4

SERIES 19HE BOILER

INSTALLATION INSTRUCTIONS

CONTENTS

Series 19HE Exploded View

.............................................page 2

Parts List.......................................................................page 2

Table of Contents..........................................................page 4

General Information......................................................page 4

Boiler Location..............................................................page 4

Codes and Regulations ................................................page 4

Chimney and Breeching .............................................. page 4

Combustion and Ventilation Air.....................................page 5

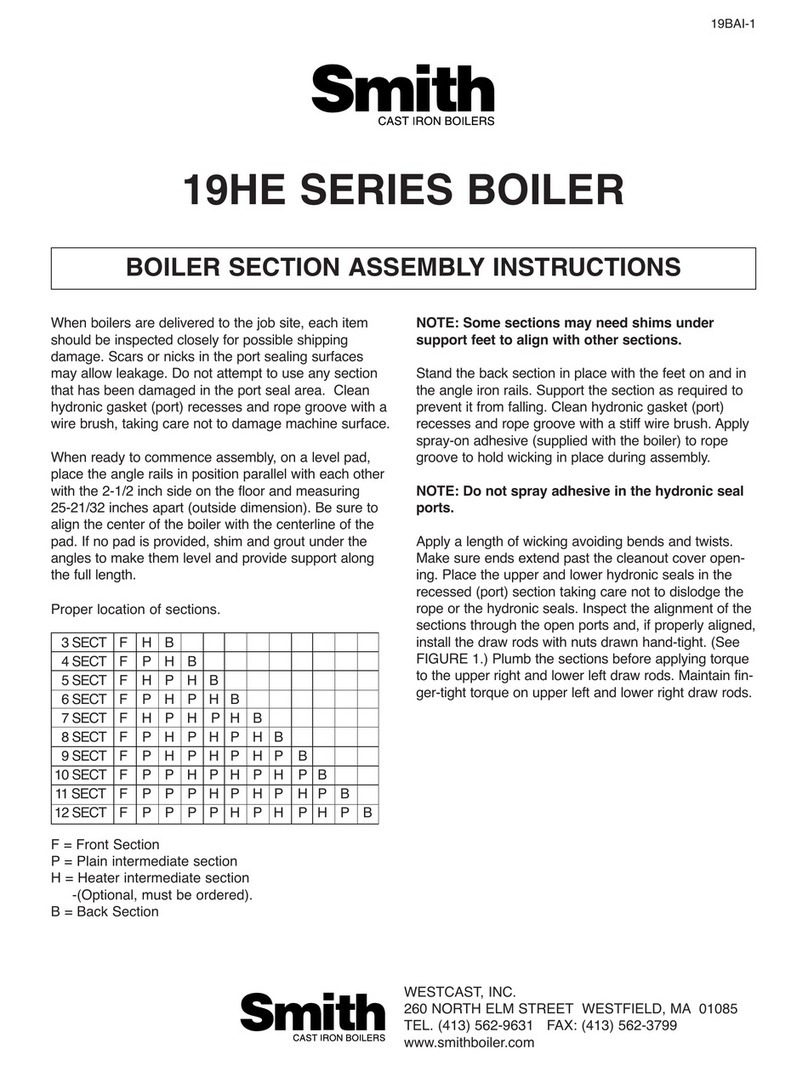

Assembly of Sections ...................................................page 5

Hydrostatic Test ............................................................page 6

Steam Piping ................................................................page 6

Water Piping ................................................................ page 7

Tankless Heaters ..........................................................page 7

Smokehood ..................................................................page 7

Burner Mounting Plate..................................................page 8

Cleanout Covers...........................................................page 9

Rear Observation Port..................................................page 9

Control Locations..........................................................page 9

Jacket ...........................................................................page 9

Safety and Relief Valves .............................................. page 9

Cleaning Boiler Waterways.........................................page 10

Start Up and Maintenance Instructions ......................page 10

Control Tappings Diagram ..........................................page 11

Warning ......................................................................page 12

1. GENERAL

Series 19HE boilers are wet-base, extended surface, vertical

flue design with integral cast flue gas collector for pressurized

firing with oil, gas or combination power burners. Upper and

lower port hydronic seals are of a special material resistant to

petroleum products and compatible with ethylene and

propylene based anti-freeze (non automotive type) which does

not contain corrosion inhibitors to protect aluminum. The flue

gas joints between sections, etc. are sealed using high

temperature (2300°F) ceramic fiber rope. Access to the heating

surface for cleaning is provided from the left hand side of the

boiler through large cast iron cover plates. A slide damper is

provided in the flue gas outlet for back pressure adjustment.

The boilers are supplied completely knocked down for field

assembly, as factory assembled blocks of sections or

completely packaged boiler-burner units. All items should be

inspected for damage upon receipt, and any damage reported

to the wholesaler and trucker. All components should be stored

in a clean, dry area.

The boilers are conservatively rated for high efficiency

performance with capability for down-firing to match connected

load. The large OBROUND upper port provides transfer area

above the water surface for dry steaming at full load.

2. BOILER LOCATION

The boiler must be installed on a smooth, level, non-

combustible floor or pad as close to the chimney or vent

location as possible to minimize breeching length. Allow

clearance around the boiler for piping, service, maintenance,

cleaning and tankless coil removal. Approximately 30 inches

on the sides is a minimum (Check local code requirements).

Do not install electrical conductors in floor or pad under boilers.

See Figure 1 for boiler floor pad requirements, and Table 1 for

minimum required pad length.

Boiler No. Min. Recommended Pad Length

19HE-3 30"

19HE-4 36"

19HE-5 42"

19HE-6 48"

19HE-7 54"

19HE-8 60"

19HE-9 66"

19HE-10 72"

19HE-11 78"

19HE-12 84"

Table 1

4 5/32" 12 27/32" 12 27/32"

25 21/32"

4 5/32"

34"

32"

JACKET SIDE PANEL

C

LOF BOILER

FLOOR

OR PAD

1 1/2" x 2 1/2" ANGLES

3. CODES AND REGULATIONS

All work in connection with the boiler, burner and controls

must be performed in strict accordance with requirements

of state and local authorities having jurisdiction over boiler

installations.

Figure 1

In the absence of such local requirements, the following should

govern:

A.S.M.E. Section IV - “Heating Boilers"

A.S.M.E. Section VI - “Care and Operation of Boilers”

ANSI/NFPA 31 - “Installation of Oil Burning Equipment”

ANSI/Z223.1 - “National Fuel Gas Code”

ANSI/NFPA 70 - “National Electrical Code”

4. CHIMNEY AND BREECHING

The breeching connection between boiler and chimney should

be as direct as possible with the minimum number of elbows

or bends. It should pitch upwards to the chimney at a rate of

1/4 inch per foot of horizontal run. Generally, the breeching

and chimney should be the same diameter as the boiler outlet

connection.

NOTE: 11 and 12 section uses adapter collar for connec-

tion to 12" diameter vent system.

For fuel conservation and sTable burner performance, the

vent connection from the boiler should not include a

barometric draft control or other opening unless the venting

system can develop an excessive draft, or is required by code.

Typically stack heights less than 50 ft will not require the use

of a barometric damper.