249.805.013 3 Date: 2021-12-09

Index

SAFETY INFORMATION 2

INDEX 3

TECHNICAL SPECIFICATIONS 4

DRAWING 5

INTRODUCTION 6

PACKAGE CONTENT ...................................................................................................................................... 6

DESCRIPTION............................................................................................................................................... 6

SAFETY FUNCTIONS ...................................................................................................................................... 7

AREA OF USE............................................................................................................................................... 7

USING FOR THE FIRST TIME ............................................................................................................................ 7

TRANSPORT ................................................................................................................................................ 8

PHYSICAL INSTALLATION 9

FASTENING THE PRODUCT TO A FLAT SURFACE................................................................................................... 9

MOUNTING THE PRODUCT ON A TRUSS............................................................................................................ 9

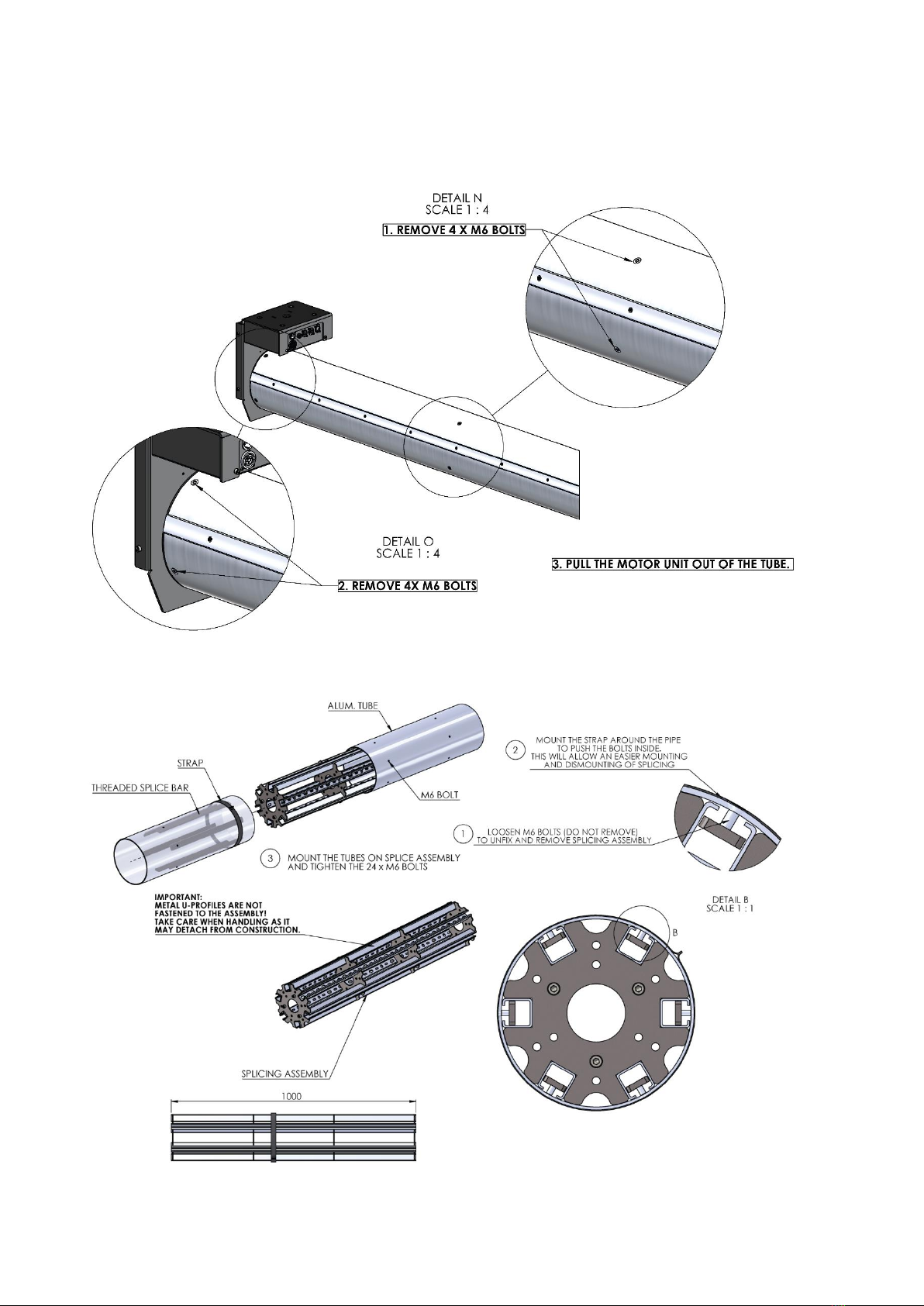

MOUNTING THE TUBE................................................................................................................................. 10

AC POWER 14

POWER CABLES AND POWER PLUG ................................................................................................................ 14

INSTALLING A POWER INPUT OR OUTPUT CONNECTOR ON A POWER CABLE........................................................... 14

DATA LINK 16

TIPS FOR RELIABLE DATA TRANSMISSION ........................................................................................................ 16

CONNECTING THE DATA LINK........................................................................................................................ 16

EMERGENCY STOP SWITCH (OPTIONAL) 17

ENABLE EMERGENCY STOP .......................................................................................................................... 18

READY TO USE ........................................................................................................................................... 18

SETUP 19

MENU SETTING.......................................................................................................................................... 19

MENU STRUCTURE ..................................................................................................................................... 20

ADJUSTABLE PARAMETERS........................................................................................................................... 22

DETAILED EXPLANATION OF PARAMETERS....................................................................................................... 23

DMX ADDRESS SETTING ........................................................................................................................... 25

ADJUSTING HARD LIMIT SWITCHES ................................................................................................................ 26

NORMAL OPERATION ................................................................................................................................. 28

SYNCHRONIZED MOVEMENTS OF MULTIPLE ROLL DOWNS................................................................................. 29

LED FUNCTIONS........................................................................................................................................ 30

ERROR AND ERROR CODES:.......................................................................................................................... 30

SERVICE AND MAINTENANCE 33

PARTS...................................................................................................................................................... 33

ON-SITE SERVICE........................................................................................................................................ 33

MAINTENANCE PLAN .................................................................................................................................. 34

CHECKLIST ................................................................................................................................................ 34

POWERCON TRUE1......................................................................................ERROR!BOOKMARK NOT DEFINED.

APPENDIX 1 - DIMENSIONS 35

APPENDIX 2 - POWERCON 37

APPENDIX 3 –BLOCK SCHEMATIC 39

ROLL DOWN - CHEAT SHEET 40