SMB TRAMPOLINE S Manual

If you have any questions,we’d be happy to help:

Technikerstraße 6/8 Fax. +49 (0) 3342 5083 -80 www.smb.berlin

DE-15366 Hoppegarten

09.04.2020

Page 1 von 9

Contents

1Mounting instructions

1.1 General information and specs Page 02

1.2 Ground properties Page 02

1.3 Mounting tool Page 02

1.4 Mounting Page 03

2Maintenance instructions

2.1 Maintenance intervals Page 04

2.2 Removal and re-mounting of the jump mat Page 05

2.3 Special characteristics Page 0

2.4 flashtramp® Page 08

Technical infor ation – TRAMPOLINE S

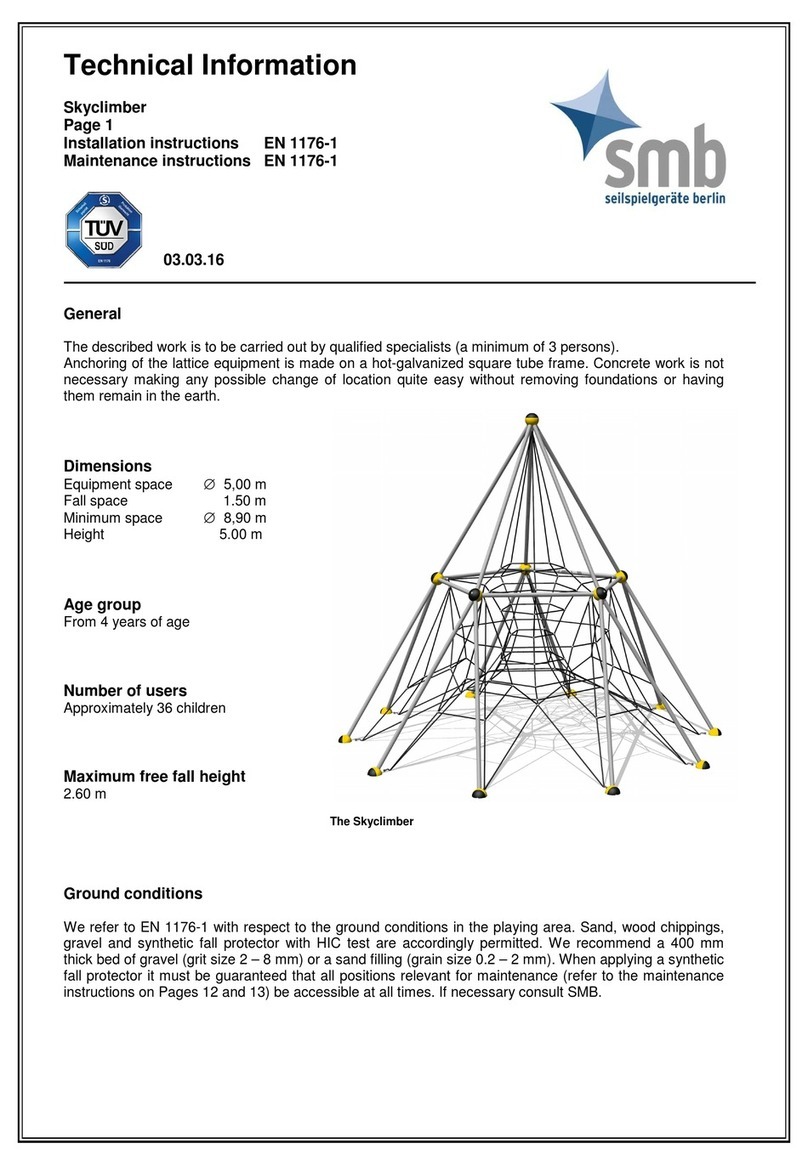

Fig. 1 – Symbolic illustration of Trampoline S with a multicolor jump mat

tuev-sued.de/ps-zert

TECHNICAL INFORMATION

TRAMPOLINE S

If you have any questions, we’d be happy to help:

Technikerstraße 6/8 Fax. +49 (0) 3342 5083 -80 www.smb.berlin

DE-15366 Hoppegarten

09.04.2020

Page 2 von 9

1 Mounting instructions

1.1 General infor ation and specs

The work described must be carried out by qualified personnel.

Due to the high intrinsic weight once fully assembled, no further anchring is required – no foundations are

needed! The trampoline is designed for assembly on ground level.

Di ensions

Equipment space: 1,25 x 1,25 m

Minimum space: 3, 5 x 3, 5 m

Jumping area: 0, 5 x 0, 5 m (0,56 m²)

Fall space: 1,50 m (measured from the inner edge of the rubber plate)

Free space: 3,50 m (height above jumping area)

Max. free fall height: 0,90 m

Weight of heaviest individual component: 130 kg (total weight of trampoline without packaging)

Age range

3 years and upwards

Nu ber of users

1 person

1.2 Ground properties

Shock-absorbent ground compliant with DIN EN 11 6-1 must be provided over the entire impact area (draft

plan). We recommend synthetic fall protection since loose fall protection material such as sand, bark mulch

or woodchips are easily transported into the inside of the trampoline an can therefore reduce the equipment’s

play value.

1.3 Mounting tool

Provided tools:

4 Piece Carrying iron

1 Piece Fixing tool

(For aintenance purposes only)

The infor ation given applies only to the individual piece of equip ent.

If ultiple pieces of equip ent are co bined, the infor ation on the individual draft plan is binding or s b ust be

consulted.

TECHNICAL INFORMATION

TRAMPOLINE S

If you have any questions, we’d be happy to help:

Technikerstraße 6/8 Fax. +49 (0) 3342 5083 -80 www.smb.berlin

DE-15366 Hoppegarten

09.04.2020

Page 3 von 9

1.4 Mounting

Once the soil has been excavated (450 mm deep) and a horizontal, even surface hase been created, the

trampoline is set up. If the ground prevents or at least hinders the ingress of water, e.g. if the soil is clay-based,

then a drainage layer should be installed.

There are a total of four drill holes (sealed with stoppers) on the sides of the frame. The bearing irons supplied

are guided through these to transport the trampoline and position it in the excavated pit (please seal the drill

holes again afterwards!). Care must be taken to ensure that the frame is positioned squarely and does not tilt.

Then fill in and seal any open spaces between the ground and the trampoline frame. The play level must be

established with shock-absorbing properties, e.g. with molded fall protection, depending on the plans.

Play

level

Drill holes for bearing

Fig. 1 – Re oving soil, di ensions

TECHNICAL INFORMATION

TRAMPOLINE S

If you have any questions, we’d be happy to help:

Technikerstraße 6/8 Fax. +49 (0) 3342 5083 -80 www.smb.berlin

DE-15366 Hoppegarten

09.04.2020

Page 4 von 9

2 Maintenance instructions

2.1 Maintenance intervals

Routine visual inspection

•Check that the interior trampoline area (the space under the jump mat) is clear of sand or garbage. To

do this, unhook the jump mat from the frame (see 2.2) and remove any dirt present. The jump mat

should then be hooked back in.

The frequency should be guided by local conditions (High/low use, vandalism, air pollution, influences of

weather).

Since locations can differ significantly (public area, school, children’s daycare centre, etc.), no generally valid

statements can be made in this regard.

We recco end that an assess ent of the aintenance interval be deter ined based on experience on

site.

Operational inspection (every six onths)

•Check the play equipment for general damage or signs of wear and tear.

•Check the inside of the trampoline for dirt (see routine visual inspection).

•Check the condition of the jump mat, spring suspension fittings and the fall protection.

More infor ation can be found on the next few pages and in Figures 3, 4 and 5.

Main inspection

The trampoline frame is made from 3-mm-thick, hot-dip galvanised sheet metal. As a result of this, a main

inspection can extend over a two-year period and can then include a check of the frame for corrision.

Infor ation regarding the type plate

The type plate (plaque) is embedded in one of the fall protection plates which are glued onto the trampoline

frame. The type plate bears the details of the manufacturer and DIN standard, as well as a serial number and

a QR code that can be used to obtain further information.

TECHNICAL INFORMATION

TRAMPOLINE S

If you have any questions, we’d be happy to help:

Technikerstraße 6/8 Fax. +49 (0) 3342 5083 -80 www.smb.berlin

DE-15366 Hoppegarten

09.04.2020

Page 5 von 9

2.2 Re oval and re- ounting of the ju p at

The DURAPTEQ® springs can be released from the jump mat suspension using the provided tool (Figures 3

an 4). To do so the hook of the fixing tool is hung in the hook notch of the spring and slowly pulled using the

rope attached to it. Once the appropriate extension of the spring has been achieved, the fastening links (chain

links) that are secured on two sides of the jump mat fall independently downwards. These fastening links

(thimbles) on the other two sides of the jump mat must be pushed out downwards once the springs have been

extended. These do not fall independently out of the spring suspension.

The jump mat is hung in position following the same procedure, but in reverse. The only difference is that the

extended springs must be hooked by hand into the fastening link (chain link or thimble).

Fig. 3 Re oval and re- ounting of the ju p at

TECHNICAL INFORMATION

TRAMPOLINE S

If you have any questions, we’d be happy to help:

Technikerstraße 6/8 Fax. +49 (0) 3342 5083 -80 www.smb.berlin

DE-15366 Hoppegarten

09.04.2020

Page 6 von 9

Fig. 4 Re- ounting of the ju p at

TECHNICAL INFORMATION

TRAMPOLINE S

If you have any questions, we’d be happy to help:

Technikerstraße 6/8 Fax. +49 (0) 3342 5083 -80 www.smb.berlin

DE-15366 Hoppegarten

09.04.2020

Page von 9

2.3 Special features

A trampoline is a dynamic piece of play equipment. This means that some of the installed materials are

subjected to powerful forces arising from friction and bending cycles while the equipment is being used. The

stress on the material of the parts in question is therefore commensurately high and signs of wear and tear

can appear over the equipment’s period of use.

s b tra polines are built so that all of the parts affected can be exchanged as required and the equip ent

can continue to be used for any years.

During the regular maintenance intervals, thse parts (BEG-bolts, lock washer for BEG-bolts and plain bearings)

must be visually checked (visual or operational inspection).

Fig. 5 Ju p at suspension, overview of individual parts

TECHNICAL INFORMATION

TRAMPOLINE S

If you have any questions, we’d be happy to help:

Technikerstraße 6/8 Fax. +49 (0) 3342 5083 -80 www.smb.berlin

DE-15366 Hoppegarten

09.04.2020

Page 8 von 9

2.4 flashtra p®

With the purchase of one of our flashtramp

®

trampolines, you have acquired one or more flashtramp

®

lighting

units. Particularly when combined with our colorful, motif jump mats, the light modules produce impressive

effects that enhance the enjoyment of play.

Two built-in high-performance LEDs make the flashtramp

®

lighting unit visibly light up. The power required is

generated simply by the user jumping.

Asse bly, aintenance, cli ate protection – sustainability is i portant to us!

With the flashtramp

®

lighting unit, you have acquired a high-quality electronic component that is already

integrated into the jump mat before delivery, which means that no additional installation work is required.

The complete encapsulation and integration into one of the wing slats protects all of the components from

external influences, such as cold, heat, dust, sunlight and shocks. Again, no aintenance is required.

Only relevant if you have received a tra poline fro our flashtra p® series –

a tra poline with LED lighting units in the ju p at.

Fig. 6 flashtra p®- lighting unit with wing la ella

TECHNICAL INFORMATION

TRAMPOLINE S

If you have any questions, we’d be happy to help:

Technikerstraße 6/8 Fax. +49 (0) 3342 5083 -80 www.smb.berlin

DE-15366 Hoppegarten

09.04.2020

Page 9 von 9

However, it is possible that a lighting unit does not work as it should, or fails completely. In this case, it must

be replaced and the faulty unit disposed of correctly or recycled.

To ensure this flashtramp

®

lighting units are WEEE-cerified.

Fig. 7 flashtra p® lighting unit

Too uch of a hussle? No proble !

Si ply send us the defective lighting unit back and we will take care of the professional disposal

for you.

Together for a sustainable future!

Table of contents

Other SMB Play Set & Playground Equipment manuals

Popular Play Set & Playground Equipment manuals by other brands

Swing-N-Slide

Swing-N-Slide LA 9466 manual

Gorilla Playsets

Gorilla Playsets Great Skye II 1500HW Assembly instructions

KidKraft

KidKraft 00400 Installation and operating instructions

Europlay

Europlay S216 Assembling manual

Community Playthings

Community Playthings H551 Paper Corner Product guide

Sove

Sove 50-170-100 Assembly instructions

Europlay

Europlay Z3636 Assembling manual

Mercia Garden Products

Mercia Garden Products 02SNO0705-V4-PEFC General instructions

BOERPLAY

BOERPLAY BBI.205.HUR installation instructions

Sove

Sove 25-300-030 Assembly instructions

Playcore

Playcore Freenotes Harmony Park Aria 2017 installation guide

Quadro mdb

Quadro mdb C0003 quick start guide