SMB Ben Nevis User manual

Technical Information

Ben Nevis

Page 1

Installation Instructions EN 1176-1

Maintenance Instructions EN 1176-1

02.06.14

General

The operations described are to be carried out by a specialist.

The rope netting pyramid should be fixed on foundations in accordance with the Technical Information.

Dimensions

Effective space 8.20 x 8.20 m

Drop 1.50 m

Minimum space 11.20 x 11.20 m

Height 5.80 m

Age group

5 years upwards

Number of users

46 children

Maximum free drop height

2.40 m

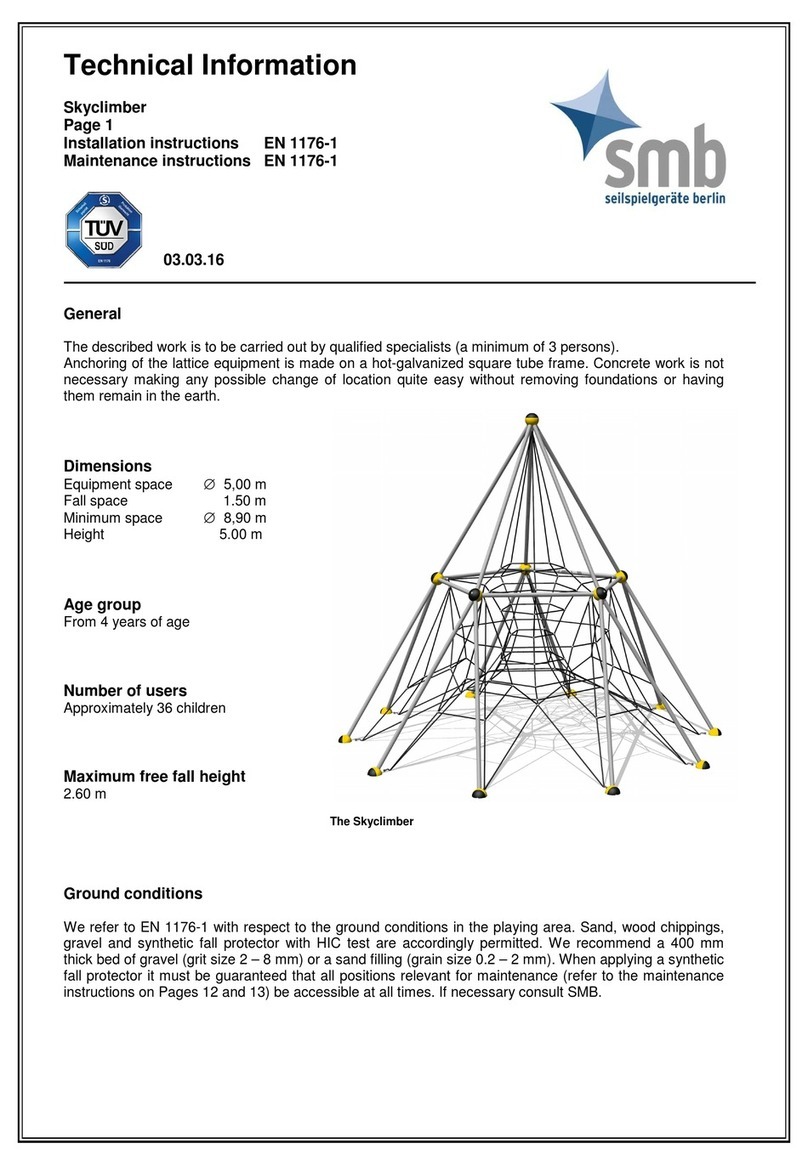

Figure 1 Ben Nevis

Ground quality

With regard to the type of ground in the play area,

please refer to EN 1176-1. According to this, sand,

wood chips, gravel and HIC-tested synthetic

protective surfaces are permitted. We recommend a

covering of gravel at least 400 mm thick (grain size

2–8 mm) or sand (grain size 0.2–2 mm). If you use a

synthetic protective surfaces it must be sure that all

relevant parts for the maintenance (see maintenance

instruction on page 5 and 6) are every time

accessibly. If necessary consult SMB.

Assembly tools

Tools supplied:

1 size 46 open-jawed spanner with extension

Additional tools required:

1 cable pulley (10 kN tensile force)

1 hemp rope, minimum D = 20 mm, length

according to requirements

1 crowbar

usual tools (hammer, pliers, screwdriver etc.) Figure 2 View from above with safety area

Technical Information smb

Ben Nevis Seilspielgeräte GmbH Berlin

Page 2 Technikerstraße 6/8

15366 Hoppegarten

Germany

Phone ++49 (0)3342 508 37 20

Fax ++49 (0)3342 508 37 80

A Corner foundation

Anchorage

B Mast plate

Mast foundation

Position of the eye bolts

and the mast plate.

Minimum concrete quality for the foundations: C20/25 (B25)

Setting time: at least 8 days

Amount of concrete required: approx. 5.8 m³

We assume that the foundation soil is organic soil. Otherwise advice should be taken on possibly altering the

size of the foundations.

! All measurements in mm !

Technical Information smb

Ben Nevis Seilspielgeräte GmbH Berlin

Page 3 Technikerstraße 6/8

15366 Hoppegarten

Germany

Phone ++49 (0)3342 508 37 20

Fax ++49 (0)3342 508 37 80

Assembly

General advice

The rope netting has been knotting by a hercules rope (an steel wire rope, which is coated with chemical

fibre). This coating could become damaged, if you move the rope over the ground. Please work carefully.

Spread out rope netting

The rope netting has been folded up following knotting in the factory. Take the netting out of the container

in accordance with the folds. The netting should be spread out in a triangular shape with the base of the

triangle lying in the diagonals of the foundations. The tip of the netting can be recognised by the

aluminium mast cap and should be lined up with foundation 3 (see schematic diagram). The

connection with foundations 1 and 2should now be created, using the tension jacks to connect the

netting to the tension rods of the foundations.

Insert the mast into the netting

Push the mast through the netting to the tip of the net. A hemp rope is attached to the netting as a guide

when threading though. Once the mast has been threaded through, place the mast cap in the mast, raise

the mast slightly by lifting it and support it temporarily on the tip. In this position, it should be ensured that

the mast supports itself on the round plate of the mast plate.

Raising the mast

When raising the mast it is essential to ensure that you pull the mast, not the net. To raise the mast, use a

cable pull (10 KN tensile force). The mast, including the netting, should be raised carefully. In particular, it

should be ensured that the mast plate is in the mast tube and is not pulled out and that the foot of the

mast is pulled onto the round plate. Once the mast has been raised higher than 45°, the connection

between the netting and foundation 3 is created. The mast should be raised higher until it is in a vertical

position. The final connection with foundation 4 is now created. Pulling the netting to the tension rods is

made easier with the aid of a crowbar, which should be placed in the curved clevis, as a result of the lever

action. Do not pull the mast with the cable pull over and above the vertical in the direction of the

tension rods (see figure 3).

Technical Information smb

Ben Nevis Seilspielgeräte GmbH Berlin

Page 4 Technikerstraße 6/8

15366 Hoppegarten

Germany

Phone ++49 (0)3342 508 37 20

Fax ++49 (0)3342 508 37 80

Fitting netting entry points

The entry ladders (if ordered) should be fitted on the space netting at the press connections marked (if

not already done in the works) and on the middle base on the eye bolts (Figure B).

Tensioning the netting

Tensioning (tensioning tools are supplied) is carried out with the tube tensioning jacks and should be performed

uniformly and crossways. Alternating at each turnbuckle in each case a short piece must become strained

till the final initial tension is achieved. Ensure that the mast is in a vertical position. Apply noticeable

preliminary tension to the rope netting. After tensioning, the lock nut should be securely tightened. Finally,

the safety ropes should be connected to the safety anchor loop via the clevises.

The first re-tensioning of the space netting

!!! Initial re-tensioning should be carried out after one to two weeks of use

(reference operational inspection for more details) !!!

Caution:

When putting the mast up and when

stretching the space network make

sure absolutely that the mast is not

pulled beyond the vertical (figure 3)!

Pull only at the mast, not at the space

net (Figure 3)!

Figure 3

Technical Information smb

Ben Nevis Seilspielgeräte GmbH Berlin

Page 5 Technikerstraße 6/8

15366 Hoppegarten

Germany

Phone ++49 (0)3342 508 37 20

Fax ++49 (0)3342 508 37 80

Maintenance instructions EN 1176-1

Visual routine inspection

Frequency will be based on local conditions (high/low use, vandalism, air pollution, effects of weather).

The inspection must be carried out by an expert or specialist company.

Check Space Net for general damage, wear and tear and damage resulting from vandalism

Check ground quality (layer of sand = protection from a fall; contamination of sand = protection from

injury)

Operational inspection (twice-yearly)

The entire Space Net should be checked for damage, particularly for breaks in the wires

On the mast cap, it should be checked that the central markings on the mast rope are between the

rope shackles

All the anchoring cables should be checked:

The lock nuts should be tightened securely to the tension jacks!

The safety ropes should be connected to the thinner traction anchor loop via the clevis

connection.

Check the preliminary tension of the Space Net and adjust tension if necessary.

Adjusting tension (see picture on page 6):

Uncover the tension lock and clean the threaded parts

Remove the lock nut

Adjust tension with the tensioning spanner SW 46 supplied

Tensioning should be carried out until it is no longer possible to tighten the tensioning spanner

manually without any great strain. When tensioning, the direction of rotation for tensioning should be

counteracted so that the inclined tension cables do not become twisted.

It should be ensured that the mast is vertical.

Fasten the lock nut again securely

Technical Information smb

Ben Nevis Seilspielgeräte GmbH Berlin

Page 6 Technikerstraße 6/8

15366 Hoppegarten

Germany

Phone ++49 (0)3342 508 37 20

Fax ++49 (0)3342 508 37 80

Main inspection (annually)

In addition to the checks in the visual and operational inspection:

Check the clevis connections: curved clevis on the inclined tension cable, straight clevis on the

tension anchor loop.

Check the safety cable for damage

Check the tension anchor in the foundations for signs of corrosion

Check that the mast plate is positioned stably on the foundation and check for signs of corrosion

Check the foundations for possible cracks in the concrete. To do this, the foundations should be

exposed in the area of the tensioning anchors.

Please note: The swaying of the mast tube is a static necessity and is therefore intentional.

In order to guarantee enjoyment when playing and a long life, the rope Space Net should be kept under

tension. The first tension adjustment should be carried out approximately one week after the first use.

Further tension adjustments will be necessary at longer intervals, depending on the loss of elasticity of

the ropes, until the natural stretch capacity of the rope has been exhausted.

Table of contents

Other SMB Play Set & Playground Equipment manuals

Popular Play Set & Playground Equipment manuals by other brands

BOERPLAY

BOERPLAY BBPE112.7BP installation instructions

BOERPLAY

BOERPLAY Tumble bars Trio H0.90-1.10-0.90 manual

Creative Playthings

Creative Playthings PINE SKYBOX SH901-700 Assembly manual

Creative Play

Creative Play DEE CLIMBING FRAME ROUND installation instructions

Playworld

Playworld 350-1637 manual

Jumpking

Jumpking BAZOONGI KIDS Circus Tent user manual

Infans

Infans TP10050 user manual

IPEMA

IPEMA TETHERBALL manual

BOERPLAY

BOERPLAY 255E404.03K.001 installation instructions

Buki

Buki Professional Studio Bougie Candles 5420 manual

Simplay3

Simplay3 Fast Track Downhill Raceway 22105 Assembly instructions

Swing-N-Slide

Swing-N-Slide TIMBER-BILT TB 1405 Assembly instructions