Technical Information smb

Carrantuohill Seilspielgeräte GmbH Berlin

Page 4 Technikerstraße 6/8

15366 Hoppegarten

Germany

Phone: ++49 (0)3342 5 08 37 20

Fax: ++49 (0)3342 5 08 37 80

Assembling the additional element inside netting (if ordered)

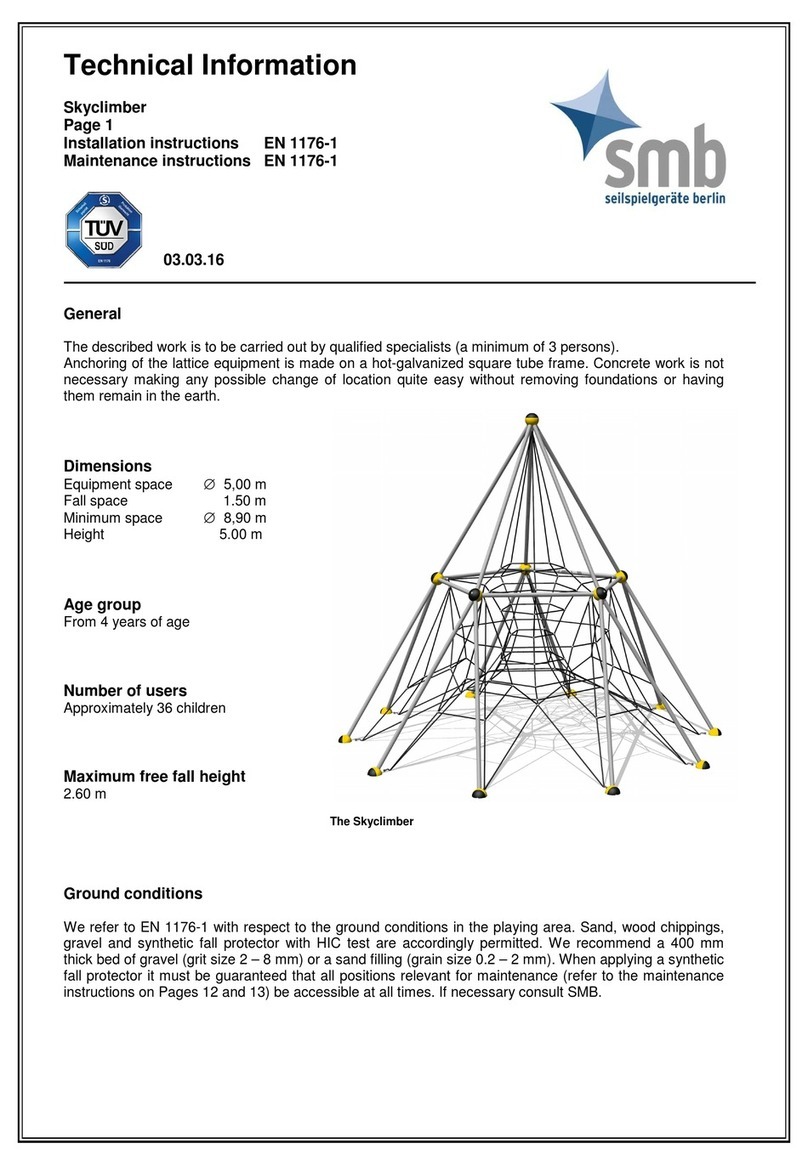

With the hollow balls still open, pull the marked straining screws

into the corresponding hollow balls (K4 and K7) via the

tensioning sleeves (size 27), thereby tightening the inside

netting. The lock nuts (size 24) on the straining screws can then

be tightened (figure 7).

Closure of the open hollow balls with the prepared ball covers

completes the assembly.

Locking the hollow balls

Lock the hollow balls with the prepared ball covers.

Maintenance instructions EN 1176-1

Visual routine inspection

Frequency will be based on local conditions (high/low use, vandalism, air pollution, effects of weather).

The surface netting should be examined for damage, especially broken strands.

The cover locks for the hollow balls should be checked.

Operational inspection (twice-yearly)

The additional element inside netting (if fitted) should be checked for tautness. Retensioning is carried

out at the tensioning point by removing the cover and increasing the tension on the tensioning sleeve

(size 27). The lock nut (size 24) (figure 7) should first be loosened. Normally retensioning at the upper

tensioning points will be sufficient (K4)

Main inspection (annual)

In addition to the checks in the visual and operational inspection:

Check the anchor frame for excessive corrosion (every two years). At the corners the anchor frame

should be exposed to the installation depth and checked for corrosion.

Check that the tube screw fittings have a firm, crack-free connection to the hollow balls. If a screw fitting

is loosened, it should be re-tightened inside the ball.

Check that the lock nuts (figure 7) fit firmly on the hollow balls.