Sinotint MA-7 Series User manual

Paint Mixing Machine

Installation and Operation Manual

Plea se read the man ual bef ore usi ng.

usin g uusin gus ing.

ZHENGZHOU SANHUI MACHINERY & EQUIPMENT CO.,LTD. OPERATION MANUAL/说明书

2/10

Contents

1. Introduction....................................................................................................3

2. Precaution:...................................................................................................4

3. Product Specifications................................................................................... 4

4. Electrical Principle Chart.............................................................................5

5. Installation...................................................................................................... 5

6. Test Running...................................................................................................8

7. Operation........................................................................................................ 8

8. Repair and Maintenance...............................................................................9

9. Special Precaution:Electrical Grounding................................................. 9

ZHENGZHOU SANHUI MACHINERY & EQUIPMENT CO.,LTD. OPERATION MANUAL/说明书

3/10

1. Introduction

Thanks for purchasing our products. Paint mixing machine is a kind of tinting machine which used for

automotive surface refinish. There are mainly two functions, one is to provide the mixing function, in order to

avoid paint color difference due to paint precipitation; the other one is to act as a paint can shelf or working table,

which is convenient for tinting operation.

Different from traditional paint mixing machine, our products are brand-new mode that worldwide originally

developed, which will bring you much convenience in installation and operation. Please read the manual carefully

and begin installation and operation after receiving detail knowledge regarding safety and operation.

Though products specifications are diversified, installation and operation method are basically similar, so

we only illustrate for a general structure mixing machine. Continuing to improve and perfect the product is our

consistent aim, we reserves the right to improve and update products, and the information in the manual is subject

to change without additional notice.

ZHENGZHOU SANHUI MACHINERY & EQUIPMENT CO.,LTD. OPERATION MANUAL/说明书

4/10

2.

2. Precaution

Precaution:

:

Please read the precaution carefully before installation.

1) Check if the voltage and frequency are accordance with what on the nameplate that stuck on the left side

plate.

2) The machine must be placed on leveling solid ground.

3) The machine should be placed in dry and well-ventilated space. Do not operate it in dangerous occasion

which may cause explosion.

4) The machine should be equipped with well grounding. Do not assemble or disassemble the machine

without permission.

5) Shake the paint well in the tins before placing in the machine.

6) All maintenance work must be done after both machine halt and power supply disconnected. NO

maintenance without disconnect power supply or during working.

7) Do not use inflammable liquid to clean the machine.

8) Children are forbidden to approach the machine.

9) Single mixing time should be no more than 30 minutes, and each interval of no less than 20 minutes.

10) Motor will get hot during working, and be careful during repair. Motor temperature generally will be

around 60° C -70° C.

3.

3. Product

Product Specifications

Specifications

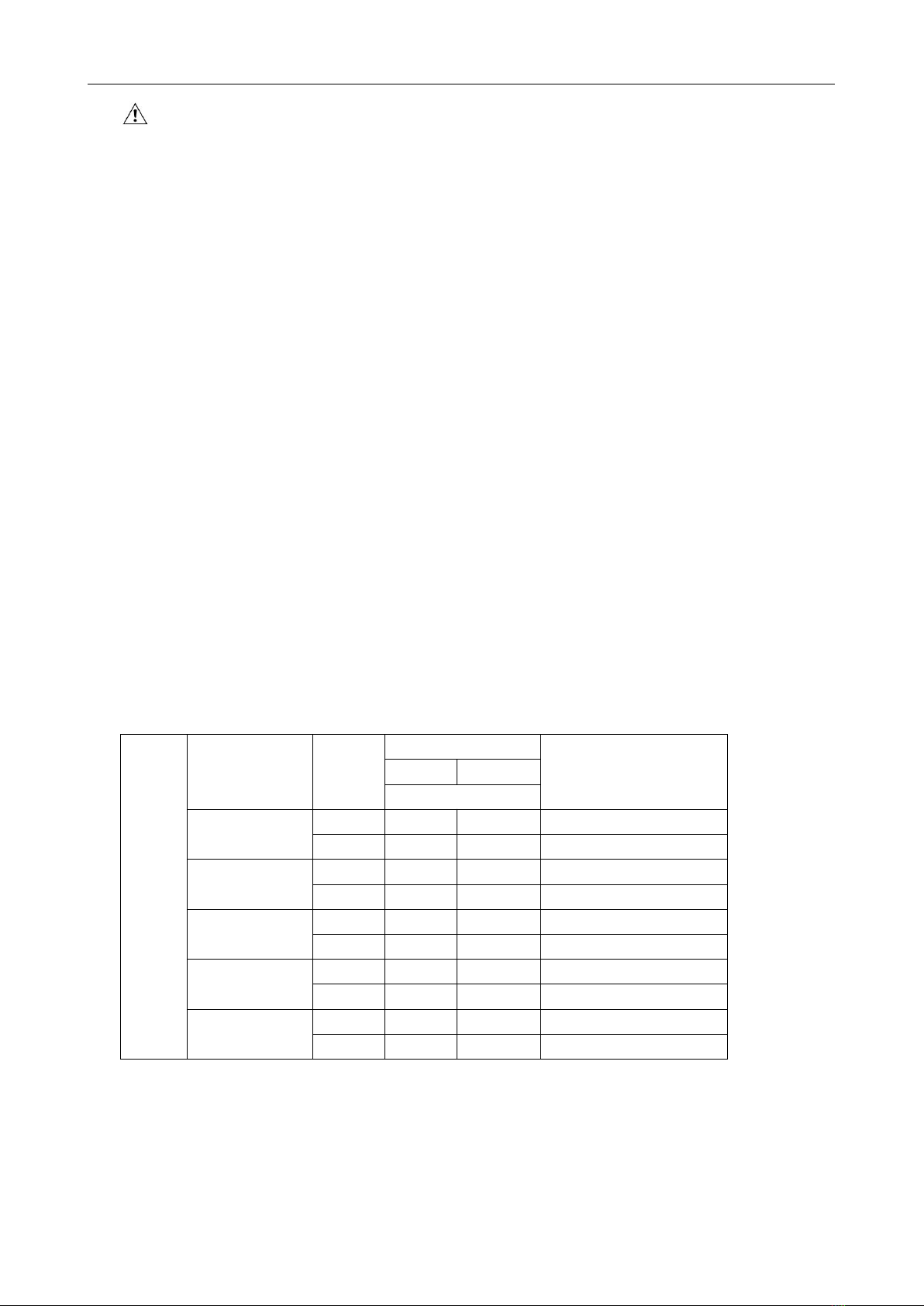

Specifications of general type mixing machine:

Series

Standard

Configuration

Shelves

Shelves for big cans

Shape Size(mm)

(L×W×H)

1

2

Total heads

MA-7 Series

5

47

44

1410X380X1828

6

57

54

1410X380X2118

MA-9 Series

5

61

57

1750×380×1828

6

74

70

1750×380×2118

MA-10 Series

5

66

62

1930×380×1828

6

80

76

1930×380×2118

MA-11 Series

5

75

70

2110×380×1828

6

91

86

2110×380×2118

MA-12 Series

5

84

78

2362×380×1828

6

102

96

2362×380×2118

Note : power of single motor is 15W, thus total power of the mixing machine is heads number X15w.

Total shelves are two kinds: 5 shelves and 6 shelves. Shelves for big cans(2.5-4L) can be 1 shelf or 2 shelves.

Note:Mixing function of the first and second bottom mixing shelf can be removed and change for storage

and displaying paint cans.

ZHENGZHOU SANHUI MACHINERY & EQUIPMENT CO.,LTD. OPERATION MANUAL/说明书

5/10

4.

4. Electrical

Electrical Principle

Principle Chart

Chart

5.

5. Installation

Installation

Open the carton box, check the articles and quantity inside according to the packing list. Take out tools and

accessories, then install the machine following the manual.

Please note: pictures shows in the manual are of standard equipment, if different, install in the corresponding

place.

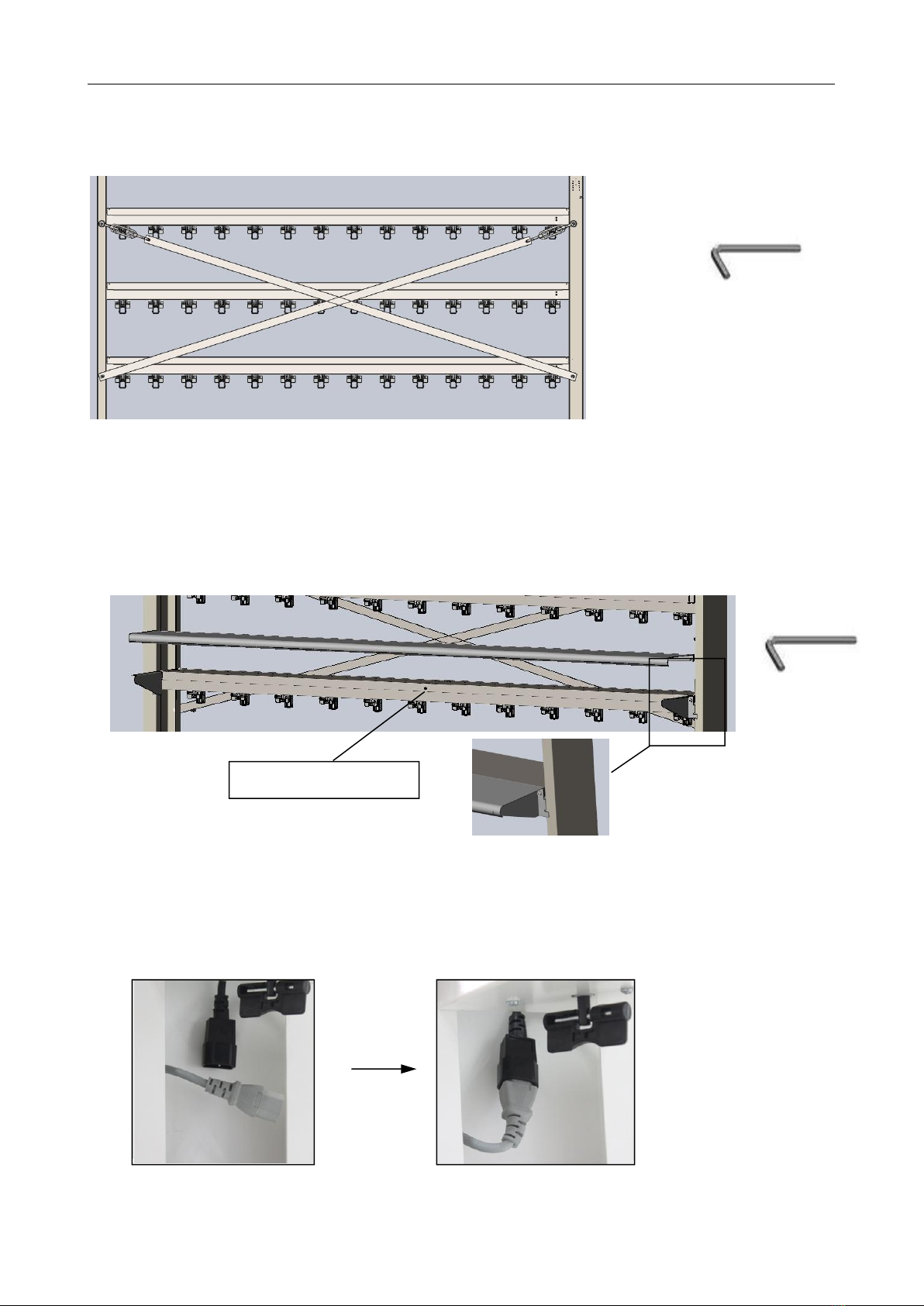

5.1. Install the bottom beam and side plates. Use the Allen Key to fix the left side plates and bottom beam with

two M8X16 screws. The same with the right one, please note the screws for fixing left and right bottom plate

are relative.

5.2. Adjust the distance of the left and right side plate after installation. Place downwards the groove of the

bottom plate into the nut bolts of the bottom beam until it arrives at the correct position.

Note: ONLY MA-12 Series offers a bottom support which shall be placed on the middle of the bottom plate.

Bottom support

Screws for fixing

bottom plate

ZHENGZHOU SANHUI MACHINERY & EQUIPMENT CO.,LTD. OPERATION MANUAL/说明书

6/10

5.3. Install mixing shelf for Big Cans(Gallon cans). Left the end with power cord, place downwards the groove of

two sides into the nut bolts on the side plate until it arrives at the correct position. Note that power cord

should not be crushed.

5.4. Install mixing shelf for Small Cans(Liter cans). Left the end with power cord, place downwards the groove of

two sides into the nut bolts on the side plate until it arrives at the correct position. Note that power cord

should not be crushed. The same with the installation of mixing shelf for Big Cans.

5.5. Install header board: place the embossment on the board into the square hole of the side plate, press down

until it arrives at the correct position.

Note:to install header board of MA-12 Series

machine, please install the accessorial header board

plate onto the side plate first as per the way

above-mentioned , then install the header board onto

the

accessorial plate.

Power cord

Power cord

ZHENGZHOU SANHUI MACHINERY & EQUIPMENT CO.,LTD. OPERATION MANUAL/说明书

7/10

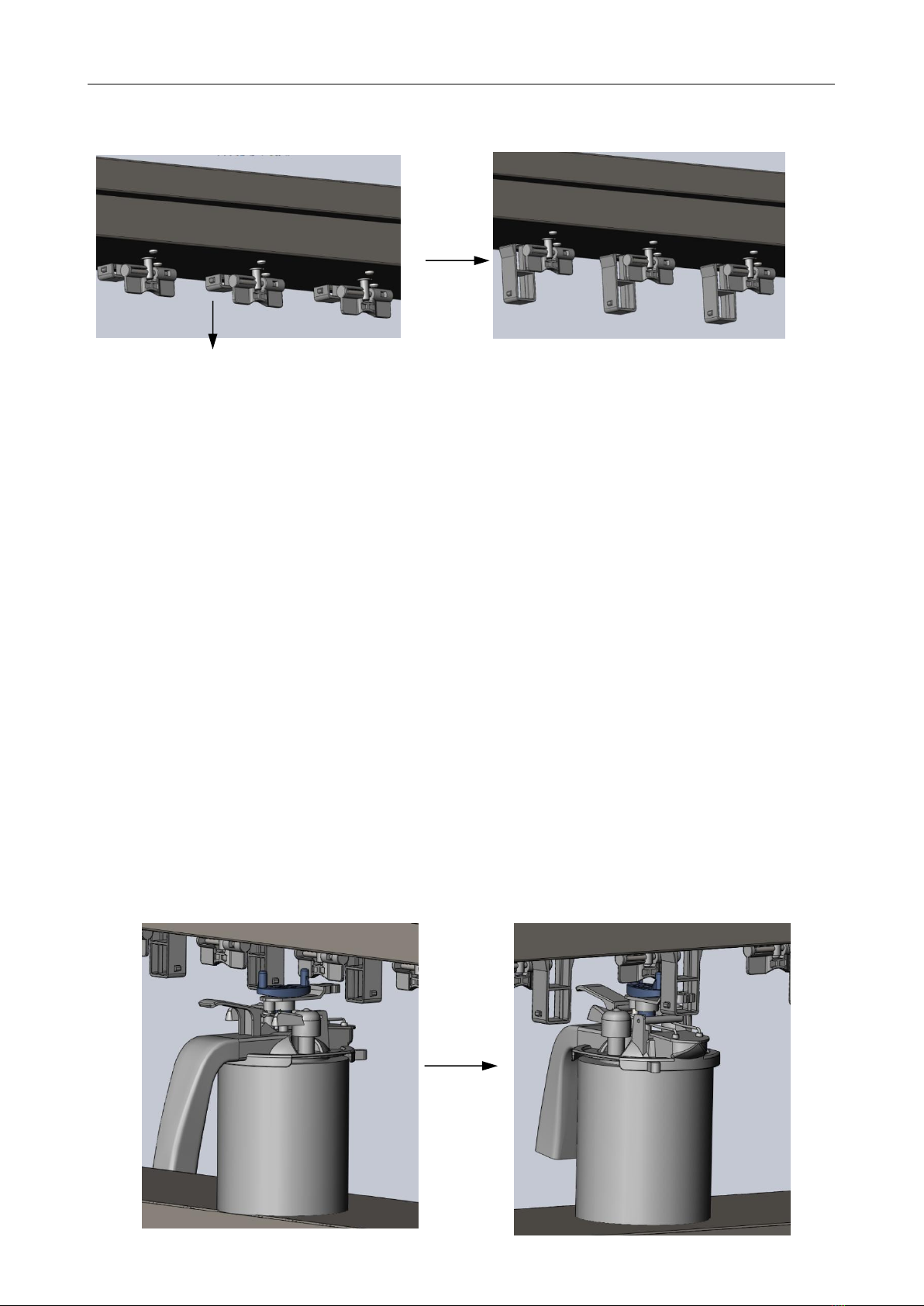

5.6. As the picture shows below, install the pulling strip with Allen Key. Screw two spiral buckles to tight the

pulling strip, making sure that the machine stands stably.

5.7. Install the working table. If there was a working table needs to be installed, install both two sides supporting

racks onto the mixing shelves with “working table top” mark. Do not tighten the screws first. Install the

working table onto the left and right supporting racks and tighten the screws. Push a screw into the central

supporting hole, and fix the working table with mixing shelf. Note that usually the working table is installed

at the second layer counted from the bottom up.

5.8. Connect the plugs at left side of each shelf to the corresponding plugs on the side plate.

Central

Central supporting

supporting hole

hole

ZHENGZHOU SANHUI MACHINERY & EQUIPMENT CO.,LTD. OPERATION MANUAL/说明书

8/10

5.9. Pull down the plastic locator on the mixing shelf, and make it stuck in the slot until a “click” is heard.

Hereto the installation has been finished.

6.

6. Test

Test Running

Running

1. Connect power supply, push upward the small circuit breaker on the machine (push downward is to

disconnect the power supply).

2. Rotate Timer Knob to enact Mixing Time no more than 15 minutes. No sooner the setting time exhausts,

the machine will stop work automatically. If you want to stop the machine during its working, you can rotate

Timer Knob at anticlockwise sense to “OFF”.

Please note: you must listen if the mixing machine has abnormal noise when your mixing machine starts

work for the first time; if there was, please stop the mixing machine and have a check.

7.

7. Operation

Operation

Please note: Mix the paint well in the cans before placing into the machine.

When placing the cans into the mixing machine, insert the limit stop collar (as picture shows) of the mixing

lids to the locator hole.

Rotate the timer knob as per the time you set, and then the mixing machine will work. Single mixing time

should be no more than 30 minutes

ZHENGZHOU SANHUI MACHINERY & EQUIPMENT CO.,LTD. OPERATION MANUAL/说明书

9/10

8.

8. Repair

Repair and

and Maintenance

Maintenance

All maintenance work must be done after both machine halt and power supply disconnected. NO

maintenance without disconnect power supply or during working.

The mixing machine quality is stable and reliable, and does not need routine maintenance.

9

9Special

Special Precaution

Precaution:

:Electrical

Electrical Grounding

Grounding

In case that some garage’s single phase current source only equipped with live line, null line, but without

earth line, please install the mixing machine as follows: find the screw on the back of the Left Side Plate(as

picture shows). There is a grounding marking below the screw. Connect one end of a copper wire with the

screw, and the other end with some metal equipment underground special for grounding. If there was no such

metal equipment, the copper wire could be connected to articles such as water pipe, heating pipe or upright

column of the steel-frame housing nearby.

Symptoms

Causation

Troublesshooting

Motor does not

work

Or is overheated

No power supply

Check the socket, the power

cord, small circuit breaker to

ensure Switch Box in charge.

Power plug loose

Open the corresponding mixing shelf, and connect the plug

again.

Miniature circuit

breaker switched off

Switch on the miniature circuit breaker.

Voltage is too low

Measure if the voltage is

located within 220V ±5%;If not,

equip with a regulator n。

Motor Capacitance is

damaged.

Change a new one。

Motor is damaged

Remove the damaged motor, install a new one, and put the

plug in the socket.

Screw for grounding

This manual suits for next models

4

Table of contents