Installation Instructions

For Showermate Universal

Single & Twin Pumps

U2.6 bar Single U1.8 bar Twin

U2.6 bar Twin

INDEX . . . . . . . . . . . . . . . . . Page No

Product Description. . . . . . . . . . . . . . . . . . . 1

Application. . . . . . . . . . . . . . . . . . . . . . . . . . 1

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

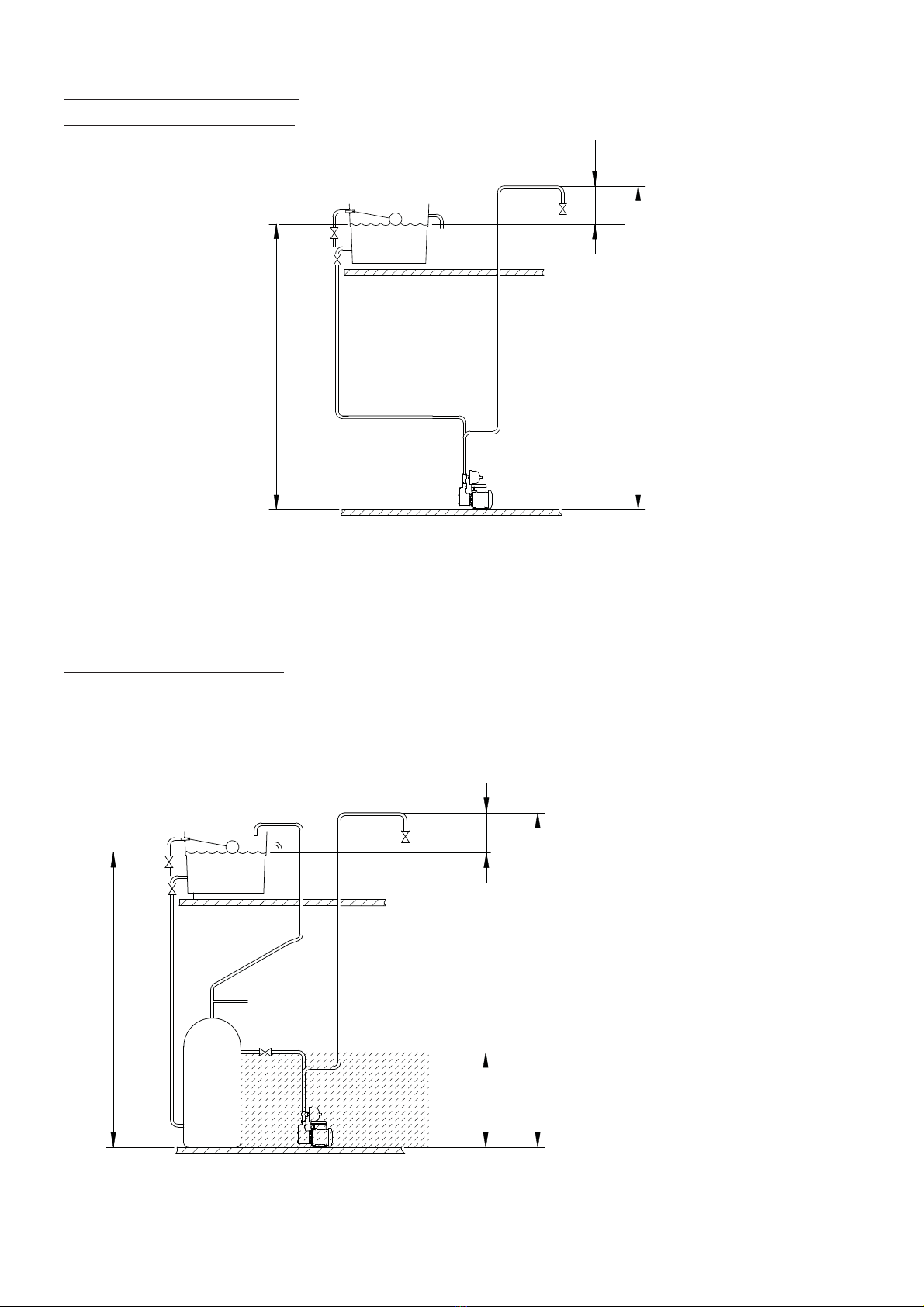

Typical Installation. . . . . . . . . . . . . . . . . . . . 2

Pump Location. . . . . . . . . . . . . . . . . . . . . . . 3

Pipework . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

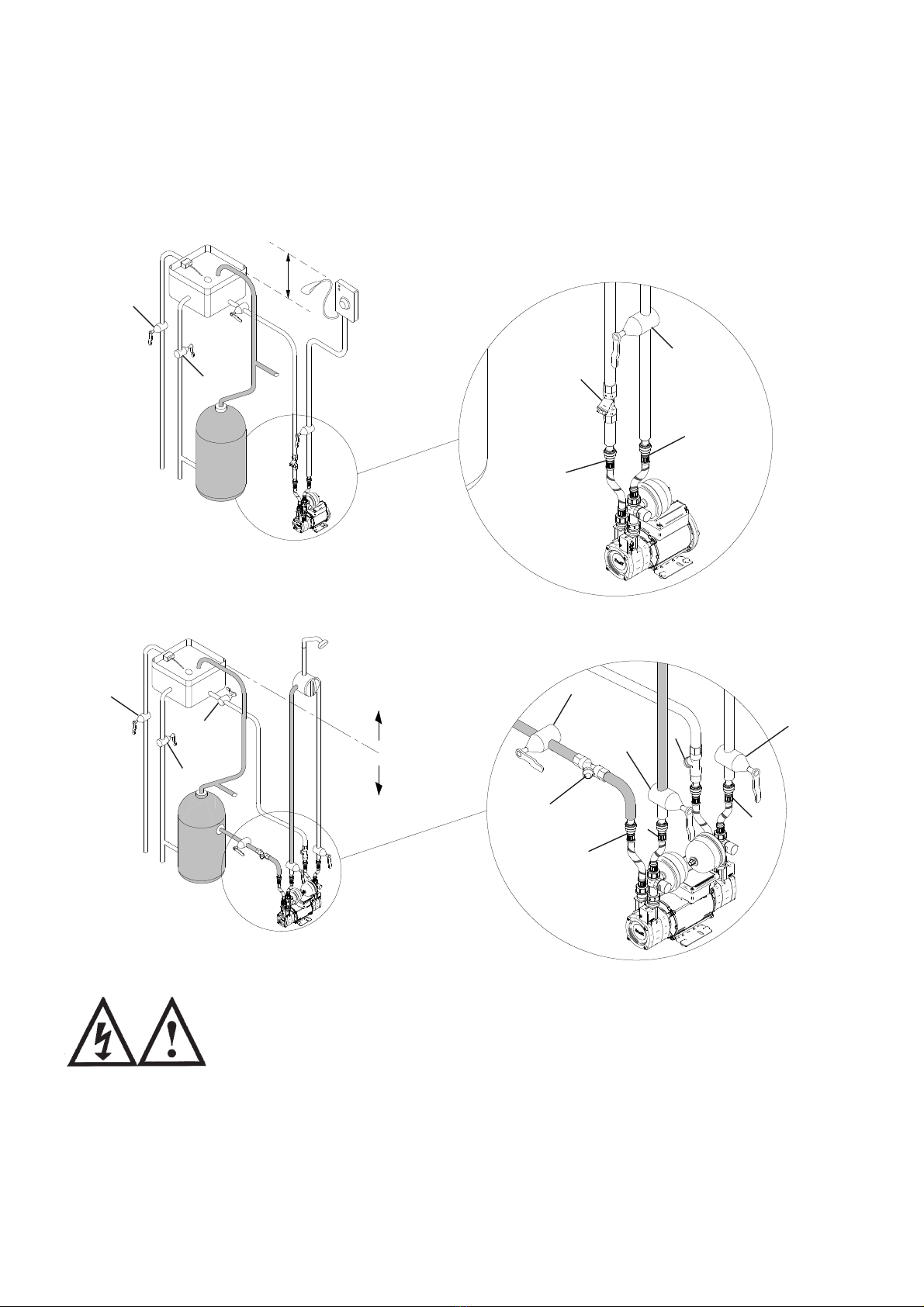

Pump Connections . . . . . . . . . . . . . . . . . . . 8

INDEX . . . . . . . . . . . . . . . . . Page No

Electrical Installation . . . . . . . . . . . . . . . . . . 12

Commissioning . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 16

Technical Specification . . . . . . . . . . . . . . . . 18

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Trouble Shooting Guide. . . . . . . . . . . . . . . . 19

Environment Protection . . . . . . . . . . . . . . . 20

PRODUCT DESCRIPTION

Electric motor driven single or twin ended peripheral pumps complete with an automatic

control system, consisting of flow switches, pressure switches, pressure vessels and

electronic control.

APPLICATION

Showermate Universal pumps are suitable for positive or negative head installation

conditions. The pumps are designed for single shower pressure boosting applications in

vented stored water systems. Inlet pressures to the pump and ambient temperatures must

not exceed the values given in the technical specifications.

This pump set must not be used for any other application without the

written consent of Stuart Turner Limited and in particular, must not be

connected directly to the mains water supply.

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible

for their safety.

Children should be supervised to ensure that they do not play with the

appliance.

WARNING - Washer/condenser dryers and condenser dryers.

The pump must not be used in the water supply line to a washer/

condenser drier or a condenser drier, which uses a constant flow of

cold water to aid the condenser drying process, as damage can occur

to the pump. If in doubt or for further information contact Stuart

Turner Ltd.

Please leave this instruction booklet with the pump as it contains

maintenance and safety information (Original Instructions)