SIGNAL INSTRUMENT Signal User manual

The SIGNAL INSTRUMENT Co. Ltd.

12 Doman Road, Camberley

Surrey, GU15 3DF

England

Tel: +44 (0) 1276 682841

Fax: +44 (0) 1276 691302

Part Number 250/335050

250SM COOLER DRYER

OPERATING MANUAL

250SM OPERATING MANUAL

Page 2 of 26 250/335050 Issue 1.01

DOCUMENT HISTORY

ISSUE AMENDMENT DATE

1.00 First Issue December 9,1996

1.01 Addition of Warranty Statement January 6, 1999

250SM OPERATING MANUAL

250/335050 Issue 1.01 Page 3 of 26

© The Signal Instrument Co. Ltd.

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system or transmitted

in any form or by any means - electronic, mechanical, photocopying, recording or otherwise - without the

prior written permission of The Signal Instrument Co. Ltd.

While we believe that the information and guidance given in this manual is correct, all parties must rely

upon their own skill and judgement when making use of it. The Signal Instrument Co. Ltd. will not assume

any liability to anyone for any loss or damage caused by any error or omission in the manual, whether such

error or omission is the result of negligence or any other cause. Any and all such liability is disclaimed.

250SM OPERATING MANUAL

Page 4 of 26 250/335050 Issue 1.01

CONTENTS

1. INTRODUCTION................................................................................................................7

1.1 Cooler............................................................................................................................................................7

1.2 Applications..................................................................................................................................................7

1.3 Getting Started ..............................................................................................................................................7

1.4 Special Requirements....................................................................................................................................7

2. SPECIFICATION................................................................................................................8

2.1 Sample Heat Removal...................................................................................................................................8

2.2 Sample Input.................................................................................................................................................8

2.3 Sample Outlet................................................................................................................................................8

2.4 Response time...............................................................................................................................................8

2.5 Peristaltic Pump ............................................................................................................................................8

2.6 Environment..................................................................................................................................................8

2.7 Power ............................................................................................................................................................9

2.8 Analogue Output...........................................................................................................................................9

2.9 Alarm Limits.................................................................................................................................................9

2.10 Alarm Relay................................................................................................................................................9

2.11 Physical Dimensions...................................................................................................................................9

2.12 Sample Path.................................................................................................................................................9

2.13 Safety ..........................................................................................................................................................9

3. INSTALLATION...............................................................................................................11

3.1 Introduction.................................................................................................................................................11

3.2 Typical Application Configurations............................................................................................................11

3.3 Basics..........................................................................................................................................................12

3.4 Location ......................................................................................................................................................13

3.5 Mains Power Connections ..........................................................................................................................13

3.6 Gas Connections .........................................................................................................................................15

3.7 Water Drain.................................................................................................................................................15

3.8 Alarm Relay................................................................................................................................................15

3.9 Alarm Connections .....................................................................................................................................15

4. BASIC OPERATION........................................................................................................17

4.1 Introduction.................................................................................................................................................17

4.2 Installation...................................................................................................................................................17

4.3 Start Up.......................................................................................................................................................17

4.4 Shut Down ..................................................................................................................................................17

5. OPERATION .....................................................................................................................18

5.1 Introduction.................................................................................................................................................18

5.2 Description..................................................................................................................................................18

5.3 Alarm Conditions........................................................................................................................................19

5.4 Using The Alarm Relay ..............................................................................................................................19

5.5 Controlling Signal Analysers......................................................................................................................20

5.6 Remote Temperature Monitoring................................................................................................................20

6. TROUBLE SHOOTING...................................................................................................21

6.1 Intermittent Water Alarm............................................................................................................................21

6.2 Output Dew Point Deviations .....................................................................................................................21

6.3 Sample Dew Point.......................................................................................................................................21

7. TECHNICAL DESCRIPTION.........................................................................................22

7.1 Description..................................................................................................................................................22

7.2 Peltier Cooling Elements.............................................................................................................................22

250SM OPERATING MANUAL

250/335050 Issue 1.01 Page 5 of 26

8. ROUTINE MAINTENANCE...........................................................................................23

8.1 Catch Pot Water Removal ...........................................................................................................................23

8.2 Peristaltic Pump Tube Replacement............................................................................................................24

8.3 Fuse Replacement........................................................................................................................................24

8.4 Spares Kit....................................................................................................................................................24

9. ROUTINE SERVICING...................................................................................................25

9.1 Policy...........................................................................................................................................................25

9.2 Servicing......................................................................................................................................................25

9.3 Spares Kit....................................................................................................................................................25

10. WARRANTY....................................................................................................................26

Tables

Table 1 Fuse and VA Rating..................................................................................................................................9

Figures

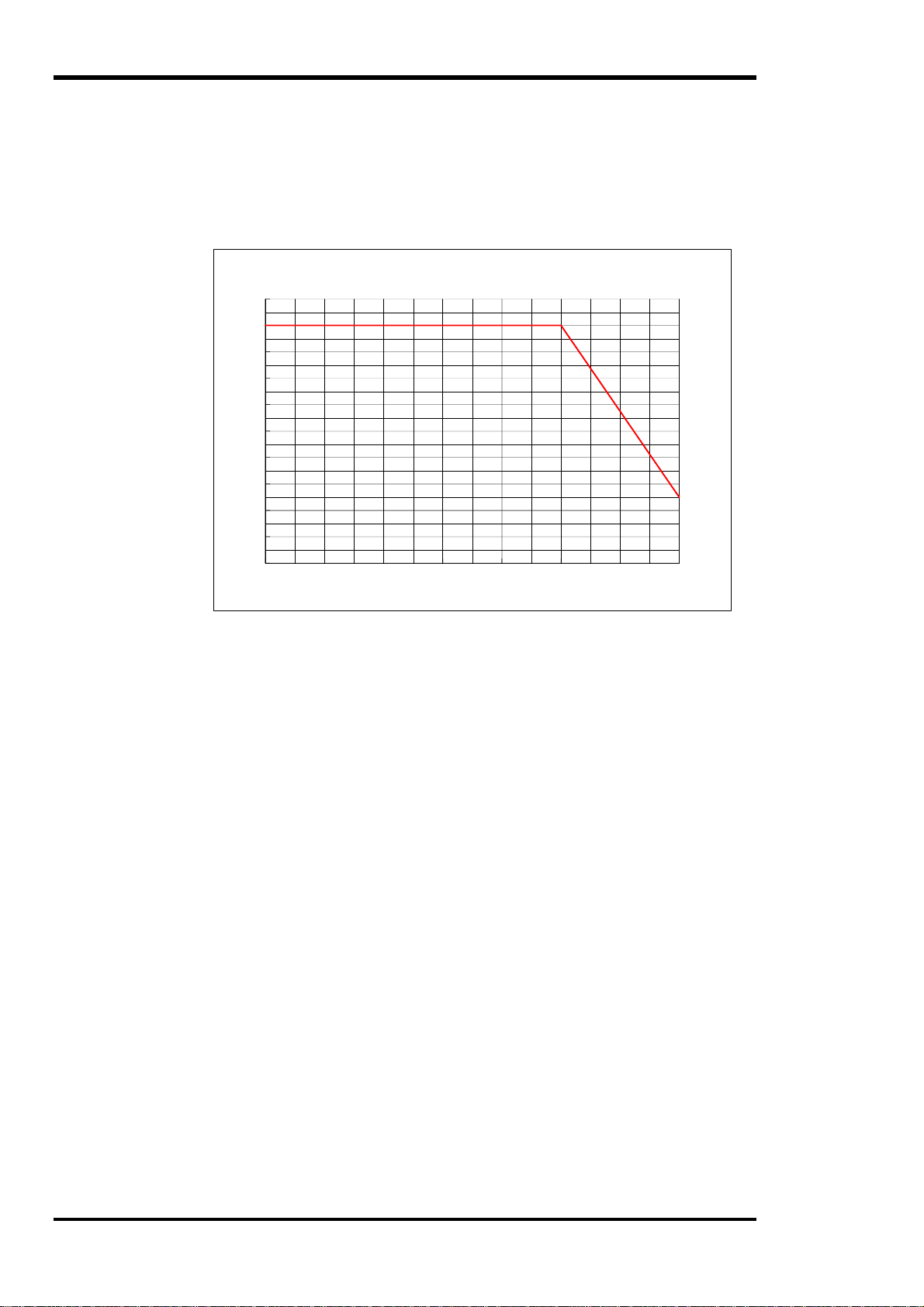

Figure 1 Channel Performance...............................................................................................................................8

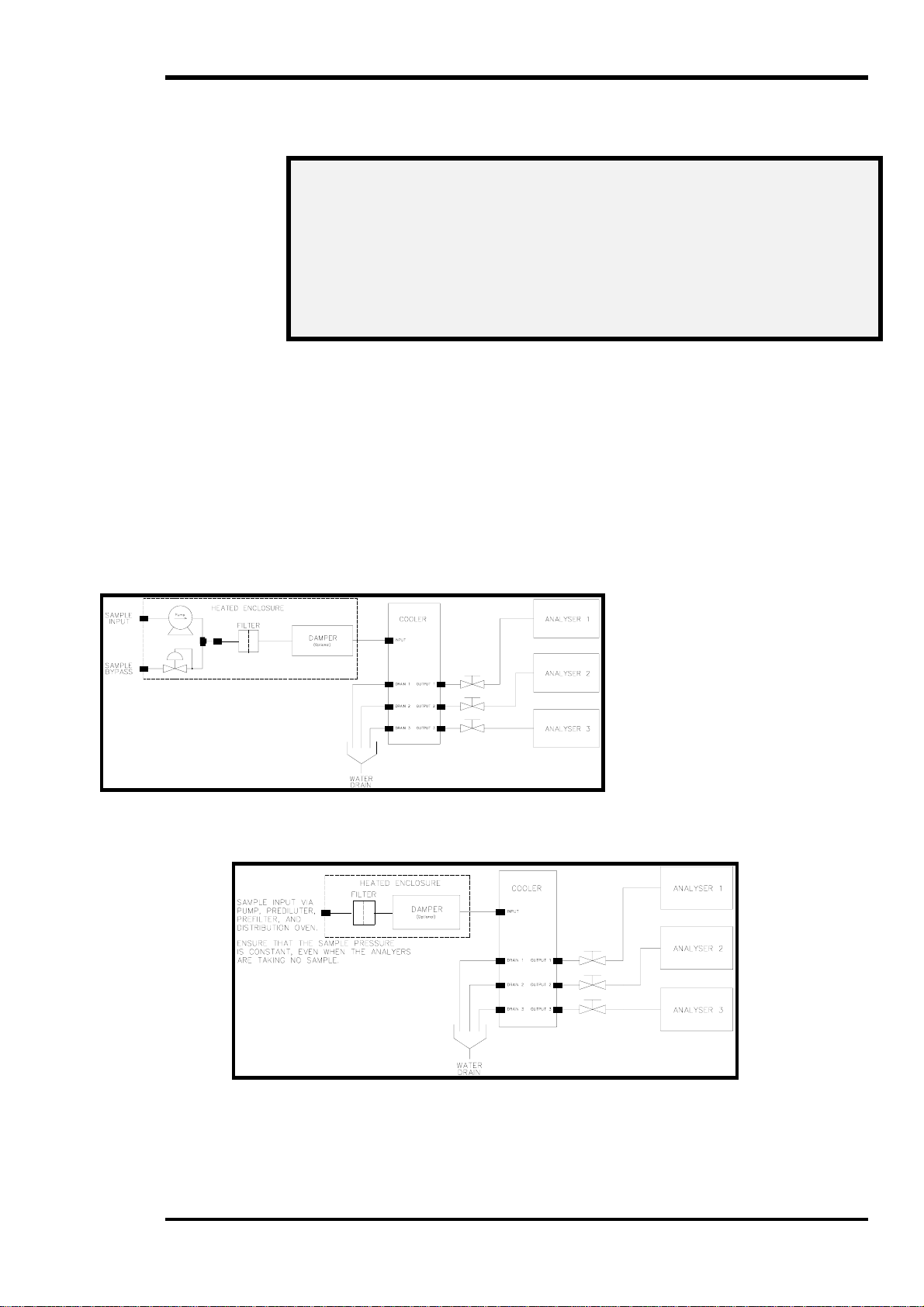

Figure 2 Typical CEM Configuration..................................................................................................................11

Figure 3 Typical Automotive Configuration........................................................................................................11

Figure 4 Sample Heat Content.............................................................................................................................12

Figure 5 Channel Performance.............................................................................................................................13

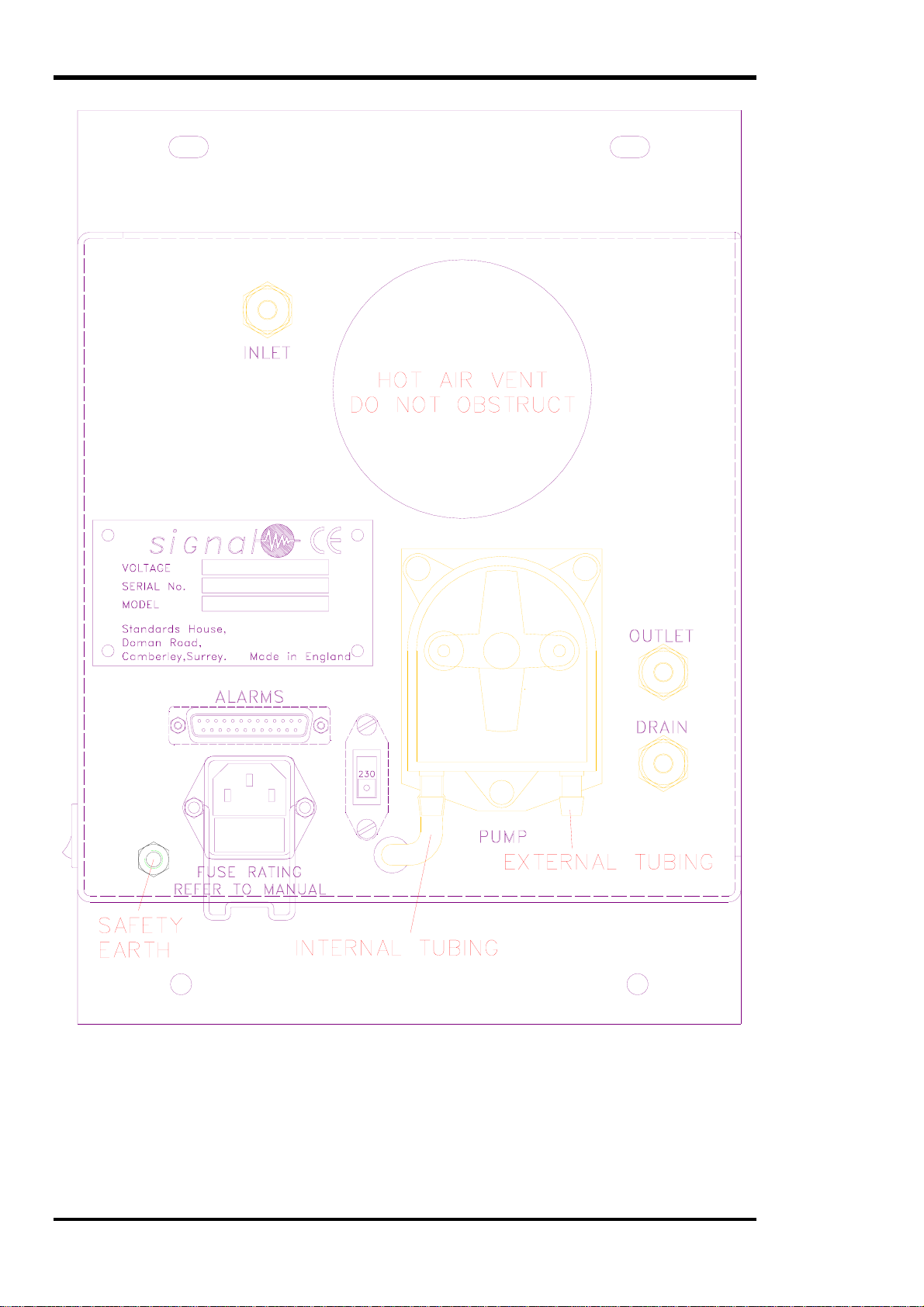

Figure 6 Connection Panel Layout.......................................................................................................................14

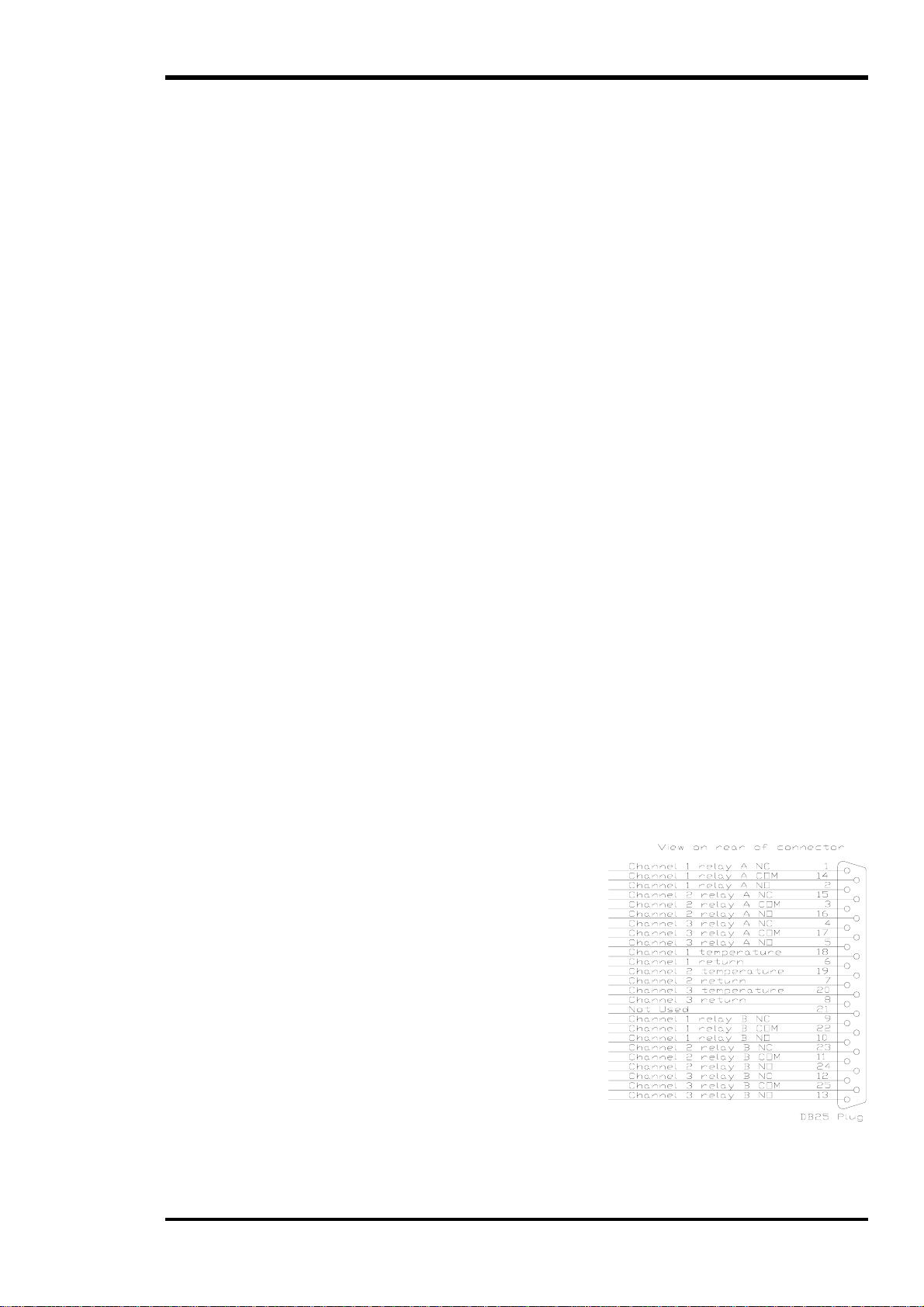

Figure 7 Alarm Connector....................................................................................................................................15

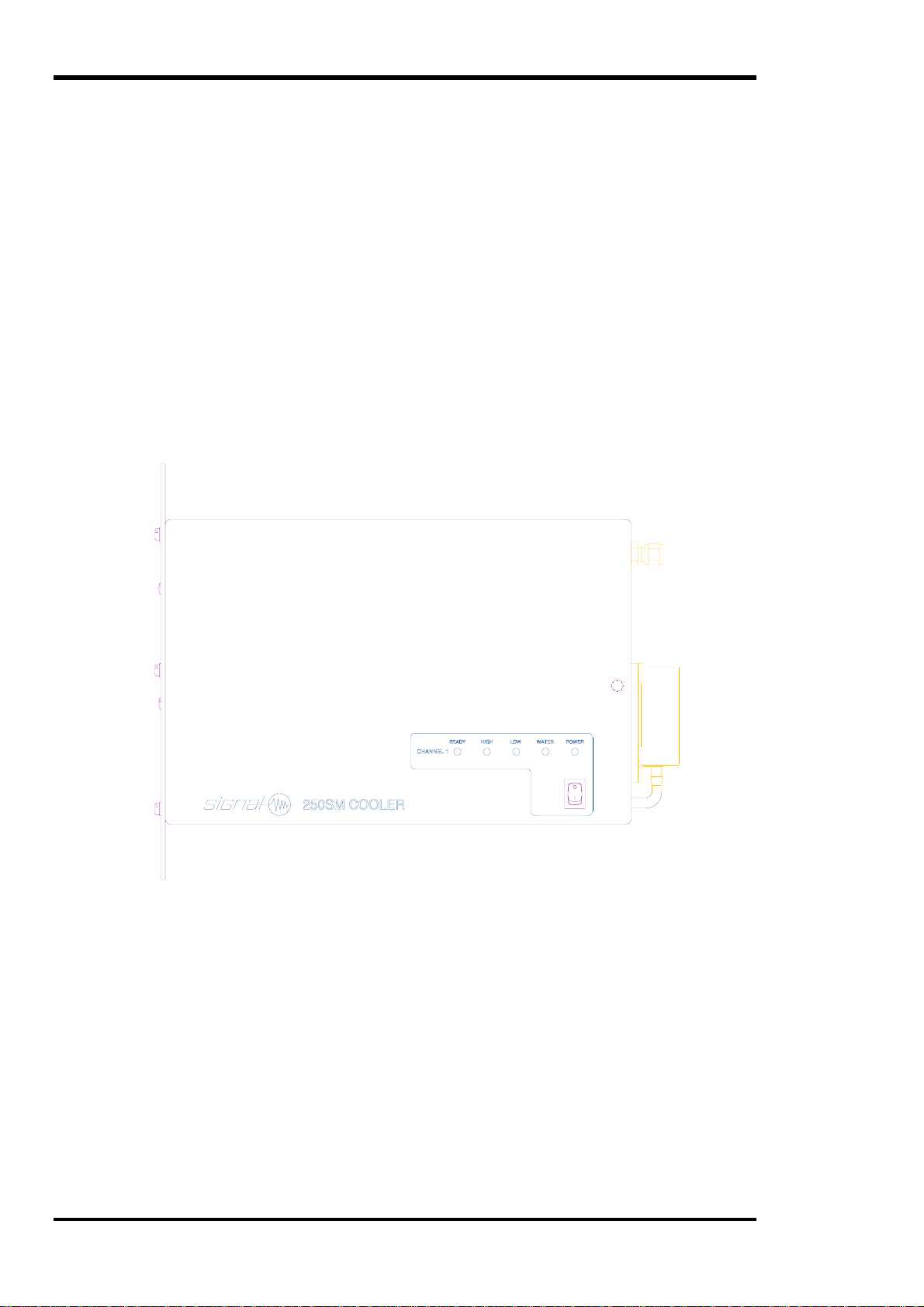

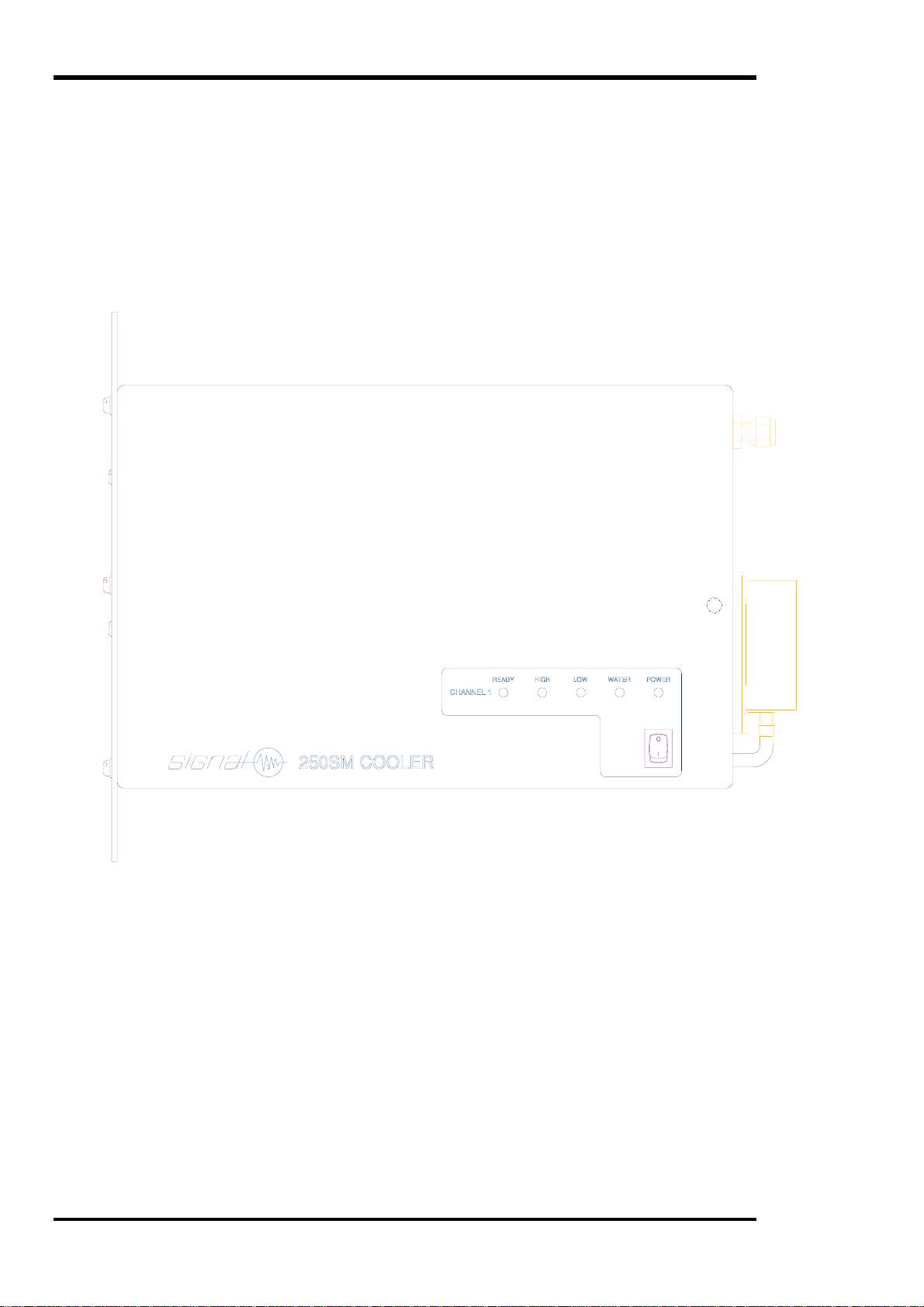

Figure 8 Front Panel Controls and Indicators ......................................................................................................18

Figure 9 Upstream Pump Control ........................................................................................................................19

Figure 10 Downstream Solenoid Control.............................................................................................................19

Figure 11 Controlling a Signal Analyser..............................................................................................................19

Figure 12 Sample Dew Point Estimation .............................................................................................................21

Figure 13 Peristaltic Tube Connections ...............................................................................................................23

Figure 14 Flow Diagram......................................................................................................................................24

250SM OPERATING MANUAL

Page 6 of 26 250/335050 Issue 1.01

250SM OPERATING MANUAL INTRODUCTION

250/335050 Issue 1.01 Page 7 of 26

1. INTRODUCTION

1.1 Cooler

1.1.1 The 250SM cooler is based on the solid state Peltier element and include a continuous

peristaltic drain pump. It is intended for OEM applications in the emissions monitoring

market.

1.1.2 A conditioned sample with a dew point of 5 °C can be obtained from a hot sample gas of

up to 210 °C and having a dew point of up to 70 °C.

1.1.3 Water and dual temperature alarms, and a temperature monitor output are a standard

feature for each channel.

1.2 Applications

1.2.1 These cooler dryer is used to provide a conditioned sample to those analysers not having

a heated sample system, or where they are susceptible to cross interference from water

vapour.

1.3 Getting Started

1.3.1 Installation.

1.3.1.1 Unless you are familiar with the installation of gas coolers, we recommend that you

read section 3 from start to finish.

1.3.2 Operation

1.3.2.1 Read all of section 4 for the minimum steps necessary to get your cooler working.

Then read all of section 5 to learn more about the cooler.

1.3.3 Maintenance

1.3.3.1 Read the section 8 to keep your cooler in first class condition.

1.4 Special Requirements

1.4.1 Location

1.4.1.1 The cooler transfers heat from the sample to the local ambient air. Cold air is taken

from local ambient at the mounting face; heat is transferred to it and it is vented out

from the opposite face. The colder the local ambient air, the more efficient the cooler

performance. The hot air must not be allowed to recirculate back to the cooler. Read

the installation section carefully.

1.4.2 Sample flow

1.4.2.1 The sample must be passed through the cooler.. This is best achieved with an upstream

heated pump and bypass control system.

1.4.2.2 Best results and reliable performance are achieved when the sample is pulse free.

1.4.3 Sample filter

1.4.3.1 A particulate filter should be fitted before the cooler.

SPECIFICATION 250SM OPERATING MANUAL

Page 8 of 26 250/335050 Issue 1.01

2. SPECIFICATION

2.1 Sample Heat Removal

2.1.1 Maximum 18 W at 25 °C ambient.

2.1.2 Figure 1 shows the maximum cooling capability over the ambient temperature range.

2.2 Sample Input

2.2.1 Maximum inlet temperature 210 °C.

2.2.2 Maximum dew point 70 °C.

2.2.3 ¼" tube fitting.

2.2.4 Inlet Pressure -5 psig to +15 psig.

2.3 Sample Outlet

2.3.1 Output Dew Point +5 °C ±0.5 °C non adjustable.

2.3.2 ¼" tube fitting per channel.

2.3.3 Maximum 3 l/min per channel.

2.3.4 Pressure difference input to output < 0.2 psig (6" WG) at 2 l/min, 190 °C, and 50 % dew

point sample.

2.4 Response time

2.4.1 Ready for use within 30 minutes of switch on with no sample flowing.

2.5 Peristaltic Pump

2.5.1 Maximum Pressure at outlet into which it will pump is 5 psig.

2.6 Environment

2.6.1 Ambient Temperature +5 °C to 40 °C.

2.6.2 Relative Humidity to 95 % non-condensing

2.6.3 Keep out of direct sunlight and other forms of radiant heat.

5 10152025303540

Ambient Temperature °C

0

2

4

6

8

10

12

14

16

18

20

Watts

Channel Capability

Figure 1 Channel Performance

250SM OPERATING MANUAL SPECIFICATION

250/335050 Issue 1.01 Page 9 of 26

2.7 Power

2.7.1 Dual voltage 115 Vac ±15% or 230 Vac ±15% selectable from the rear panel.

2.7.2 Mains fuse sizes are all 5 x 20 mm. HBC

2.8 Analogue Output

2.8.1 Non-isolated voltage output proportional to channel temperature in the range 0 - 50 °C.

100 mV represents 1 °C. Accuracy ±0.7 °C over the range.

2.8.2 Continuous short circuit allowed. Recovery < 15 min.

2.9 Alarm Limits

2.9.1 High

2.9.1.1 Channel temperature > 5 °C above the control temperature.

2.9.2 Low

2.9.2.1 Channel temperature < 1 °C below the control temperature.

2.9.3 Water

2.9.3.1 Alarm when there is more than 20 mL of static water in the catch pot.

2.10 Alarm Relay

2.10.1 Volt free dual change-over relay contacts with the de-energised sate representing the

alarm condition.

2.10.2 Contact ratings 1 A at 50 Vdc.

2.10.3 Isolation > 10 MΩat 50 Vdc.

2.11 Physical Dimensions

2.11.1 Width 218 mm.

2.11.2 Body Height 220 mm.

2.11.3 Height including mounting ears 300 mm.

2.11.4 Depth from mounting face 374 mm.

2.11.5 Only the ears are free from protrusions on the mounting face. Refer to section 3

2.11.6 Weight 15 kg.

2.12 Sample Path

2.12.1 Materials in contact with the sample are :-

2.12.1.1 316 Stainless Steel

2.12.1.2 PTFE

2.12.1.3 PVDF

2.13 Safety

2.13.1 The cooler has been constructed in accordance with prescribed safety standards. All

hazardous circuits are shielded.

Supply 115 Vac 230 Vac

VA 180 180

Fuse 4 AT 2 AT

Table 1 Fuse and VA Rating

SPECIFICATION 250SM OPERATING MANUAL

Page 10 of 26 250/335050 Issue 1.01

250SM OPERATING MANUAL INSTALLATION

250/335050 Issue 1.01 Page 11 of 26

3. INSTALLATION

3.1 Introduction

3.1.1 Installation requires the use of a tool set compatible with electrical and pneumatic skills.

A suitable set of tools for a minimum installation consists of and electricians flat bladed

screwdriver for the mains connections, a sharp knife for cutting PTFE tubing, a 9/16"

(14.3 mm) A/F spanner for ¼" fittings. Full installation of chart recorder, and other

features may require the use of a soldering iron plus solder, wire cutters, wire strippers,

small pliers, and a working knowledge of the equipment to be connected. Plumbing in

stainless steel will require the use of pipe cutters and benders. We, or our local agents,

can offer an installation service if you do not have the necessary skills.

3.2 Typical Application Configurations

CAUTION

THE COOLER MUST NOT BE USED WITHOUT A

SAFETY EARTH CONNECTION.

After connection to a source of hot sample, the inlet port may become hot.

TAKE PRECAUTIONS AGAINST BURNS.

Figure 2 Typical CEM Configuration

Figure 3 Typical Automotive Configuration

INSTALLATION 250SM OPERATING MANUAL

Page 12 of 26 250/335050 Issue 1.01

3.3 Basics

3.3.1 Cooler performance is a compromise between installation environment and sample

condition.

3.3.2 The ambient temperature surrounding the cooler sets an upper limit to the amount of heat

that can be extracted from the sample.

3.3.3 The amount of heat to be removed is a function of the sample dew point and temperature,

and the rate of heat removal is directly proportional to flow rate.

3.3.4 Estimate the heat extraction rate required to cool 1 L/min sample using Figure 4 and

calculate total rate by multiplying by the required flow rate..

3.3.5 From the performance graph in Figure 5 determine the maximum ambient temperature

allowed for this performance.

3.3.6 In severe cases it may be necessary to provide air conditioning for the cooler to reduce

the ambient temperature or to add another cooler to spread the load.

0 1020304050607080

Raw Sample Dew Point °C

0

2

4

6

8

10

12

14

16

18

20

22

Watts

100 °C

145 °C

191°C

210°C

Sample Heat Content

For each L/min Sample Flow and for various Sample Temperatures

Figure 4 Sample Heat Content

250SM OPERATING MANUAL INSTALLATION

250/335050 Issue 1.01 Page 13 of 26

3.4 Location

3.4.1 Observe the environmental limitations listed in the specification section.

3.4.2 The cooler is designed to be mounted at the rear of a rack system to keep the rack panel

space clear. It must be mounted so that the inlet (on the mounting face) has access to

cold air. It will vent heated air into the rack. This air must be prevented from circulating

back to the inlet.

3.5 Mains Power Connections

3.5.1 Mains Voltage

3.5.1.1 Check your local mains voltage. It must fall inside the ±15% limits of the nominal

115 Vac or 230 Vac settings of the mains selector switch.

3.5.1.2 Set the switch to the corresponding setting and check that the fuse ratings and types

fitted comply with those given is section 2.7. A spare set of fuses is supplied in the

accessory kit.

3.5.2 Wiring

3.5.2.1 The mains lead supplied with the analyser is colour coded and must be connected

according to the following instructions to make the cooler safe for use.

3.5.2.1.1 Connect the BROWN wire to the LIVE (L) pin of the mains plug.

3.5.2.1.2 Connect the BLUE wire to the NEUTRAL (N) pin of the mains plug.

3.5.2.1.3 Connect the GREEN/YELLOW wire to the EARTH (E) pin of the mains plug.

3.5.2.2 Earthing

5 10152025303540

Ambient Temperature °C

0

2

4

6

8

10

12

14

16

18

20

Watts

Channel Capability

Figure 5 Channel Performance

INSTALLATION 250SM OPERATING MANUAL

Page 14 of 26 250/335050 Issue 1.01

3.5.2.2.1 The cooler must be used with a safety earth. If your mains supply has no earth

terminal, a separate earth must be connected to the M6 stud on the rear panel. This

stud can be used to provide a common ground or screen when data logging. Consult

a qualified electrician if you have no earth at all.

Figure 6 Connection Panel Layout

250SM OPERATING MANUAL INSTALLATION

250/335050 Issue 1.01 Page 15 of 26

3.5.2.3 No Local Earth

3.5.2.3.1 If the local mains supply does not provide an earth connection, you must supply an

independent one. Consult a qualified electrician.

3.5.2.3.2 A mains distribution panel should be installed to provide earthed power outlets for

the cooler and all associated equipments. You may wish to include extra facilities

for data recording or computer facilities at the same time.

3.6 Gas Connections

3.6.1 Input

3.6.1.1 The input must be filtered to prevent accumulation of particulate within the cooling

channels.

3.6.1.2 The input should also be pressurised, within the limits in the specification, to create

flow through each channel. The flow should be pulse free to prevent water carry-over.

The possibility of water carry-over is increased if down stream pumping is used.

3.6.1.3 An input bypass must be provided so that the inlet pressure is controlled if all analysers

are switched off or are calibrating and not using sample gas. Automotive applications

normally have an up-stream heated sample pump with a bypass control and prefilter as

part of the sample system. CEM applications will need at least a heated pump and

bypass regulator. You can purchase standard parts from us if you wish. Contact our

sales department.

3.6.1.4 Connect the sample source to the ¼" fitting labelled INPUT.

3.7 Water Drain

3.7.1 Condensate from the sample is removed by a peristaltic pump on the rear panel. The

condensate may be acidic and should be treated as hazardous waste in accordance with

your local regulations. Typical contents could include Nitric Acid, Nitrous Acid,

Sulphurous Acid, Sulphuric Acid, Carbonic Acid. Ensure that all pipe work and fittings

used to route the water to a safe dump point are resistant to these acids and any others

that could be produced when your sample gas comes into contact with water.

3.7.2 The outlet of the peristaltic pump should not be restricted.

3.7.3 Connect silicon or other suitable tubing to the outlet (nozzle to the right of the pump and

attached to the pump tube) of each peristaltic pump and route to the drain point.

3.7.4 It is important that the drain point is insulated against ambient temperature to protect

against freezing. This would block the pipe and prevent water removal.

3.8 Alarm Relay

3.8.1 The cooler has an independent alarm relay.

The relay has two independent change-over

contact sets available on the rear panel. The

contacts are only rated for low power (refer

to section 2.10) and must be used with an

auxiliary relay to control mains operated or

high power devices.

3.9 Alarm Connections

3.9.1 The output connector and pin out is the same

as that used on the 200SM series of rack

mounted coolers. Only the connections for

channel 1 are used in this cooler. It is

important to preserve the EMC compliance

by using the connector supplied in the

accessory kit with a suitable braided cable.

The cable braid must have a continuous

connection between the cooler and the

Figure 7 Alarm Connector

INSTALLATION 250SM OPERATING MANUAL

Page 16 of 26 250/335050 Issue 1.01

measurement or control equipment. A screened junction box will be necessary if the

cable is to be split to serve multiple outlets.

3.9.2 Figure 7 shows the connector pin identification.

200SM SERIES OPERATING MANUAL BASIC OPERATION

250/335050 Issue 1.01 Page 17 of 26

4. BASIC OPERATION

4.1 Introduction

4.1.1 The following instructions guide you through the steps necessary to achieve sample

cooling.

4.1.2 The cooler has no controls other than the mains on-off switch making it a very simple

device to use.

4.1.3 It is very important that the installation section is read and understood before using the

cooler. The location, environment, and sample conditions all affect the performance and

must be taken into account if a consistent and reliable performance is to be obtained.

4.2 Installation

4.2.1 Install the cooler in accordance with section 3 ensuring that the environmental conditions

are met and that the mains selector switch has been set to suit your local mains supply.

4.3 Start Up

4.3.1 Ensure that there is no sample flow to the analysers. One way is to set all analysers to

measure a ‘ZERO’ gas.

4.3.2 Operate the front panel mains switch and observe the power indicator glowing for each

fitted channel. Wait for the READY indicator on each fitted channel to glow.

4.3.3 The cooler is now ready for use. Select ‘SAMPLE’ on each analyser and cool, de-

humidified sample will be supplied.

4.4 Shut Down

4.4.1 Turn off the sample flow to each analyser. Turn the mains power switch off.

OPERATION 250SM OPERATING MANUAL

Page 18 of 26 250/335050 Issue 1.01

5. OPERATION

5.1 Introduction

5.1.1 This section gives a detailed explanation on the use and operation of the cooler.

5.2 Description

5.2.1 The cooler is contained in a 5U case suitable for bench or rack mounting. All pneumatic

and electrical connections are on one panel. Another panel contains channel indicators

and the mains power switch.

5.2.2 Indicators

5.2.2.1 There is a row of indicators on the front panel showing the cooler status. When the

cooler is switched on, the POWER indicator will glow. Indicators coloured RED warn

that the cooler is not available for use.

5.2.2.2 READY glowing means that the cooler is ready to use.

5.2.2.3 HIGH glowing means the temperature is too high and that the cooler is not ready for

use.

5.2.2.4 LOW glowing means the cooler temperature is abnormally low and indicates a

possible problem. An abnormally low temperature could result in freezing any residual

water in the chamber and causing a blockage. Turn off the sample flow through the

cooler.

o

nt Panel Controls and Indicators

250SM OPERATING MANUAL OPERATION

250/335050 Issue 1.01 Page 19 of 26

5.2.2.5 WATER glowing means that water from the chamber has been ejected into a safety

‘catch pot’ due to abnormal sample pressure surges. Immediately turn off the sample

flow to prevent water carry-over into the analyser. Refer to section 8 for instructions

on clearing the catch pot.

5.3 Alarm Conditions

5.3.1 The appearance of any RED indicator will activate an internal relay. The relay has two

independent change-over contact sets available on the rear panel. The contacts are only

rated for low power and must be used with an auxiliary relay to control mains operated

devices.

5.4 Using The Alarm Relay

5.4.1 The relay contacts can be use to sound a warning alarm and to automatically switch the

sample pump off, or to set Signal Series III analysers to their standby states. Take care

not to exceed the relay contact ratings. An auxiliary relay will be required if you are

driving mains loads or other high voltage, high current devices.

5.4.2 Upstream Pump Control

5.4.2.1 The alarm relay can be used to control an upstream pump so that it will stop if an alarm

condition exists. A latching

relay with a bush-button

start is required. If

sufficient damping can be

provided so that pressure

pulses do not occur when

the pump starts or stops, the

latching relay may not be

necessary.

5.4.2.2 Connect all normally open

contacts from each channel

in series. When an alarm condition exist, the pump will be automatically turned off.

5.4.3 Analyser Valve Control

5.4.3.1 The alarm relay for a particular

channel may be used to control

a downstream solenoid valve

so that there is no flow to an

analyser when an alarm

condition exists. There should

be sufficient damping in the

system so that operating the

solenoid valve does not cause

significant pressure pulses.

5.4.3.2 Connect the normally open

contacts in series with the

control valve. The valve

will close whenever an

alarm condition exists.

24 Vdc

Cooler Channel Relay

Pump Control Relay

Start

Button

Figure 9 Upstream Pump Control

24 Vdc Solenoid

Valve

Cooler Channel Relay

Figure 10 Downstream Solenoid Control

SLEEP

0V

Cooler

Channel

Relay

Signal Analyser

Remote

Connector

Figure 11 Controlling a Signal Analyser

OPERATION 250SM OPERATING MANUAL

Page 20 of 26 250/335050 Issue 1.01

5.5 Controlling Signal Analysers

5.5.1 All Series III analysers have a remote ‘SLEEP’ control activated by a contact closure.

This places the analyser into standby mode after purging the measurement path with zero

gas. It is important that the plumbing includes sufficient damping to prevent significant

pressure pulses.

5.5.2 Connecting one of the relay change-over contacts to these inputs will ensure that the

analyser does not take sample until the cooler is switched on, has reached temperature,

and no error conditions exist. Refer to the operating manual supplied with the analyser.

5.6 Remote Temperature Monitoring

5.6.1 An independent buffered voltage output is available on the rear panel for the remote

monitoring of channel temperature. The output is referenced to the local ground. It can

be connected to most data logging or chart recording devices. The output is a nominal

100 mV/°C and covers the range 0 °C to +40 °C.

Table of contents