Slim's Detailing SLIMS149 User manual

1.2. General Safety

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

WARNING!Disconnect from mains power before changing accessories or servicing.

Maintain the sander/polisher in good condition (use an authorised service agent).

Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

Use the sander/polisher in a suitable work area. Keep area clean, tidy and free from unrelated materials. Ensure that there is adequate

lighting.

Before use, check abrasive pad condition. If worn or damaged replace immediately.

WARNING! Always wear approved eye or face protection when operating the sander/polisher.

If dust is generated, use face, dust, or respiratory protection in accordance with COSHH regulations.

Depending on use, sander/polisher noise level may exceed 85dB - in which case wear safety ear defenders.

Remove ill fitting clothing, ties, watches, rings, other loose jewellery and contain and/or tie back long hair.

Wear appropriate protective clothing and keep hands and body clear of moving parts.

Maintain correct balance and footing. Ensure the floor is not slippery and wear nonslip shoes.

Keep children and unauthorised persons away from the work area.

Always use the sander/polisher with the side handle securely screwed in.

Ensure the workpiece is correctly secured before operating the sander/polisher. Never hold workpiece by hand and check the workpiece to

ensure there are no protruding nails, screws, rivets, etc.

FUSE RATING

THIS PRODUCT MUST BE

FITTED WITH A

5 AMP FUSE

INSTRUCTIONS FOR:

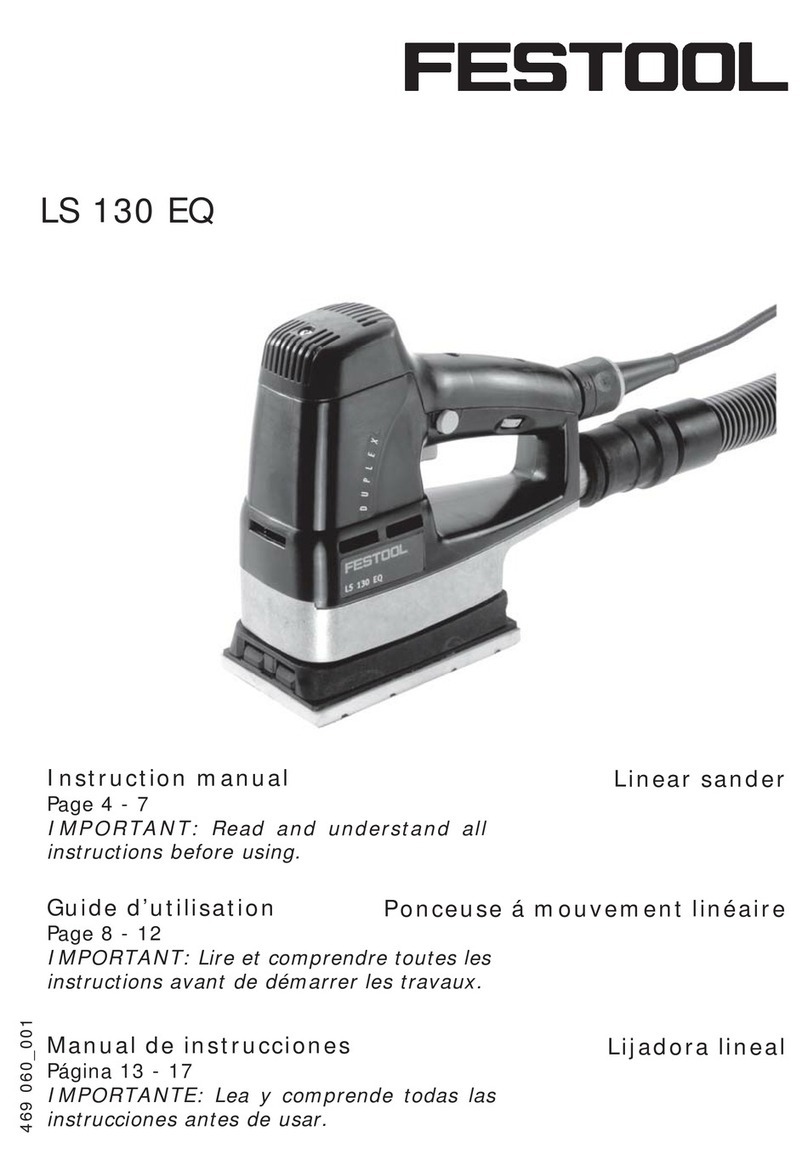

600W 150MM RANDOM ORBITAL DUAL

ACTION SANDER/POLISHER

MODEL NO: SLIMS149

1. SAFETY

1.1. ELECTRICAL SAFETY

WARNING! It is the responsibility of the owner and the operator to read, understand and comply with the following:

You must check all electrical products, before use, to ensure that they are safe. You must inspect power cables, plugs, sockets and any other

connectors for wear or damage. You must ensure that the risk of electric shock is minimised by the installation of appropriate safety devices. A

Residual Current Circuit Breaker (RCCB) should be incorporated in the main distribution board. We also recommend that a Residual Current

Device (RCD) is used. It is particularly important to use an RCD with portable products that are plugged into a supply which is not protected by an

RCCB. If in any doubt consult a qualified electrician. You may obtain a Residual Current Device by contacting your Sealey dealer.

You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity at Work Act 1989 requires that all portable electrical appliances, if used on business premises, are tested by a

qualified electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of those

appliances and the safety of the appliance operators. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply. See 1.1.1. and 1.1.2.

and use a Portable Appliance Tester.

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure

that none is loose.

1.1.6. Important: Ensure that the voltage marked on the appliance matches the power supply to be used and that

the plug is fitted with the correct fuse - see fuse rating at right.

1.1.7. DO NOT pull or carry the appliance by the power cable.

1.1.8. DO NOT pull the plug from the socket by the cable.

1.1.9. DO NOT use worn or damaged cables, plugs or connectors. Immediately have any faulty item repaired or

replaced by a qualified electrician. When a BS 1363/A UK 3 pin plug is damaged, cut the cable just above

the plug and dispose of the plug safely. Fit a new plug according to the following instructions (UK only).

a)Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b)Connect the BROWN live wire to the live terminal ‘L’.

c)Connect the BLUE neutral wire to the neutral terminal ‘N’.

d)After wiring, check that there are no bare wires, that all wires have been correctly connected, that

the cable outer insulation extends beyond the cable restraint and that the restraint is tight.

Double insulated products, which are always marked with this symbol , are fitted with live (brown) and neutral (blue) wires only.

To rewire, connect the wires as indicated above - DO NOT connect either wire to the earth terminal.

1.1.10. Products which require more than 13amps are supplied without a plug. In this case you must contact a qualified electrician to ensure that a

suitably rated supply is available. We recommend that you discuss the installation of an industrial round pin plug and socket with your

electrician.

1.1.11. If an extension reel is used it should be fully unwound before connection. A reel with an RCD fitted is preferred since any appliance

plugged into it will be protected. The cable core section is important and should be at least 1.5mm², but to be absolutely sure that the

capacity of the reel is suitable for this product and for others which may be used in the other output sockets, we recommend the use of

2.5mm² section cable. If an extension reel is to be used outdoors, ensure it is marked for outdoor use.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Slim's product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

Refer to

instruction

manual

Wear ear

protection

Wear eye

protection

Wear

protective

gloves

Wear

a mask

Original Language Version SLIMS149 | Issue:2- 18/08/16

LEAD PAINT WARNING!

Paint once contained lead as a traditional ingredient. The dust from the removal of such paint is toxic if inhaled or ingested and must, therefore,

be avoided. The following action must be taken before using the sander/polisher on a surface that you suspect may have contained lead in the

paint.

1. User must determine potential hazard relating to age of paint to be removed. (Modern paints do not contain lead).

2. DANGER! Keep all persons and pets away from the work area. The following are particularly vulnerable to the effects of lead paint dust:

Expectant women, babies and children.

3. We recommend personal protection by using the following safety items:

a) Paint Spray Respirator

b) PE Coated Hooded Coverall

c) Latex Gloves

4. Take adequate measures to contain the paint dust, flakes, and scrapings.

5. Continue to wear safety equipment as in 3 above, and thoroughly clean all areas when task is complete. Ensure that paint waste is disposed of,

in sealed bags or containers, according to local authority regulations.

Model No:............................................. SLIMS149

Power:................................................... 600W

No load speed:...................................... 1500-6800rpm PADS: SLIMS149

Orbit size:.............................................. ø8mm Optional Pad: PTC/150A Stick-on (Firm)

Pad:....................................................... ø150mm Optional Pad: PTC/150SA (supplied) Stick-on(Soft)

Thread:.................................................. 5/16”UNF Replacement Pad: PTC/150VA

Weight:.................................................. 2.26 kg

Vibration:............................................... 2.3m/s²

Uncertainty:............................................1.15m/s²

Noise power:..........................................91dB(A)

Noise pressure:................................... 80dB(A)

WARNING! Before use, ensure that you have read and understood Section 1 Safety Instructions.

5.1. Attach the correctly rated sanding disc (not supplied) to the sanding pad.

5.2. Plug the sander/polisher into the mains power supply.

5.3. Ensure that the speed scroll switch is set to the lowest setting before starting the sander/polisher (fig.1). Grip the handle and turn on by

pushing switch (fig.1) forward. Let go of the switch and the machine will continue running. Increase the speed of the sander/polisher using

the variable switch located at the rear of the sander/polisher (fig.1).

Note: The sander/polisher is designed for dry use only. DO NOT use with water or any other liquids.

WARNING! DO NOT plug sander/polisher into the mains power supply before it is fully assembled.

Screw the sanding pad onto the spindle (fig.1). To remove pad, hold spindle with the spanner supplied whilst unscrewing the pad.

Avoid unintentional starting.

DO NOT use the sander/polisher for a task it is not designed to perform.

DO NOT operate the sander/polisher if any parts are damaged or missing. This may cause failure and/or injury.

WARNING! DO NOT sand any materials containing asbestos.

DO NOT carry the sander/polisher by the electrical cable.

DO NOT connect to a standard vacuum cleaner to extract dust as damage to the cleaner may result.

DO NOT get the sander/polisher wet or use in damp or wet locations.

DO NOT use the sander/polisher with water, for dry use only.

DO NOT operate the sander/polisher if you are tired or under the influence of alcohol, drugs or intoxicating medication.

DO NOT use where there are flammable liquids, solids or gases such as paint solvents or waste wiping or cleaning rags.

DO NOT leave the sander/polisher running unattended.

DO NOT carry the sander/polisher with your finger on the power switch.

When not in use disconnect from the power supply and store in a safe, dry, childproof area.

WARNING! The warnings, cautions and instructions in this manual cannot cover all possible conditions and situations that may occur. It

must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be applied

by the operator.

Lightweight, compact sander/polisher with variable speed control from 1500 to 6800rpm. Dual action orbit of Ø8mm helps cover more surface

during use. Powered by a 600W motor with a slide on/off switch on top. Soft-grip for added comfort. Supplied with mains cable.

3. SPECIFICATION

2. INTRODUCTION

4. ASSEMBLY

5. OPERATION

fig.1

Original Language Version SLIMS149 | Issue:2- 18/08/16

WARNING!Disconnect sander/polisher from power supply before changing accessories, servicing or performing maintenance. Replace or

repair any damaged parts. Use genuine parts only, unauthorised parts may be dangerous and will invalidate the warranty.

6.1. After each 50 hours use (or as required), remove dust by blowing air through the side vents and around the pad bearing. Periodic cleaning

will prolong machine life.

6.2. Change pads when required. Ensure pad and disc RPM ratings are equal to the machine rating. If the disc becomes unbalanced, it will

cause the bearings to wear.

6.3. When not in use store in a safe, dry, childproof location.

6.4. Check brushes every 200 hours of use. To access the brushes refer to fig.2. Undo the screws in the side of the motor casing and slide

off the covers. Using a small screwdriver lift the brush spring to one side and slide the brush out of its holder. If the brush is worn to half

of its original length, it should be renewed. Using thin nosed pliers pull the brush connector off its connector. Slide the new brush into its

holder. Refit the brush connector. Position the spring so that it bears down onto the end of the brush. Remember to renew brushes as a

pair. Fit rear covers back into place and retain it with the screws.

6.5. All other service and maintenance must be carried out by an authorised service agent.

6. MAINTENANCE

fig.2

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted,

taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable and requires disposal, drain off any fluids (if applicable)

into approved containers and dispose of the product and the fluids according to local regulations.

WEEE Regulations

Dispose of this product at the end of its working life in compliance with the EU Directive on

Waste Electrical and Electronic Equipment (WEEE). When the product is no longer required, it must be disposed

of in an environmentally protective way. Contact your local solid waste authority for recycling information.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

0333 222 9943

Slim's Detailing

Unit 2,Baird Road,

Enfield,

Middx. EN1 1SJ

www.slimsdetailing.co.uk

Original Language Version SLIMS149 | Issue:2- 18/08/16

WARNING! – Risk of Hand Arm Vibration Injury.

This tool may cause Hand Arm Vibration Syndrome if its use is not managed adequately.

This tool is subject to the vibration testing section of the Machinery Directive 2006/42/EC.

This tool is to be operated in accordance with these instructions.

Measured vibration emission value (a): 2.3m/s²

Uncertainty value(k): 1.15m/s²

Please note that the application of the tool to a sole specialist task may produce a different average vibration emission. We recommend that a

specific evaluation of the vibration emission is conducted prior to commencing with a specialist task.

A health and safety assessment by the user (or employer) will need to be carried out to determine the suitable duration of use for each tool.

NB: Stated Vibration Emission values are type-test values and are intended to be typical.

Whilst in use, the actual value will vary considerably from and depend on many factors.

Such factors include; the operator, the task and the inserted tool or consumable.

NB: ensure that the length of leader hoses is sufficient to allow unrestricted use, as this also helps to reduce vibration.

The state of maintenance of the tool itself is also an important factor, a poorly maintained tool will also increase the risk of Hand Arm Vibration

Syndrome.

Health surveillance.

We recommend a programme of health surveillance to detect early symptoms of vibration injury so that management procedures can be modified

accordingly.

Personal protective equipment.

We are not aware of any personal protective equipment (PPE) that provides protection against vibration injury that may result from the

uncontrolled use of this tool. We recommend a sufficient supply of clothing (including gloves) to enable the operator to remain warm and dry and

maintain good blood circulation in fingers etc. Please note that the most effective protection is prevention, please refer to the Correct Use and

Maintenance section in these instructions. Guidance relating to the management of hand arm vibration can be found on the HSC website

www.hse.gov.uk - Hand-Arm Vibration at Work.

Table of contents

Popular Sander manuals by other brands

DeWalt

DeWalt DWE6423-QS Original instructions

Mountfield

Mountfield PATRIOT EB0300 user manual

Wen

Wen HB6319 instruction manual

Alpha Professional Tools

Alpha Professional Tools AIR-680 instruction manual

FESTA

FESTA 28040 Manual for use

Ingersoll-Rand

Ingersoll-Rand 8416-B Series Operating and maintenance manual