Smach SUDE 100 User manual

1

BATCH FREEZER

USER GUIDE

(OPERATING MANUAL)

for

MODEL: SUDE 100

Manual Number: V 000 - 17.04.2012

2

1.TABLE OF CONTENTS

1. Table of Contents

2. Contact Details & Help Desk

3. Congratulations And Thank You

4. Electrical Connection Notice

5. Warnings and Precautions

6. Proper use and Safety Notices

7. Operating Procedure

8. Clearance Parameters

9. Control buttons

10.Beater assembly

11.Dispensing cover assembly

12.Beater-machine assembly

13.Dispensing cover-machine assembly

14.Making ice cream

15.Dispensing the ice cream

16.Cleaning and sanitizing the machine

17.Bacteria growth table

18.Possible failures and solutions

3

2.CONTACT DETAILS & HELP DESK

Smach Gıda Makine San.Tic.A.Ş

ADDRESS AND CONTACT DETAILS

Smach Gıda Makine San.Tic.A.Ş

Guzelyurt Mah.5762 Sok.No 5/A

Orta Olcekli San.Bol.

Manisa/TURKEY

Tel: +90 236 233 39 29

Fax: +90 236 236 12 59

E-Mail: [email protected]om.tr

When calling Smach have the following information ready:

1. Freezer Serial Number: Found on body panel

Write down the serial number in this box

2. This Model Number: MODEL SUDE 100/500

3. A brief description of the problem

4

3.CONGRATULATIONS AND THANK YOU!

Congratulations ―and thank you for acquiring a Ice Cream Machine manufactured

especially in Turkey by Smach Gıda Makine A.Ş.

If you encounter a problem with the Smach Ice Cream Machine please contact your local

Service Technician

Please familiarize yourself with the machine by taking some time to study this User Guide.

If you get to know this little ice-cream factory, it has the potential of making good profit.

Notice and no warrantee: These pages are provided as a service and informational purpose only,

and on the assumption that the recipient of the machine and the operator of the machine is

competent to perform the required tasks, including, but not limited to operation and/or repair of

power equipment, for which the information is provided, and that person is knowledgeable and

mindful of proper safety precautions. Neither Smach, nor any of their respective employees make

any claims about the suitability or fitness of the information contained herein which is provided

strictly on an "as-is" basis, without any express or implied warranty, guarantee, assurance of

quality, conformity of specifications, reliability, functionality, or suitability. In no event shall Smach

and/or its employees be held liable, whether in contract or tort, to any party for any direct, indirect,

punitive, or consequential damages, including, but not limited to lost profits and business

interruption, arising out of any errors, typographical or otherwise, inaccuracies, omissions, or

delays arising out of or pertaining to the use, reliance on, or inability to use any type of information,

part, or good, even if notified in advance about the possibility of such action. Information in this

manual is subject to change without notice. All rights reserved.

5

4.ELECTRICAL CONNECTION NOTICE

1. Please make sure that the power supply conforms to the electrical data label (Rating

Plate).

2. Check the data label (Rating Plate) for the required circuit breaker amperage. Only plug

into an electrical wall socket that complies with the required amperage of the machine

3. Machine should be installed according to the local authority electrical code/regulations it

is used in, as well as to other work health and safety requirements. If you are not sure,

please contact your local authority for details.

4. ―this symbol indicates the presence of electric shock hazards. Inside the

enclosures of the machine there are electrical shock hazards, therefore, do not remove

any panels if you are not a qualified technician of an authorized service provider.

5. WARNING: To avoid risk of injury from electric shock, if you are not a qualified and duly

authorised service technician, do not open the enclosure panels on the sides and back of

the machine

6. The power supply must be properly grounded to prevent electrical shock. Check with a

qualified installer for compliance.

5. WARNINGS & PRECAUTIONS

Keep your Freezer clean and tidy! When it needs repairing, work with an authorized

Smach service agent.

The service technician or installer must be a suitably qualified and authorized person and

must amongst other things ensure the following:

1. That the Freezer is properly grounded (earthed).

2. The fuse must be 220-240V, 50 Hz 16 Amp.

3. Never open the panels to reach inside the Freezer body. (Only by authorized technicians).

4. Do not clean the machine with high-pressure water.

5. Technical maintenance must be done by authorized technicians.

6. Only use food-grade lubricant when changing or replacing the O-rings on the pistons.

NOTICE: Smach Gıda Makine A.Şwill not take any responsibility if the users do not follow all the instructions

as described in this User Guide.

6

6. PROPER USE OF THE BATCH FREEZER

When properly used and cared for the Machine will provide a consistent quality Ice

Cream. Like all equipment used to manufacture food products it will require daily cleaning

and regular maintenance. A specified amount of care and attention is required including

but not limited to everything prescribed in this manual.

SAFETY NOTICES

Smach is concerned about the safety of the person/s using the machine. Therefore please

take note and abide by amongst others, the following WARNINGS:

The weight of the Machine is no less than 105 kg. Moving it must only be

done by persons who are trained and qualified to move a weight of at least

105 kg in the shape and size of the machine.

A potential risk exists if the User Guide instructions and other safety

precautions are not strictly followed.

Do NOT allow untrained personnel to operate the Batch Freezer.

Do not use the Machine before studying this User Guide. Failure to follow this

instruction may result in equipment damage, poor performance, health

hazards or personal injury.

Do not allow anyone to attempt any repairs to the Machine unless the main

power supply to it has been disconnected from the power supply point.

Do NOT insert or remove the beater from the freezing barrel while the

Machine is connected to the power supply. First isolate the power supply.

Do NOT remove the hopper lid unless you are filling or re-filling the hopper

with the mix

Do NOT switch ON the Machine at the wall socket switch when the following

has not yet been done: (a) the beater is inserted properly (b) the barrel head

is fitted correctly and the four nuts screwed on correctly and tightly, and (c)

the barrel is flooded with Mix

When removing, replacing or cleaning the removable parts do so with caution

because the beater blades have sharp edges that can easily cause injury.

Always follow local authority food safety and other health codes.

Always follow in-store operating and food hygiene safety and other health

codes.

7

7. OPERATING PROCEDURE

1. Always wash your hands with soap and potable water before assembling the machine.

(Preferably use new paper towels to dry your hands)

2. Only use the removable parts after they have been washed sanitized and air-dried.

3. Fit the beater assembly only when the Machine is powered off.

4. Follow all the instructions of this manual and the operating procedures of the store

owner, and at all times follow recognised in-store hygiene procedures, in particular those

in respect of dairy products.

5. Repairs must be done by the persons who are authorized by Smach, if not, any product

failure warrantee will become invalid and void.

8. CLEARANCE PARAMETERS

This Machine is air-cooled and must have a clearance of at least 50cm between the back

side and any other object behind it. There must be a clearance of at least 50cm between

the sides of the freezer and any adjacent object. If not, the freezer will not work properly.

Position the machine for easy accessibility for cleaning, servicing and maintenance. A

clean environment is also essential for the proper performance of the freezer.

Attention: The freezer must not be exposed to direct sunlight. If it stands in direct sunlight

the performance will decrease. As the air temperature increases the performance

decreases. This is true for all refrigeration equipment.

Cool air is the best friend of the machine! It just hates HOT air !!!!

8

9. CONTROL BUTTONS

Buttons:

1. STOP: When pressed machine stops, nothing works

2. CLEAN: When pressed only beater works, it rotates the

water and clean the cylinder

3. PRODUCTION: When pressed both beater and cooling start

working, machine makes the ice cream according to desired

consistency

4. DISPENSE: When pressed both beater and cooling are still

working, beater speed increases to push the ice cream towards

to cover. Use this button when the buzzer whistles (production

is ready).

9

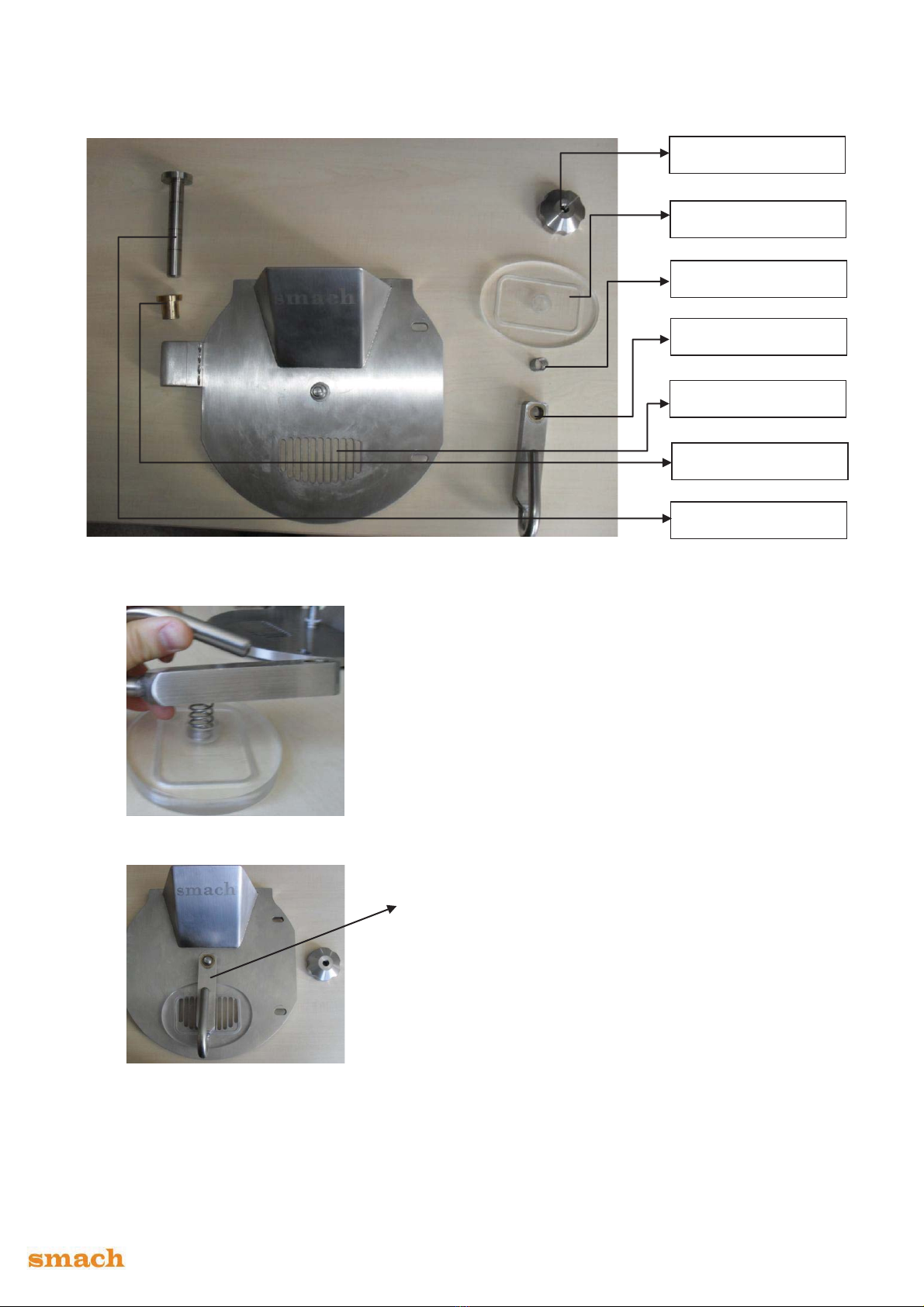

10. BEATER ASSEMBLY

1.

2.

Beater Seal

Scraper

Blades

Springs

Beater Shaft

Set the spring to the shaft and both push and rotate

the spring to clockwise so it will go over the shaft

easily

Fit the seal seals (lubricated of front and bach

surfaces with food grade gress) and blades

Scraper blades have chamfers They

MUST be at the seal side of shaft

10

11. DISPENSING COVER ASSEMBLY

1.

2.

Dispensing Cover

Draw Cover

Spring

Handle

Handle Nut

Bush

Motion Pin

Assemble the handle, draw cover (with its lubricated

(food grade gress)o-ring) and spring as seen in the

picture

Fit the assemled parts to the dispensing cover

11

3.

4.

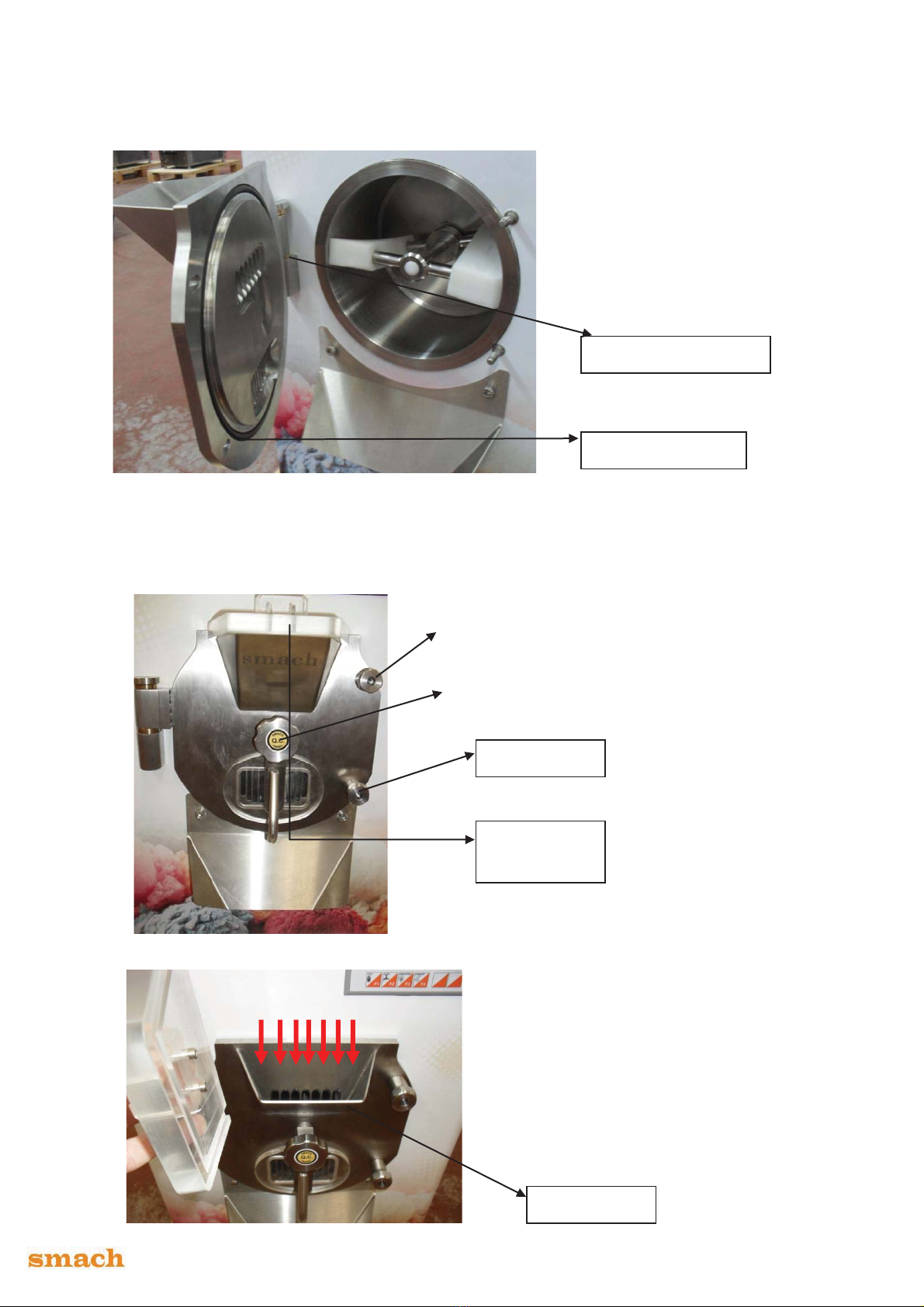

12. BEATER-MACHINE ASSEMBLY

1.

Tighten the handle with the nut

Place the bush and motion pin as seen in the

picture

Make the blades springy by two hands and

press them the to place inside of the cylinder

12

13. DISPENSING COVER-MACHINE ASSEMBLY

14. MAKING ICE CREAM

1.

2.

Fit the cover o ring and place the

dispensing cover to the machine by

aligning motion pin to the machine

bush

machine bush

Close the dispensing cover an tight it with the

handle nuts

cover o-ring

handle nut

Remove the hopper cover and charge the ice

cream mix the the hopper (the bottom line of

the hopper is the maximum mix capacity of

cooling cylinder, so do not charge any mix

above this line)

hopper

cover

hopper

Also tight the handle nut

13

3.

15. DISPENSING THE ICE CREAM

Close the hopper cover and set the desired

time and pres "production"button

When the ice cream is ready, buzzer sounds.

after buzzer sounds you can dispense the ice

cream. press dispense button on the screen

and then rotate the draw cover to

counterclockwise to get out the ice cream

14

16. CLEANING and SANITIZING THE MACHINE

1. Firstly, set the Freezer to the “CLEAN” mode and wait 3 minutes.

2. Fill the hopper with cold water and allow the machine to run for 2-3 minutes before

draining the water into the bucket.

3. Refill the hopper with warm water and Sanitizer as per the sanitizer manufacturer’s

instructions.

4. Allow the machine to run for approximately 5 minutes before draining the liquid into

the bucket.

5. Repeat step 4 until the water runs clear.

6. Set the control button to STOP mode and then switch off the power at the wall socket

and unplug the power cable.

7. Undo and remove the screws of the Dispense cover.

8. Remove and disassemble the parts.

9. Wash and sanitize all parts as per your local requirements and allow the parts to air-

dry. Do not use any chemicals other than the approved Sanitizer during the cleaning

process.

10. Assemble all the parts, ensuring the O-rings and their groves are properly lubricated.

11. Start by lubricating the harmonica-shaped Beater Shaft seal and slip it onto the

beater shaft:

a. Place the beater into the barrel and turn it slowly until it locks into position.

b. Lubricate the smaller O-rings, slip them onto the piston and place the piston

into the dispense head.

c. Lubricate the large O-ring and place into the back of the dispense head.

12. Place the Dispense cover back onto the machine and tighten the screws

For optimal machine-performance, the condenser must be cleaned from dust and dirt

regularly by an authorized technician.

Notice: During cleaning and maintenance, follow all instructions given in this User Guide, otherwise, Smach

Gıda Makine A.Şwill not take any responsibility of unwanted results.

When you want to wash the machine, be sure

everything is closed. then charge the water from the

hopper and then pres clean button. after seconds

open the draw cover and remove wase water . after

that open the dispensing cover and clean and

saniteze all the parts.

15

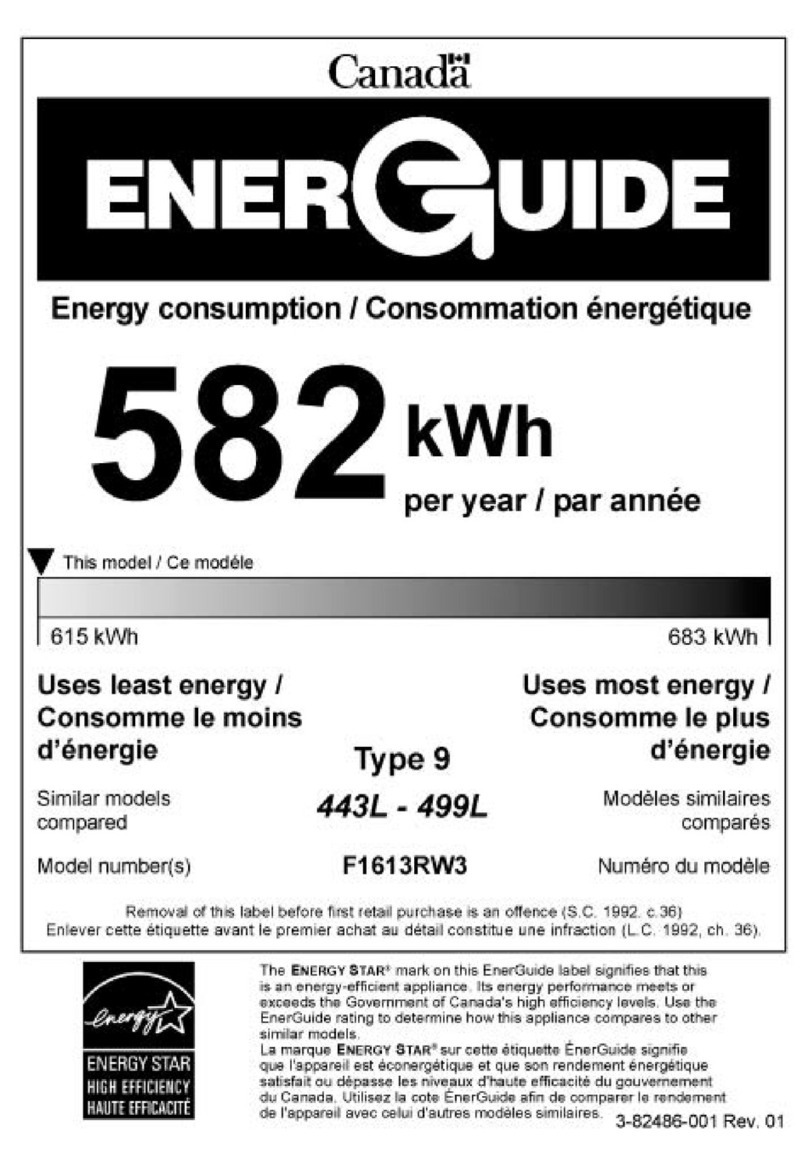

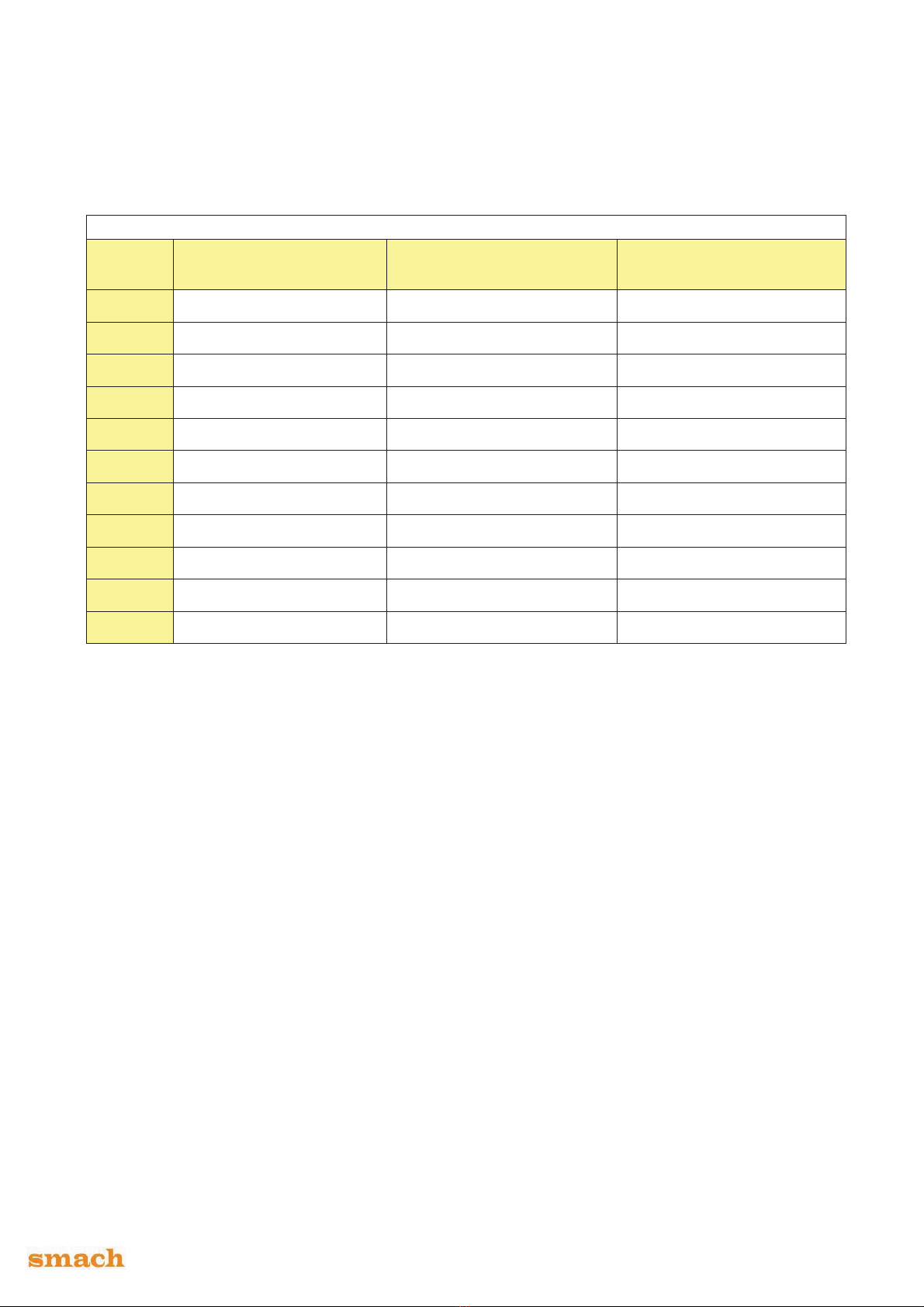

17. BACTERIA GROWTH TABLE:

E. coli multiplication under varying temperature conditions

Time Number of organisms at 5ºC

generation time = 3 hours Number of organisms at 20ºC

generation time = 1 hours Number of organisms at 37ºC

generation time = 20 min

0 time 1 1 1

1 hour 1 2 8

2 hours 1 4 64

3 hours 2 8 512

4 hours 2 16 4,096

5 hours 2 32 32,768

6 hours 4 64 262,144

7 hours 4 128 2,097,152

8 hours 4 256 17,000,000

9 hours 8 512 130,000,000

10 hours 8 1,024 1,100,000,000

16

18. POSSIBLE FAILURES AND SOLUTIONS

Attention: DO NOT ALLOW ANY TECHNICAL MAINTENANCE OR REPAIRS BEFORE

DISCONNECTING THE FREEZER FROM THE POWER SUPPLY.

If the solutions listed below in the Trouble Shooting guide do not resolve your operational

problems, call an authorized service agent for further assistance.

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

1 Machine does not run No electricity//power Check if plugged in and switch on at wall

socket

Control button mode is wrong Set the control button "Production"

2 Compressor starts, then

stops after a few seconds. No air circulation Check the clearances around the machine

and ensure that it is at least 50cm.

3 Machine works, but no

product comes from the

Dispense Cover.

Over refrigiration Use less time to run the production

The beater is rotating

counterclockwise Call Smach

4 Machine runs, but Product

is too soft Low refrigiration Use more time to run the production

5 Mix leaks from the

Dispense Cover

Dispense Cover O-ring is

missing Drain the machine and add O-rings

Dispense cover bolts are not

tightened sufficiently or are

tightened unevenly

Tighten Disphense cover screws evenly

and properly

6 Buzzer does not sound Buzzer is defective Call Smach

Table of contents

Other Smach Freezer manuals

Popular Freezer manuals by other brands

Electrolux

Electrolux EU 0562 C Installation and instruction manual

Frigidaire

Frigidaire FFU14FC4AW3 Factory parts catalog

Electrolux

Electrolux A 2780 - 1 GT operating instructions

ROWAN ELECTRIC APPLIANCE

ROWAN ELECTRIC APPLIANCE BD-50 owner's manual

Smeg

Smeg CR326AP installation instructions

Electrolux

Electrolux ERB 2623 Installation and instruction manual