SmartAV Smart Console E72 User manual

Smart Console™

Elite series

Installation Guide

For

Smart Console™ E72

2

2 E72 Smart Console™ Installation Guide March 2007

Index

Before you start opening boxes – Preparation 3

Furniture specification

Unpacking

3

5

Initial Assembly 5

Initial Connections 6

Physical Configuration Guide 7

Powering Up 9

Plate 1: Module bays 7

Plate 2: Rear of rack showing connection points 10

Plate 3: Rear left of console showing connection points 11

Plate 4: Rear of console showing Video conection points 11

Plate 4: E72 mounting points 12

Plate 6: Example angle bracket 12

Plate 7: E72 dimensions 13

Plate 8: Further E72 dimensions 14

Plate 9: Inserting modules 15

Plate 10: Inserting modules 2 16

16

3

E72 Smart Console™ Installation Guide Mar 2007 3

Congratulations! You have just purchased the world’s most ergonomically advanced

console. Your E72 Smart Console™ should provide you with many years of

trouble free operation, however it is important for you to properly install and

configure your console prior to operation.

This document contains instructions for assembly, connection and configuration of

your E72 Smart Console™. If you experience any problems or need any assistance

please contact your local distributor first or you can contact SmartAV technical

support in Australia via telephone on: +61 2 9648 6744 or via email on

Before you start opening boxes – Preparation

Let us go through what is needed before installation can be completed.

All the Elite series Smart Consoles™ are comprised of two parts: a control surface

(also referred to as ‘the console’) and a rack-mounted computer. A series of cables

connect these to each other. Ideally the rack-mounted computer will be located in

your machine room and four units of rack space should be allocated to it. From

there, a second Ethernet connection is required from the rack-mounted computer to

your mix engine or to the local area network (LAN) your mix engine is connected to.

Both the control surface and the rack-mounted computer will require mains power.

It will also be necessary to have a few helpers around for lifting, moving and

positioning the control surface part, as it is too large to be lifted by one person.

Please observe all safety and lifting precautions to prevent injuries.

Furniture specification:

The Smart Console™ Elite 72 (or E48) is designed to be dropped into a correctly

prepared unit of studio furniture. Refer to Plates 7 and 8 that detail the dimensions

of the cut-out required in your studio furniture. For stability, it is recommended that

the furniture feature a cross-beam below the console connecting the left and right

supporting legs.

The console itself is supported by three M6 screws which fit into mounting holes on

each side of the console. Refer to Plate 5.

The most desirable method of mounting is to attach an steel angle bracket of the

appropriate size via these mounting holes. This angle bracket is then mounted either

to the furniture itself or to a sub-frame within the furniture so that the top surface of

the furniture is flush with the top of the console surface. Refer to Plate 6 for an

4

4 E72 Smart Console™ Installation Guide March 2007

example of this type of construction method. In this case you may use the m6 screws

provided. In this case you MUST ensure that at least 15mm of the thread of each m6

screw is entirely within the console when fully mounted.

Alternatively the console may be attached to the furniture directly by passing screws

or bolts through the furniture into the console's mounting holes. In this case you

must source your own screws and you MUST ensure that at least 15mm (and no

more than 25mm) of the thread of each m6screw is entirely within the console when

fully mounted.

The console furniture should be rigid and should not rely on the console for its

structural integrity.

Note also that there will need to be sufficient clearance at the back of the console to

allow the rear bolster to be opened so that modules may be added and removed. The

clearance must also allow room for rear connecting cables and ventilation. See Plates

7 and 8 for exact measurements.

In the unlikely event of needing to service your console, you may also need to

remove the access panel in the rear of the console. This rear panel is held in place

with 10 screws that can be removed with a normal Phillips head screwdriver. Please

keep this in mind when designing your furniture.

5

E72 Smart Console™ Installation Guide Mar 2007 5

Unpacking

The following items should be included in your shipment:

•The control surface (unpopulated – that is without modules)

•Various modules depending on the particular console configuration ordered

•The rack computer

•The Arc™ Scribble Strip scanner

•A marker pen for the Scribble Strip

•An optional monitor arm

•Two power cables

•One five-metre network cable

•One shorter cross-over network cable

•One five-metre VGA cable

•One five-metre RCA cable

•Manuals

•Pre-installed Software (including backup disks of the Microsoft Windows XP

install disk, SmartAV install disk, and a drivers disk)

Initial Assembly

Firstly position the control surface in your studio furniture. Once the console has

been carefully lowered into the correctly sized space in your studio furniture, attach

the console using the three m6 screws on either side of the console . These screws

should pass through a weight bearing part of the furniture.

Next, ensure nothing inside the rack PC has been shaken loose by the vibration that

occurred during transit. To do this open the lid and check the seating of the PCI and

AGP cards, the RAM chips and the IDE cabling to the motherboard utilising all the

appropriate anti-static precautions.

Once you have done this reattach the lid and secure the rack computer into suitable

rack mountings in your machine room, ensuring there is adequate space for

ventilation and cooling.

Carefully unpack the modules, but at this stage resist the temptation to fit any of

them into the console.

6

6 E72 Smart Console™ Installation Guide March 2007

Initial Connections

Now that the control surface is securely positioned and the rack-mounted computer

is bolted into location it is time to start connecting the various cables.

Begin with the mains power for each unit. The IEC socket is located on the left-hand

side of the back of the control surface if you are facing the back of the unit. Refer to

Pointer A on Plate 3. The rack PC is connected to mains power using the socket

indicated by Pointer B in Plate 2.

ENSURE MAINS POWER IS SWITCHED OFF AT THE SOCKET BEFORE CONNECTING

Next connect the supplied five-metre network cable to the socket on the Rack PC

marked by Pointer F in Plate 2. The other end should be connected to the rear of the

control surface (see Pointer D in Plate 4). Note there are two network sockets on the

rack and it is important to connect the correct one to the control surface.

If the supplied network cable is not long enough then ensure the cable used is a

Category 5 twisted-pair Ethernet cable suitable for 100 MB data speeds. It is

important that the console and the rack must be directly connected with a straight-

through type network cable and not connected via a LAN.

Now connect an Ethernet cable from the remaining network socket on the rack (see

Pointer C on Plate 2) to your mix engine or to your LAN where your mix engine is

also connected. If you connect directly between the rack and your mix engine you

will need to use the supplied crossover cable. A straight-through network cable

should be used if connecting the console to a LAN.

If your console includes a Scribble Strip Scanner, position the Scanner on the

Arc™. The Scanner has two spring-loaded wheels at the bottom and one at the top.

Position the bottom wheels against the black strip running along the lower edge of

the Arc™ and gently push the Scanner upwards while tilting the top of the

Scanner firmly downwards onto the Arc™. When the top wheel is aligned with the

black strip on the upper edge of the Arc™ there will be a click and the Scanner is

now in place. Connect the cable emerging from the Scanner to the console – the

socket for this is at the opposite end of the console to the power connection (see

Pointer A in Plate 4).

If your console includes a Scribble Strip Scanner there will be an RCA cable

supplied that needs to be connected between the console and the rack. Connect one

end of this RCA cable to the RCA socket on the rear of the console (see Pointer B in

Plate 4). Connect the other end of the RCA cable to the RCA socket marked ‘AV’ on

the back of your rack. Pointer E in Plate 2 indicates this socket.

7

E72 Smart Console™ Installation Guide Mar 2007 7

Now run the VGA cable from the VGA port on the control surface (indicated by

Pointer C on Plate 4) to the VGA input on the back of rack (indicated by Pointer D on

Plate 2).

Physical Configuration Guide

It is now time to start populating the console with the modules. However, let us first

look at the different types of modules and note the various legal positions they may

occupy in the console. With the exception of EQ and Fader modules, modules can

be identified by the name printed on the top-left or bottom-left corner.

Running horizontally through the middle of the chassis of every Smart Console™

Elite is a series of VFD display modules (also referred to as ‘Fader displays’ in Smart

Console user documentation) that separate the console into top and bottom halves.

Modules that are designed for the top half can never be positioned in the bottom half

and similarly modules for the lower part can never be fitted into the upper section.

Upper modules can be identified by their different profile and the fact that they are

longer than the lower modules.

All modules used with the Smart Console™ Elite are designed to fit vertically

aligned with either a VFD section with a display or a VFD section without a display,

depending on their function. For example, a Fader module can only be fitted below

a display section but not below a non-display section.

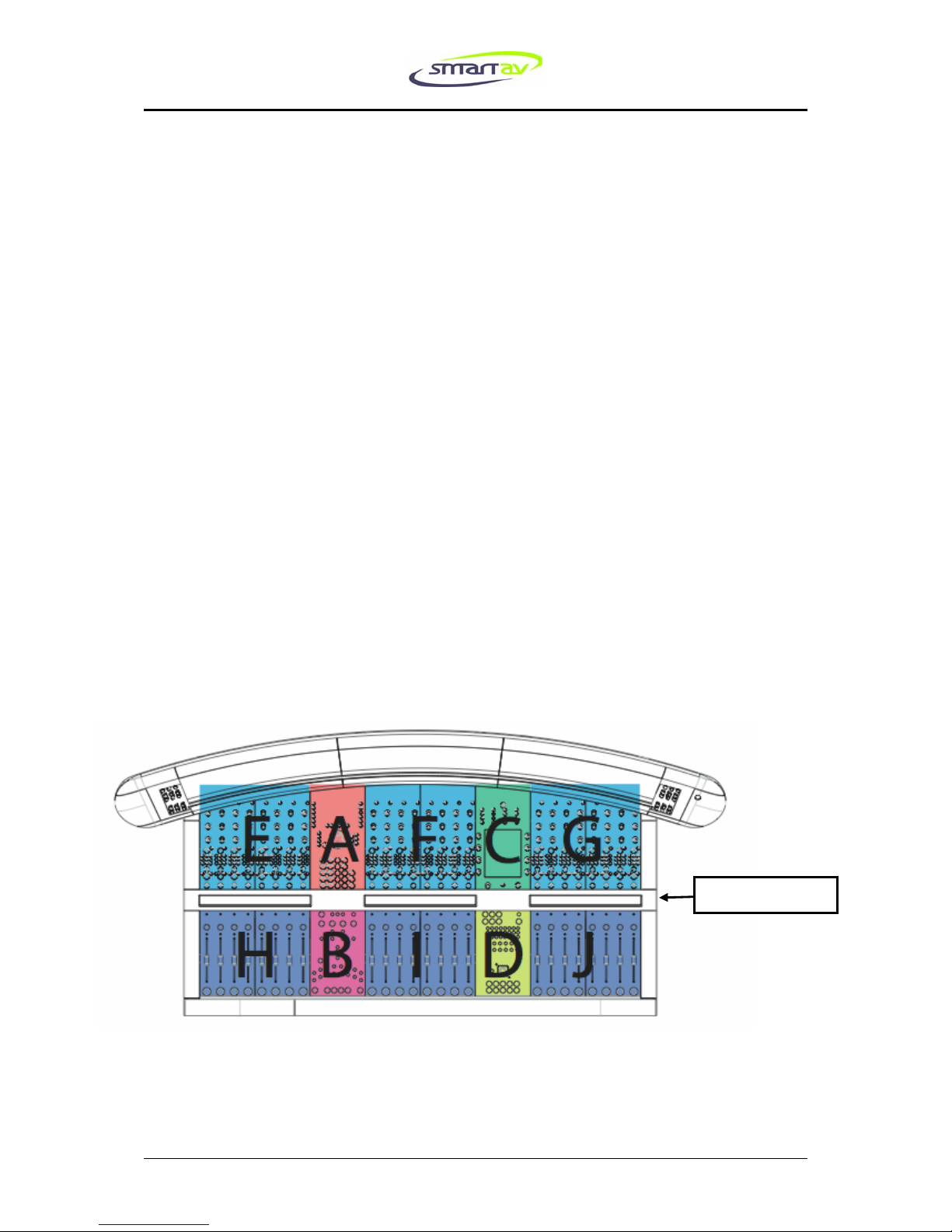

Every E72 has sixteen module bays, eight above the VFD modules and six below.

Plate 1: Module bays

VFD Displays

8

8 E72 Smart Console™ Installation Guide March 2007

Every console must have a Monitor Panel and an Expert Panel fitted as a pair

either in sections A and B or in sections C and D respectively as shown above.

Every console must also have an Upper Active Panel and a Lower Active Panel

also fitted as a pair in the remaining bays out of the A/B and C/D pairs.

Generally the upper and lower Active Panels are fitted to bays C and D, however

some users, such as left-handed engineers, may prefer them fitted in A and B. They

can of course be changed at will due to the hot-swappable nature of the console.

Now let us turn our attention to the bays denoted by E, F, G, H, I and J in the above

diagram. Two modules fit in the bays represented by each letter. The bays E, F and G

can either house a pair of EQ/AUX Modules or a double width module such as the

upper part of the Post Panel Module or a pair of blanking panels if this bay is

unused. EQ/AUX Modules and blanking panels can be mixed.

The bays H, I and J can either house a pair of blanking or Fader Modules or a

double width module such as the lower part of the Post Panel Module. The Post

Panel Module is an optional extra and not necessary for the operation of a console.

It is possible to fit a lower Post Panel Module without the upper module or vice

versa.

Similarly, the Fader Modules would ideally be fitted with EQ/AUX Modules

directly above them but the console will operate correctly if this is not the case.

Note that modules designed for bays A and C will not fit in bays E, F and G and vice

versa. Modules designed for bays B and D cannot be fitted in bays H, I and J.

Now it is time to begin populating the console with the modules. Insert the modules

one at a time, making sure to observe the legal positioning rules described above.

The technique for inserting a module is as follows:

Open the rear and front bolsters by grasping the ends of them and lifting them

upwards so they unlatch thus allowing them to swivel downwards and away from

the body of the console.

Each module has a handle-end and a connector-end. Position the module in the bay

so the connector-end slides in first while the handle-end is still raised slightly (see

Plate 9). Next lower the handle-end of the module so it is flush with the base of the

bay and, while keeping downward pressure on the connector-end, push the module

into place with the handle (see Plate 10). The modules will only click into place if the

switch under the handles is lifted. Once the module is seated make sure the switch is

pushed back down to ensure it is secured. Removing the modules is the reverse

procedure – lift the switch first before pulling out the module.

In the case that the console is not fully populated please install blanking-panels that

have been provided to complete the surface.

9

E72 Smart Console™ Installation Guide Mar 2007 9

Powering Up

The correct order for powering up the parts of your Smart Console™ for the first

time is as follows:

First, switch on the rack PC using the switch indicated by Pointer A in Plate 2. Then

power on the console via the switch indicated in Plate 3 by Pointer B. On the right-

hand end of the Arc™ press the silver start button. Each module correctly installed

in the console should shortly begin to flash the Light Emitting Diode (or LED) in the

upper left corner. The Arc™ should also flash the top-left-most LED (not including

meters) in both segments. If any modules do not flash their top-left-most LED then

re-seat them in the chassis of the console.

Next, the rack PC will automatically boot. Assuming all connections have been made

correctly then the control surface will go into its default state where all the top-left-

most LEDs will cease flashing. The screen on the Upper Active Panel should also

illuminate.

Congratulations! You are now ready to configure your mix engine to operate with

the Smart Console™. Please refer to the Engine Configuration Guide(s) relevant to

your audio engine(s) for further instructions.

10

10 E72 Smart Console™ Installation Guide March 2007

Plate 2: Rear of rack showing connection points.

11

E72 Smart Console™ Installation Guide Mar 2007 11

Plate 3: Rear left of E72 console showing connection points.

Plate 4: Rear of E72 console showing Scribble Strip™ Scanner connector (A), the

RCA cable connector (B), the Ethernet cable connector (C), and the SVGA connector

(D).

12

12 E72 Smart Console™ Installation Guide March 2007

Plate 5: E72 mounting points.

Plate 6: An example of the suggested angle bracket mounting procedure.

M6 mounting screws

13

E72 Smart Console™ Installation Guide Mar 2007 13

Plate 7: E72 dimensions.

14

14 E72 Smart Console™ Installation Guide March 2007

Plate 8: Further E72 dimensions.

Note: Threaded mounting posts are 6.5mm in diameter and 32mm long. Please leave

120mm clearance at rear of console for bolster to open, for ventilation and for rear

connecting cables.

15

E72 Smart Console™ Installation Guide Mar 2007 15

Plate 9: Inserting modules.

Plate 10: Inserting modules 2

Table of contents

Other SmartAV Music Mixer manuals