Smitec POSYC 3401 Service manual

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 1

Smitec S.p.A., viale Vittorio Veneto 4, 24016 San Pellegrino Terme (BG), Italy, www.smitec.it

Installation, use and maintenance manual

INDUSTRIAL COMPUTERS

POSYC 3401/3402

BEFORE STARTING UP THE INDUSTRIAL COMPUTERS POSYC 3401/3402, CARE-

FULLY READ THIS MANUAL AND FOLLOW ALL INSTRUCTIONS, IN ORDER TO EN-

SURE MAXIMUM SAFETY

The technical data and the drawings in this manual might have been modified later; always

refer to the latest version.

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 2

Summary

1 Preface ....................................................................................................................................................... 3

2 General warnings ...................................................................................................................................... 4

3 Safety instructions .................................................................................................................................... 6

3.1 General information ............................................................................................................................ 6

3.2 Precautions during handling and assembly ........................................................................................ 6

4 Product description .................................................................................................................................. 7

5 Technical data ........................................................................................................................................... 8

5.1 Electrical characteristics ..................................................................................................................... 8

5.2 Electrical characteristics ..................................................................................................................... 8

5.3 Mechanical characteristics .................................................................................................................. 9

5.3.1 Mechanical dimensions ............................................................................................................... 9

5.3.1.1 Front view ............................................................................................................................ 9

5.3.1.2 Side view ........................................................................................................................... 10

5.3.1.3 Rear view (recommended panel cut)................................................................................. 11

5.4 Hardware features ............................................................................................................................ 12

5.4.1 Basic hardware ......................................................................................................................... 12

5.4.1.1 POSYC 3401 ..................................................................................................................... 12

5.4.1.2 POSYC 3402 ..................................................................................................................... 12

5.5 Order codes ...................................................................................................................................... 13

5.6 Accessories ....................................................................................................................................... 13

6 Connections and LEDs ........................................................................................................................... 14

6.1 Top panel view .................................................................................................................................. 14

6.2 Side panel view ................................................................................................................................. 15

6.3 PWR connector ................................................................................................................................. 16

6.4 Ethernet ports ................................................................................................................................... 18

6.5 FLXIO port ........................................................................................................................................ 19

6.6 I/O connector .................................................................................................................................... 20

7 Installation ............................................................................................................................................... 22

7.1 Panel mounting ................................................................................................................................. 22

7.2 Environmental requirements ............................................................................................................. 22

7.3 Electrical connections ....................................................................................................................... 23

8 Use ........................................................................................................................................................... 24

8.1 Touch screen .................................................................................................................................... 24

8.2 Side USB ports ................................................................................................................................. 24

8.3 Micro SD card ................................................................................................................................... 25

9 Ordinary maintenance ............................................................................................................................ 26

9.1 Cleaning the touch screen sensor .................................................................................................... 26

9.2 Replacing the clock battery ............................................................................................................... 26

10 Analytical index ..................................................................................................................................... 27

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 3

1 Preface

This manual provides all necessary information for the installation, use and maintenance of industrial comput-

ers POSYC 3401/3402.

The instructions included in this manual are addressed to the following professionals:

The present instructions must be made available to all the above individuals.

User User is a person, a company or an institution that buys the equipment and

uses it for the purposes it was designed for.

User/operator User or operator is a person authorized by the user to operate on the equip-

ment.

Specialized personnel It refers to all persons with specific competence, able to recognize and avoid

the dangers deriving from the use of the equipment.

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 4

2 General warnings

These assembly instructions are an integral part of the equipment, and must be kept for future reference until

decommissioning.

The user should be informed that the present instructions reflect the state of the art at the moment when the

equipment was sold; they will remain fully acceptable despite subsequent upgrades based on new experienc-

es.

In order to make the manual consultation easier, the following symbols have been adopted:

DO NOT USE THE EQUIPMENT, NOR MAKE ANY INTERVENTION BEFORE INTE-

GRALLY READING AND UNDERSTANDING THIS MANUAL.

IN PARTICULAR, ADOPT ALL SAFETY PRECAUTIONS AND PRESCRIPTIONS INDICATED IN THIS

MANUAL.

THE EQUIPMENT CANNOT BE USED FOR PURPOSES DIFFERENT THAN THE ONES DESCRIBED IN

THIS MANUAL; SMITEC S.p.A. SHALL NOT BE HELD RESPONSIBLE FOR ANY DAMAGES, INCON-

VENIENCES OR ACCIDENTS DUE TO THE NON-COMPLIANCE WITH THESE PRESCRIPTIONS.

Indication of “PROHIBITED ACTION”.

The symbol "DANGER" is used when the non-respect of the prescriptions or the tampering

of organs can cause serious harm to people or things.

The symbol “USE OF INDIVIDUAL PROTECTIONS” means that protective gloves must be

worn.

Indication of “INFORMATION OF PARTICULAR RELEVANCE”.

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 5

The safety prescriptions aim at establishing a series of behaviors and obligations to be complied with, while

performing the activities described later on in this manual.

These prescriptions constitute the prescribed method of operating the device, in a way that is safe for person-

nel, equipments and environment.

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 6

3 Safety instructions

3.1 General information

3.2 Precautions during handling and assembly

Do not install or use the equipment before integrally reading and understanding this manual.

In case of difficulties of interpretation, contact SMITEC technical service.

It is absolutely forbidden to use the equipment for different purposes than the ones de-

scribed in this manual. The technical data and the drawings in this manual might have been

modified later; always refer to the latest version. All upgrades can be requested to SMITEC

S.p.A. directly.

Make sure that the personnel is qualified and adequately informed about the risks he may

run and how to avoid them.

POSYC 340X series industrial PCs can be used only after the classification of the machine

operating area and after checking the safety levels, which must correspond to the assembly

safety levels.

Use adequate tools during the assembly, in order to avoid crushing or abrasions.

Metal components and sharp surfaces may cause cuts and tears. In case of contact, be very

careful and wear the personal protection equipment.

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 7

4 Product description

The POSYC is an ARM-based computer designed primarily as a human-machine interface (HMI) process-con-

troller, with I/O (depending on the model) and integrated FLXIO bus controller.

The user interface has a flat color display with a 7 “diagonal LED illuminated and a touch screen pointing sys-

tem integrated into the product.

The touch screen system offers features of robustness and ease of use, difficult to obtain with other common

pointing devices such as mouse, track-ball and mouse pad.

Being completely integrated into the appliance, it is particularly suitable even in industrial applications that re-

quire resistance to external agents such as dust, humidity, water, oils, etc., which would be harmful for standard

devices.

Since it is sufficient to exert a slight pressure with a finger on its surface to make an immediate pointing, this

system is the main “User Friendly” feature of the POSYC computer.

In order to meet the most different interfacing needs, POSYC nevertheless provides the possibility to connect

also standard input / output devices, such as keyboard, mouse, track-ball, monitor, etc.

The POSYC calculation capability is given by the ARM® Cortex® A9 i.MX6SX 1GHz processor with 1GB

DDR3L RAM memory.

The storage of data and programs on non-volatile support is entrusted to a 4GB micro SD memory.

The position of the device inside the POSYC is such that it can be extracted without opening it. The main ad-

vantage of the micro SD card is its exceptional resistance to accidental shocks and vibrations.

POSYC 340X

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 8

5 Technical data

5.1 Electrical characteristics

5.2 Electrical characteristics

The following characteristics refer to the standard POSYC computer load as supplied, without any connected

peripheral device.

All the technical information reported in this section are consistent with the hardware con-

figuration of the POSYC computer produced at the date of writing of this document. With the

aim of improving or updating the product technologically, SMITEC S.p.A. reserves the right

to change the technical features of the POSYC computer without notice.

Operating temperature 0° ÷ +50°C when operational

Storage temperature -20° ÷ +60°C when not operational

Relative humidity 0 ÷ 90% (without condensation)

Protection degree IP65 on the front (according to IEC 60529 and type 1 UL)

IP20 on the back (according to IEC 60529)

Maximum altitude 2000 m a.s.l

Main power supply voltage (PWR) 24 VDC (-15% ÷ + 20% according to IEC 61131-2) from

CLASS 2 power supply (UL)

Current consumption Max 0.40A @ 24VDC

Absorbed power Max 9.60 W

Auxiliary power supply voltage (I/O) 24 VDC (-15% ÷ + 20% according to IEC 61131-2) from

CLASS 2 power supply (UL)

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 9

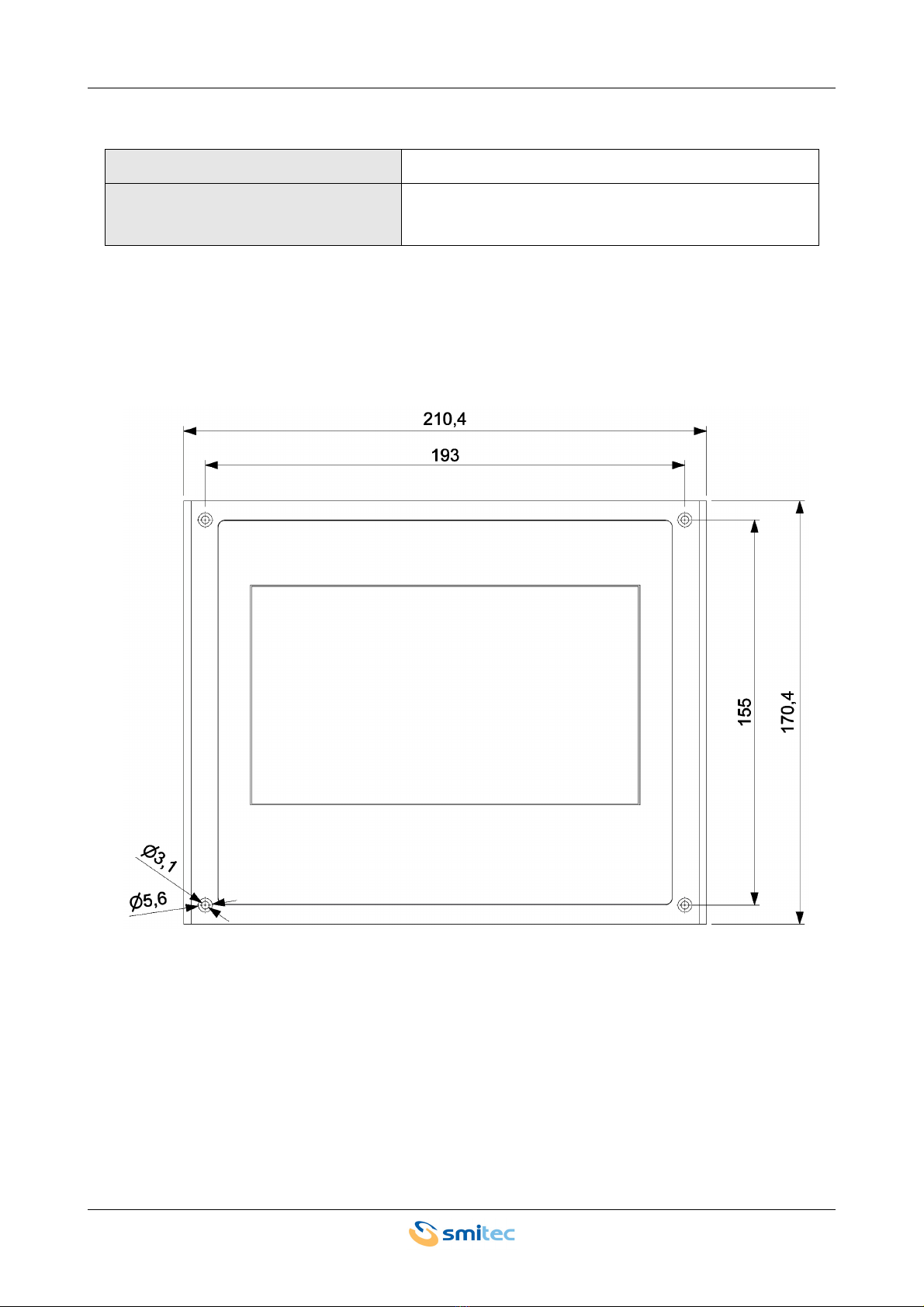

5.3 Mechanical characteristics

5.3.1 Mechanical dimensions

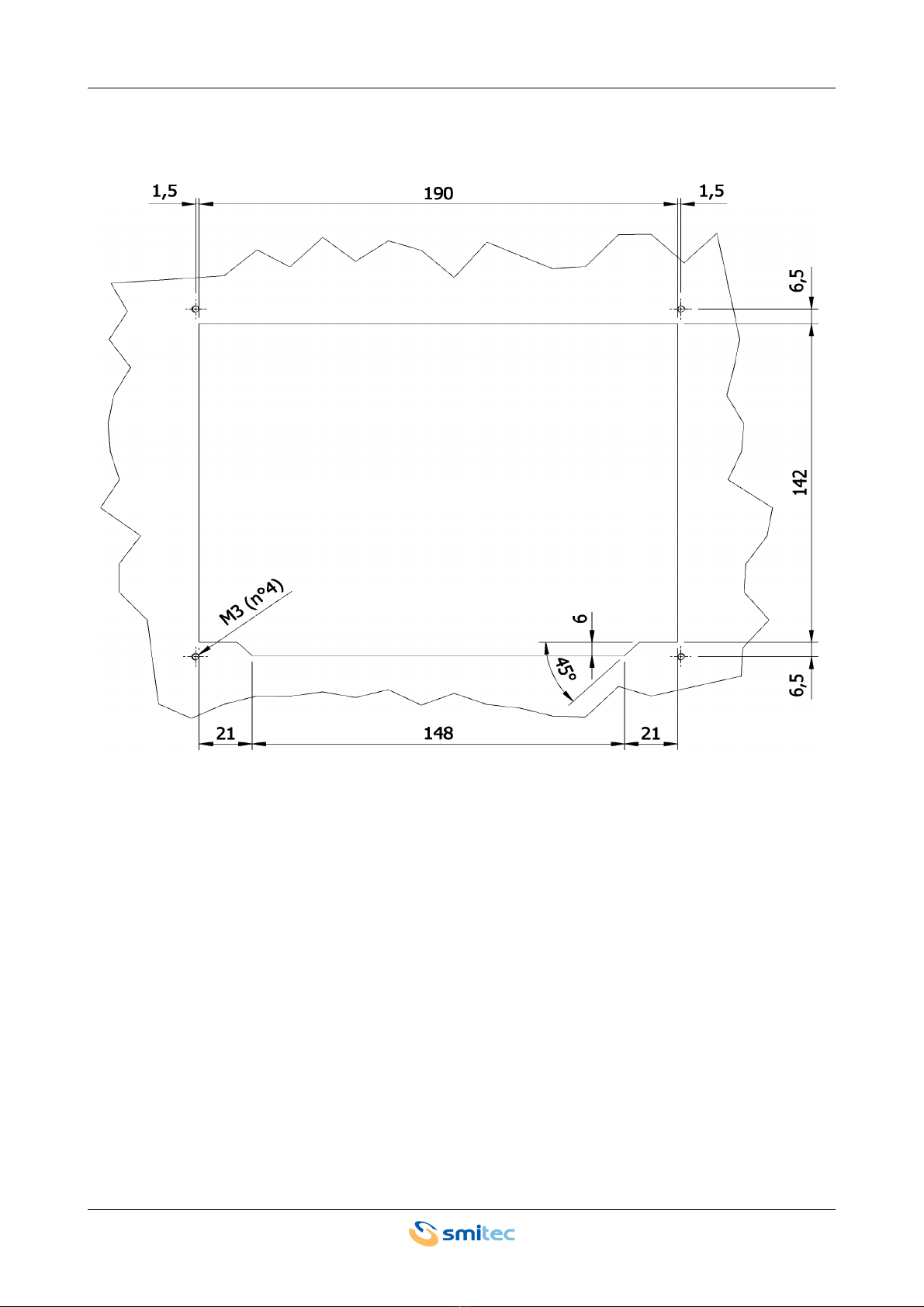

5.3.1.1 Front view

The computers Posyc 3401/3402 need to be fixed on a stable and rigid panel provided with 4xM3 metal thread-

ed hole, min. 1.5mm deep. Use 4xM3x10mm Fe/Zn (not countersunk head type) screws, min. class 8.8, tight-

ened at 1Nm.

Fixing Front panel with 4 through holes of 3.2 mm

Weight Model 3401: 0.83 kg

Model 3402: 0.78 kg

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 10

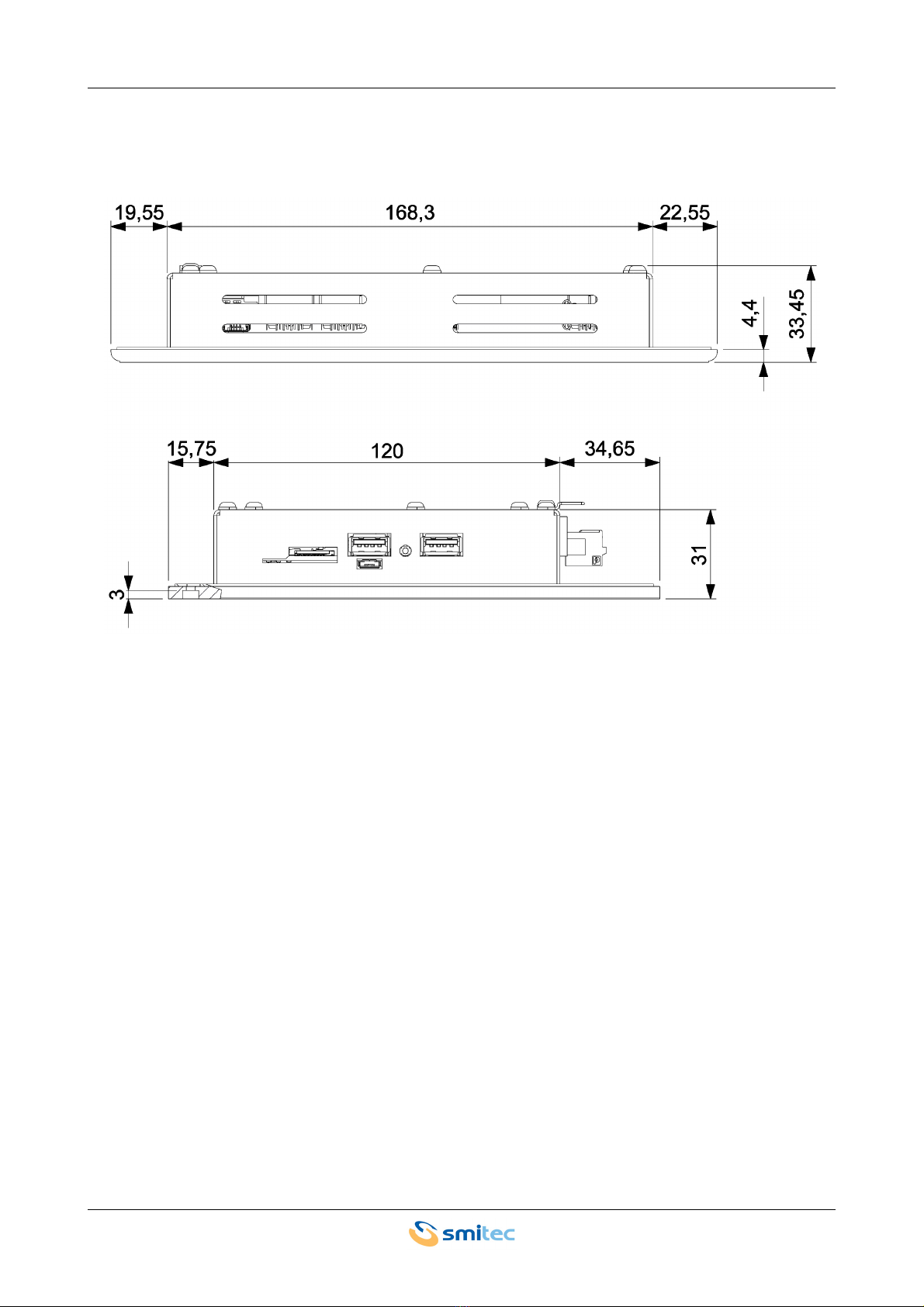

5.3.1.2 Side view

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 11

5.3.1.3 Rear view (recommended panel cut)

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 12

5.4 Hardware features

5.4.1 Basic hardware

5.4.1.1 POSYC 3401

Basic hardware with the following additions.

5.4.1.2 POSYC 3402

Basic hardware with the following additions.

The hardware whose features are described is the minimum guaranteed in the product and

functionally tested; some peripherals possibly present in addition to the purchased product

are not guaranteed neither for production continuity nor for functionality.

Processor ARM® Cortex® A9 i.MX6SX 1GHz

Memory 1GB DDR3L

Display 7 “color LED TFT, 800x480 16M with integrated touch-panel

Touch screen sensor 4 resistive wires

Side USB ports 2 x 2.0

Micro SD card 4GB with Linux operating system

Ethernet ports 2 x 10/100 Mbps

FLXIO ports 3 (isolated)

I/O

Current consumption power input (VI): 2.0A max

4 24V digital I/O (isolated): max single channel output current: 0.5A

Total current withdraw-able from the outputs (VO and I/O): 2.0A max

4 digital inputs 24V (isolated): according to IEC 61131-2 Type 1 and

Type 3

Ethernet ports 1 x 10/100 Mbps

FLXIO ports 3 (not isolated)

I/O Not present

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 13

5.5 Order codes

5.6 Accessories

The POSYC 3401/3402 industrial computers come with a power connector. The same can be ordered sepa-

rately as well as other accessories not included in the POSYC.

Below is the list of order codes.

* = Supplied with POSYC

** = Supplied only with model 3401

Order code Model Description

KZ010501 3401 Hardware base PC with I/O, 2 Ethernet, FLEXIO bus isolated

KZ010528 3402 Hardware base PC without I/O, 1 Ethernet, FLXIO bus not isolated

KZ010573 3402

AUDION (UL) Hardware base PC without I/O, 1 Ethernet, FLXIO bus not isolated

Order code Article

KF101074 24VDC connector (Phoenix Contact cod.1851232) *

KF101049 I/O connector (Phoenix Contact cod.1738856) **

KE050082 Micro SD flash disk, minimum class 4, 4GB capacity (with Linux operating system)

KE020040 Micro SD flash disk, minimum class 4, 4GB capacity (empty)

TB010554 CR2032 3V lithium coin cell battery *

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 14

6 Connections and LEDs

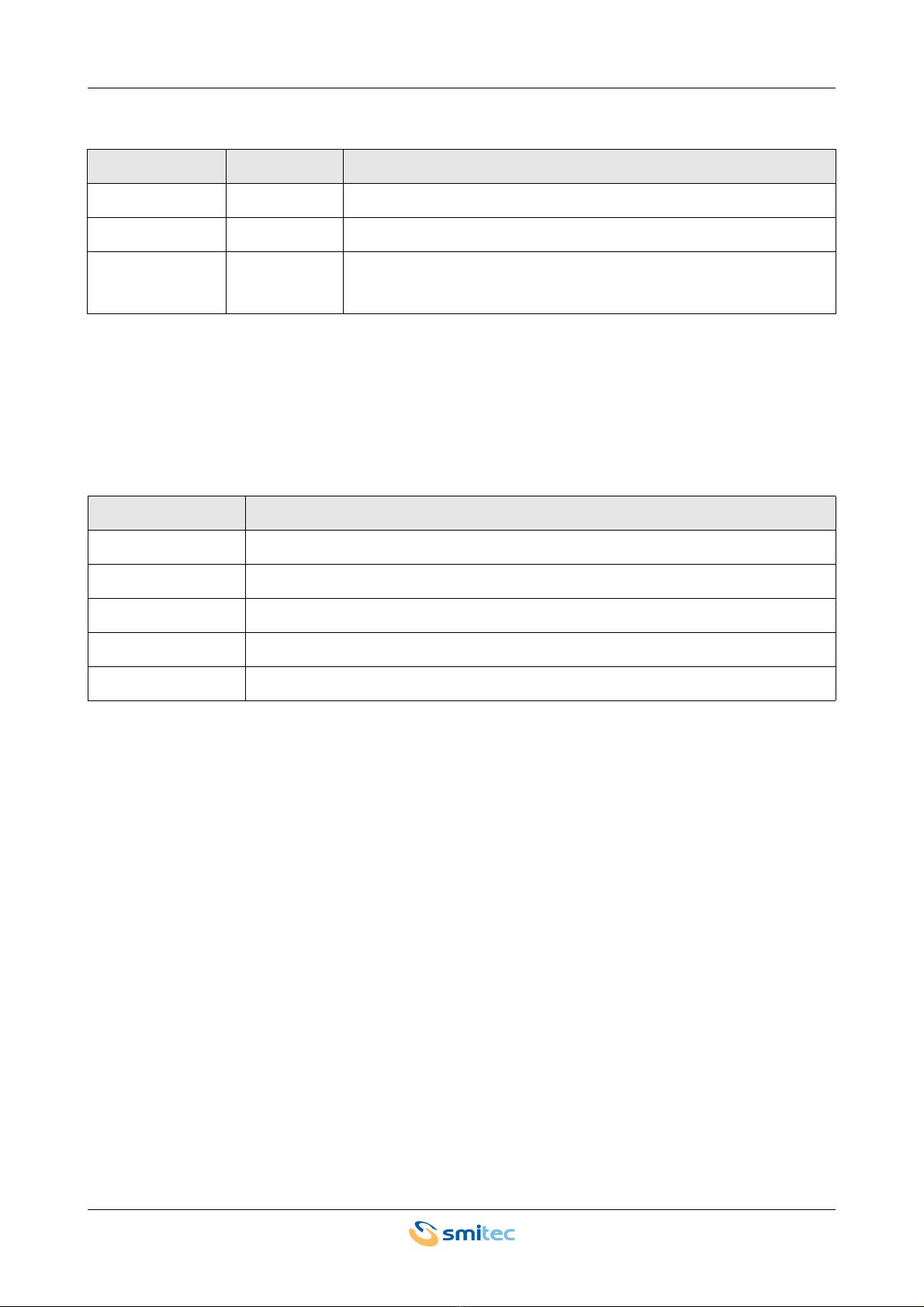

6.1 Top panel view

The following figures show the connectors on the top of the POSYC:

POSYC 3401

POSYC 3402

Name Function

PWR 24 VDC power supply connection

FE Earth protection connection

ETH 1 Ethernet communication port 1

ETH 2 Ethernet communication port 2 (only for POSYC 3401)

I/O 24V digital inputs and outputs (only for POSYC 3401)

L0 FLXIO communication port 1

L1 FLXIO communication port 2

L2 FLXIO communication port 3

ETH 1 ETH 2 I/O L0 L1 L2 PWR FE

ETH 1 L0 L1 L2 PWR FE

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 15

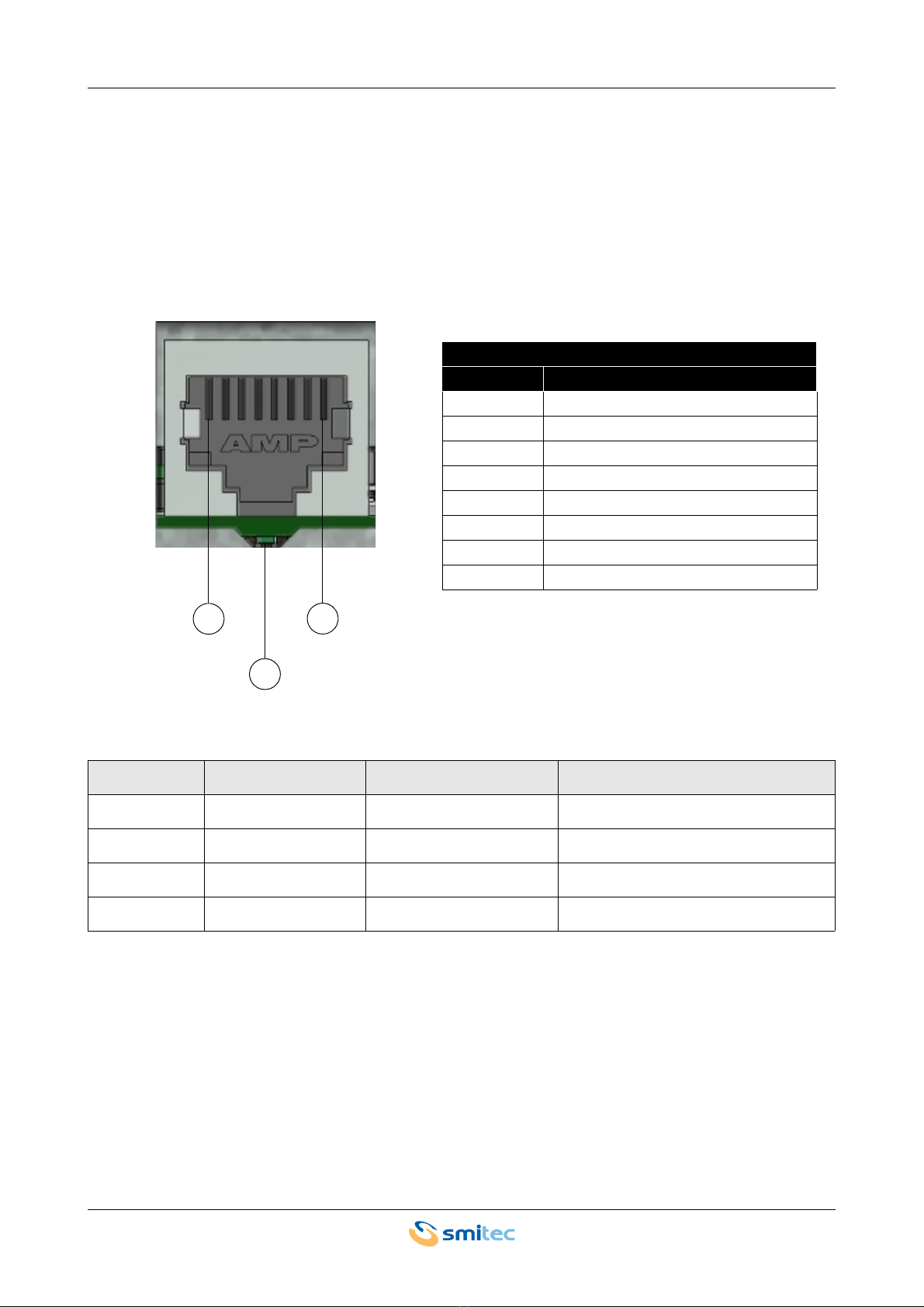

6.2 Side panel view

The following image shows the connectors on the side of the POSYC:

POSYC 3401/3402

Name Function

MSD Socket for micro SD card

USB AB AB type USB micro port (for SMITEC internal use only)

RESET Reset button

USB 1 Port 1 USB 2.0

USB 2 Port 2 USB 2.0

RRed LED: indication of operating status of the device (depends on the application)

O Orange LED: indication of operating status of the device (depends on the application)

GGreen LED: indication of operating status of the device (depends on the application)

MSD

USB 1 USB 2

RESET

ROG

USB AB

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 16

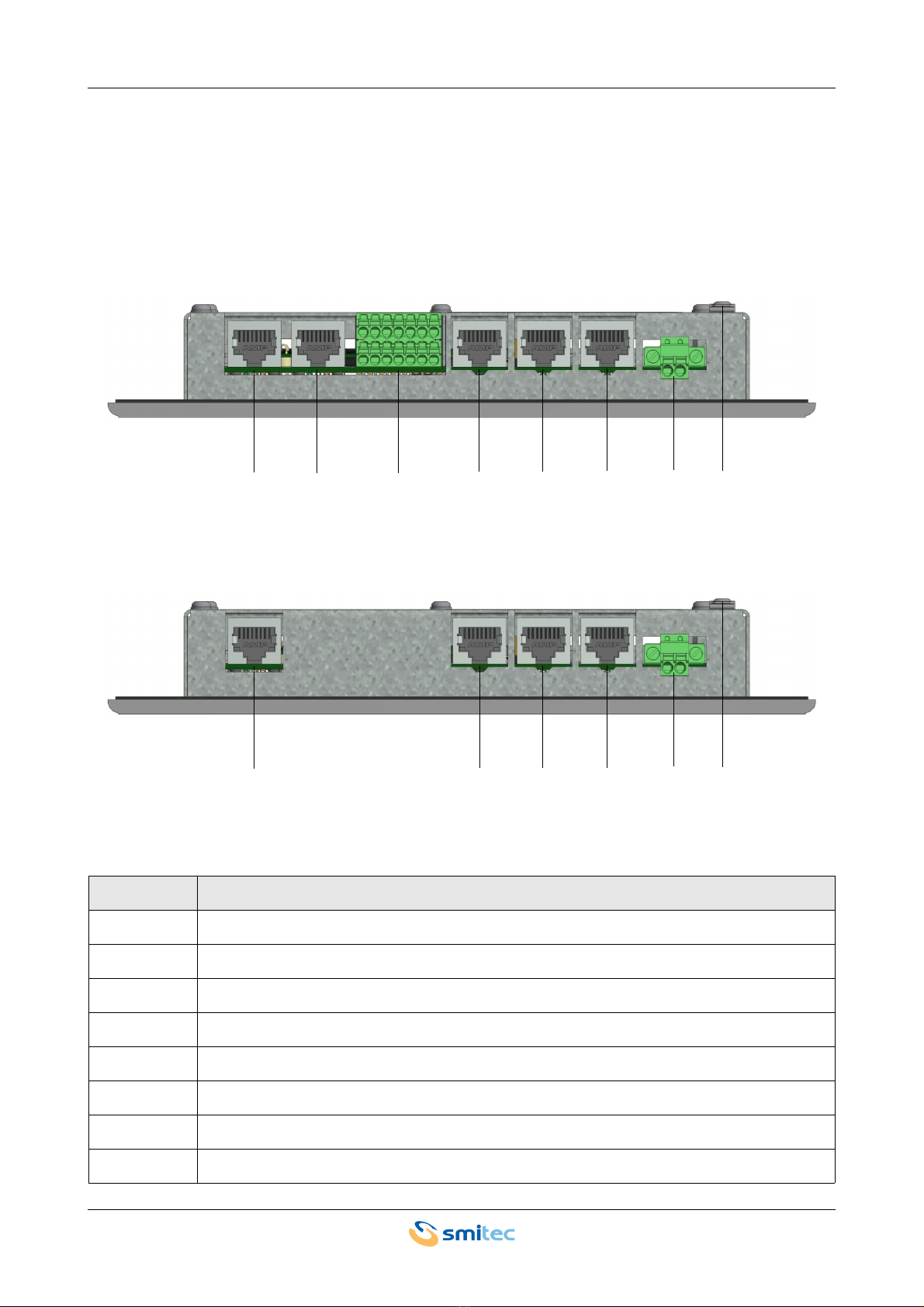

6.3 PWR connector

The connector used to power the POSYC 340X, has spring contacts to facilitate wiring of individual cables.

Connector type: Phoenix Contact FK-MCP 1,5/2-STF-3,81 (1851232) * **

Order code: KF101074

Features Conductors cross section

Connection in accordance with EN-VDE Solid min. 0,14 mm²

Rated voltage 320V Solid max. 1,5 mm²

Rated current

8A Stranded min. 0,14 mm²

Stranded max. 1,5 mm²

Insulating material PA Stranded, with ferrule without plastic

sleeve min. 0,25 mm²

Inflammability class according to

UL 94 V0 Stranded, with ferrule without plastic

sleeve max. 1,5 mm²

Stripping length 9 mm Stranded, with ferrule with plastic sleeve

min. 0,25 mm²

Screwdriver to be used for open-

ing the connections 0,6 x 3,5 mm Stranded, with ferrule with plastic sleeve

max. 0,5 mm²

*= Use only 75°C cables

**= Use only copper conductors

Supply 24VDC

Pin Signal

1 VM (24 VDC)

2GND

1

2

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 17

CAUTION

ATTENTION

Use a cable with a suitable cross-section, sized correctly according to the through-current.

A cable with a section smaller than that required may cause fire due to overheating phenom-

ena generated by the cable itself.

To ensure compliance with the EMC 2014/30 / EU directive, the length of the cables must

not exceed a length of 30 meters.

The POSYC 340X is a high-tech electronic device, sensitive to electrostatic discharge

(ESD) phenomena. Pay the utmost attention to prevent such phenomena, complying with

the provisions of the law, in order to avoid damage to the device.

Utilisez un câble de section appropriée, dimensionné correctement en fonction du courant

traversant. Un câble de section inférieure à celle requise peut provoquer un incendie en rai-

son de phénomènes de surchauffe générés par le câble lui-même.

Pour garantir la conformité avec la directive EMC 2014/30 / EU, la longueur des câbles ne

doit pas dépasser 30 mètres.

Le POSYC 340X est un appareil électronique de haute technologie, sensible aux phéno-

mènes de décharge électrostatique (ESD). Faites très attention à ce que ces phénomènes

ne se produisent pas, dans le respect des dispositions légales, afin d’endommager l’appa-

reil.

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 18

6.4 Ethernet ports

Depending on the model, there are one or two 10/100 Mbps Ethernet ports that use standard RJ45 Ethernet

connectors.

The Ethernet port has two LEDs. The first one, in green color, marked with the letter L, indicates if the door is

connected. The second, orange, marked by the letter A, indicates the state of activity of the door itself, or if the

door is communicating.

LED Color State Function

L Green OFF Not connected

LGreen ON Connected

A Orange OFF No activity

AOrange BLINK ON Communicating

LA

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 19

6.5 FLXIO port

The POSYC 3401/3402, are equipped with three FLXIO doors; the ports are isolated in the model 3401 unlike

the model 3402. This proprietary field bus is based on an RS485 electrical interface and allows a reliable real-

time control of complex applications.

The connections are made via the RJ45 connectors; the following illustration shows the pinout of one of the

connectors and the behavior of the LED (S).

This fieldbus requires a minimum CAT 5 type shielded cable, headed with RJ45 connectors.

Refer to the FLXIO and FLXMOD integration manual (DK400076) for using these buses.

LED Color State Function

S Green Slow flashing (1Hz) Initialization of the bus

SGreen OFF Absent communication

S Green ON Communicating

SGreen Fast flashing (5Hz) Communication error

FLXIO port

Pin Signal

1DATA+

2 DATA -

3GND

4NC

5NC

6 Self-addressing service

7 Reserved

8 Reserved

18

S

Industrial computers POSYC 3401/3402 Installation, use and maintenance manual - EN

Ver. 1.03 20

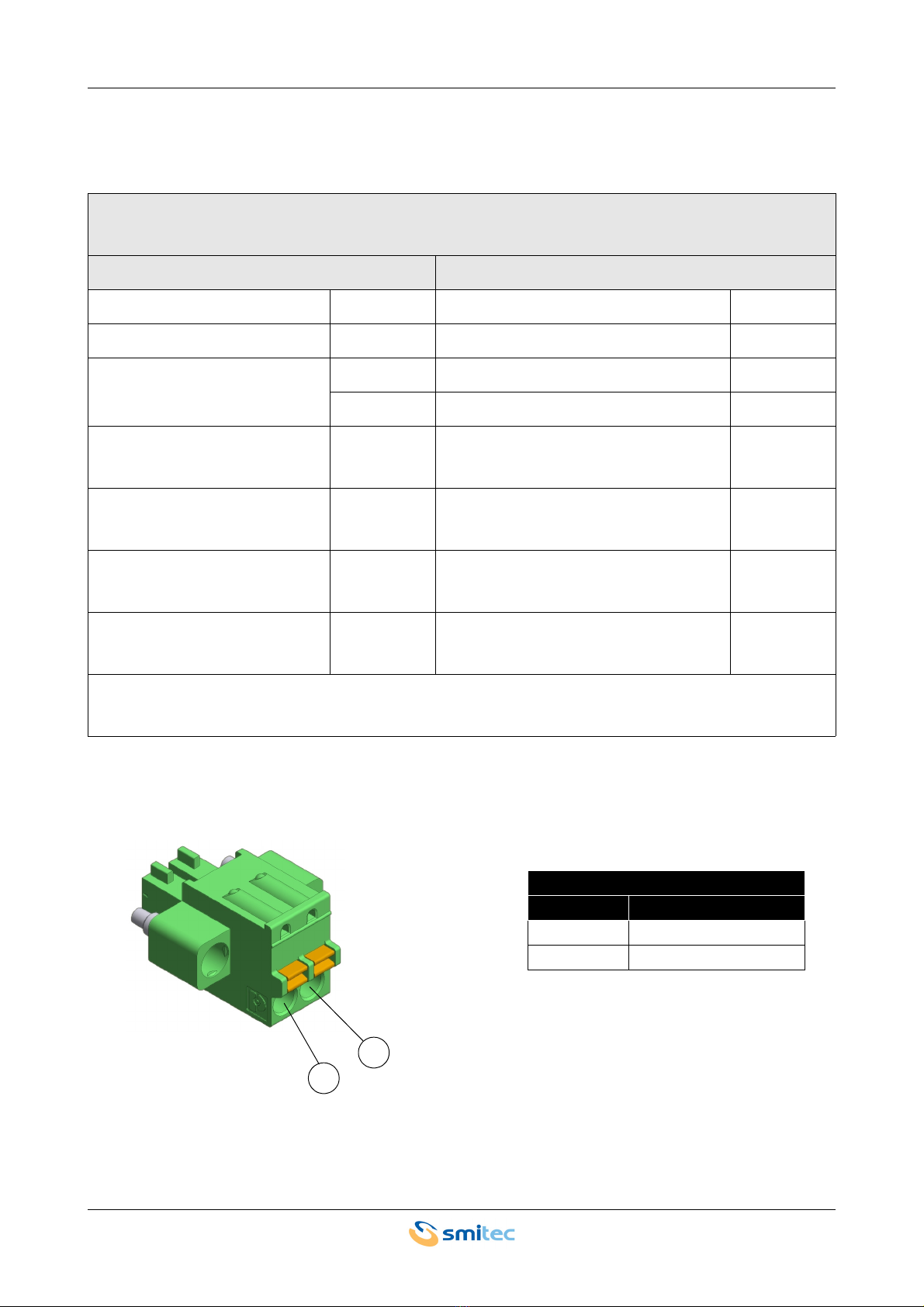

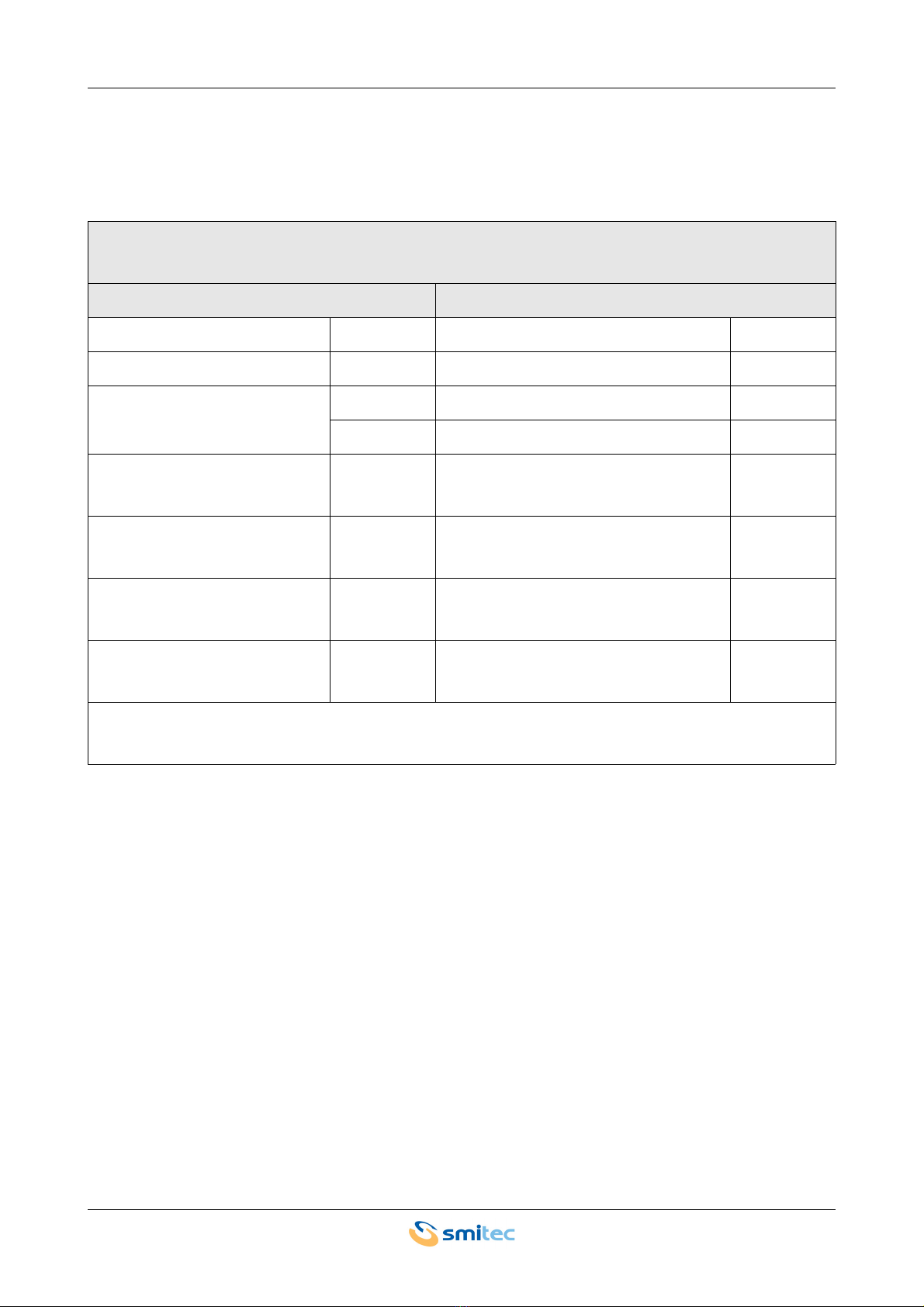

6.6 I/O connector

The connector used for the wiring of the digital I / O of the POSYC 3401/3402 is detachable and has spring-

loaded contacts to facilitate the wiring of the individual cables:

Connector type: Phoenix Contact FMCD 1,5/ 7-ST-3,5 (1738856) * **

Order code: KF101049

Features Conductors cross section

Connection in accordance with EN-VDE Solid min. 0,2 mm²

Rated voltage 160V Solid max. 1,5 mm²

Rated current

8A Stranded min. 0,2 mm²

Stranded max. 1,5 mm²

Insulating material PA Stranded, with ferrule without plastic

sleeve min. 0,25 mm²

Inflammability class according to

UL 94 V0 Stranded, with ferrule without plastic

sleeve max. 1,5 mm²

Stripping length 10 mm Stranded, with ferrule with plastic sleeve

min. 0,25 mm²

Screwdriver to be used for open-

ing the connections 0,6 x 3,5 mm Stranded, with ferrule with plastic sleeve

max. 0,75 mm²

*= Use only 75°C cables

**= Use only copper conductors

This manual suits for next models

1

Table of contents