system, using an analoge voltmeter on a 10 volt DC

range, measure the voltage across terminals 1 & 2 on

the central panel. If no voltage is present, disconnect the

signal wiring from terminals 1&2 on the central panel

and repeat the test. If a voltage of between about 2-8

volts is now present then a short circuit exists on the

signal wiring or a repeater panel has been wired with the

signal wires reversed (check the polarity of the wiring

with the meter with the signal wires disconnected from

the repeater. Number 1 should be positive).

Reconnect the central panel and disconnect each

part of the signal wiring until the fault clears. The last

part of the wiring to be disconnected has the fault on it.

If no voltage was present at the central panel

after disconnecting the signal wires,

rst ensure that the

panel is set to be a central. If it is then

t a service

exchange board (Remember. A board can be “borrowed”

from another, less critical, location and used to get a

system running).

If the system fault only appears on one section of

the system, look for a broken wire or loose terminal

between the section with the system fault and the rest of

the system.

Contact Line fault.

This indicates that the wiring between the

transmitter in the alarm panel showing the system fault,

and the termination board is open or short circuit. A

service fault will be showing at the same time. This fault

(or faults) indicates which cable has the problem on it.

e.g. if a panel is showing a number 4 system fault and

say, pressure fault on nitrous oxide, the cable connected

to condition 4 on the nitrous oxide service on the

transmitter is broken or shorted to common or earth.

Note that unused inputs to transmitters must be

connected to common with a resistor to prevent a

system fault (see Transmitter section).

On Remote Transmitters and Plant To Alarm

Interfaces a 5mm round yellow LED provides warning for

a contact Line Fault when present at that transmitter.

Power Failure.

Check that the mains supply is sound. If sound,

check the fuses on the power supply board and replace

as necessary. If sound,

t service exchange boards.

IMPORTANT NOTE. If any control or

transmitter boards are replaced, ensure

that the replacement boards are set for the

correct channels. Carry out anti-confusion

tests when work is complete.

7

Appendix A - Cable types

Use only the following types of cable for wiring the alarm system:-

SWA

Overall screened cable

Single core cable in steel conduit. Must not contain any other cables.

A minimum cable size of 0.5 sq.mm is recommended. Solid cable such as telephone cable should NOT be used.

Continuity of screen, armouring or conduit must be maintained at all times. Particular

attention should be given to plastic junction boxes. Multicore cables must not be shared with

other systems.

Appendix B - System Faults

0. . . . . No fault

1. . . . . Incoming signal fault

2. . . . . Power failure

3. . . . . Incoming signal and power faults

4. . . . . Contact line fault

5. . . . . Contact line and incoming signal faults

6. . . . . Contact line and power faults

7. . . . . Contact line, power&incoming signal faults

8. . . . . Flashing circuit failed

9. . Flashing circuit&incoming signal faults

8

CABLE ENTRIES

SIGNALS

SIGNALS

Surface Mounting box

TRANSMITTERMEDCONMAINS

25153

60

M

1

0

4

6

A

SDX-15

FA ILURE

SYSTEM

ON

POWER

CHANGE

ENTONOX

OXIDE

NITROUS

EMERGENCYEMERGENCY

PLANT

PLANT

FA ULT

FA ULT

PLANTPLANT

VACUUM

AIR

MEDICAL

CYLINDERSCYLINDERS

CYLINDERSCYLINDERS

FAULT

PRESSURE

NORMAL

FAULT

PRESSURE

FA ULT

RESERVE

NORMAL

FA ULT

PRESSURE

FAULT

RESERVE

IMMEDIATELY

CHANGE

NORMAL

FAULT

PRESSURE

FAULT

RESERVE

IMMEDIATELY

CHANGE

CHANGE

NORMAL

FAULT

PRESSURE

FA ULT

RESERVE

IMMEDIATELY

LIQUID

REFILL

REFILL

LIQUID

NORMAL

OXYGEN

324

9

SIGNALS

FIXINGS

VIEW OF

SIGNALS

MAINS

BOTTOM VIEW

TRANSMITTERMEDCON

CABLE ENTRIES

324

Flush Mounting box

M

1

0

4

4

B

29

295

BACK BOX

251

57

7

225

SECTIONAL

BEZEL .

OXYGEN

NORMAL

LIQUID

REFILL

REFILL

LIQUID

IMMEDIATELY

RESERVE

FAULT

PRESSURE

FAULT

NORMAL

CHANGE

CHANGE

IMMEDIATELY

RESERVE

FAULT

PRESSURE

FAULT

NORMAL

CHANGE

IMMEDIATELY

RESERVE

FAULT

PRESSURE

FAULT

NORMAL

RESERVE

FAULT

PRESSURE

FAULT

NORMAL

PRESSURE

FAULT

CYLINDERS CYLINDERS

CYLINDERS CYLINDERS

MEDICAL

AIR VACUUM

PLANT PLANT

FAULT FAULT

PLANT PLANT

EMERGENCY EMERGENCY

NITROUS

OXIDE ENTONOX

CHANGE

POWER

ON

SYSTEM

FAILURE

SDX-15

DECLARATION OF CONFORMITY

EU EMC Directive 2014/30/EU

The Low Voltage Directive 2006/95/EG

Medical Devices Directive 93/42/EEC

Manufacturer

Shire Controls Ltd

Studio 3 Channocks Farm,

Gilston, Harlow

Essex CM20 2RL

United Kingdom

Product Type

SDX-15 Plant Alarm System

Includes

SDX-15 Plant Alarm

SDX-15 Remote & Internal Transmitter

SDX-15 Plant To Alarm Interface

SDX-RTX1 Transmitter

SDX-15 Interfaces

Year of manufacture 2021

Standards used

To which this declaration relates is in

conformity with the following standards:

EN60601-1-2 4th Edition 2015

Emissions Standard for Medical Equipment

EN55011, Class A 2016 + A1:2017

Emissions Standard for ISM Equipment

EN60601-1-2 4th Edition 2015

Immunity Standard for Medical Equipment

EN61000-4-2 2009

ESD Requirements

EN61000-4-3 2006 + A1 + A2

Radiated Susceptibility

EN61000-4-4 2016

Electrical Fast Transient Burst Requirement

EN61000-4-5 2017

Surges Requirements

EN61000-4-6 2014

Conducted Susceptibility

EN61000-4-8 2012

Magnetic Field Immunity

EN61000-4-11 2017

Voltage Dips and Interruptions

Authorised representative

Technical Director

Signature

10

Shire Controls Ltd

Studio 3, Channocks Farm

Gilston

Harlow

Essex

CM20 2RL

Tel. (01279) 434399

www.shirecontrols.com

Table of contents

Popular Security System manuals by other brands

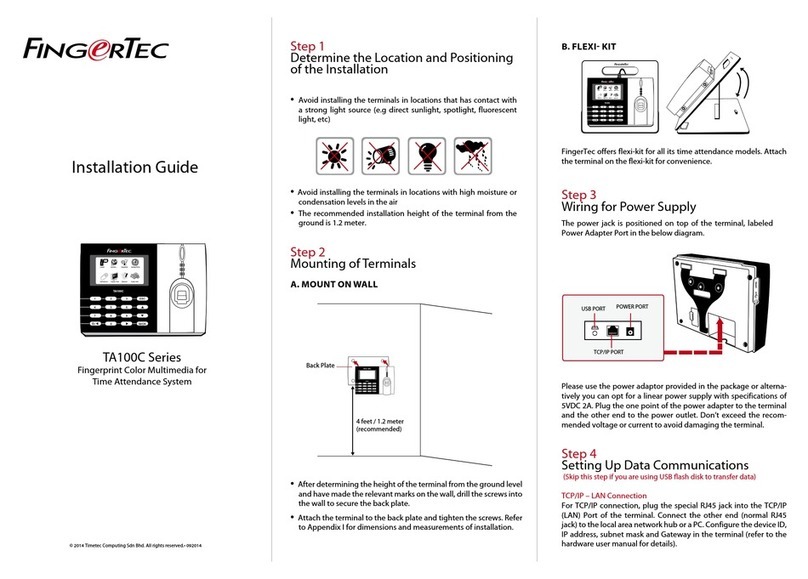

FingerTec

FingerTec TA100C installation guide

Verint

Verint Nextiva S4200-BZ user guide

Directed

Directed Power Sports Installer and owner guide

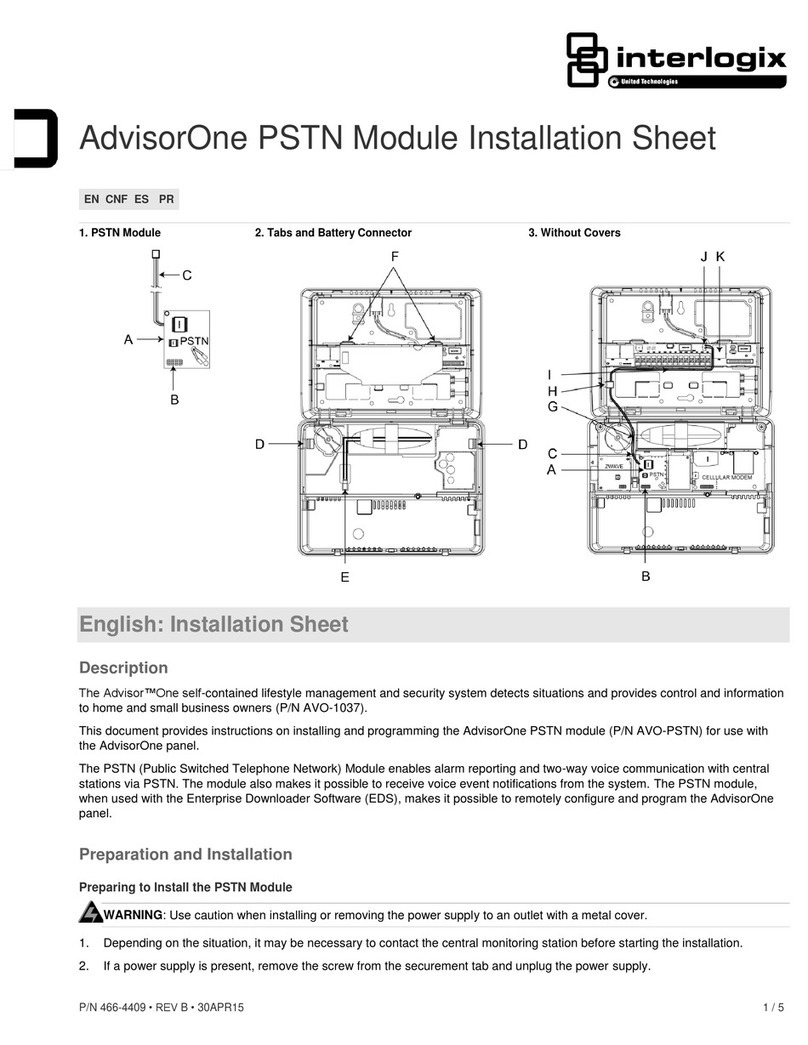

United Technologies

United Technologies Interlogix AdvisorOne Installation sheet

My ADT

My ADT Ademco Vista-10P quick guide

Inner Range

Inner Range CONCEPT IQ. PLUS Programmer's manual