SilverStar SPOT 150 User manual

SPOT150

www.yagang.com

USER MANUAL

135

°

135

°

180

°

180

°

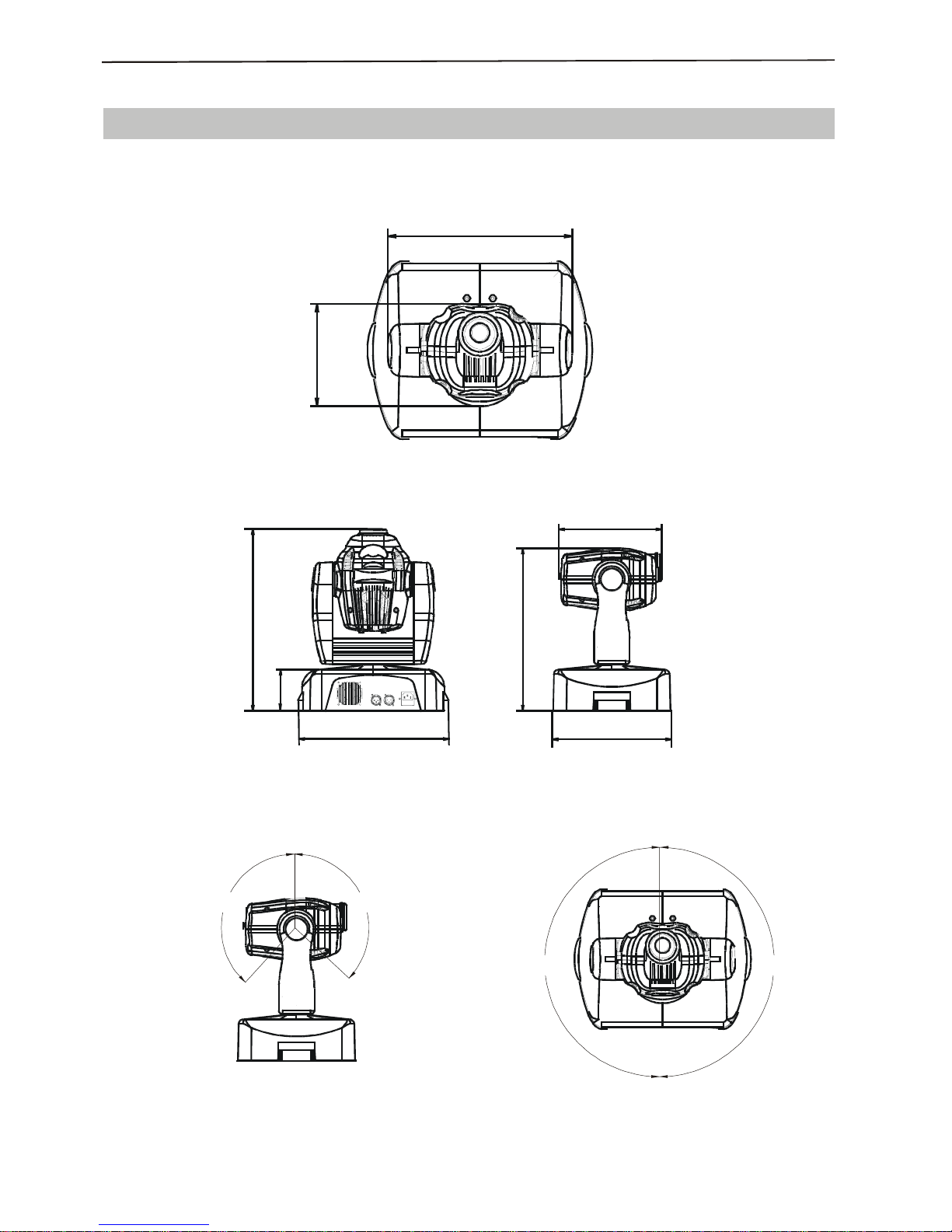

.1

.

25cm

17cm

29cm

40cm

30cm

370cm

450cm

11cm

DIMENSIONS

¾

¾

¾

¾

¾

¾

¾

¾

¾

¾

¾

¾

¾

Don't touch the metal parts of light during devise is working.

Don't open the cover for there have no parts the user can repair.

Don't operate the light without lamps.

If the light equipment doesn't as light as before or there have some destroy with lens or

other parts, please contact the distributor in time.

When you want to retransfer the products, you had better use the original package to

shockproof.

Please make sure that the power already cut off before you install or repair products.

Do not look the lamp house directly to prevent hunting the eyes.

Keep the space between light equipment and combustible things more than 0.5 meter.

If you want to change the lamp, please make sure that the light is cool enough and the

power already cut off.

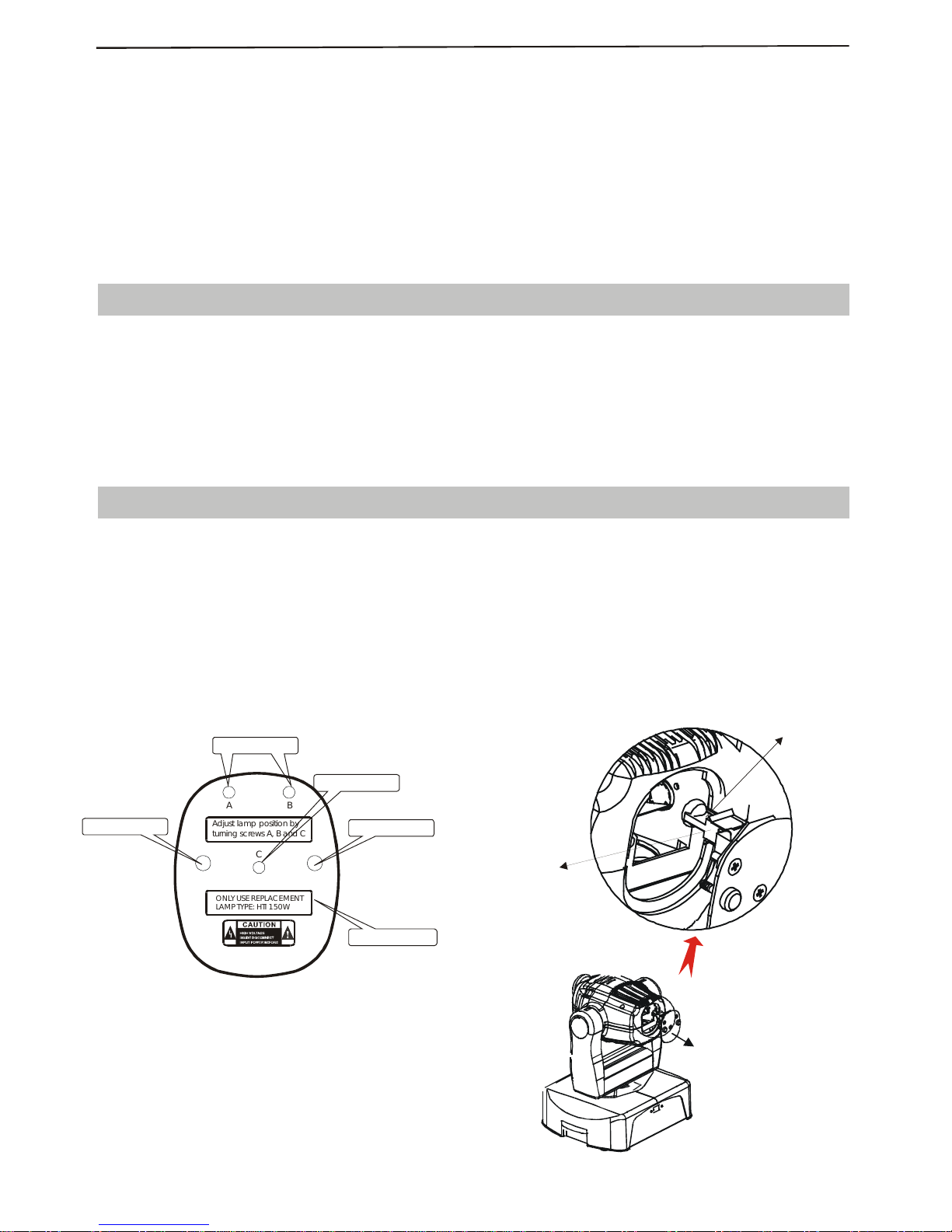

Unscrew the 2pcs M4 screws from the cover for change lamp at the back of light, then

take the cover for change lamp and lamp out of product together.

Insert the lamp into lamp holder.

Please don't use your hand to touch the mirror cover of lamp during installation. Please

use soft cloth to wipe clean if you touch it to provide the light effect.

Put in the cover for change lamp carefully and screw on 2pcs M4 screws.

WARNING

INSTALL THE LAMP

AB

C

Adjust lamp position by

turning screws A, B and C

ONLY USE REPLACEMENT

LAMPTYPE:HTI 150W

Bulb Faceplate

Pict.1 Pict.2

ACCESS SCREW

ACCESS SCREW

Adjust lamp position

Adjust lamp position

HTI 150W LAMP

LAMP HOLDER

.3.

OPEN BOX TO CHECK

INSTALLATION

ATTENTION

¾

¾

¾

¾

¾

¾

¾

¾

This product use new high temperature-resistance project plastic to make. It has a

b

eautiful surface to show the characteristic of new stage lights. Y It is made accord CE

standard. It accord with the international DMX512 agreement. Single or several can be

used at same time. It could be used in different place.

The product use HTI 150w discharge bulb and 10 different colors, 8 different affect

circumgyrate patterns. Strobe speed can be adjusted. Light touch control switch and

code display make operation easier. When you receive the product, take it gently and

check if there is problem which cause in transportation. At the same time please pay

attention to see if the following parts enclosed:

1 Power line

1 safty line

1 User manual

1. Please confirm whether the voltage you have is same as signed on the light before

install.

2. Installed by technician. It muse be placed safety and at best light angle.

3. Must keep space between light equipments and combustibles more than half a meter.

Keep space between light equipments and wall more than 0.15 meter.

4. The fans and vent-pipes should not be jammed by other equipment or decorate

materials.

5. There is a safty line connection hole at the bottom of light. Please use a safty line that

could stand 10 times of light's weight to drill through fuse line connection hole to help

install in safety view.

6. The light must be fixed installed.

7. In safety view please put earth line into the ground.

Please do not open the bottom cover by yourself without permission. Operate it accord

the user manual. Please call the technician in case the machine broken down.

Do not use it under the damp and rain.

Pay attention to prevent the light from strong bump.

Prevent the dust into the product

Keep the vent-pipe well while working.

Keep the plug insert well before put into power.

¾

¾

¾

¾

¾

Don't look the lamp directly to prevent make some destroy with eyes.

Don't light or extinguish frequently, otherwise the life span of the light tube will be

shortened.

In view of the special characters of lamp.

Don't touch the product and draw the power line if your hand is wet.

Keep the space between light equipments and the lighted things more than one meter.

.2

.

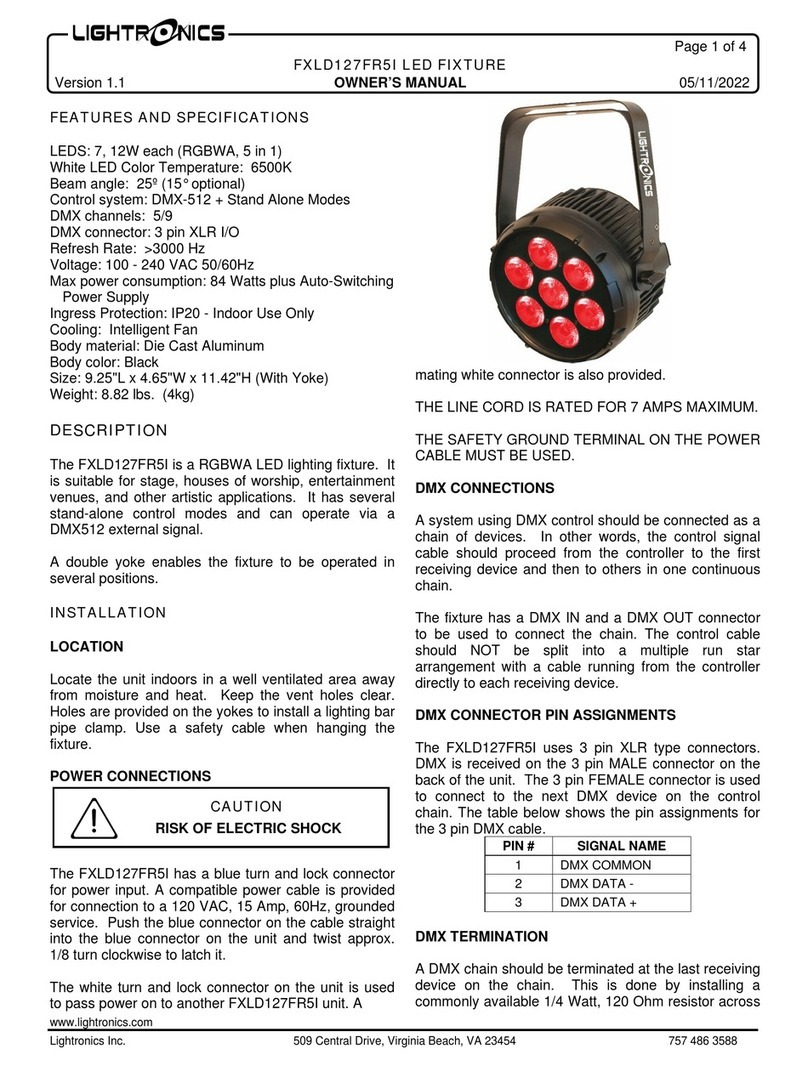

: Please remember the signal output of last machine must connect the attached circle

plug. The circle plug connect a 120 resistance between 2 feet and 3 feet canon plug. The

signal reflects phenomena can be avoided by using circle plug during DMX 512 signal

transfer.

The product use 3 feet XLR plug. If the controller you use is 5 feet XLR plug, you must

use a interchange line from 5 feet to 3 feet as following picture:

Note

Ω

¾

Light 1

Controlsingalinput

Outputandinput connecttogether Outputand inputconnecttogether

Lignt NLight 2

5Pins canon( )plug

Pin 1: GND(SCREEN)

Pin 2: Signal(-)

Pin 3: Signal(+)

Pin 4: N/C

Pin 5: N/C

3

Pin 1: GND(SCREEN)

Pin 2: Signal(-)

Pin 3: Signal(+)

Pins canon(socket)

5Pins canon(socket)

Pin 1: GND(SCREEN)

Pin 2: Signal(-)

Pin 3: Signal(+)

Pin 4: N/C

Pin 5: N/C

3plug

Pin 1: GND(SCREEN)

Pin 2: Signal(-)

Pin 3: Signal(+)

Pins canon( )

The transform of the controller line of 3 pins and 5 pins (plug and socket)

Pin 1: Screen

Pin 2: Signal -

Pin 3: Signal +

3 pins canon plug of DMX512 connect circuit

TERMINATOR

PIN 3

PIN 2

DMX TERMINATOR

CONNECTION

Connect a 120

Ω

(OHM) resistor across

p

ins 2 and 3 in an XLR plug and insert

into the DMX OUT socket on the last

unit in the chain.

INSTRUCTION & FUNCTION

¾

¾

¾

When you use the product first time or after change lamp, you can adjust 3pcs screws on

the cover for change lamp to change the station of lamp to get the best light effect.

The product use international standard DMX512 signal. Through use light touch switch

and code show screen you can easy to set DMX start channel and make function

operation.

Each equipment must be given a DMX start address so that the correct projector

responds to the correct control signals. This DMX start address is the channel number

from which the projector starts to listen to the digital control information being sent

out from the controller. The equipment has 7 channels, so set the No. 1 projector s

address 001, No. 2 projector s address 008, No. 3 projector s address 015, No. 4

projector s address 022, and so on.

“” `

``

`

.5

.

INSTALLING THE PROJECTOR

Bracket Fixing

Hole

M8x25

Bolt

P a s s safety fixing

through these holes

The projector should be mounted via its bracket using one M12 bolt.

The bracket itself attaches to the underside of the projector with two(2)M8x25 bolts

provided.

Always ensure that the projector is firmly anchored to avoid vibration and slipping whilst

operating.

Always ensure that the structure to which you are attaching the projector is secure and is

able to support a weight of 11Kg for each equipment.

For safety the projector should have a secondary fixing with a safety chain through the

holes on the underside of the unit.

WARNING: The projector should NEVER be lifted or carried by the yoke.

FUSE F6.3A/250V

FUSE HOLDER

LEN

L = BROWN

E = GREEN/YELLOW

N = BLUE

POWER SUPPLY MAINS

Use the plug provided to connect the mains power to the projector paying attention to the

voltage and frequency marked on the panel of the projector.

It is recommended that each projector is supplied separately so that they may be

individually switched on and off. IMPORTANT It is essential that each projector is

correctly earthed and that electrical installation conforms to all relevant standards. Power

consumption of the equipment is 280W.

CONTROL CONNECTIONS

¾

Connect the XLR-XLR control line from the DMX output of controller to DMX input of

each product and connect the DMX output of the first one to the DMX input of the

second one. Connect all products in this way. Then use the attached circle plug to

connect the signal output of last machine like picture show:

.4.

PANEL CONTROL

¾

¾

¾

¾

Press FUNC key continuous, the code screen will show the function operate code in

proper order. Every function operate code corresponding special function as following:

When the led screen shows the operation code which you need, press UP or DOWN

button, then the led screen will shows N (means NO) or Y(meansYES).

When the equipment reset itself, the led screen will shows , After reset, the led

screen shows address code. Press the ENTER button, then the this function

confirm(YES) or no valid(NO).

DMX signal ,sound ,automatic or master/slave working mode selection, the newest

selection valid.

888

Code Parallelism Function

X line reverse ,YES/NO

Set address code

Reset,YES/NO

DMX control

Auto-procedure

Sound control

Slave

1

2

3

4

Y line reverse ,YES/NO Enter Yes No

Enter Yes or No

Enter Yes (increase) or No decrease

Yes

→

→

→()

or

Parallelism Operate

5

000

001

002

003

.6.

¾

¾

The display shows the DMX start address after the projector is switched on (if you have

already set the DMX start address and saved it, the screen will display the last setting).

TO SET THE DMX STARTADDRESS :

Press the UP or DOWN buttons and the display will show the DMX start address.

Confirm your choice by pressing the ENTER button, this will save and set the DMX

start address. The display will show the latest setting each time the projector is powered

up. To control the projector with a DMX controller the DMX start address must be set.

Ensure that none of the Stand-Alone options are set or they will interfere with correct

DMX operation.

5

PAN

4

0-255

140-255

121-139

0-360

o

stop

7

speed

6

TILT

0-255

0-255

fast to slow

0-270

o

1

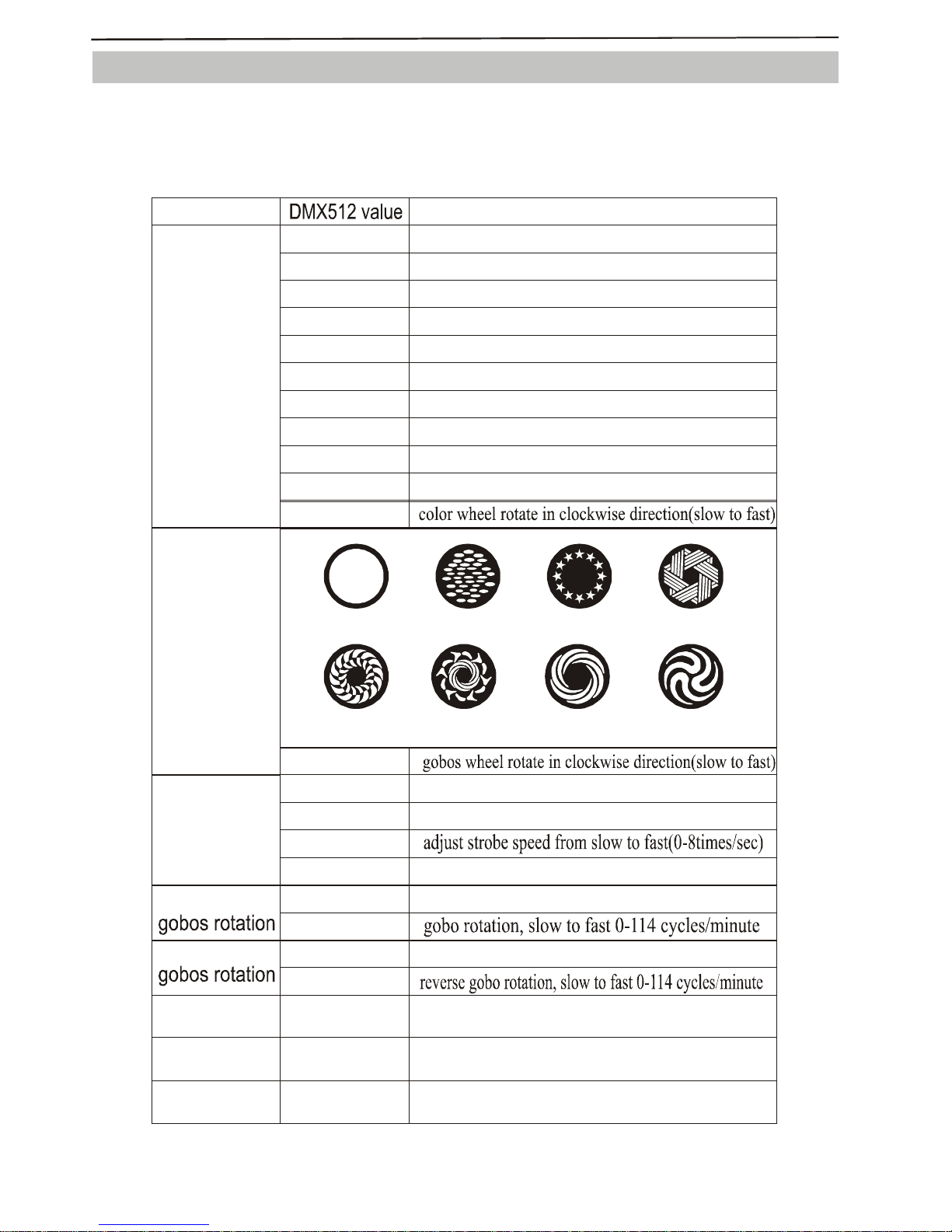

color

2

Gobos

4

3

Strobe

channel

5-120

0-4

241-255

151-240

86-150

0-85

200-255

180-199

200-255

160-179

140-159

120-139

100-119

80-99

60-79

40-59

20-39

0-19

stop

close light

open light

close light

orange

p

ale blue

green

rose red

pink

dark blue

p

ale green

yellow

Red

white

Function

224-255

192-223

160-191

128-159

96-12764-9632-630-31

DMX 512 OPERATE MODE

¾

¾

If all channels are 255,the light equipment reset.

The product has 7 operate channels and use international standard DMX512 signal. The

details as following:

.7

.

Beampath:

SPECIFICATION

¾

¾

¾

¾

¾

¾

¾

¾

¾

¾

¾

¾

¾

¾

¾

Rated voltage: AC220~240V, 50/60Hz

Rated power: 200W

Bulb: HTI 150W

Electric strength: 1.5kv

Insulation resistance:>2M

Channel: 7 channels

Signal: DMX512

Control mode: DMX512 controller

Color: 9 colors + white, rainbow effect

Design: 7 different gobos + white beam, rainbow effect

Strobe: 0-8 times/SEC, adjustable

Rotation angle: horizontal:370 , vertical:265

Size: 370 275 375mm

Net weight: 11kg

Other effect: auto cut off while high temperature, focus adjustable, reset without any

sound.

Ω

××

oo

6m

4m

2m

0m

2m

4m

6m

5m

3m

1m

1m

3m

5m

0m 5m

BEAM DIAMETER

.8.

13

.9

.

ELECTRICALDIAGRAM

MAINTAIN

ANNOUNCEMENT

¾

¾

¾

¾

The optical lens and illuminators must clean regular to protect a better effect. You can

clean them accord the light's operate times and the using situation. Use soft cloth and

original glass cleaner to clean. You'd better clean exterior optical system every 20 days

and inside optical system every 60 days at least.

Do not use organic solvent such as alcohol to clean the cover of light.

When we delivery the goods out of factory, it's function is good and package is well. All

users must obey all noted attentions and operate rules. We won't serve free of charge

repair if the destroy be caused by your own wrong operate. All the problems which be

caused by not operate accord the user manual also not the duty of distributor.

We won't inform again if there have any more changes of user manual.

.10

.

FAULTY

PHENOMENON FAULTYANALYSIS FAULTY PART

PART No.

Power plug loose

Whole light cann't

work

No light from bulb

Power fuse faulty

Reach the lifespan or bed

Temperature switch faulty

Ballast faulty

Plug cable for PC

T3.15A 5*20DIA

27-00-0005-01

09-00-3151-00

07-07-0150-00

11-10-0010-00

08-07-0013-00

06-03-Z009-00

quality of bulb

Trigger faulty

150w ballast

10A105C temperature switch

Electronictrigger

HTI 150w

Bulb light but

Complete motor can

Not work. No light in

The screen and fans

can not work

Transformer faulty 150W/10.8V/24Vtransformer

Main board faulty LT-150 main board

06-00-B056-00

26-2A-LT150DRV3-00

Bulb lighting ,whole

light normal but fans

cannot work

Fan on head of light faulty

Fan on bottom of light faulty

80*80*25 DC12V/0.4A

60*60*25 DC 12V/0.4A

16-00-0007-01

16-00-0011-00

Lamp holder faulty 150 lamp holder 07-11-0014-00

BULBAND FANS NORMAL

Complete light

reseat but can

not be controlled

Complete light

can not reposition Main board faulty

whether the signal cable

good or not

LT-150 main board

LT-150 show board

5 meters cable sets

Gobos not rotatewheel can

Strobe can not work

Can not adjust pan

Can not adjust tilt

Gobos wheel can

not work Motor for Gobos faulty

Motor for rotate faulty

Motor for strobe faulty

Motor for pan faulty

Motor for tilt faulty

Fourlines step motor

Fourlines step motor

Fourlines step motor

Fourlines step motor

Fourlines step motor

Fourlines step motor

15-00-0007-00

15-00-0006-00

15-00-0007-00

15-00-0007-00

15-00-0005-00

15-00-0004-00

15-00-0016-00

main

board

can

not

work

Motor for colorwheel faulty

26-2A-LT150DRV3-00

26-2A-LT300DI-00Show board faulty

27-04-0010-00

Fourlines step motor

COMMON FAULTYMAINTAIN

Color not rotatewheel can

Table of contents

Other SilverStar Light Fixture manuals

Popular Light Fixture manuals by other brands

Exitronix

Exitronix Mesa Series installation instructions

Rush

Rush MH 2 Wash user manual

Dialighting

Dialighting IS200-MH user manual

Cantar Pool Products

Cantar Pool Products Full Moon Owner's Manual & Installation Instructions

ARRI

ARRI Claypaky XTYLOS AQUA User information

Robe

Robe Color Spot 575AT user manual