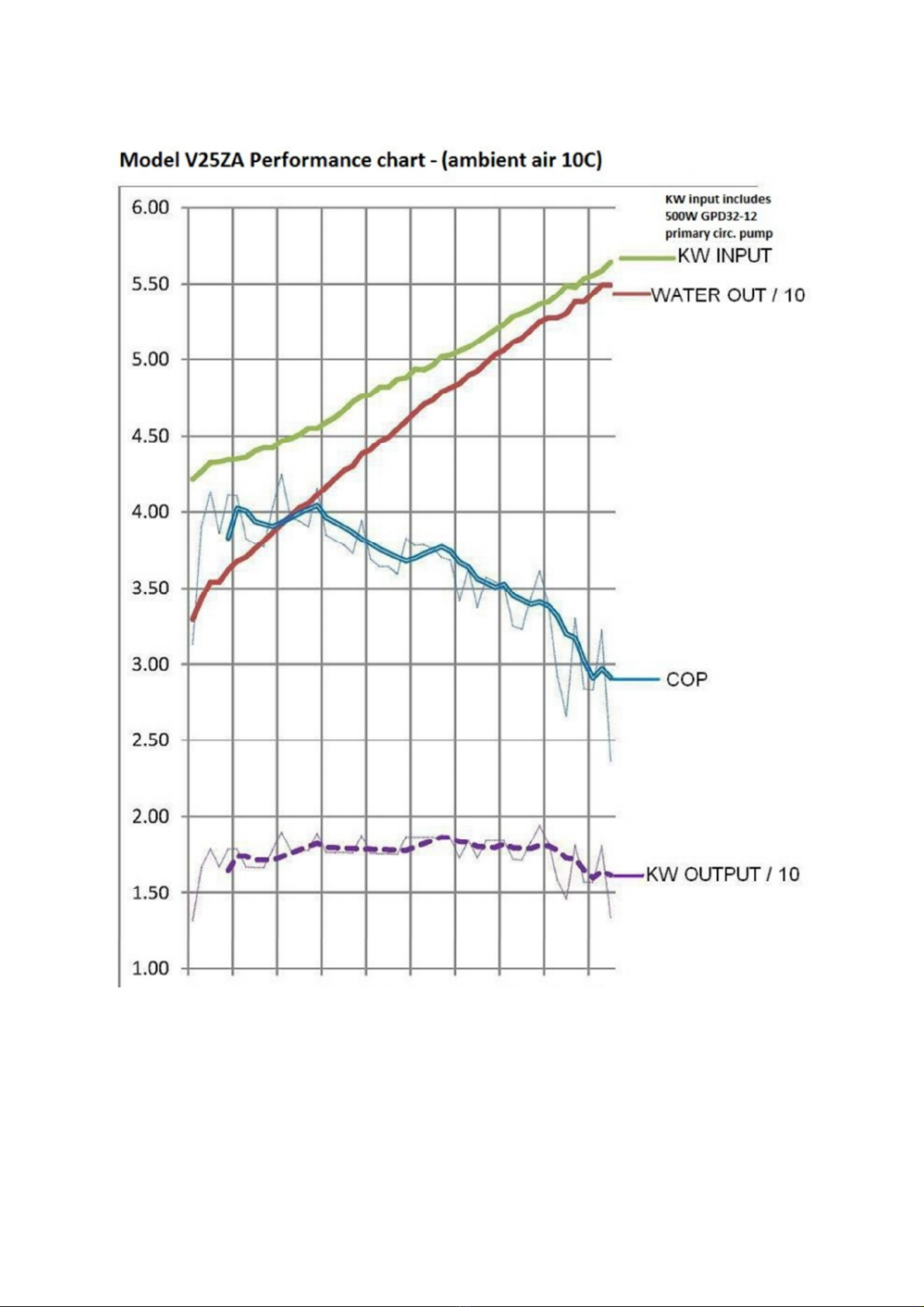

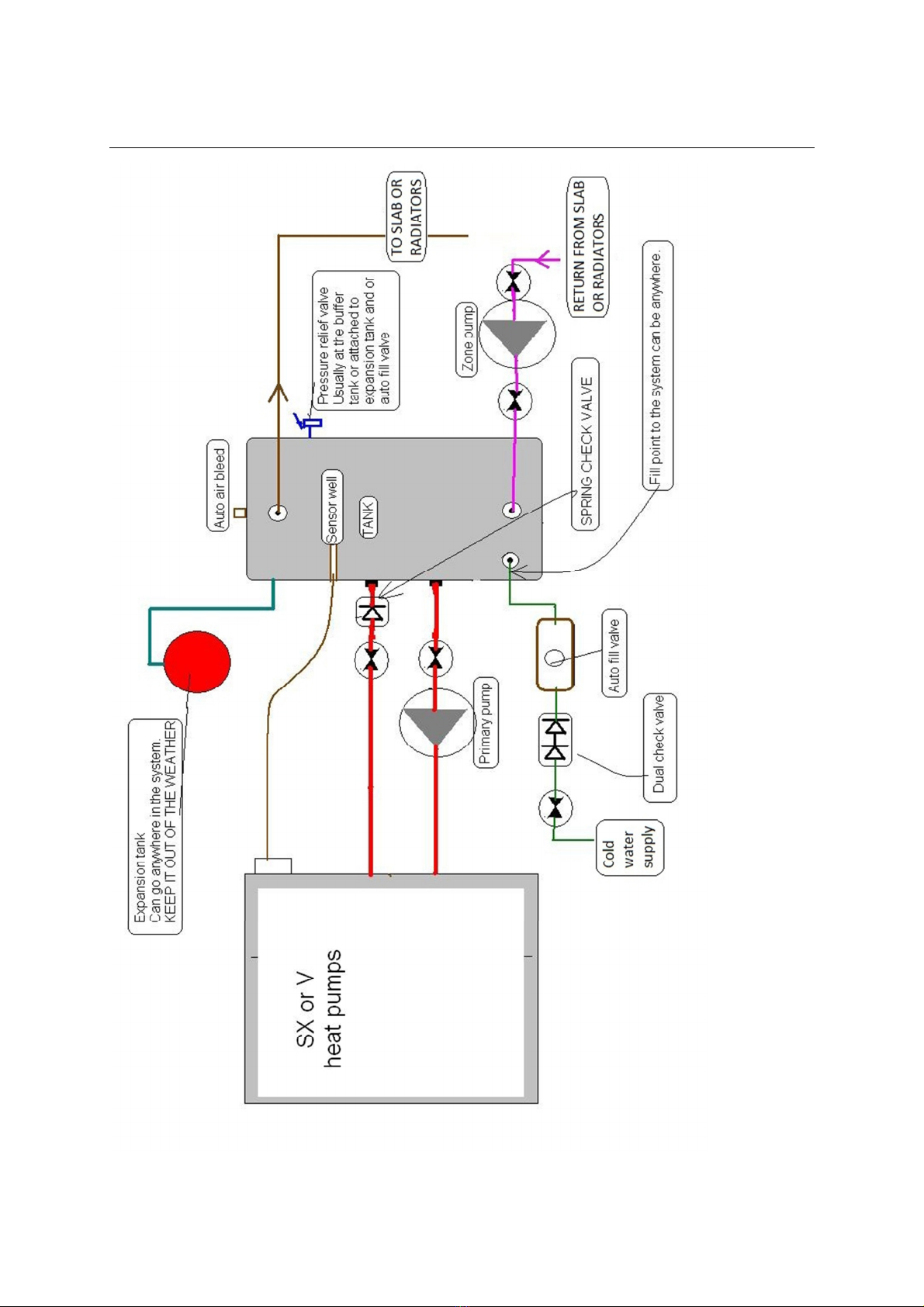

Skyline Energy SX-20BZA User manual

This manual suits for next models

10

Table of contents

Other Skyline Energy Heat Pump manuals

Popular Heat Pump manuals by other brands

gledhill

gledhill BMA 180 HP-DEM Installation & servicing instructions

Daikin

Daikin Altherma EHVH/X16S18+26CA Installer's reference guide

Daikin

Daikin 4MXL36TVJU Service Manual Removal Procedure

Emerson

Emerson Copeland EazyCool ZX Series Application guidelines

York

York 161038-YUM-A-1205 User's information manual

Carrier

Carrier 38BNE018-036 owner's manual

Heat Controller

Heat Controller HBH/V Compact Installation, operation & maintenance manual

Dimplex

Dimplex HPWH 300 Installation and operating instructions

Daikin

Daikin Altherma 3 H MT F installation manual

Toshiba

Toshiba HWS-1403XWHT6-E owner's manual

Nibe

Nibe FIGHTER 360P quick start guide

Ochsner

Ochsner AIR BASIC 109 Operating manual/installation manual

VOKERA

VOKERA AriaPRO 004 M User instructions

Nibe

Nibe AirSite GreenMaster-HP 12 Series Installer manual

CIAT

CIAT µConnect Simplified user manual

SkyLine

SkyLine MACON 270-SS Installation & owner's manual

Carrier

Carrier 50CP Installation, Start-Up and Service Instructions

Sanyo

Sanyo ECO-i WCHDZ32053 datasheet