Siyang 380J-3 User manual

SIYANG

四洋

R

380J-3

MARINE DIESELENGINE SET

OPERATION MANUAL

EASTCHINASHIPBUILDINGINSTITUTE FACTORY

December2003

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

1

SIYANG

四洋

R

CONTENTS

1.General precautions·························································································· 1

2.Introduction······································································································· 2

Fig 380J-3 marine diesel engine set overall dimension ······························· 3

2.1 Description of the engine set···································································· 4

3.0 General engine data······················································································· 5

4.0 Main structure of engine··············································································· 6

4.1 Fuel system································································································ 6

4.2 Lubrication system ··················································································· 6

4.3 Cooling system ························································································· 7

4.4 Electric system ·························································································· 8

4.5 Gearbox ····································································································· 8

4.6 Electrical diagram····················································································· 9

4.6.1 Electric system parts description························································ 12

4.6.2 Instruments panel················································································· 12

4.7 Starting precautions ················································································ 12

4.8 Check before starting·············································································· 12

5. Operation of engine······················································································· 12

5.1Starting······································································································ 12

5.2Starting by Spring starter (if installed) ··················································· 13

5.3 Operation ································································································· 15

5.4 Stopping··································································································· 15

6.Routine maintenance ····················································································· 15

6.1 Initial attention························································································· 15

6.2 Routine maintenance periods ································································ 16

6.3 Lubrication oil specification ·································································· 16

6.4 Gearbox oil specification ······································································· 17

6.5 Main spanner torque setting··································································· 17

6.6 Tighten sequence for cylinder heads bolts············································ 18

6.7 Check of lubrication oil level································································· 18

6.8 Lubrication oil change············································································ 18

6.9 Alternator belt tension············································································· 18

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

2

SIYANG

四洋

R

6.10 Gearbox oil check and change ···························································· 18

6.11 Priming the fuel system········································································ 18

6.12 Drain the coolant··················································································· 19

6.13 Changing fuel filter element ································································ 19

6.14 Idling speed adjustment ······································································· 19

6.15 Valve clearance adjustment ································································· 19

6.16 Starting and running the engine while the lifeboat

is hooked in davits or free fall rig ························································ 19

6.17General precaution about electrical system········································· 19

6.18Stroage ···································································································· 20

7. Trouble shooting···························································································· 21

7.1 Difficult in starting the engine ······························································· 21

7.2 Insufficient output ··················································································· 21

7.3 Black smoking from exhaust································································· 22

7.4 Low lube oil pressure ············································································· 22

7.5 Engine knocking····················································································· 22

7.6 Engine overheating················································································· 23

7.7 Engine over speed or override······························································· 23

Appendix 1:380J-3 diesel engine set delivery list·········································24

Appendix 2:Tools supplied with 380J-3 marine diesel engine set ···········24

Appendix 3:Spare parts supplied with 380J-3 marine diesel engine set ····25

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

1

SIYANG

四洋

R

1.GENERALPRECAUTIONS

⑴. Ensure that the engine is securely mounted.

⑵.Ensure that the ventilation and combustion air dusts are not obstructed.

⑶.Keep the engine and surrounding areas clean.

⑷.Never allow any part of the body to come into contact with high

pressure fuel oil when testing injection equipment.

⑸.Avoid contact with exhaust pipe when the engine is, or has recently

been running .These parts can be very hot and can cause severe burns.

⑹.Rectify all fuel water and oil leaks as soon as possible.

⑺.Isolate the battery when working on the engine.

⑻.All drive belts must receive regular attention.

⑼.Keep electrical contacts free from corrosion etc by smearing them with

petroleum jelly.

⑽.Batteries under charge release explosive gases, therefore the battery

compartment must be well ventilated at all times. Never allow any

smoking, sparks or flames near the batteries.

⑾.Wear protective goggles when handing liquids which is harmful to

eyes, for example, battery acid. If any of these substances are splashed in

the eyes, wash out thoroughly with clean water.

⑿Many liquids used in engines are harmful if taken internally .In the

event of accidentally swallowing oil, fuel, antifreeze or battery acid obtain

medical assistance immediately.

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

2

SIYANG

四洋

R

2.INTRODUCTION

The SIYANG make marine diesel engine set, type 380J-3 is based on

380C diesel engine and adapted for lifeboat Propulsion conforming to the

latest requirements include SOLAS 1974,1996 Amendments.

It is essential that the operators read carefully the main points in this

manual before the engine is put into service.

Reference is made to:

“CHECKS BEFORE STARTING” “STARTING” “OPERATION” and

“STOP” .

The engine must be able to start and operate under the most severe

conditions. Therefore the engine set must be carefully maintained in

accordance with this manual.

The information , specification, illustrations, instructions and statements

contained within this publication are given with our best intentions and are

believed to be correct at the time going to press. As our continued technical

development, We reserve the right to amend any technical information with

or without prior notice.

While every effort is made to ensure the accuracy of the particulars

contained within this publication neither the manufacturer or dealer shall in

any circumstances be held liable for any inaccuracy or the consequences

thereof.

User of this manual are advised that the specification details apply to

380J-3 engine set and not to any one particular engine. In case of difficulty,

consult East China Shipbuilding Institute Factory, China or a local

distributor for further advice and technical assistance.

The information given is subject to the company’s current condition and

is for the assistance of users and is based upon results obtained from tests

carried out at the place of manufacture. Our company doesn’t guarantee that

the same results will be obtained elsewhere under different conditions.

When purchasing parts, or giving instruction for the clients repairs,

please refer to engine part catalogue and specify ESCI Factory. Our

company can not be responsible for any damage arising from the parts that

have not been supplied by our company.

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

3

SIYANG

四洋

R

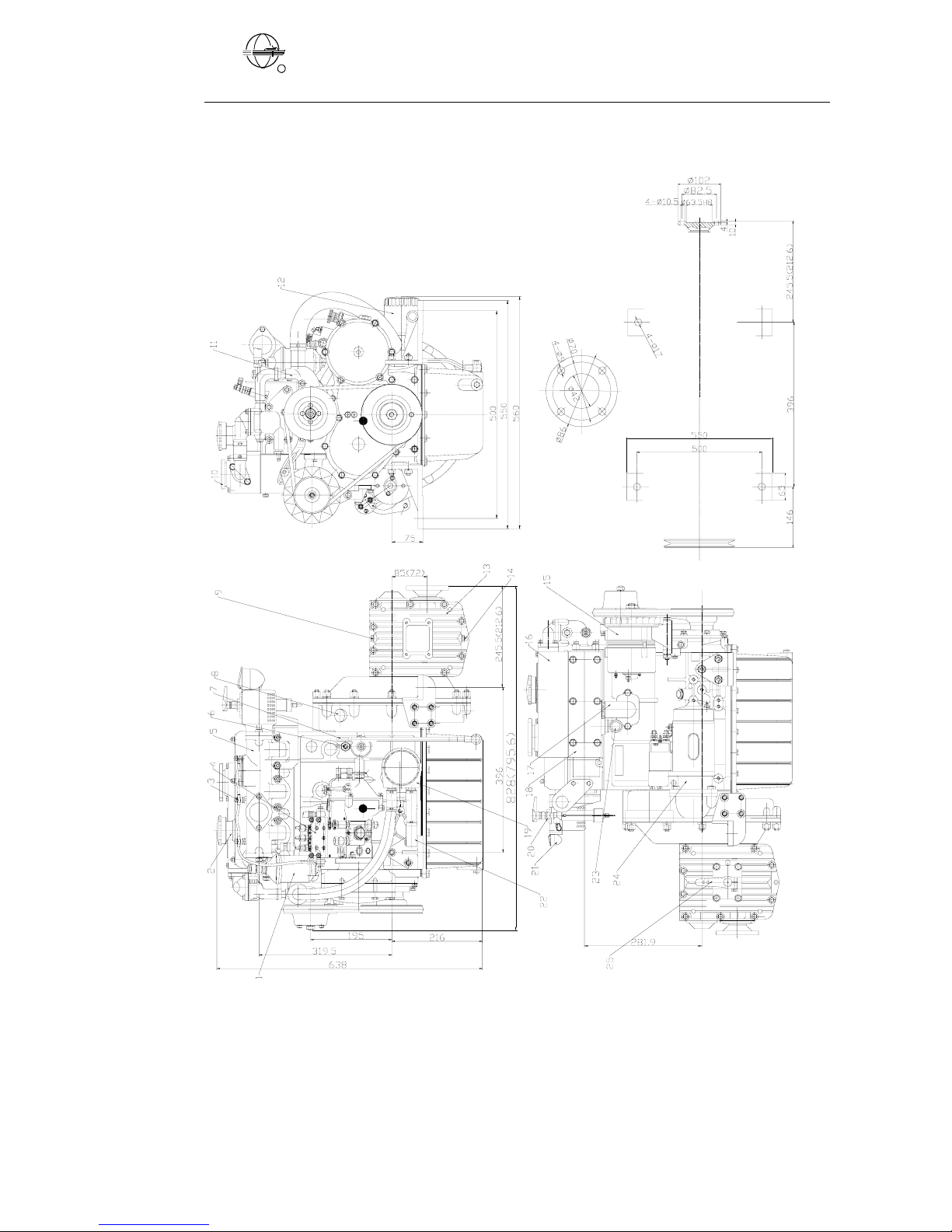

Exhaust flange

Note:Thedimensioninbracketisonlyformatching ZF12Mgearbox.

Fig.380J-3 marine diesel engine set overall dimension

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

4

SIYANG

四洋

R

2.1 DESCRIPTION OFTHE ENGINE SET

1. Fuel filter

2. Breather

3. Fuel injector

4. Injection pump

5. Inlet manifold

6. Outlet cock

7. Lube oil dipstick

8. Tachometersensor

9. Gearbox dipstick

10.Expansion tanker cap

11.Fresh waterpump

12.Lube oil filter

13.Gearbox

14.Gearbox oil screw

15.Alternator

16.Expansion tanker

17.Lube filling cap

18.Exhaust body

19.Lube cooler

20.Either pump

21.Starting liquid reservoir

22.Water inlet pipe

23.Water outlet pipe

24.Starting motor

25.Gearbox handle

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

5

SIYANG

四洋

R

3. GENEARALENGINE DATA

Type 380J-3

Model In line, vertical, water cooled

four stroke

Combustion chamber Direct injection

Number of cylinders 3

Bore×stroke (mm) 80×90

Total displacement (liters) 1.357

Firing order 1→3→2

Compression ratio 18:1

Rated output (kw/rpm) 20.6/2800

Fuel oil consumption at rated output (g/kw·h) ≤255

Lube oil consumption at rated output (g/kw·h) ≤2.72

Air consumption in 10 minutes (m3) 16.148

Lubrication method Splashed and forced

Method of cooling Water coolant

Direction of rotation Counter clockwise

(Looking on flywheel end)

Method of starting Electric option spring starter

Method of operation Mechanical direct translating

or flexible shaft remote operation

Exhaust temperature at rated output (℃) ≤550

Overall dimension (L×W×H) (mm) 828 (796)×560×638

Weight (kg)200

Note: the dimension in bracket is only formatching ZF12M gearbox

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

6

SIYANG

四洋

R

4.MAIN STRUCTURE OFENGINE

4.1 FUELSYSTEM

The fuel system are important controlling components of the diesel

engine. They are composed of injectors, fuel filter, injection pump and

high and low pressure pipes and various connections. The feed pump

draws fuel from the fuel tanker and deliveries it to the filter. The fuel, after

passing through the filter, passes into the injection pump. The fuel passes

into the high pressure pipe then to the injector which atomizes the fuel to

fine droplets for combustion. Small amount of fuel passes through the oil

return pipe into the fuel tanker

Fuel pump timing ……………………. 24~27゜TDC

Injection pressure ……………………. New: 20.5Mpa/used: 20Mpa

Diesel oil conforming GB252-87 light diesel fuel grades No.0 or No.-35

or to USA specification ASTM D-975-77 Grades NO.1-D and 2-D.If the

engine has to work in areas with extremely low ambient temperatures, use

fuel with good clog characteristic. Clog point(CFPP) -25℃.

4.2 LUBRICATION SYSTEM

The lubrication system is made up of an oil sump, an suction strainer, an

oil pump, lube cooler ,filter and various pipes. The oil pump draws the lube

oil contained in the oil sump through oil suction strainer then the lube oil

flow into lube cooler and lube filter. The lube oil in main oil passage is

separated into three flows. One passes through main bearing and flow into

connecting rod bearing; The second passes through the camshaft bearing

and flow the sloping oil passage to lubricate the valve rocker arm shaft liner;

the third one flow into timing idle gear bearing. Cylinder liner, piston, piston

pin, connecting rod l shells etc are splash or atomized lubricated.

The lubrication oil should be added properly. If it is added to much, it

would be burning; if added to less, the bearing shells would be burnt. It is

ideal to add the oil until its level reaches between the upper and low marks

on the dipstick. When the oil level goes down to the low mark, lube oil

should be added. Before starting the diesel engine, the oil level should be

checked.

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

7

SIYANG

四洋

R

Lube oil pressure ……………..…………….98kpa ~120kpa at idle.

250~390kpa at rated output.

Oil sump capacity……………………………5.2liters.

SCG-025/ZF12M Gearbox sump capacity….. 0.75liters/0.56 liters.

4.3 COOLINGSYSTEM

The cooling system of the engine set is of forced circulative water

cooling close type, which consists of lube oil radiator, water tanker, water

pump, rubber pipe etc.

The cooling system of the engine is closed water cooling system.

The cooling liquid comes from the keel cooler through the lube oil

cooler and water pump to the engine block, cylinder head, water cooling

exhaust pipe and outlet then feed back to keel cooler to make circulation

cooling.

Too high cooling temperature will cause the lamp in the control

panel to light up and acoustic alarm to function.

Water temperature …………..75~95゜C.

Antifreeze concentration of 40% should be used as an all year round

coolant. This concentration will give low temperature protection down to

-25゜C.

Additionally, 40% concentration will protect the cooling system from

corrosion.

Warning:Antifreeze contains Glycol and otherconstituents which

are toxic if taken internally, and can be absorbed in toxic amounts

underprolonged skin contact.

If antifreeze is swallowed accidentally, medical advice should be

sought immediately.

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

8

SIYANG

四洋

R

Fuel

tank

Fig Piping layout

1.Cooling water pump 2.Lube cooler 3. Keel cooler 4.Lube oil pump 5.Lube oil filter 6.Pressure

control valve 7.Main bearing 8.Camshaft bearing 9.Rocker arm 10 Overflow pipe11. Fuel oil filter

12.Fuel feed pump 13. Fuel injection pump 14. Fuel high pressure pipe 15. Fuel injection nozzle 16.

Water exhaust pipe 17. Fuel oil inlet

4.4 ELECTRIC SYSTEM.

The electric system is composed of battery charging alternator,

starting motor, relay regulator, switch, alarm buzzer, alarm lamps and

instruments.

If without FQ spring starter, two separated charging battery should be

need. The customers choose and use either one of two electric diagrams.

Voltage: 12V.

Startermotor: 2.5kw

Alternator: 750W

4.5 GEARBOX

Gearbox reduction ratio for SCG 025-3: …....2.74/2.67 (Forward/reverse)

Gearbox reduction ratio for ZF12M: …...........2.63/1.95 (Forward/reverse)

Rotation direction of propeller …………….. Clockwise (forward)

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

9

SIYANG

四洋

R

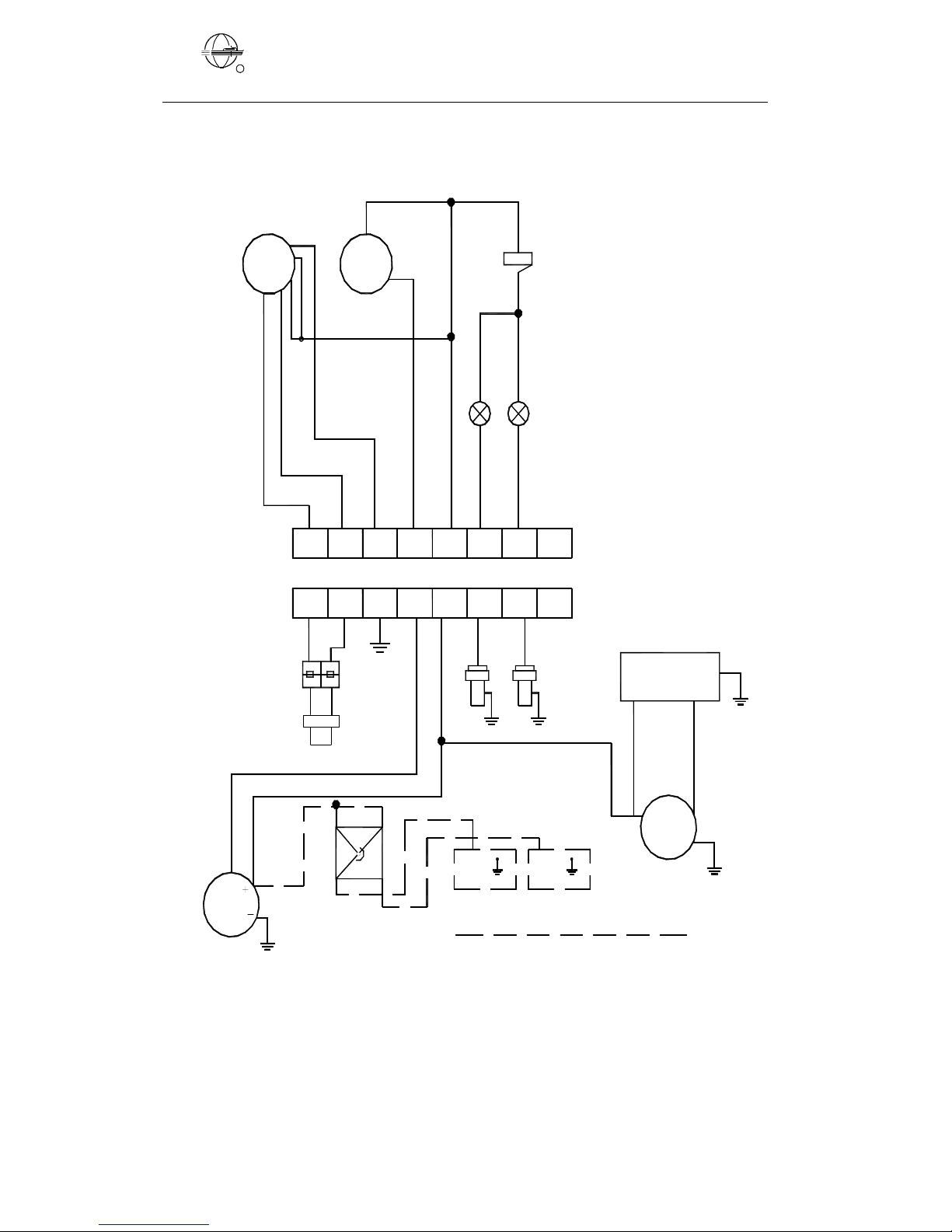

4.6 ELECTRICALDIAGRAM

Pressure sensor

Temp. sensor

Change over

Battery switch

Tachometer sensor

G

Starter

Generator

Items with dotted line not

included in normal delivery.

Battery 1

12 Volt

Battery 2

12 Volt

Double

charge diode

-+

50mm2

G+G

-

50mm2

B+

Armature

F

Magnetic

1

1

31

4

5

6

Tachometer

Low oil pressure alarm

High water temp. alarm

Voltage

regulator

65

342

234 65

1098711

97 81011

Discharge alarm

CAP

12

G

12

3

21

Switch

+Buzzer

Diode

Fig Electric diagram 1

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

10

SIYANG

四洋

R

Pressure sensor

Temp. sensor

Change over

Battery switch

Tachometer sensor

G

Starter

Generator

Items with dotted line not

included in normal delivery.

Battery 1

12 Volt

Battery 2

12 Volt

-+

50mm2

G+G

-

50mm2

B+

Armature

F

Magnetic

1

1

31

4

5

6

Tachometer

Low oil pressure alarm

High water temp. alarm

Voltage

regulator

65

342

234 65

87

7 8

G

3

21

Switch

+Buzzer

Fig Electric diagram 2

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

11

SIYANG

四洋

R

4.6.1 ELECTRIC SYSTEM PARTS DESCRIPTION

Following parts is installed either engine side or panel side

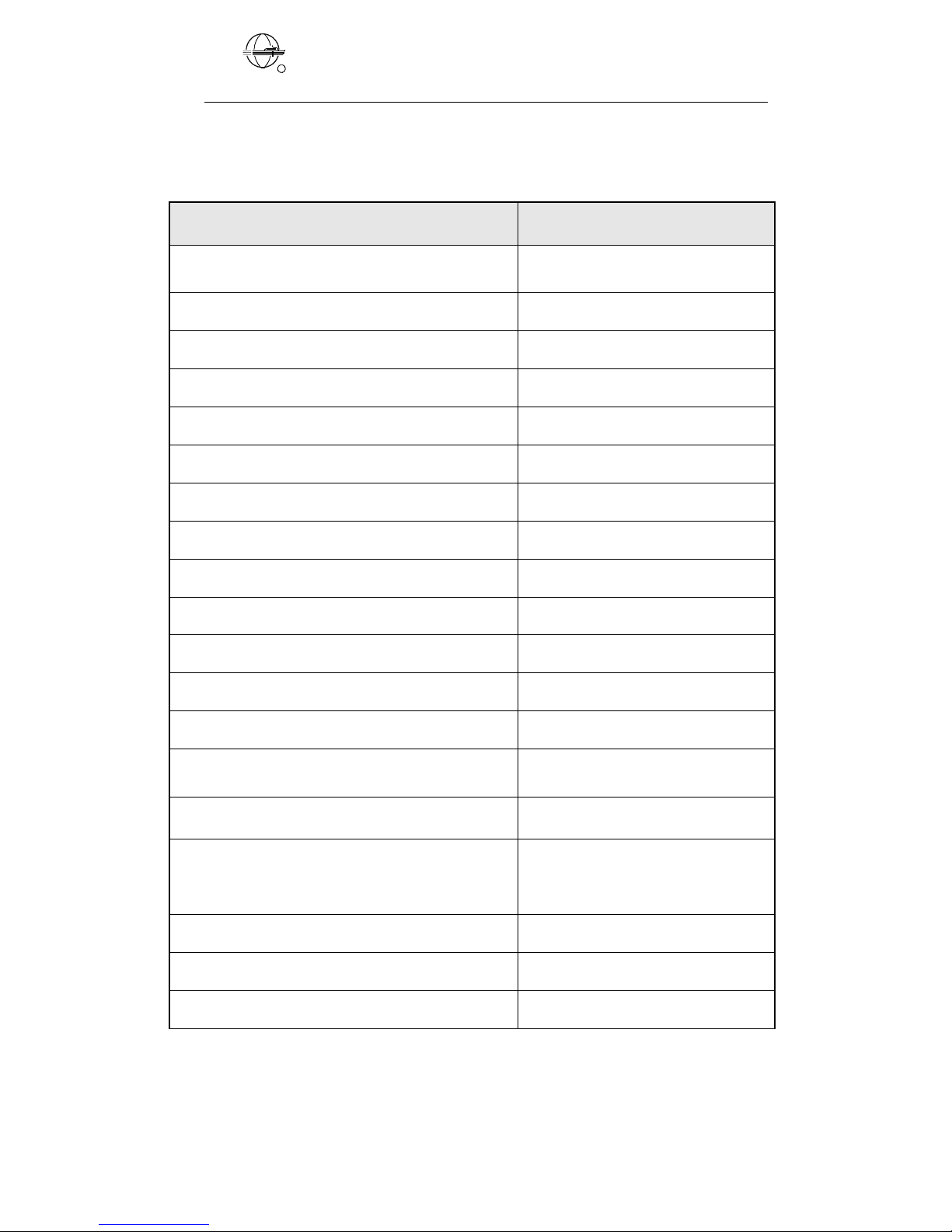

Item Electric diagram 1 Electric diagram 2

Tachometer ZS12109.Y0 ZS12109.Y0

Starting switch JK290 JK290

Buzzer FMQ-2715 FMQ-2715

Alarm lamp (watertemp.) AD11-16 AD11-16

Alarm lamp (lube pressure) AD11-16 AD11-16

Charge indicating lamp AD11-16 AD11-16

Tachometer sensor ZG912346 ZG912346

Temperature sensor WB9311 WB9311

Lube pressure sensor YB1011 YB1011

Starting motor QD138C QD138C

Battery voltage 12V 12V

Voltage regulator FT111 FT111

Generator JFW17H1 JFW17H1

Diode IN5408 (No fitted)

Capacity CB822 IUOJ400V (No fitted)

Charging diode 702R 702R

4.6.2 INSTRUMENTS PANEL

According the choice of the buyer, the engine set is normally fitted one

of the two instruments panel.

1. Tachometer 2. Alarm buzzer and lamp 3.Starting switch 4. Charging

lamp (no fitted in Electric diagram 2.)

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

12

SIYANG

四洋

R

4.7 STARTINGPRECAUTIONS

Starting any engine can be dangerous in the hands of inexperienced

people. Before attempting to start any engine ,the operator should be fully

conversant with starting procedure and controls.

①.Ensure that the batteries are in serviceable condition and correctly

connected.

②.Check that the oil levels in the engine and the gearbox are correct.

③.Check that the fuel tank is full and that the system is primed.

④.Check that the all water drain plugs and cocks are closed. Check that

water inlet valves, if fitted, are opened.

⑤.Check that water level in the expansion tank is filled up with mixture

of water/antifreeze (40%).

4.8 CHECKS BEFORE STARTING

①.Oil level in oil sump and gearbox.

②.Coolant level in the expansion tanker.

③.Battery main switch is on .Oil pressure light and changing light will

now be on and the buzzer will sound.

5 OPERATION OFENGINE

5.1 STARTING

①Before attempting to start the engine ,the operator should be familiar

with the safety precautions as described earlier.

②Move the speed/gearbox lever into the neutral position by means of the

control lever.

③Turn the switch to energize the starting motor.

Release immediately, if the engine start ,and it will return to position

“0”.The alarm light as well as the buzzer should now be off.

④If the engine should fail to start ,due to poor battery condition ,turn the

battery switch to the second start battery and repeat the starting procedure.

⑤If the engine fail to start within 15 seconds ,despite good battery

condition ,release the switch and investigate the cause .The starting motor

should be allowed to cool for at least 15 seconds before attempting to

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

13

SIYANG

四洋

R

restart.

⑥At low temperature it may be necessary to ease the starting by means

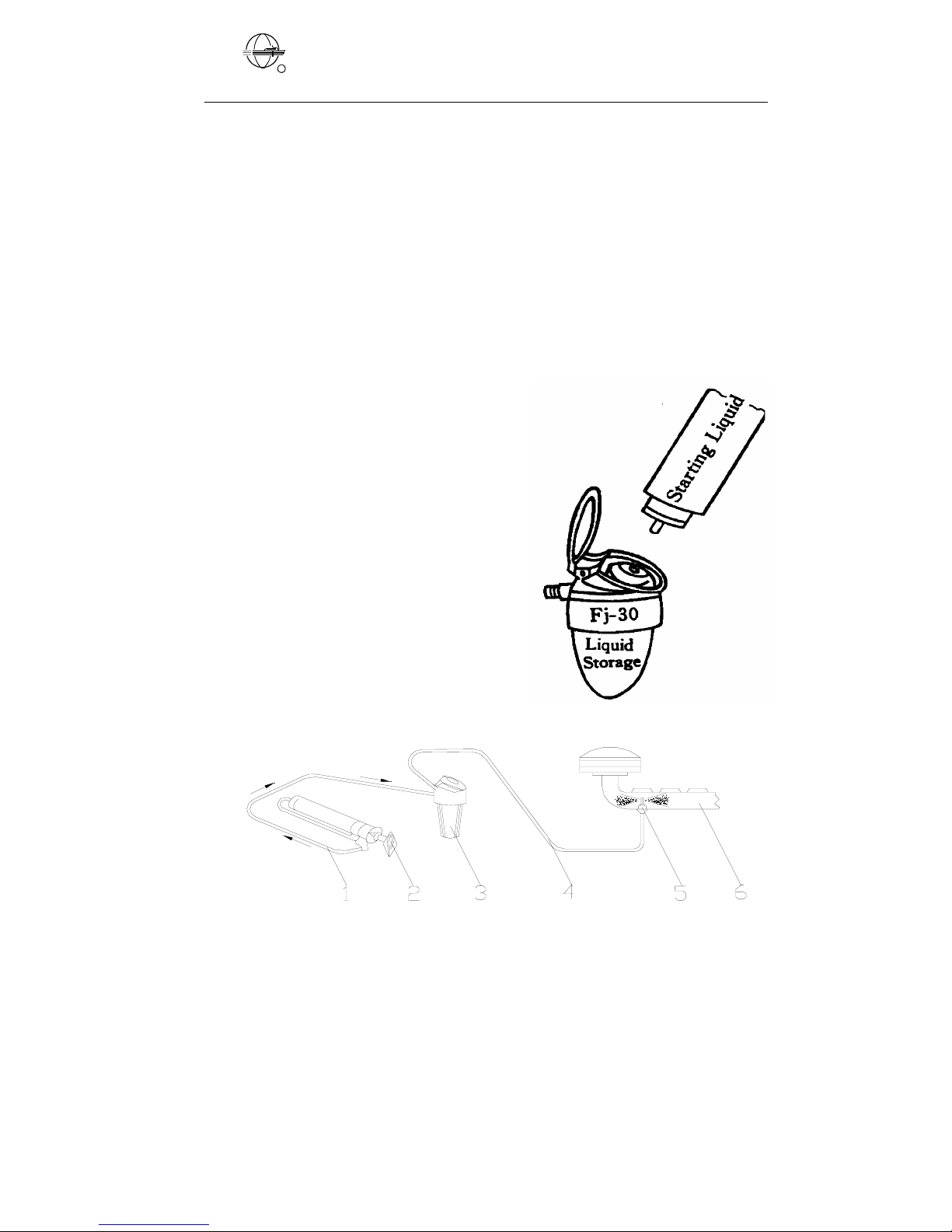

of the start gas.

The operation method is shown as follows:

(1).Open the dust cover of the liquid storage. Insert the pouring liquid

pressure can into the hole of the liquid storage. Squeeze the can to pour

the liquid into liquid storage.

(2).Set the gearbox at idle

position and put the handle of

fuel rack at mid-position.

(3).Start the engine. At the

same time, operate the

hand-pump until the engine

runs stably.

(4).If knocking appears while

the engine is starting; the

operation of hand-pump must

be slowed or stopped, so as to

regulate the injecting liquid

quantity for starting the engine

stably.

CAUTION: Keep away from all heat sources (even sun

light).The liquid is highly flammable.

5.2 STARTING BY SPRING STARTER (IF INSTALLED)

1.Air pipe 2.Hand pump 3.Liquid 4.Liquid pipe 5.Injector 6.Air inlet pipe

low temp. starting liquid pouring system

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

14

SIYANG

四洋

R

According to the buyer requests, we can install and supply the FQ

engine starter (hand starting) for the engine starting.

This starter makes use of man-power to press its spring to store the

energy. The engine is rotated, as the energy relives at a moments and causes

the engine running over the speed of starting revolution of the engine quickly,

and then the engine is starting.

Operation order and method:

1. Press the reset button.

2. Insert the handle, anticlockwise rotation, press the butterfly spring to

fully pressing state.(The red mark is appearing).

3. The energy will relieve at a moment when the lever is pressed. At

that time the engine speed rises over the starting revolution of the

engine, then the engine is starting.

Note: The step-lever must be situated in unabated pressure state

when the engine makes use of the FQ type starter.

4. If it is necessary to rotate the engine with the hands, press the reset

button and draw-up the reliever lever and then the engine can be

rotated with the handle.

Fig. Spring starting motor

287.6

release handle

116

DIR

130

DIR

reset button

cranking bar

125.75

37.75

75

78

APPROX

Note: 1. When use the FQ starter, never open the decompression.

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

15

SIYANG

四洋

R

5.3 OPERATION

If one or more alarm do not go out, or light up when the engine runs,

the engine should be stopped at once to trace the reason.

When all function are normal, engage the gearbox by pushing the

control lever forward or backward.

Increase the speed gradually if possible, allowing the engine to warm

up, before going full speed.

In case of emergency, the lever can be moved into full speed position

immediately.

5.4 STOPPING

Move control lever into neutral position.

Allow the engine to idle for appr.2 minutes to cool.

Stop the engine.

Switch off the battery main Switch.

If fresh water is only used, all of cooling water must be drained out from

the cooling system when the ambient temperature is below 5℃(except anti-

freeze coolant is used)

6 .ROUTINE MAINTENANCE

The engine has passed the lifeboat engine test programmer before

delivery. Still however the engine is not completely run in.

It is recommended to operate the engine moderately during the first

hours after it has been put into service. Full speed only for short periods

during the first 15-20 hours.

6.1 INITIALATTENTION

1.Check and tighten all hose clamps and unions, paying particular

attention to the fuel system.

2.Check and tighten all external nuts and bolts, particularly mounting

bolts, shaft coupling bolts and exhaust manifold bolts and nuts.

3. Check belt tension, see ALTERNATOR BELT TENSION section.

4.Check lubrication oil and water coolant level .

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

16

SIYANG

四洋

R

6.2 ROUTINE MAINTENANCE PERIODES

Period Attention

After the first 15 hours or after the

first 3months See INITIAL ATTENTION

Before start or weekly

Check engine oil level.

Check coolant level.

Check fuel level in tank.

Grease stern gland

Every 3 months or 25 hours Check gearbox oil level

Check battery condition

Every year or 200hours

Change gearbox oil and lube oil

Change lube oil filter

Check alternator belt tension

Check electric connect

6.3 LUBRICATION OILSPECIFICATION

Temperature in starting ℃Mono-grade Multi-grade

Below -15 5w 5w /30

Between and -15

4 10w 10w/30

Between and 4

30 20/20 w 15w/30

10w/30

Above 30 30

15w/40

20w/40

The temperatures mentioned in the table are the ambient temperatures

at the time when the engine is started.

However, if the running temperatures are much higher than the starting

temperatures a compromise must be struck and a higher viscosity oil used ,

providing starting is satisfactory. Multi grade oils overcome the problem,

provided they have a suitable specification .

The engines must be run on heavy duty lubricating oils, meeting the

requirements of API CC.DEF2101D, MIL-L-2104B or MILL-L-46152A/B

EAST CHINA SHIPBUILDING INSTITUTE FACTORY

17

SIYANG

四洋

R

Straight mineral oils are not suitable, neither are oils of less detergency than

specified.

API CD, Series 3, or MIL-L-2104C/D oils can inhibit the running in

process in new or reconditioned engine but can be recommended for

engines running at high load factor, particularly in conjunction with high

ambient temperatures.

Following or equivalent types of oil can be used:

Mobile Delvac 1300 series

Shell Rimula ×oil

Esso lube XD3+

Chevon Delco Super 3

Fina Solna 3

Norol Marine TMA 300

BP energol DS3

Gulfpride Seies 3

Elf Disal HD3

Texaco URSA S3

Castrol Deusol RX super

Amocol New Supper ACE3

6.4 GEARBOX OILSPECIFICATION

Automatic Transmission Fluid -ATF

FORD Specification M 2 C-33 G

GM Specification ATF DEXRON ⅡD

EXXON ATFD or ATF

(or refer to gearbox manual )

6.5 MAIN SPANNER TORQUE SETTINGS

DESCRIPTION N•M

Flywheel bolt 60

Cylinder head nut 140

Connecting rod bolts 70

Prop. shaft coupling bolts (acid proof) 70

Crankshaft main bearing 125

Table of contents

Other Siyang Engine manuals

Popular Engine manuals by other brands

Leadshine

Leadshine iSV2-RS Series user manual

MTU

MTU 12V4000M93 series operating instructions

MTU

MTU C13 operating instructions

Northern Lights

Northern Lights M80A13S Operator's manual

Detroit Diesel

Detroit Diesel MBE 4000 Service information

Briggs & Stratton

Briggs & Stratton 130200 Series Operating and maintenance instructions