Skytron TVII User manual

Page 15

TVII

HANDLE CAMERA

SYSTEM

OWNERS MANUAL

12/03

Page 16

Page 1

SKYTRON, a Division of the KMW Group, Inc. (SKYTRON) warrants all new products sold by it directly or through a dealer or other

authorized representative, with exception to replacement parts, spares, bulbs (surgical lights), pads, and accessory items (surgical tables)

to be free from defects in material or workmanship, under normal use and service, for a period of two (2) years.This warranty shall include

the cost of repair or replacement of defective parts including the cost of service labor and travel time to the site of equipment use. Delays

caused by the user in accessing the equipment for repair will be chargeable at the normal hourly rate for service by SKYTRON’s authorized

service representative.The warranty period shall begin with the initial operation or one (1) year after receipt of the product, whichever shall

occur first.

Replacement parts, spares, bulbs (surgical lights), pads and accessory items (surgical tables) are warranted to be free from defects in

material or workmanship, under normal use and service, for a period of ninety (90) days from receipt by the ultimate user, with exception

to replacement parts supplied by SKYTRON, for products under warranty, which shall be covered for any remaining period of the original

product warranty, or for 90 days, whichever is of greater benefit to the ultimate user.

SKYTRON’s responsibility and liability shall be limited to the repair or replacement of any part which we, SKYTRON, determine to be

defective within the applicable warranty period. Minor adjustments required as a result of normal wear during the use of the product within

the warranty period are not covered under warranty.The labor portion of this warranty is covered by SKYTRON’s Authorized Service Agent.

Repairs made by others are not authorized nor covered by SKYTRON with respect to labor costs.

SKYTRON shall not be liable for any other expense, loss or damage, whether direct, incidental, consequential or exemplary arising in

connection with the sale or use of or the inability to use SKYTRON products.

NO EXPRESS WARRANTY IS GIVEN BY SKYTRON WITH RESPECT TO ITS PRODUCTS EXCEPT AS SPECIFICALLY SET FORTH

HEREIN. ANY WARRANTY IMPLIED BY LAW, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICU-

LAR PURPOSE, IS EXPRESSLY LIMITED TO THE TWO-YEAR AND 90-DAY TERMS SET FORTH ABOVE. THE FOREGOING STATE-

MENTS OF WARRANTY ARE EXCLUSIVE AND IN LIEU OF ALL OTHER REMEDIES.

No dealer, agent, employee or other representative of SKYTRON is authorized to extend or enlarge this warranty.

SKYTRON STANDARD LIMITED WARRANTY

Although current at the time of publication, SKYTRON'S policy of continuous development makes this

manual subject to change without notice.

12/03

TITLE PAGE

Model ID................................................................................................................................................... 2

Special User Attention.............................................................................................................................. 3

Introduction .............................................................................................................................................. 4

Installation ................................................................................................................................................ 5

CameraInstallation............................................................................................................................. 5

Camera Removal ............................................................................................................................... 5

Counterweight .................................................................................................................................... 5

Sterilizable Cover ............................................................................................................................... 6

Operation ................................................................................................................................................. 7

Camera Control Unit ................................................................................................................................ 8

Camera Specifications ............................................................................................................................. 9

System Components ............................................................................................................................. 10

Wiring Diagram....................................................................................................................................... 11

Damaged Shipment Claim Procedure.................................................................................................... 12

TABLE OF CONTENTS

Page 2 MODEL ID

STELLAR SERIES

ST23TV

ST29TV

ST2323TV ST2923TV

ST29TV23 ST232323TV

ST292323TV ST29TV2323

Page 3

SPECIAL USER ATTENTION

Tohelpassurethehighestdegreeofoperatingsafety

for user and patient, SKYTRON has provided pre-

cautionary instructions throughout this manual.

Aswith theoperation ofany surgicallight, allhospi-

talpersonnel shouldbeawarethata certainamount

ofcare mustbeexercised tomaintainpatientsafety

andto keepyour SKYTRONSurgical Lightperform-

ing at peak efficiency.

The following is a summary of the important pre-

cautionary instructions:

•Connectorfaceplatemaybe wallmounted,installed

in a cabinet or installed on a Skyboom carrier.

•Make sure Main Power Switch on the light fixture

Wall Control is in the OFF position before installing

or removing the camera.

•Make sure Camera Assembly is securely locked

in lighthead before moving lighthead into use posi-

tion.

•Sterilizablecover must beremoved prior to remov-

ing camera.

•Do not attempt to focus or position the lighthead

using the camera body.Damage to the camera ro-

tation motor may result.

•Do not push in the Camera Release Button on the

LightheadAttachmentRingabove thesterilehandle,

asthis will cause the camera to disengage from the

lighthead.

•Refer to Skytron Stellar Series or Millennium Gold

Series operators Manual for light fixture operation.

ML24TV

ML2424TV

ML242424TV

MODEL ID

MILLENIUM SERIES

Page 4 INTRODUCTION

SKYTRON’S TVII Handle Camera System provides high quality video to camera ready (TV Series)

lightheads. The Sony single chip camera provides quality levels that are comparable to many 3 chip

systems. The system design permits transport from room to room, wherever other TV Series lightheads

are available. The camera control unit can be connected to any existing monitor. A convenient wall jack is

providedforcameracontrol connection. TheTVIIsystem canbe usedon SKYTRONStellarseries(ST23TV

and ST29TV) or Millennium Gold series (ML24TV) camera ready lightheads (ST23TV lighthead shown in

thispublication). TheTVlightheads maybesingle radialarmmounted, partof a multiplelightheadfixture or

combined with a SKYTRON Skyboom on a Central mount fixture,

The TV series lighthead option includes the Cam-

eraReady Lighthead,a counterweightfor usewhen

thelight isto be operatedwith thecamera removed,

a sterilizable camera cover that is used for a posi-

tioning/focushandleand aconnector faceplate with

a 50 foot coaxial cable that connects to the cam-

era/lightfixture.

The connector faceplate allows a quick connect or

disconnect point for the camera control unit. The

faceplate is mounted near where the camera con-

trol unit is to be located. It can be wall mounted,

installedwithin acabinetsuch asa nurse documen-

tation center or installed on a SKYTRON Skyboom

Equipment Carrier. Refer to page 10 forTV system

components.

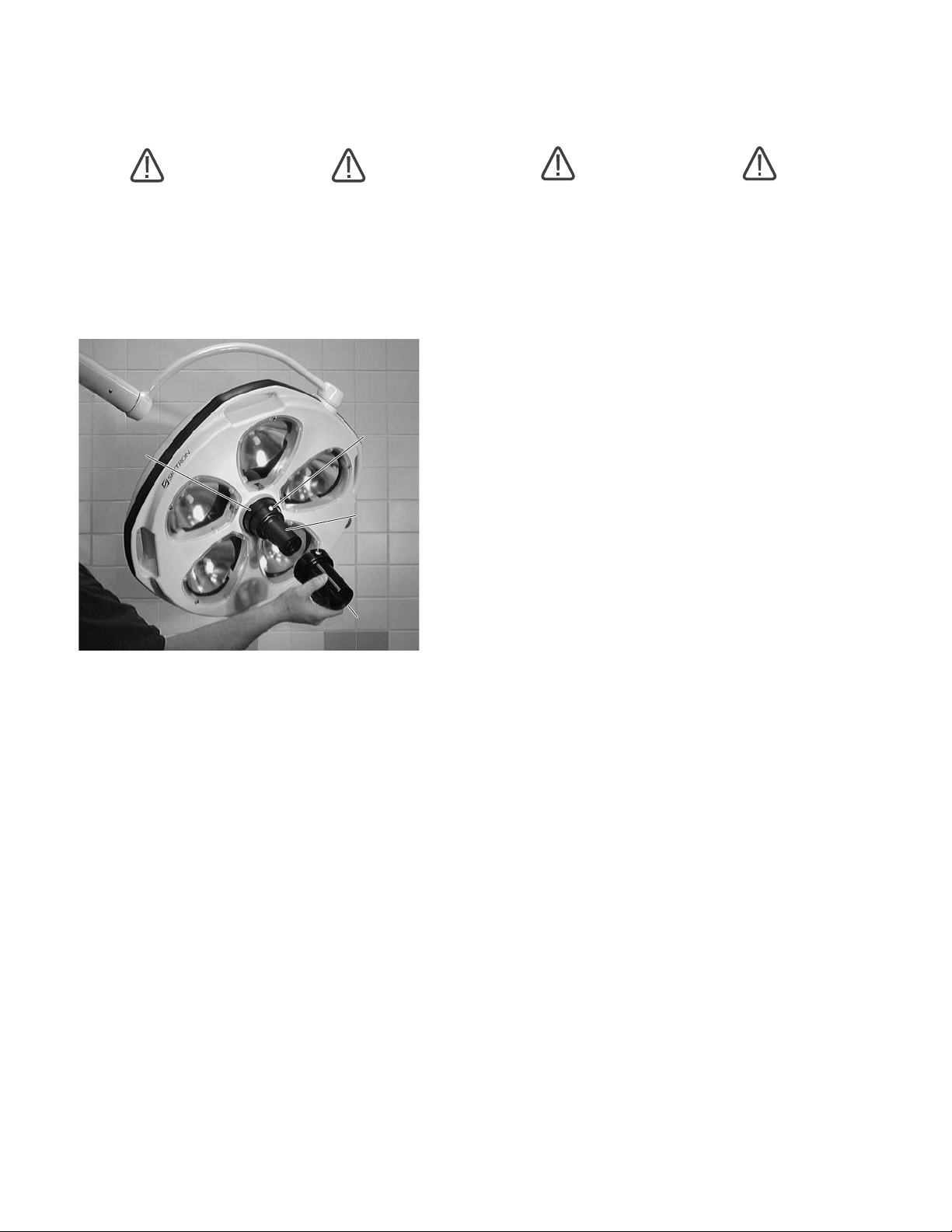

The TVII Handle Camera system consists of the

camera, a camera control unit and a control cable.

The camera mounts in the center of the lighthead

and the sterilizable cover allows sterile positioning

and focus control for the lighthead.

Figure 1.TVII Handle Camera in ST23TV Lighthead

Page 5

Camera Installation

CAUTION

Make sure Main Power Switch on the

light fixture Wall Control is in the OFF

positionbeforeinstalling orremoving the

camera.

Use the following procedure to install the camera

system.

CAUTION

Make sure Camera Assembly is se-

curely locked in lighthead before mov-

ing lighthead into use position.

Camera Removal

Toremovethe cameraassemblyfromthelighthead,

hold the camera firmly, and press the camera re-

lease button on the lighthead attachment ring (fig-

ure 3). Carefully pull the camera assembly straight

out of the attachment ring.

NOTE

Sterilizablecover mustbe removedprior

to removing camera.

Counterweight

Thecounterweight mustbeinstalled tomaintainthe

proper weight required to balance the lighthead

when the camera is not installed.

Install the counterweight in the lighthead and en-

sure that it is fully engaged by pulling and slightly

turning it. Refer to figure 4.

To remove the counterweight from the lighthead,

hold the counterweight firmly, and press the cam-

era release button on the lighthead attachment ring

(figure 3).

Figure 2.

Figure 3.

LIGHTHEAD

ATTACHMENT RING CAMERA RELEASE

BUTTON

Move lighthead to the full down position, and turn

the lighthead so it faces up as shown in figure 2.

Insert the Camera Assembly into the lighthead at-

tachment ring. Push and twist the camera to lock it

into position. Pull out on the camera to verify that it

is fully locked into position.

Figure 4. Counterweight

INSTALLATON

COUNTERWEIGHT

Page 6

Figure 5.

LIGHTHEAD

ATTACHMENT

RING

COVER

LOCKING

PINS

CAMERA

ASSEMBLY

STERILIZABLE

COVER

Sterilizable Cover

CAUTION

Do not attempt to focus or position the

lighthead using the camera body. Dam-

age to the camera rotation motor may

result.

The camera has a sterilizable cover that, when in-

stalled, allows sterile positioning and focus control

for the lighthead. There is also a non-sterile focus

knobon the lighthead.

Toinstallthesterile cover, aligntheholes inthecover

with the cover locking pins on the camera attach-

ment ring and slide the cover on until it locks on the

two pins. See figure 5. To remove the sterile cover,

push the two white pins in and remove the sterile

cover.

CAUTION

Do not push in the Camera Release

ButtonontheLightheadAttachmentRing

above the sterile handle, as this will

causethe camerato disengagefrom the

lighthead.

Recommended sterilization parameters for the

sterilizable cover:

a. Prevac, 270° F, 4 minutes

b. Gravity Wrapped, 250° F, 30 minutes

c. Gravity Flash, 270° F, 3 minutes

Always consult current AORN journal recommen-

dations for proper sterilization procedures.

Page 7

SIDE

FOCUS KNOB

Figure 6.

NOTE

Refer to Skytron Stellar Series or Mil-

lennium Gold Series operators Manual

for light fixture operation.

OPERATION

Turn main power switch on at theWall Control. Ad-

just the intensity control. The intensity control must

be set to at least 20% for the camera to produce a

video signal.

The focus of the bulbs within the lighthead can be

adjustedby rotatingthe sterilizablecover orthe side

focus knob. See figure 6.

Page 8

Camera Control Unit

TheCamera ControlUnit providescontrols for cam-

era rotation, manual or automatic adjustment of Iris

(Aperture), Zoom and Focus. Refer to figure 9 for

control locations.

Description of Controls

MAIN POWER Switch -supplies powertothe cam-

era and control unit. Switch illuminates (green)

when power is ON.

CAMERA ROTATION - allows clockwise and

counterclockwise rotation of the camera. Press the

button for clockwise rotation. Press the for

counterclockwise rotation.

FOCUS - controls the focus of the camera lens.

When Main Power switch is turned ON the Focus

control is set to automatic. To operate the Focus

control manually, press the AUTO button. The Fo-

cus symbol will display on the monitor when in the

manual mode. Press the or button as re-

quired to obtain proper focus. Pressing the but-

ton sets the focus in the telephoto range. Pressing

the buttonsetsthe focusin thewideangle range.

Press the AUTO button again to activate the auto-

matic function.

Figure 9. Camera Control Unit, front view

Camera Control Unit Configuration

1. Attach the Coaxial Cable from the connector on

thefaceplate tothe camera controlunit (CCU). See

figure 7.

BNC

CONNECTOR

2. Connect the video out cable (SVHS or BNC)

from the camera control unit to the monitor.

3. Connect the power cord to the CCU and plug

into 120 VAC outlet. See figure 8.

Figure 8. Camera Control Unit, back view

120VAC INPUT

POWER CORD

CONNECTOR

BNC

VIDEO OUTPUT

CONNECTOR

BNC

CAMERA CABLE

CONNECTOR

SVHS

VIDEO OUTPUT

CONNECTOR

Figure 7. Camera Control Connector

Faceplate

MAIN

POWER

FOCUS

BRIGHT UP

D ZOOM

DISPLAY

CAMERA

ROTATION

ZOOM

AE

AUTO

IRIS DOWN FREEZE

Page 9

ZOOM - controls the image size. To make the sub-

ject larger, press the button. To make the sub-

ject smaller, press the button.

AE AUTO - allows automatic control of both IRIS

and BRIGHT functions.

BRIGHT - adjusts both the gain and iris using an

internal algorithm according to a brightness level

freelyset bythe user.Exposure iscontrolled bygain

when dark, and by iris when bright.

IRIS (Aperture) - controls the video signal bright-

ness by opening or closing the iris of the camera to

allow more or less light to enter the camera. When

Main Power switch is turned ON the Iris control is

set to automatic. To operate the Iris control manu-

ally, press the AE AUTO button. The “F” stop set-

ting will display on the monitor when in the manual

mode. Press the UP button to increase the bright-

ness. Press the DOWN button to decrease the

brightness. Press the AE AUTO button again to ac-

tivate the automatic function.

UP / DOWN - used with IRIS and BRIGHT options.

D ZOOM - controls digital zoom function. When

activated, extends zoom ratio from 10X to 40X.

DISPLAY - displays the current iris, zoom and fo-

cus settings on the monitor.

FREEZE - press to capture present view “snap-

shot”. Press again to resume normal operation.

TheHandle Camerasystem consistsof aLighthead

handle mounted, super compact color CCD cam-

era with a 10X zoom, high speed auto focus lens.

Controls are provided for camera rotation, focus,

zoom, Bright - Iris adjustment, digital zoom and

freeze. Composite and SVHS outputs are avail-

able.

SPECIFICATIONS:

Image Sensor 1/4" IT, Super HAD CCD

with Digital Signal Proces-

sor (DSP)

Video Signal Out Composite or SVHS

Picture Elements 768 (H) x 494 (V)

Resolution 470TV lines

Lens 10x Zoom f=4.2 to 42 mm

(F1.8 to F2.9)

Zoom Ratio 40x (10x optical, 4x digital)

Angle of View (H) Approx. 46 degrees (wide

end) to 5.0 degrees (tele

end)

Min. Object Distance 10mm (wide end) :

1000mm (tele end)

Iris Automatic/Manual

Min. Sensitivity 2.0 Lux

S/N Ratio 50dB +

White Balance Auto

Electronic Shutter 1/1 to 1/10,000 sec., 22

steps

Gain Auto/Manual (-3 to 28dB,

2dB steps)

AE Control Auto, Manual, Priority

mode, Bright, EV comp.

Back light comp.

Page 10

1 B1-420-08 CAMERA..............................................................................................1

2 B1-410-76 SLEEVE, sterilizable, camera cover ....................................................1

3 B1-420-02 COUNTERWEIGHT ............................................................................1

4 H7-010-47 CABLE ASSEMBLY, coaxial, RG59, 50 ft. ...........................................1

5 B1-420-30 CONNECTOR & FACEPLATE, camera control...................................1

6 B1-420-07 CAMERA CONTROL UNIT .................................................................1

7 B9-211-04 POWER CORD, camera control unit ...................................................1

8 H7-010-29 CABLE, coaxial, RG59 (specify length) ............................................. SP

H7-010-23 CONNECTOR, BNC, male ..................................................................2

Item Part No. Description Qty.

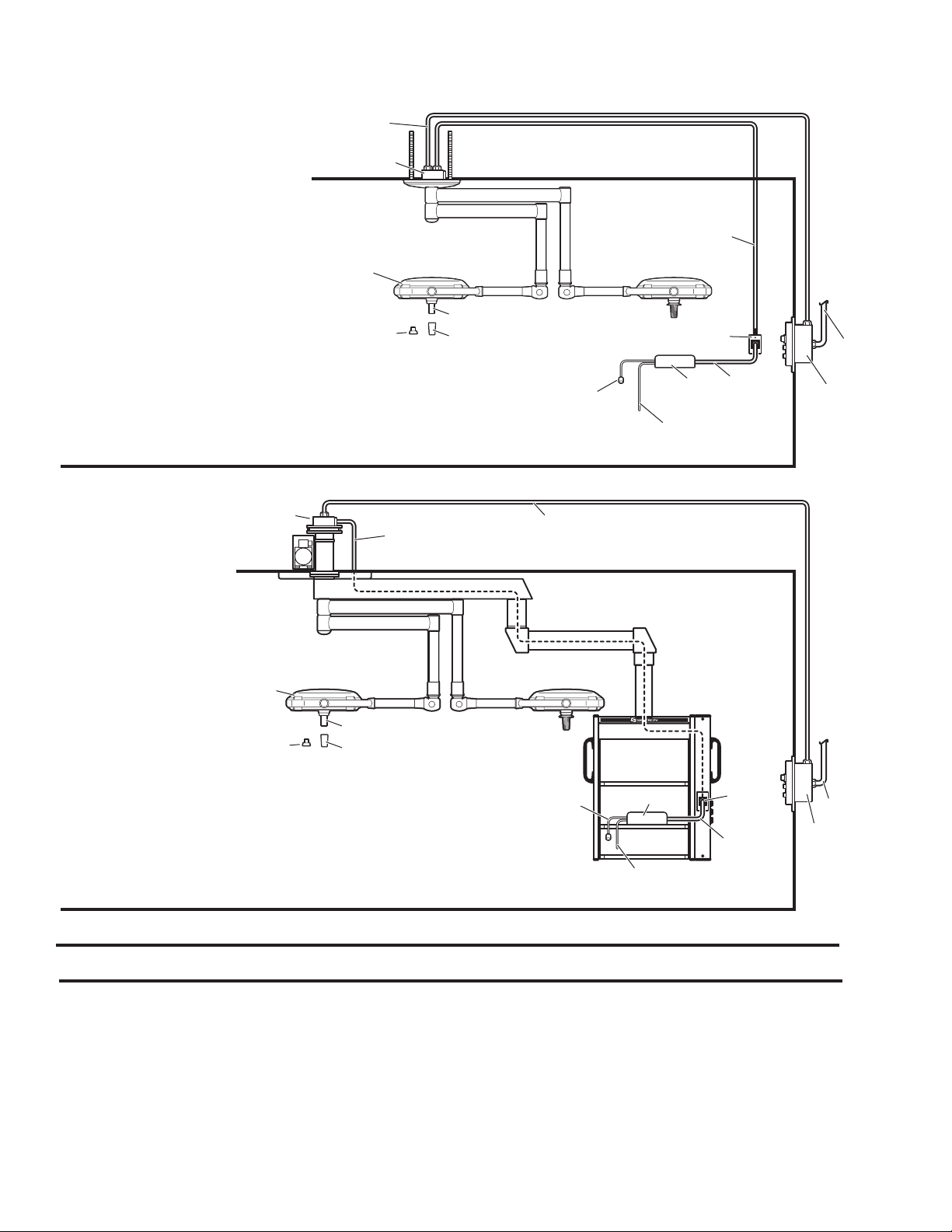

Lighthead J-Box

4

Wall Control

120V In

5

8

Video "out"

(customer supplied BNC or SVHS)

7

12 AWG Wiring

As Required

(customer supplied)

6

Camera Ready

Lighthead

Wall Control

120V In

Camera Control J-Box

412 AWG Wiring

As Required

(customer supplied)

Camera Ready

Lighthead

1

Video "out"

(customer supplied BNC or SVHS)

6

8

5

TV-II HANDLE CAMERA

SYSTEM COMPONENTS

(SKYBOOM CENTRAL MOUNT)

TV-II HANDLE CAMERA

SYSTEM COMPONENTS

32

7

1

32

NOTE

Connector Faceplate

may be

•Wall mounted

•Installed in a cabinet

•Installed on Skyboom

carrier

SYSTEM COMPONENTS

Page 11

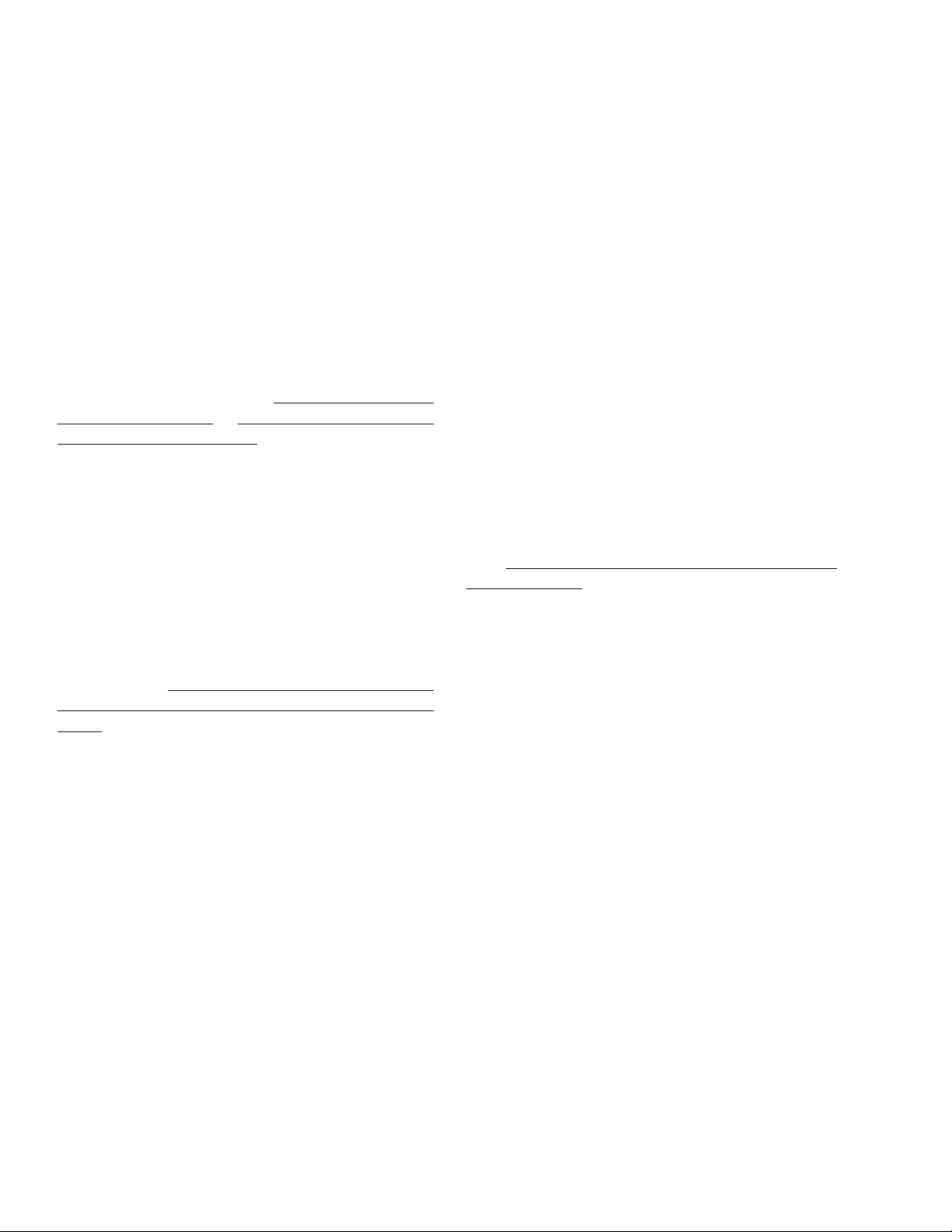

TVII CAMERA SYSTEM

WALL

CONTROL

BOX

GWR

TIME

MENU

FOCUSIRIS ZOOM

CAMERA

ROTATION

MAIN

POWER

EXECUTE

DOWN

UP

DISPLAY

AUTO AUTO

DATE

1

2

3

4

5

6

1

RED - DC POWER +

BLACK - DC POWER

-

YELLOW - MOTOR POWER

BROWN - MOTOR POWER

GREEN - VIDEO OUT

ORANGE - VIDEO OUT

2

3

4

5

6

PCB #2

VPS (VIDEO POWER SUPPLY)

M

TS

POWER

CORD

CAMERA CONTROL UNIT

B1-420-07

AC INPUT 120V

HANDLE CAMERA

B1-420-08

CABLE #1

FACEPLATE

BNC

CONNECTOR

SIGNAL IN

DISPLAY VIDEO OUT

COMPOSITE,

S-VIDEO

BNC OR SVHS

PCB #1

VFB (VIDEO FILTER BOARD)

CAMERA

ROTATION

MOTOR CABLE #2

COAXIAL CABLE ASSEMBLY

RG59U - 50' H7-010-47

Page 12

DAMAGED SHIPMENT CLAIM PROCEDURE

Whenever a shipment suffers damage while in the

custodyof the transportation company, the respon-

sibilitylies withthetransportation company, and the

value of the damages can be collected from the

transportation company if the proper procedures

arefollowed.

When a shipment is received in a damaged condi-

tion and due to the appearance of the containers

such as a broken crate, torn wrapping, or smashed

carton,the contentsmayhavebeendamaged. That

factshould be noted on theBill of Lading offered by

the transportation company. An example of an ap-

plicable statement would be; "Received in good or-

der except as noted" or "Crate damaged, possibil-

ity of concealed damage." The addition of these

typesof statements on the shippingdocuments will

automatically give grounds for starting a claim.

Ifdamage cannot beidentified on theexterior of the

container,butisfoundwhenthe containerisopened,

further unpacking should be stopped immediately

and the container with all wrapping or packing ma-

terials should beheld. The transportationcompany

should be notified so an inspector can be sent.

Failureto followeither of thesetwoprocedures may

result in an inability to file a claim and collect for

damagedone. Returningthecontainertothesender

without such an inspection may prevent filing a

claim, because it will divide the responsibility for

damage and in many cases the

transportation company will return the shipment to

the sender without charge after the inspection.

The claim itself may be filed by either the shipper

or consignee, but the consignee must notify the

transportation company and the shipper that the

damage has occurred. Remember that refusal of

theshipmentorfailuretonote thepossibilityofdam-

ageonthe shippingdocuments mayjeopardize the

claim. Also, acceptance of a damaged shipment

which has been processed properly to allow for

filing a claim, will not jeopardize the position of the

consignee. In any case, SKYTRON will see that

damage which is not the fault of the consignee or

his agents is corrected, if the transportation com-

pany does not honor the claim, as long as

SKYTRON receives the full cooperation of the

consignee in filing the claim.

Some of the papers needed for filing a claim are in

thehandsof theconsingnee afterthe shipmenthas

been received. If SKYTRON must file a claim, we

will request these papers by name from the con-

signee at such time as the claim is under discus-

sion. We will require the originals of these papers

and not copies.

Knowledge of the procedures outlined above and

yourcooperation in submitting damagedshipment

claims will help both you, our customer, and

SKYTRON by assuring the integrity of our prod-

ucts from manufacturing to installation.

Page 13

Page 14

s:\commdept\1skytron\lights\Stellar\tvII\TVIIowner

500036th StreetS.E.,Grand Rapids,MI 49512

1-800-SKYTRONor1-616-957-0500 • FAX 1-616-957-5053

Table of contents