Contents

1. SAFETY INFORMATION...........................................................................................1

1.1 Stipulations in the Manual ..................................................................................... 1

1.2 Safety Overview..................................................................................................... 1

1.3 Electrical / Mechanical Safety............................................................................... 2

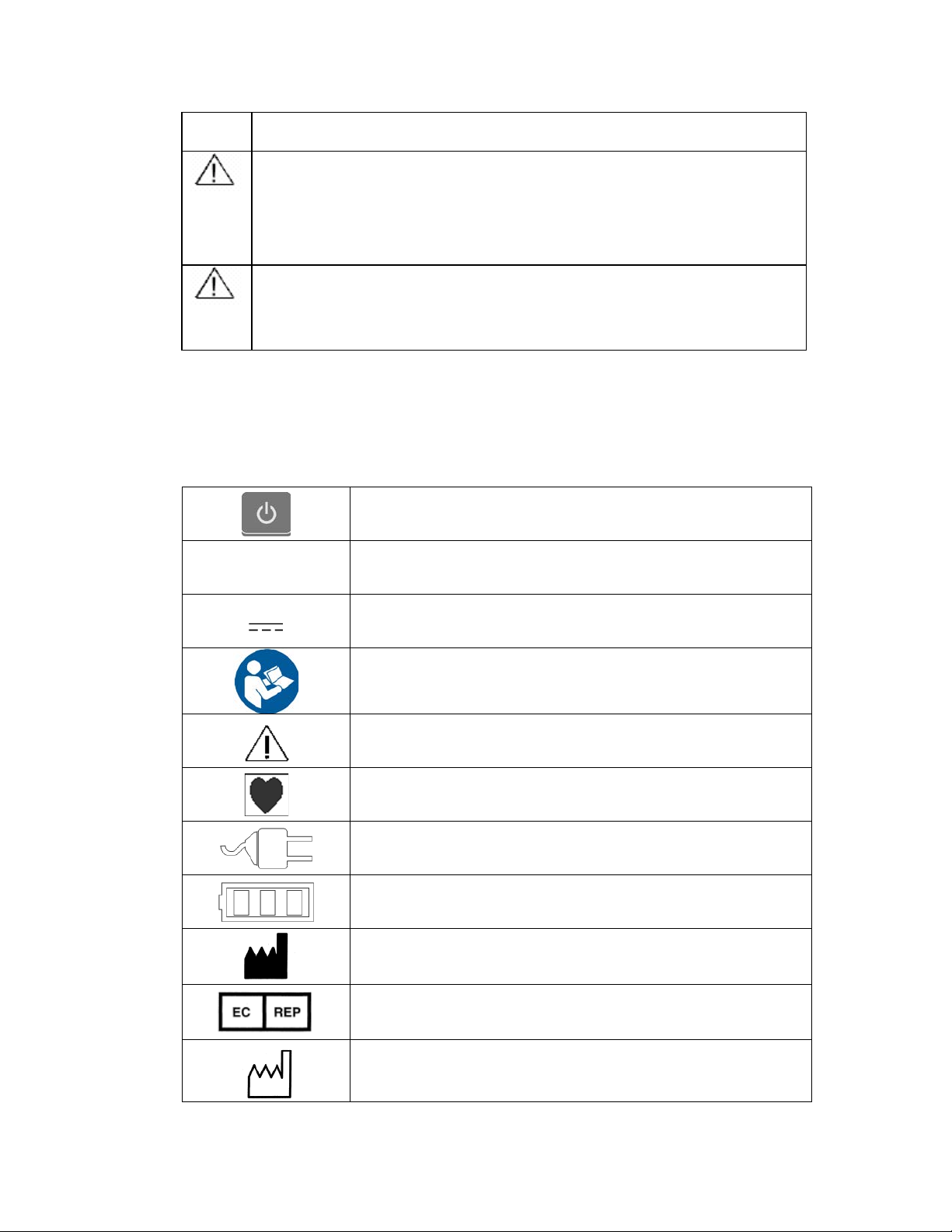

1.4 Symbols and Labels............................................................................................... 4

2. PRODUCT INTRODUCTION.....................................................................................6

2.1 Overview................................................................................................................ 6

2.2 Designations Represented by Models.................................................................... 6

2.3 Operating Principle and Range of Application...................................................... 7

2.4 Technical Characteristics and Parameters.............................................................. 7

2.6 Standard RS232 Interface .................................................................................... 12

2.7 Multi-Channel Injection....................................................................................... 12

3 . OPERATING METHODS.........................................................................................13

3.1 Pump Installation................................................................................................. 13

3.2 Power On ............................................................................................................. 14

3.3 Power On/Off and System Self-test..................................................................... 14

3.4 Installation of Infusion Components.................................................................... 15

3.5 Selection of Infusion Mode.................................................................................. 16

3.6 Infusion Parameters Setup ................................................................................... 22

3.7 Advanced Parameter Setup .................................................................................. 24

3.8 Bolus Function..................................................................................................... 28

3.9 Lighting Function................................................................................................. 28

3.10 Communication with Main Unit........................................................................ 28

3.11 Sleep Mode ........................................................................................................ 29

3.12 Keyboard Lock................................................................................................... 29

3.13 Management of the Battery Recharging ............................................................ 29

4. ALARM PRESENTATION........................................................................................30

4.1 Alarm of Non Operation ...................................................................................... 30

4.2 Alarm of Not Calibration..................................................................................... 30

4.3 Alarm of Occlusion.............................................................................................. 30