Shopsmith 11" User manual

Shopsmith, Inc.

11” Bandsaw

WARNING

• Read the Safety section and complete the

Setup procedures before operating the

Shopsmith 11” Bandsaw.

• Mount the Bandsaw on Shopsmith equip-

ment only.

• Use only Shopsmith parts and accessories on

your Bandsaw. Mounting the Bandsaw on

non-Shopsmith machinery or using non-

Shopsmith parts could create a hazardous

condition and will void your warranty.

Table of Contents

Introduction .............................................. 2

Safety ......................................................... 2

Terms to Know......................................... 5

Specifications............................................ 7

Electrical Requirements.......................... 7

Assembly .................................................. 8

Alignment ............................................... 11

Operations .............................................. 21

Bandsaw Speeds .................................... 22

Making a Cut .......................................... 22

Helpful Cutting Hints ........................... 24

Ripping & Crosscutting ........................ 25

Resawing................................................. 26

Making Bevel Cuts ................................ 26

Cutting Round Stock ............................. 27

Making Duplicate Cuts......................... 27

Compound Cutting ............................... 27

Cutting Particle Board,

Plastics & Metals ................................. 28

Offsetting the Blade............................... 29

Removing & Mounting Blades ............ 30

Maintenance ........................................... 33

Sharpening Blades ................................. 33

Resurfacing Guide Blocks .................... 34

Cleaning the Bandsaw .......................... 35

Lubricating Bandsaw ............................ 35

Storing the Bandsaw.............................. 36

Bandsaw Tires ........................................ 36

Waxing the Bandsaw............................. 37

Maintenance Schedule .......................... 38

Troubleshooting .................................... 38

Correcting Blade Lead .......................... 38

Troubleshooting Guide ........................ 39

SHOPSMITH 11” BANDSAW 555943

Page 2

Introduction

The Shopsmith Bandsaw gives you the ability

to crosscut, rip, resaw, pad saw, plus cut

bevels and round stock. The Bandsaw is also

useful for compound cutting, creating shapes

that appear to be carved. You can cut both

natural and man-made woods, most plastics

and some metals with the Bandsaw. Also,

whentheShopsmithSpeedReducer (optional)

is attached to the Shopsmith Mark V, you can

properly cut an even wider range of materials

(the Speed Reducer cannot be used with the

Power Station or Power Stand).

The Shopsmith 11" Bandsaw will accomplish

many woodworking operations that are diffi-

cult or impossible with other tools. Basically,

the Bandsaw blade is an endless loop (or

“band”) of saw teeth revolving on two large

wheels. The thin, flexible blades allow you to

cut curves and other irregular shapes. The

fast cutting action makes it easy to resaw

thicker boards into thinner ones. But these are

just two of the operations your Bandsaw will

do. As you work with this machine, you’ll

find it has many other features that add ease

and versatility to your woodworking.

Safety

The Shopsmith Bandsaw has many built-in

safety features. But the effectiveness of these

features depends on you. Power tool safety is

no more than good common sense. To protect

yourself from injury: READ, UNDERSTAND

AND FOLLOW ALL the information in this

manual. Themeanings of WARNINGS, CAU-

TIONS and NOTES are:

WARNING

• A WARNING is given when failure to follow

the directions could result in injury or loss of

limb or life.

CAUTION

A CAUTION is given when failure to follow

the direction could result in temporary or

permanent damage to the equipment.

NOTE

A NOTE is used to highlight an important

procedure, practice or condition.

General Safety Rules for All

Power Tools

WARNING

• Read, understand and follow this instruction

manual and the manual for whichever power

source(s) you will be using (Mark V, Power

Station or Power Stand).

• Ground all tools (unless double-insulated).

• Keep guards in place and in working order.

Most injuries occur on unguarded power

tools.

• Remove adjusting keys and wrenches before

attempting to operate any tool.

• Do not wear loose clothing, ties, gloves or

jewelry. Roll sleeves up above your elbows,

wear nonslip footwear, and tuck long hair

under a hat.

• Do not operate power tools if you are fatigued

or taking medication or are under the influ-

ence of alcohol or drugs.

• Do not use power tools in damp, wet or

explosive atmospheres.

• Keep work areas well-lit, clean and free from

clutter.

Page 3

SHOPSMITH 11” BANDSAW 555943

• Do not force the tool. It will do the job better

and safer at the rate for which it was de-

signed.

• Do not use a tool or accessory to do a job for

which it was not designed.

• Repair or replace damaged parts before fur-

ther use. If a strange noise or vibrations

develops, turn off and unplug the machine.

Correct the problem.

• Use clamps, fixtures and other devices to hold

workpieces when practical.

• Do not overreach. Keep proper footing and

balance at all times.

• Do not try to stop the tool by grabbing the

workpiece or any part of the tool. Turn off

the tool and let it come to a complete stop by

itself.

• Do not leave the tool running unattended.

• To discontinue operations, turn the power

off. Don’t leave the tool until it comes to a

complete stop.

• Avoid unintentional starting. Make sure the

switch is in the “Off” position before plugging

in or unplugging the tool.

• Keep tools sharp, clean and maintained ac-

cording to the instruction manual.

• Make your workshop childproof. Unplug

tools, use padlocks and master switches, and

remove starter keys.

• Keep children away. All visitors should stay

a safe distance from power tools and wear eye

and ear protection.

Eye Protection

• Always wear eye protection when you use

power tools. Use goggles, safety glasses or a

face shield to protect your eyes.

• Goggles completely surround and protect

your eyes. Many goggles will also fit over

regular glasses. Be sure your goggles fit

closely, but comfortably.

• Safety glasses don’t fog as easily as goggles

and can be worn all the time. Regular glasses

normally have only impact-resistant lenses.

They are not safety glasses.

• A face shield protects your entire face, not

just your eyes.

Safety Rules for the Bandsaw

WARNING

• Mount the Bandsaw only on the Shopsmith

Mark V, Power Station or Power Stand.

Mounting the Bandsaw on non-Shopsmith

machinery or using non-Shopsmith machin-

ery or using non-Shopsmith parts could cre-

ate a hazardous condition and will void your

warranty.

• Use only Shopsmith parts and accessories on

your Bandsaw.

• Do not remove stock or scraps until the blade

has stopped.

• Maintain proper adjustment of blade ten-

sion, blade guides and bearings.

• Keep the upper guide adjusted to a maximum

of 1/4" above the stock.

• Never reach close to the blade or under the

table while the tool is running.

• Hold stock firmly against the table.

SHOPSMITH 11” BANDSAW 555943

Page 4

• Never reach close to the blade or under the

table while the tool is running.

• Hold stock firmly against the table.

• Never attempt a turn tighter than the blade

will allow; otherwise, the blade might break.

• Use a push stick to finish a resawing or rip-

ping cut.

• Keep your hands, fingers and other parts of

your body out of the danger zone.

• Support long stock with a roller stand.

• Hold round stock in a V-block.

• Never cut extremely small stock. Cut small

components from larger stock.

• If the blade breaks, turn off the machine and

stand away until it stops.

• Whenever you mount and operate the

Bandsaw on the Mark V, secure the acces-

sory mount lock, headstock lock and the

Bandsaw mounting tubes. Do not exceed the

speed setting “D”.

• Never turn on the tool with stock pressed

against the blade.

• If you hear a ticking sound or other unusual

noise, stop the Bandsaw immediately. A tick-

ing sound often indicates a damaged blade.

• Never reach close to the blade or under the

table to make adjustments, clear away chips

or for any reason whatsoever while the ma-

chine is running. Turn off the machine and

let the blade come to a complete stop.

• Keep your hands outside the DANGER

ZONE-which is in front of the blade for the

width of the table insert, and as high as the

blade guard. See page 4. Never push the

workpiece with your hand in line with the

blade. If your hand slips, you can cut yourself

severely.

Page 5

SHOPSMITH 11” BANDSAW 555943

Terms to Know

Familiarize yourself with the various parts of

the Shopsmith Bandsaw:

1. Cover-This lightweight cover completely

encloses the working parts of the Bandsaw,

protecting you while the machine is run-

ning.

1a. Window and slot - allows for modifying

blade tension with cover installed.

2. Cover Screws/Washers-These screws/

washers secure the cover in place.

3. Table-The table supports the work. It’s split

at the front so that you can mount and

remove blades. It also has an adjustable T-

slot extrusion, for smooth and precise cross-

cutting with the optional Shopsmith Miter

Gauge (505700).

4. Table Insert-This insert supports the work

around the blade. It’s keyed to prevent it

from turning in the table and being dam-

aged by the blade.

5. Table Leveling Screw-This screw and its

knurled nut keeps the two sides of the table

level across the front and helps keep the

table flat and true.

6. Dust Chute-The dust chute allows connec-

tion of a standard 2-1/2" hose for dust

collection.

7. Mounting Tubes-These eccentric tubes

quickly mount the Bandsaw to the

Shopsmith Mark V, Power Station or Power

Stand. They are offset so that the drive

shaft of the Bandsaw can be easily aligned

with the power source (upper auxiliary

spindle on the Mark V).

8. Lower (Drive) Wheel-The lower wheel

drives the Bandsaw blade in an endless

loop.

9. Upper (Idler) Wheel-The upper wheel is

free-running. Its position can be adjusted

to tension the blade.

10. Upper Blade Guide-The upper blade guide

consists of a roller bearing to back up the

blade and guide blocks to keep the blade

running straight above the work. The guide

DANGER ZONE!

Keep hands fingers clear

of these areas:

√In front of each blade,

√each side of the insert,

√up to the blade guard.

2

2

2

6

7

5

4

3

1

1a

SHOPSMITH 11” BANDSAW 555943

Page 6

blocks may be reversed to twist the blade 30

degrees to the right for special operations.

11. Blade Guard-The guard attaches to the

upper blade guide assembly. When prop-

erly adjusted, it protects you from cutting

yourself on the unused portion of the blade.

12. Lower Blade Guide-The lower blade guide

consists of a roller bearing to back up the

blade and guide blocks to keep the blade

running straight below the work. Like the

upper blade guide, the guide blocks can be

reversed to twist the blade 30 degrees.

13. Auto-Track Roller Bearing-This roller bear-

ing keeps the blade properly positioned on

the wheels.

14. Blade Tensioning Screw-By turning this

screw with the 5/32" Allen wrench, you

can adjust the blade tension.

15. Blade Tension Scale-This scale indicates the

proper blade tension for any blade 1/8"-1/

2" wide.

16. Height Lock Handle-With this handle, you

can raise and lower the upper blade guide,

then secure it in position. The handle is in

the “locked” position when pointing

straight back. Turn the handle 90 degrees

to the right to release the upper blade guide

assembly.

17. Upper Blade Guide Adjusting Knob-This

knob adjusts the front-to-back position of

the upper guide blocks.

18. Lower Blade Guide Adjusting Knob-This

knob adjusts the front-to-back position of

the lower guide blocks.

19. Trunnions-The trunnions attach the table

to the Bandsaw and allow it to be tilted

from being perpendicular to 45 degrees

right and 5 degrees left (with the auto-stop

removed). A tilt scale has been stamped on

the trunnions.

20. Tilt Indicator-When correctly set, this ver-

nier scale indicates the table angle to the

nearest 1 degree.

21. Tilt Lock-This handle secures the table in

position at any angle in the tilt range.

22. Table Auto-Stop-This bolt beneath the table

automatically sets the table tilt perpendicu-

lar to the blade.

23. Drive Shaft & Hub-The drive shaft trans-

fers power from a motor to the Bandsaw.

(The hub is not used with the Power Stand.)

11

10

12

14

13

9

8

15

19

20

16

17

18

23

22

21

Page 7

SHOPSMITH 11” BANDSAW 555943

Specifications

These specifications of the Shopsmith

Bandsaw give you an idea of its capabilities:

Capacities

The Bandsaw will cut stock up to 6" thick.

With the blade in the normal position, the

cutoff capacity is 10-1/2", which is the dis-

tance across the machine’s throat. However,

with the blade offset 30 degrees right, you can

cut off (freehand) any length of stock up to 3-

7/8" wide.

Available Blades

The Shopsmith Bandsaw accepts continuous-

loop blades 72" long and 1/16"-5/8" wide.

Shopsmith offers a variety of blades from 1/

16" wide to 5/8" wide for cutting wood, plas-

tics and nonferrous metals.

NOTE

To use a 1/16" blade with the Bandsaw, you

must install and use Cool Blocks (Part No.

555374).

Blade Mounting System

Bandsaw blades are mounted on two cast

aluminum wheels 11" in diameter. Both

wheels are covered with rubber tires to pro-

tect the teeth of the blades and provide trac-

tion. The idler (upper) wheel revolves on

needlebearings, while the drive (lower) wheel

revolves on sealed ball bearings. The blades

are tensioned by adjusting the position of the

idler wheel. Blade tracking is first set and

controlled by a preset roller bearing.

Table

The table surface is 13-1/2" x 15-1/2". The

table can be tilted from 0 degree to 45 degrees

right (away from the frame). If the table auto-

stop at “0”, which helps to quickly set the

table perpendicular to the blade.

Speed

The Bandsaw operates best at speeds be-

tween 700 rpm and 1,050 rpm. In “Feet Per

Minute” (fpm), the speed range is 2,000 fpm

to 3,000 fpm. If you use the Shopsmith Mark

V to power the Bandsaw, the speed range is

“Slow” to “D”.

Overall Dimensions and

Weight

Overall, the Shopsmith Bandsaw is 22" wide

(right to left), 30-3/8" high (top to bottom),

and 15" deep (front to back). It weighs 45

pounds.

Electrical Requirements

Circuit

With the Shopsmith Mark V as the power

source, the 1-1/8 hp motor develops 2 hp and

pulls 13-14amps and 115 volts on 60Hz elec-

tricity. The circuit should be rated at least 15

amps. If you use fuses, make sure they are of

the time-delay type.

With the Shopsmith Power Station as the

power source, the 3/4 continuous hp motor

pulls 10 amps and 115 volts on 60Hz electric-

ity. It will develop a maximum of 1hp. The

circuit should be rated at least 15amps. If you

use fuses, make sure they are of the time-

delay type.

Withthe Shopsmith Power Stand as thepower

source, the 1/2hp motor pulls 7.8 amps. The

circuit should be rated at least 15 amps. The

motors run on 115 volts, 60Hz. If you use

fuses, make sure they are of the time-delay

type.

Grounding

The circuit you use should be properly

groundedto protect you from electrical shock.

The plugs on the Mark V, Power Station and

Power Stand have three prongs. The recep-

SHOPSMITH 11” BANDSAW 555943

Page 8

tacle should have three corresponding holes.

Do not modify the plug. If it will not fit the

outlet, have the proper outlet installed. If you

have a two-hole receptacle, use a temporary

adapter to plug in the Mark V. The grounding

lug or wire on the adapter MUST be con-

nected to a permanent ground, such as a

grounded outlet box. The temporary adapter

should be used only until a properly

grounded outlet can be installed. (Adapters

are not allowed in Canada.) If you are unsure

as to whether your outlet box is grounded,

ask a licensed electrician.

Extension Cord

If you use an extension cord, be sure it’s a

three-conductor cord with a grounding plug

and receptacle. The wire gauge must be large

enough to prevent loss of power and over-

heating.

Tools and Supplies Needed:

Power coupling kit (555124)-not needed if

you mount the Bandsaw on the Power

Stand or Power Station (The power cou-

pling kit is standard equipment with all

Mark V’s manufactured after April, 1985.

It is not included with the Bandsaw.)

5/32" Allen wrench (provided)

Adjustable wrench or 1/2" wrench

Clean shop rag

Mineral spirits

Powered graphite

10-wt. machine oil (optional)

Paste floor wax or paste furniture wax

PREPARE THE POWER SOURCE

AND BANDSAW

NOTE

Steps 1-7 assume the power source is the

Mark V. If you are going to use the Power

Station or Power Stand as the power source

for your Bandsaw, follow its respective in-

struction manual for preparing the power

source.

1. Choose the power source you will be

using with your Bandsaw (Shopsmith

Mark V, Power Station or Power Stand).

Loosen the accessory mount lock and in-

sert the eccentric tubes (51) into the holes.

The long end goes up. Orient the top

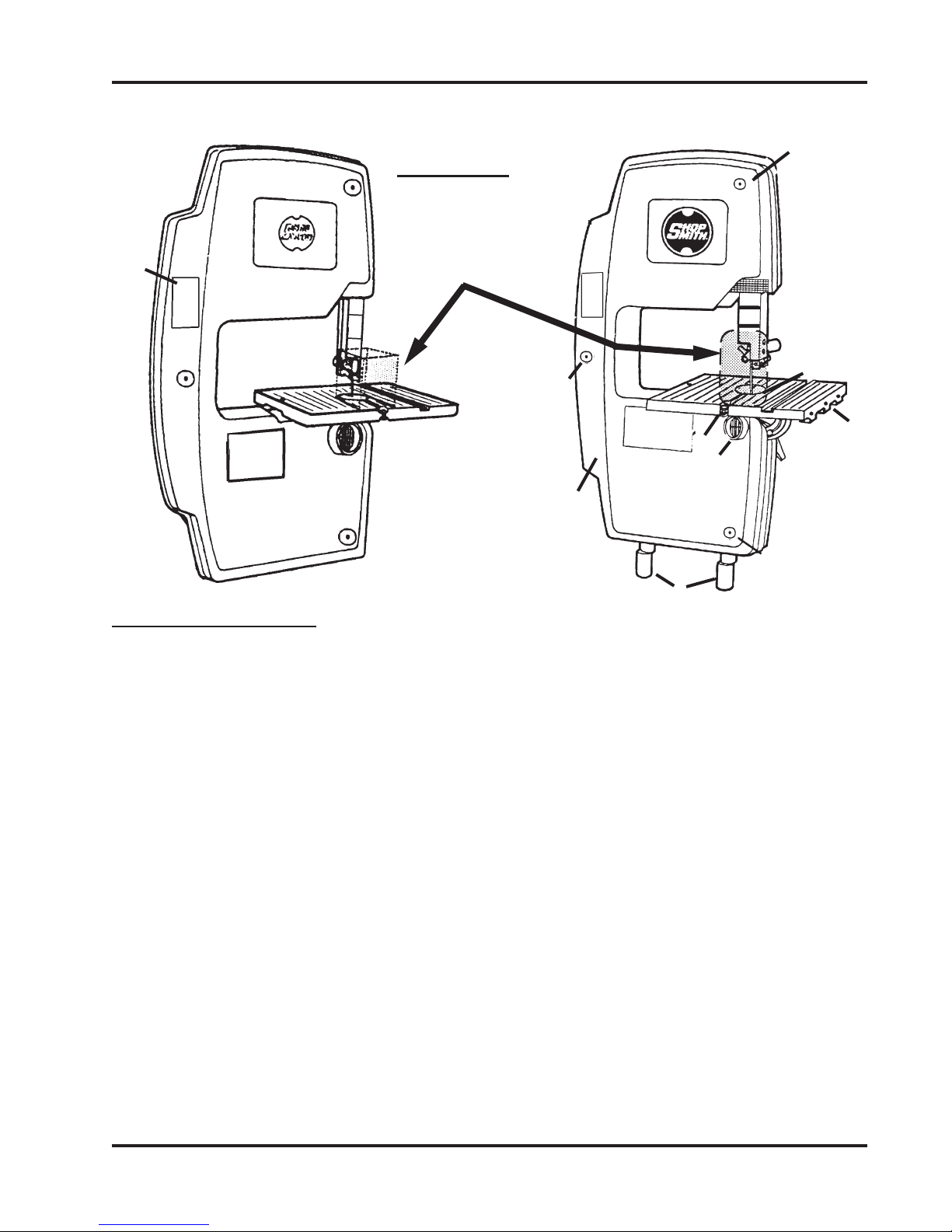

portion of the eccentric tubes away from

the power source, as shown in Fig, 1.

Leave the accessory mount lock

untightened for now.

Cord Length

25 ft.

50 ft.

100 ft.

Minimum Wire Size

14 AWG

12 AWG

10 AWG

Do not use an extension cord with loose wires

or damaged insulation. Also, do not let the

connection between the power cord and ex-

tension cord lie on damp or wet surface.

Assembly

The Shopsmith Bandsaw is sent to you par-

tially unassembled, though a 1/4" blade is

already installed. Leave in the blade for all

Assembly and Alignment instructions. Relax

and take your time. Clear a space on your

workbench and get your tools ready. The

numbers in parentheses refer to the Parts List

and Exploded View (printed separately.) Fig. 1

Page 9

SHOPSMITH 11” BANDSAW 555943

2. Your Bandsaw should look like Fig. 2

(with the table not yet installed). Remove

the three screws and washers then the

cover (6), as shown in Fig. 3.

3. Back out the setscrews (5) in the base of

the Bandsaw, as seen in Fig. 4. Place the

Bandsaw on the tubes, as seen in Fig. 5.

Don’t tighten the setscrews yet.

Fig. 2 Fig. 3

MOUNT AND ALIGN THE DRIVE

HUBS

4. If you have not already done so, mount a

drive hub on the Mark V headstock’s up-

per auxiliary spindle. Use the long hub

with a 5/8" center hole and four grooves in

the circumference.

Fig. 4

Fig. 5

5. Slide the Mark V headstock toward the

Bandsaw until the two drive hubs are 1/4"

apart, as illustrated in Fig. 6.

6. Horizontally align the Bandsaw hub (52)

to the Mark V hub by hand-rotating the

eccentric tubes, as seen in Fig. 7. You have

up to 1/4" movement to the right or left.

When the two hubs are horizontally

aligned, tighten the accessory mount lock,

as illustrated in Fig. 8.

7. Vertically align the Bandsaw hub to the

Mark V hub (shown in Fig. 9) by lifting the

Bandsaw until the tops of the hubs are at

the same height. When holding the

Bandsaw in vertical alignment, use a 5/

32"Allen wrench to tightenbothsetscrews,

as shown in Figs. 10 and 11. You may want

a helper to lift and hold the Bandsaw

while you are tightening the setscrews.

Fig. 6 Fig. 7

Fig. 8 Fig. 9

Fig. 10 Fig. 11

SHOPSMITH 11” BANDSAW 555943

Page 10

PREPARE THE BANDSAW AND

TABLE ASSEMBLY

8. Inspect the inside of the Bandsaw and

wipe away any dirt of foreign material.

Use a clean shop rag and mineral spirits or

turpentine,but becareful aroundtheblade.

It’s sharp!

9. When the table is clean, wax the top sur-

face and the miter gauge slots with paste

floor wax or paste furniture wax. Apply

wax sparingly, then buff it thoroughly. A

good coat of wax improves the machine’s

operation by helping the wood slide

smoothly over the table and the miter

gauge slide easily in the table slot.

NOTE

Don’t use car wax or spray furniture polish

on the Bandsaw. Car wax offers good protec-

tionfor metal, but it’s extremely hard andhas

little value as a lubricant. Furniture polish

isn’t hard enough. Paste floor wax or furni-

ture wax protects and lubricates.

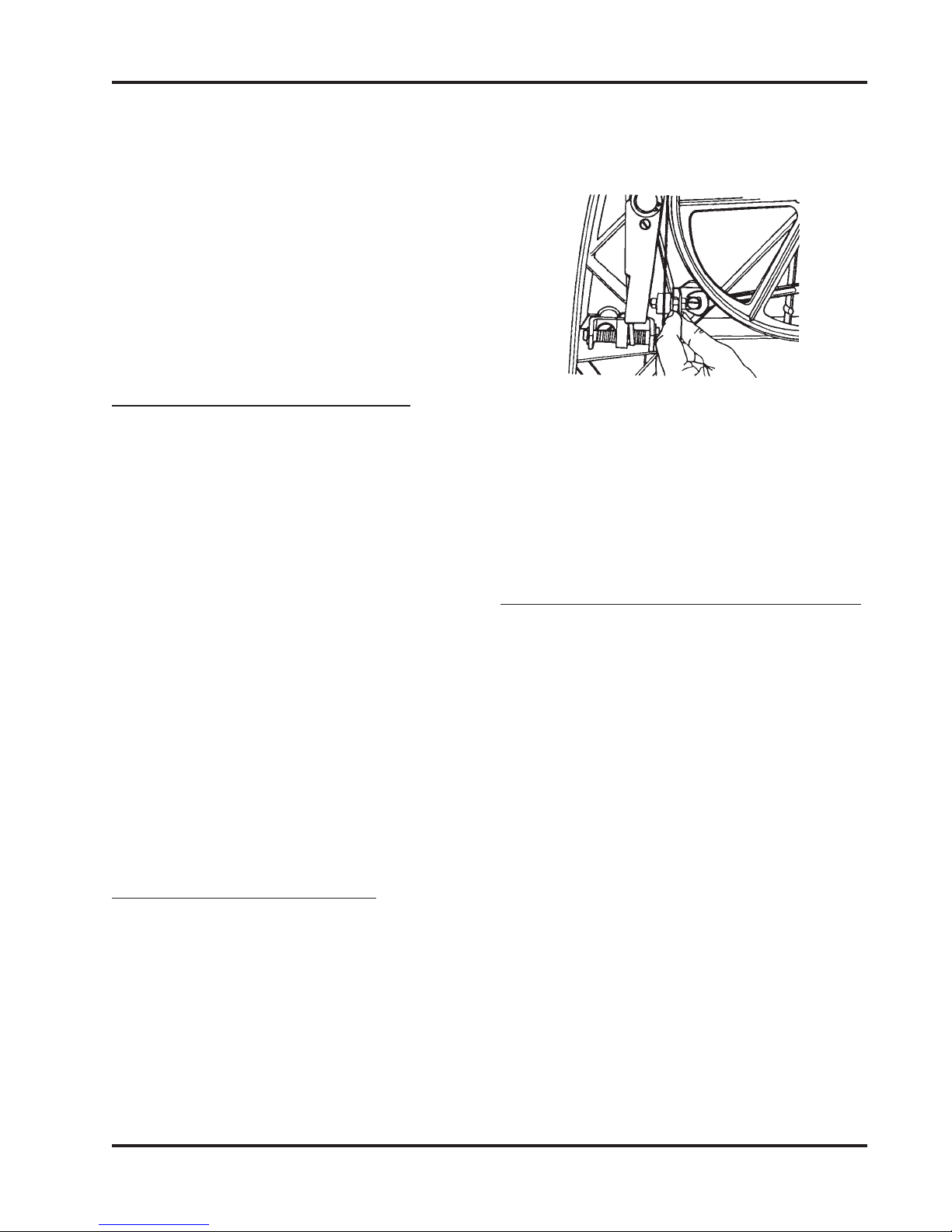

10. Loosen the tilt lock (44) and lubricate the

trunnions (37) with powdered graphite,

rocking them back and forth as you apply

the graphite, as seen in Fig. 12. (You will

do this periodically, as discussed in the

Maintenance Schedule, on page 34.)

Fig. 12

Fig. 13

11. Apply graphite to lubricate the blade

tensioning screw (23), upper blade guide

post (71), and the threads of the upper and

lower blade guide adjusting knobs

(82,104).

We recommend powdered graphite for lubri-

cating the Bandsaw because it’s dry and

doesn’t attract sawdust. On some parts, oil

will mix with sawdust and form a gummy

substance that prevents these parts from op-

erating smoothly. However, if you can’t get

graphite, you can apply a light 10-wt. ma-

chine oil (such as sewing machine oil) spar-

ingly. Use only 1-2 drops. Apply oil to all the

parts that need lubrication, with the excep-

tion of the trunnions. If you don’t dust the

trunnionswithgraphite, youshould waxthem.

INSTALL THE TABLE

12. Position the trunnions (37) at approxi-

mately 25 degrees and lock them. Fig. 13

shows the exposed trunnions. Hold the

table (87) perpendicular to the blade, and

mount the table on the Bandsaw, as dem-

onstrated in Fig. 14. Make sure the table

leveling bolt (89) and the table insert (95)

are removed.

13. Insert a thin shim washer (48) between the

table (87) and each trunnion bracket.

14. Attach the table to the Bandsaw with bolts

(35) and thick washers (34), as shown in

Fig. 15. Finger tighten only.

Fig. 14

Page 11

SHOPSMITH 11” BANDSAW 555943

Fig. 18

Fig. 16

Fig. 19

15. Screw the socket head screw (91) in the

hole located at the back of the table, as

seen in Fig. 16.

16. Attach a hex nut (92) to the socket head

screw, as shown in Fig. 17.

Fig. 17

Fig. 15

Alignment

Your Shopsmith 11” Bandsaw comes to you

pre-aligned from the factory. It is important

to check all of the following alignment and

adjustment procedures, if you have prob-

lems with your cut accuracy. Also, it is impor-

tantto recheck themat regular intervals. These

steps are to be preformed using the already

mounted 1/4" wide blade and in the sequence

presented.

Tools Needed:

7/16" or adjustable wrench

5/32" Allen wrench

1/2" wrench

Precision square

Medium screwdriver

Medium Phillips screwdriver

Small (#0) Phillips screwdriver

WARNING

• The Bandsaw MUST be disconnected (or

unplugged) from its power source before per-

forming any alignment, adjustment, mainte-

nance or repair procedure. Do NOT rely

solely on the power switch.

• DO NOT install the power coupler at this time

or attempt to run the Bandsaw until you have

completed the remainder of the procedures in

thissection. It is dangerous torun the Bandsaw

until it is COMPLETELY aligned, adjusted

and inspected.

Blade Tracking System

Bandsaw blades revolve in an endless loop

on two wheels, the drive wheel (28) and the

idler wheel (24). Each of these wheels is

covered with a thin rubber tire to protect the

teeth of the blade and provide traction. The

idler (upper) wheel pivots on an arm (19), and

this arm is drawn upward by a flat spring (15).

17. Loosen and return the Bandsaw’s trun-

nion to “0”, where the table is supposed to

be perpendicular to the blade. Lock the

trunnion. See Fig. 18.

18. Install the leveling bolt (89) and knurled

nut (88) on the table, as in Fig. 19.

SHOPSMITH 11” BANDSAW 555943

Page 12

This mechanism compensates for slight in-

consistencies in blade length and tensions the

blade.

The tension is adjusted by turning the blade

tension screw (23) to the left of the idler wheel.

This screw moves the flat spring, increasing

or decreasing tension. The proper tension for

various blades is indicated on a scale above

the blade tensioning screw. See Fig. A-1.

Unlike many other bandsaws, blade tracking

for the Shopsmith Bandsaw is done automati-

cally with no need for adjustment. A roller

bearing to the right of the blade tension indi-

cator keeps the blade properly positioned on

the wheels.

A Bandsaw blade is supported and guided

from both above and below. See Fig. A-2. The

lower blade guide consists of a roller bearing

(98) to back up the blade and two guide

blocks (101,106) to keep it from twisting. Each

guide block is adjusted side-to-side by loos-

ening an Allen screw (100), and front-to-back

by turning the lower blade guide adjusting

knob (103). You need only to adjust the lower

blade guide roller bearing side-to-side. This

is done by loosening the mounting bolt (110).

The upper blade guide is similar, but it has

two additional adjustments. The upper blade

Fig. A-1

Fig. A-2

guide’s roller bearing (63) is adjusted front-

to-back by turning two screws (68). The blade

guide post (71) and roller bearing can be

adjusted side-to-side with the mounting bolts

(64). The entire assembly can be raised and

lowered after loosening the upper blade

guide’s height lock handle.

Aligning the Blade Tension Scale

The blade tension scale (12) is aligned at the

factory, and under normal conditions it

shouldn’t need adjustment. To check the

blade tension scale’s alignment, perform the

following steps:

NOTE

View the tensioning screw through the window.

1. Release the blade tension so the blade is

completely slack on the wheels.

2. Loosen the screw (10) near the top of the

scale, as seen in Fig. A-3.

Fig. A-3

Pivot Arm

Flat

Spring

Blade

Tension

scale

Blade

Tension

Screw

Auto-track

roller bearing

Upper

Wheel

Page 13

SHOPSMITH 11” BANDSAW 555943

3. Rotate the scale so it’s left edge (above the

notch) is parallel to and even with the red

indicator bar.

4. Hold the scale in position and tighten the

screw.

5. Re-tension the blade to the 1/4" setting on

the scale.

6. Spin the upper wheel (24) several times to

make sure the blade is turning freely.

Adjusting the Roller Bearings

The Shopsmith Bandsaw uses roller bearings

to keep the blade tracking properly on the

wheels and to provide support for the blade

during cutting operations. These bearings

are adjusted at the factory and should seldom

need further attention. However, it’s a good

idea to check the alignment of these bearings

each time you change blades.

You must mount and tension a blade in the

Bandsaw before you can properly adjust the

bearings. The blade should be centered on

the three roller bearings. The back of the

blade should rest against the auto-track roller

bearing. The lower blade guide’s roller bear-

ing. Also, the blade should be no more than

1/64" away from the upper blade guide’s

roller bearing. Be careful when you make

adjustments, since the blade is sharp.

Auto-Track Roller Bearing

The auto-track roller bearing (56) is near the

blade tension scale, at the upper left side of

the machine. The bearing guides the blade

onto the upper wheel. The front-to-back po-

sition of this bearing is fixed and shouldn’t be

altered. However, the mounting bracket can

be moved side-to-side so that you can center

the bearing behind the blade.

1. If the blade appears off center, loosen the

1/2" mounting bolt (59) that holds the

bracket (57) to the Bandsaw frame, as

shown in Fig. A-4.

Fig. A-4

2. Slide the bracket sideways until the slot in

the bearing is centered behind the blade

and tighten the mounting bolt.

3. Be careful to keep the sides of the bearing

parallel to the blade when tightening this

bolt.

Lower Blade Guide’s Roller Bearing

The roller bearing (98) directly below the

Bandsaw table serves two functions: It guides

the blade onto the drive wheel and it backs up

the blade beneath the table while you’re cut-

ting. Like the auto-track roller bearing, its

front-to-back position is fixed and shouldn’t

be changed. However, the entire lower blade

guide assembly, including the bearing, may

be adjusted side-to-side.

1. If adjustment is needed, loosen the guide

blocks (101,106)-if you haven’t done so

already-and pull them out about 1/16"

from the blade.

2. Loosenthe 1/2" mounting bolt (110) which

holds the lower blade guide assembly to

the Bandsaw frame, as seen in Fig. A-5.

The head of this mounting bolt can be

reached from the back of the Bandsaw, just

above the trunnion.

SHOPSMITH 11” BANDSAW 555943

Page 14

3. Slide the lower blade guide sideways until

the bearing is centered behind the blade,

tighten the mounting bolt, and reset the

guide blocks.

4. Again, be sure to keep the bearing parallel

to the blade as you’re tightening the bolt.

Adjusting the Upper Blade Guide’s

Roller Bearing

The upper blade guide’s roller bearing (63)

backs up the blade above the table. Unlike the

other two bearings, it can be adjusted side-to-

side and front-to-back.

1. Use a 7/16" wrench to remove the blade

guard, as shown in Fig. A-6.

Fig. A-5

2. Set the height of the upper blade guide to

about 1" above the table.

3. Use a 5/32" Allen wrench to loosen the

guide blocks. Pull them away from the

blade about 1/16".

Fig. A-6

Fig. A-7

4. Use a 1/2" wrench to loosen the two

mounting bolts (64) which hold the guide

post bracket (70) to the Bandsaw frame, as

seen in Fig. A-7.

5. Swing the upper blade guide sideways

until the bearing is centered behind the

blade, then tighten the mounting bolts.

The upper blade guide’s roller bearing

must also be adjusted so that it’s no more

than 1/64" away from the back of the

blade. This distance should remain the

same no matter what the position of the

upper blade guide is above the table.

6. Before you adjust the upper blade guide’s

rollerbearing front-to-back, check the dis-

tance from the bearing to the blade close

to the table and 5"-6" above the table.

7. If the upper roller bearing presses against

the back of the blade or if it’s farther away

than 1/64" at both the high and low posi-

tion, you’ll need to adjust the upper blade

guideroller bearing forward or backward.

If this distance is inconsistent or if the

bearing seems to press against the blade

more at one position than at the other, you

also need to change the tilt of the guide

post. Both adjustments are similar and

are performed at the same time.

8. Loosen the 1/2" jam nuts on the two guide

post adjusting screws (68), as seen in Fig.

A-8, then proceed in this manner:

Fig. A-8

Page 15

SHOPSMITH 11” BANDSAW 555943

Tomovetheguidepost and bearing closer

to the blade (without changing the tilt of

the guide post) turn both of the adjusting

screws an equal number of revolutions

counterclockwise.

To move the guide post and bearing away

from the blade (without changing the tilt

of the guide post), turn both of the screws

an equal number of revolutions clock-

wise.

9. If the bearing is not the same distance

away from the blade close to the table and

5"-6" above it, turn each screw equally in

opposite directions. This will change the

tilt of the guide post.

For example, to move the bearing closer

to the blade when the blade guide is at its

lower position, turn the top adjusting

screw clockwise, and the bottom adjust-

ing screw counterclockwise.

To move the bearing away from the blade

at this position, reverse the procedure.

Figs. A-9 and A-10 show making adjust-

ments.

Fig. A-9 Fig. A-10

Getting these adjustments just right may

take some time, but once you’ve got them

right they will seldom need attention.

Here are a few tips to help make this

procedure a little easier:

•Markyour starting positionwitha grease

pencilandturn the screws only 1/4 revo-

lution at a time until you see how much

the bearing moves with each minor ad-

justment.

•Be sure that when you lock the upper

blade guide height lock handle, the up-

per blade guide’s roller bearing does

not push the blade away from the lower

blade guide roller bearing.

•Each adjustment of the post will change

the tension on the upper blade guide’s

height lock. To adjust the lock tension,

follow the procedure described in “Ad-

justing the Upper Blade Guide’s Height

Lock” in this section. Once you’ve com-

pleted these adjustments to your satis-

faction,hold the screw from turning with

a screwdriver and tighten the jam nuts.

See Fig. A-11.

Check each roller bearing one more time.

Withthe bearings correctly adjusted,theblade

should ride in the center of all three of them.

The back of the blade should lightly contact

the auto-track roller bearing and the lower

blade guide’s roller bearing, and it should be

no more than 1/64" away from the upper

blade guide’s roller bearing no matter what

the position of that bearing is above the table.

10. Reattach the blade guide.

WARNING

Never attempt to operate the Bandsaw with-

out the blade guard in place.

Fig. A-11

SHOPSMITH 11” BANDSAW 555943

Page 16

Adjusting the Upper Blade Guide’s

Height Lock

The upper blade guide can be locked at any

height 0"-6" above the table. To change the

height of the blade guide:

1. Swing the upper blade guide’s height

lock handle 90 degrees to the right to

loosen the locking mechanism.

2. Adjust the upper blade guide so that it’s

no more than 1/4" above the surface of the

stock to be cut.

3. Lock the guide in place by swinging the

handle so that it points straight back (to-

ward the outfeed side of the table).

4. Ifthe movementof the upperblade guide’s

height lock seems stiff (or loose), you

need to adjust the tension on the locking

spring (72). This tension is set by a small

headless screw (73) in the left side of the

guide post retainer between the mount-

ing bolts. There should be enough ten-

sion to hold the guide post securely when

locked in place, but not so much that the

lock handle is difficult to operate or that

the guide post will not slide easily when

the lock is released. See Fig A-12.

•To increase the lock tension, turn the

adjusting screw counterclockwise.

•To reduce the tension, turn it clock-

wise.

NOTE

The tension on the blade guide’s height lock

is correctly set when you unlock the handle

and the upper blade guide drops smoothly

to 1/4"-1/2" above the tabletop, with no need

to pull it down.

Adjusting the Upper Blade Guide’s

Column Post Screw

The nylon screw (65) is adjusted at the at the

factory and should need only periodic check-

ing. It helps control side-to-side movement of

the column post within the column bracket.

Tightenthe nylon screw with a 3/8" wrench to

put more pressure on the column post (thus

eliminating more side to side movement”.

Loosen the nylon screw to put less pressure

on the column post. See Fig. A-13.

ADJUST THE T-SLOT EXTRUSION

1. Use a precision square to double check

your miter gauge for squareness. See Fig.

A-14. Adjust the miter gauge to be square,

if needed.

Figure A-12 Figure A-13

Figure A-14

Figure A-15

Figure A-16

Page 17

SHOPSMITH 11” BANDSAW 555943

2. Place the miter gauge in the table’s T-slot.

3. Use a 5/32" Allen wrench to remove the

expansion screw found in the center of the

miter gauge’s guide bar. See Fig. A-15.

4. Use a medium Phillips screwdriver to

adjust the tension of each of the five screw

(94) which attach the T-slot extrusion to

the table, as shown in Fig. A-16. The

tension should be such that the miter

gauge will both travel freely in the T-slot

and have a snug fit. After adjusting the

screws, replace the expansion screw in

the miter gauge guide bar.

ALIGN THE TABLE TO THE BLADE

1. With the miter gauge still in the T-slot,

place the precision square against both

the face of the miter gauge and the blade.

See Fig. A-17.

NOTE

The precision square’s “blade” must contact

the Bandsaw blade on either the blade’s

gullet or a tooth set away from the square. If

it is positioned on a tooth which is set toward

the square, alignment will not be accurate.

Figure A-17

2. Keep the square on the miter gauge, and

slide the miter gauge and square forward

until the base of the square reaches the

Bandsaw blade, as in Fig. A-18. If there is

agap between the square and the Bandsaw

blade or if the blade gets in the path of the

square, adjust the table (as the left hand is

doing in Fig. A-19) until the gap is elimi-

nated-or the blade is no longer in the path

of the square.

When the table is square to the blade, the

square’s blade should slide along the

Bandsaw blade without any gaps or inter-

ference. After you have adjusted the table,

recheck the table’s alignment by repeating

this step.

Figure A-18

Figure A-19

Figure A-20

3. Use a 1/2" wrench to securely tighten the

four bolts (35) attaching the table to the

Bandsaw. See Fig. A-20. It is easier to

tighten the front two bolts, then tilt the

table 15 degrees-25 degrees to tighten the

remaining two bolts. After tightening,

reset the table at 0 degree and lock the

trunnion.

NOTE

To assure the accuracy of the table’s align-

ment, test cut a piece of scrap wood and

check for squareness. If it is not square,

repeat Steps 2 and 3.

4. Remove the miter gauge from the table.

Then raise the Bandsaw’s saw guard all

the way and lock it.

SHOPSMITH 11” BANDSAW 555943

Page 18

5. Place a precision square along the side of

the blade and on the table, as in Fig. A-21.

6. If the blade is square to the table, use a 5/

32" Allen wrench to adjust the table height

screw (91) to touch the Bandsaw casting. If

the blade is not square to the table, loosen

the trunnion, make the necessary adjust-

ment and lock the trunnion. Now adjust

the table height screw. See Fig. A-22

Figure A-21 Figure A-22

Figure A-23

7. Hold the table height screw in place, while

you use a 1/2" wrench to tighten the hex

nut against the table, see Fig. A-23.

ALIGN THE TABLE SCALE TO THE TRUN-

NION SCALE

1. If the “0” marks on the table scale and the

Bandsaw’s trunnion scale so not align, use

a medium Phillips screwdriver to slightly

loosen the table scale’s screws (32), as

shown in Fig. A-24. Align the “0” marks

and retighten the screws.

ADJUST THE BLADE GUIDES

1. Turn the blade guide adjusting knobs,

shown in Figs. A-25 and A-26, until the

front edges of the guide blocks are just

short of the bottom of the gullets between

the teeth, as illustrated in Fig. A-27. If the

guide blocks extend beyond the gullets,

the teeth will nick the sides of the blocks,

wearing away the blade guides and dull-

ing the blade.

Figure A-24

Figure A-25

Figure A-26

Figure A-27

2. With the locking screws (76,100) loose,

push each of the four guide blocks-two in

the upper blade guide and two in the

lower blade guide-toward the blade until

they just barely clear it on each side. This

clearance should be about .003-.005". Figs.

A-28-A-31 show adjusting the four guide

blocks.

An easy way to gauge the distance of the

blades from the blocks is with tape. Put a

piece of cellophane tape on each side of

the blade, then push the blocks in until

they touch the tape. Tighten the locking

screws and remove the tape. Again, refer

to Figs. A-28-A-31. Many woodworkers

use notebook paper or a crisp dollar bill to

Page 19

SHOPSMITH 11” BANDSAW 555943

gauge the guide clearance. Use which-

ever works best for you.

Be careful that the guide blocks do not

press the blade to one side or the other.

The blade should not be deflected when

the blocks are properly set, as shown in

Fig. A-32.

NOTE

Adjust the blade guides very carefully:

−−

−−

−If the guide blocks are too close to the

blade or too far forward, the blade guides

may interfere with the running blade.

−−

−−

−If the guide blocks are too far apart or too

far back, the blade may “lead”-wander off

the pattern line to one side or the other.

−−

−−

−If you’re sure the blade guides are prop-

erly adjusted and the blade does not operate

freely, check if the blade is bent or has a

“high spot” at the weld.

−−

−−

−If the blade continues to lead no matter

how you adjust the guides, follow the proce-

dure described in “Correcting Blade Lead”

in the Troubleshooting section on page 34.

Figure A-28

Figure A-29

Figure A-30

Figure A-31

Figure A-32

3. Spin the upper (idler) wheel by hand to be

certain the blade guides don’t interfere

with the action of the blade. Also, watch

the blade as it slips between the guide

blocks. Check that the teeth remain in

front of the blocks throughout the revolu-

tion of the blade. If the blade does not spin

freely or the teeth stray behind the blocks,

readjust the blade guides.

WARNING

Use only Shopsmith Bandsaw blades for your

Bandsaw. If you use other blades, be certain

that they are of premium quality, are 72" long

(plus or minus 1/2"), and are between 1/16" and

5/8" wide. ANY OTHER BLADES ARE UN-

SAFE. Also, when using 1/16" blades, you must

install Cool Blocks (Part No. 555374) in place of

the standard metal blade guides.

INSTALL THE TABLE INSERT

1. The table insert (95) has two clips on its

underside, as shown in Fig. A-33. Put the

blade into the insert’s slot so the solid part

of the insert is on the blade’s tooth side.

Figure A-33

SHOPSMITH 11” BANDSAW 555943

Page 20

2. Clip the insert in its hole, as in Fig. A-34,

with the clips going into the table first.

Figure A-34

Figure A-35

Figure A-36

3. Snapdown the front of the insert, as shown

in Fig. A-35.

4. Use a very small Phillips screwdriver (96)

to adjust the leveling screws (90) through

holes in the insert so it is uniformly flush

with the edge of the Table. See Fig. A-36.

5. Reattach the Bandsaw cover with the three

screws and washers.

Alignment and Adjustment

Safety Checklist

When you’ve finished aligning and adjusting the

various parts of your Bandsaw, review your

work according to this checklist. Make copies of

it and perform each item before operating you

Bandsaw, especially when it has set idle for more

than a few days.

1. Is the Bandsaw blade properly mounted and

tensioned.

2. Is the blade centered on the roller bearings?

Does it rest against the auto-track roller bear-

ing and lower blade guide’s roller bearing,

while remaining no more than 1/64" away

from the upper blade guide’s roller bearing?

3. Are the blade guides properly adjusted?

4. Is the height of the upper blade guide’s height

lock properly adjusted?

5. Is the upper blade guide positioned no higher

than 1/4" above the stock, and is locked

securely in place?

6. Does the blade operate freely?

7. Is the table insert in place and flush with the

table top?

8. Is the table properly aligned to the blade?

9. Is the table adjusted to the correct work angle

and is the tilt lock secured?

10. Are the drive hubs properly aligned?

11. If you’re using the Mark V or Power Station

to power the Bandsaw, is the power coupler

installed correctly? Are both the accessory

mount lock and the headrest lock tightened

on the Mark V? Is the carriage locked on the

Power Station?

12. If you’ve mounted the Bandsaw on a Power

Stand, is the V-belt properly tensioned and

the pulley guard in place?

This manual suits for next models

1

Table of contents

Other Shopsmith Saw manuals