6.4 Magnetism Switch Control

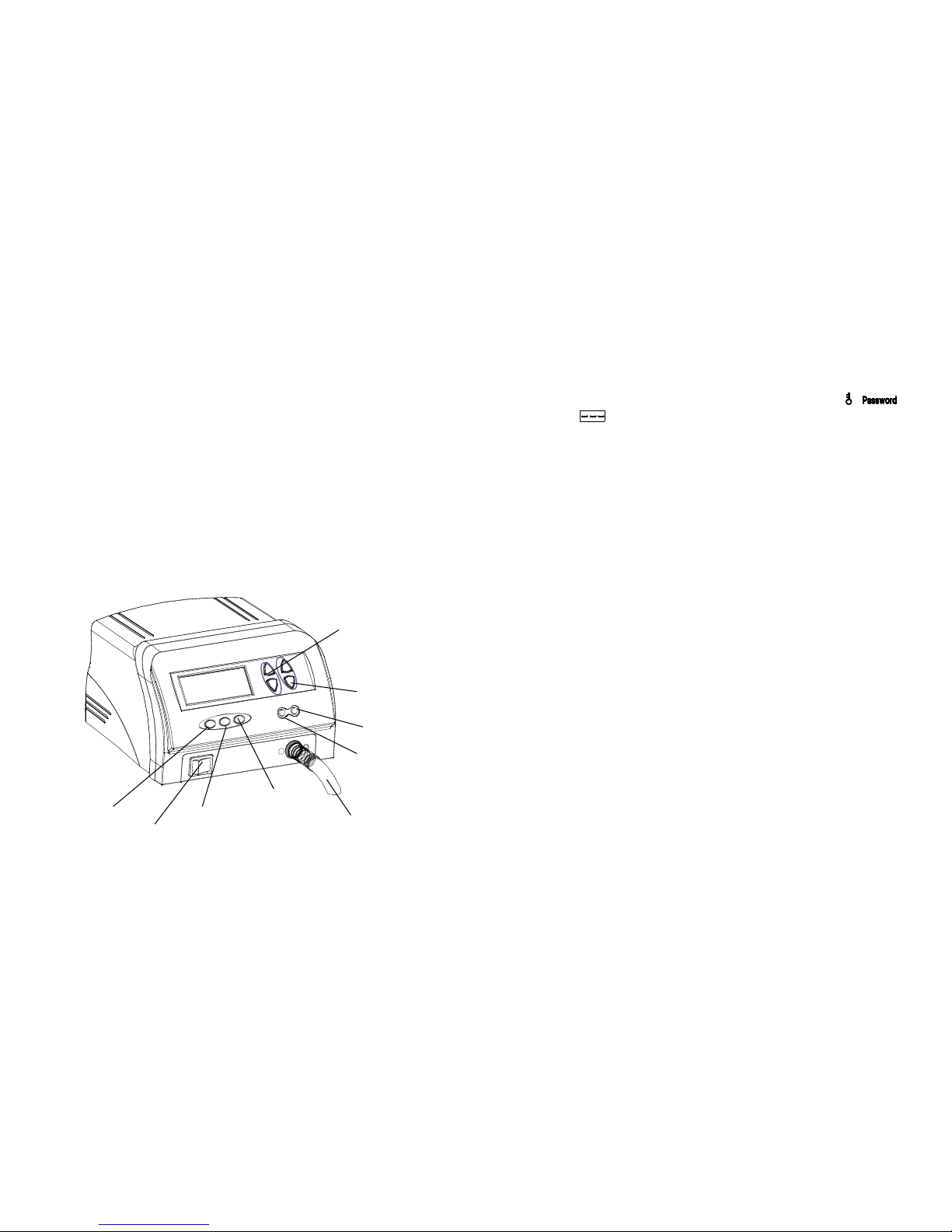

1. Press the “POWER” key and switch on the power supply to the SMD rework

system.

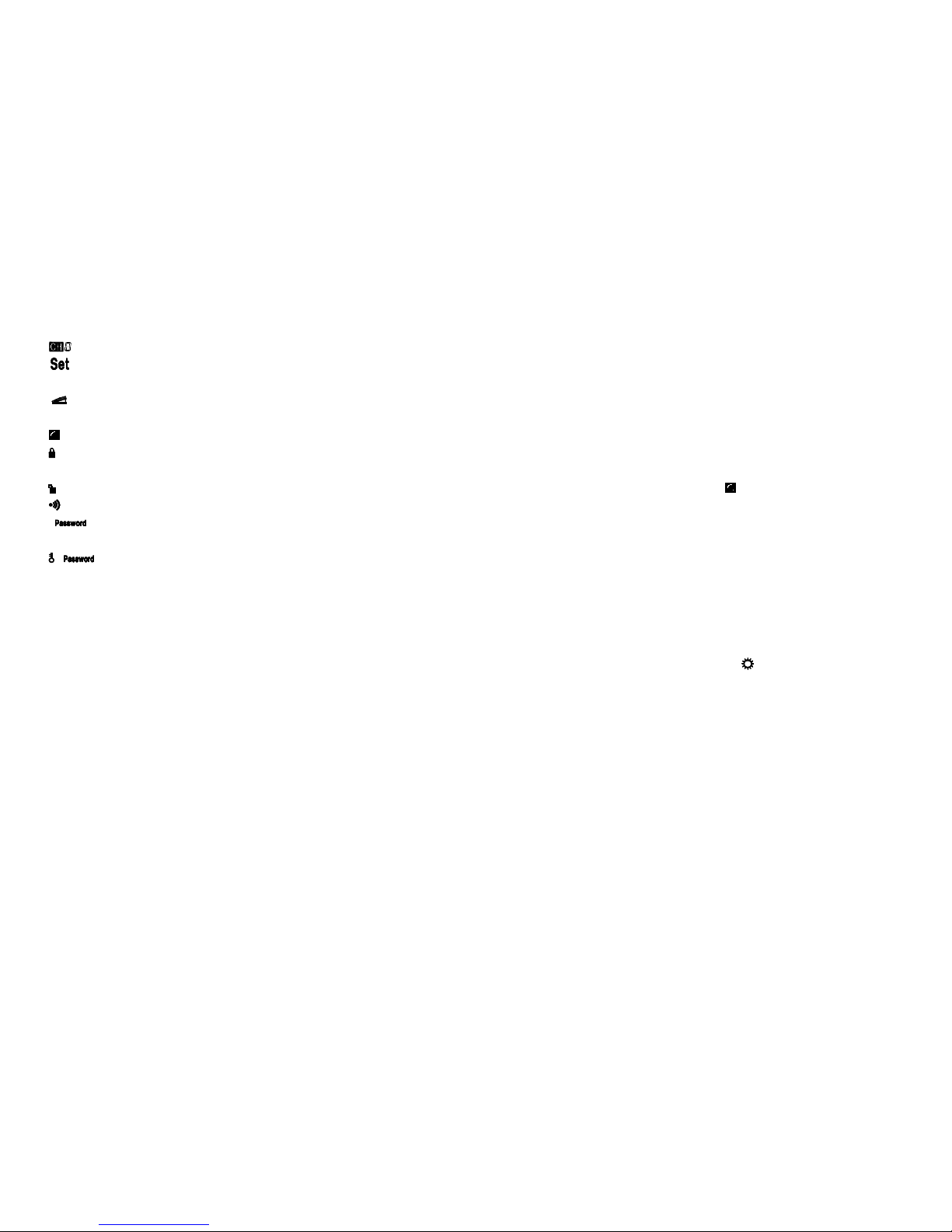

2. If the LCD does not display “ ”, it means the system is completely

controlled by the magnetism switch. As when taking down the handle from the

holder, the system comes into the working state. At the moment, the pedal

switch has no effect.

3. When the handle is took down from the handle holder, the system comes to

work in the current work channel until the work time ends. At the moment, it

can press any key (except “POWER” and “INFO” keys) to return work mode.

4. If putting the handle on the handle holder, the system will come into the

sleeping state at once.

5. When working in the lock state, the LCD displays “ ”. At the moment, the

system only can work in the CH1 channel, and cannot switch the channel and

change parameter values.

6. When working in the unlock state, the LCD displays “ ”. At the moment,

whatever is in the work state or in the sleeping state, the system can switch

channel and change parameter values, and work in the different channel “CH0”

or “CH1” or “CH2” or “CH3”with different parameter values. The parameter

values setting method is as following:

a) Press “CH1” or “CH2” or “CH3” key to switch the current work channel.

Press any key (except “POWER” or “INFO” or “CH1” or “CH2” or

“CH3” key) to the “CH0” channel with current parameter values. For

example, if pressing “CH0” key, the system will work at the “CH0”

channel.

b) The system can work at the different channel with different parameter

values which including temperature, time and airflow. The setting

methods are as followings:

Press TEMP “▲” or “▼” key to set the temperature and the

temperature range is 100℃~500℃. The setting method refers to

“6.1 temperature setting”.

Press AIR “▲” or “▼” key to set the airflow and the airflow range is

6~200. The setting method refers to “6.2 airflow setting”.

Press “INFO” and AIR “▲” or “▼” keys at the same time to set the

work time and the time range is 1~999seconds. The setting method

refers to “6.3 work time setting”.

c) All the parameter settings work in the “CH0” channel. When setting the

values of temperature or time or airflow, the “CH0” will be the current

channel and the setting values will be saved into the “CH0” channel.

d) If need to set the channel “CH1” or “CH2” or “CH3” with different

parameter values, press “SAVE” key not loosely and then press “CH1” or

“CH2” or “CH3” key about one seconds to save the parameter values in

the “CH0” channel to the corresponding channel “CH1” or “CH2” or

“CH3”.

6.5 Pedal Switch Control

1. Press the POWER key and switch on the power supply to the SMD rework

system.

2. If the LCD displays “ ”, it means the system is controlled by the pedal

switch when taking down the handle from the holder.

5. Spring the pedal in the work state and then the system comes to the sleeping

state.

6. Spring the pedal switch not loosely in the sleeping state and then the system

comes to the work state. The time parameter window will display “---”, it

means the system will be in the work mode until loosing the pedal switch.

7. Spring the pedal switch and then loose in the sleeping state, the system comes

to work in the current channel which the LCD displaying. Till the work time

window displaying “OFF”, the system cools down to 100℃ and then into

sleeping state.

8. When working in the lock state, the LCD displays “ ”. At the moment, the

system only can work in the CH1 channel, and cannot switch the channel and

change parameter values.

Page7 Page8