SnowDogg xp series User manual

116992140 Rev CPATENTS PENDING

216992140 Rev C

XP INSTALLATION/REFERENCE MANUAL

Table of Contents

1. Warnings/Vehicle Application .......................pg. 2

2. About the plow ...............................................pg. 3

3. Registration Information/Website .................pg. 3

4. Snowplow Mounting/Dismounting ...............pg. 4

5. Mechanical Installation.............................. pg. 5-6

6. Harness Installation ....................................pg. 7-9

7. Storage and Maintenance.............................pg. 10

8. Parts Diagram and BOM ......................... pg. 11-14

a. Lift Frame ............................................... pg. 11

b. Moldboard............................................... pg. 11

c. Hydraulic Power Unit ........................ pg. 12-13

9. Hydraulic/Electrical Operation ............... pg. 15-16

10. Troubleshooting ..................................... pg. 17-19

11. Snow Plowing Tips ..................................... pg. 18

12. Warranty...................................................... pg. 19

WARNING

Many newer trucks are equipped with air bags. DO NOT

under any circumstances disable or remove or relocate

any sensors or other components related to the operation

of the air bags.

WARNING

Always follow the vehicle manufacturers

recommendations relating to snowplow installation. For

recommended vehicle models refer to the SnowDogg

Application Chart and Selection Guide.

WARNING

Vehicles equipped with air bags are designed such

that the air bags will be activated in a frontal collision

equivalent to hitting a solid barrier (such as a wall) at

approximately 14 mph or more, or, roughly speaking, a

frontal perpendicular collision with a parked car or truck

of similar size at approximately 28 mph or more. Careless

or high speed driving while plowing snow, which results

in vehicle decelerations equivalent to or greater than the

air bag deployment threshold described above, would

deploy the air bag.

WARNING

Make sure plow is properly attached before moving

vehicle.

WARNING

Do not move plow while servicing or place body parts

between or under plow parts while moving plow.

WARNING

When transporting, position plow so as not to block vision

or plow headlights.

WARNING

DO NOT change blade position when traveling.

WARNING

DO NOT exceed 40 mph when transporting plow.

WARNING

Do not exceed 10 mph when plowing.

WARNING

Always lower blade when vehicle is not in use.

WARNING

Read this manual carefully before operating this

snowplow.

CAUTION

Vehicle application recommendations are based on the

following:

• The vehicle with the snowplow installed must comply

with applicable Federal Motor Vehicle Safety Standards

(FMVSS).

• The vehicle with the snowplow installed must comply

with the vehicle manufacturer's stated gross vehicle and

axle weight ratings (found on the driver-side door corner

post of the vehicle) and the front and rear weight distribu-

tion ratio. In some cases, rear ballast may be required to

comply with these requirements.

• In some cases there may be additional limitations and

requirements.

• Available capacity decreases as the vehicle is loaded

with cargo or other truck equipment, or snowplow acces-

sories are installed.

• If there is uncertainty as to whether available capacity

exists, the actual vehicle as configured must be weighed.

316992140 Rev C

WELCOME!

Congratulations on your purchase of a SnowDogg plow! The SnowDogg plow by Buyers Products is a

heavy-duty, professional grade plow built for your toughest plowing applications. By using this manual for

maintenance and safety instructions, you can be sure to optimize the life of your plow.

Your dealer can provide expert assistance and service and is the first line of support. They have first hand

knowledge of your plow and the conditions in your area.

Be sure to register your plow after purchase at www.snowdoggplows.com. The required information is

shown on the Registration Data Sheet. Registration is required to activate your two year warranty.

REGISTRATION DATA SHEET

Owner’s Information

Name:

Company:

Address:

Phone:

Fax:

E-mail:

Purchased From:

Purchase Date:

Plow Model:

Plow Serial#:

HPU Serial #:

Truck Model:

Truck Year:

Register your plow at www.snowdoggplows.com to activate your two year warranty.

416992140 Rev C

Mount/Dismount Instructions

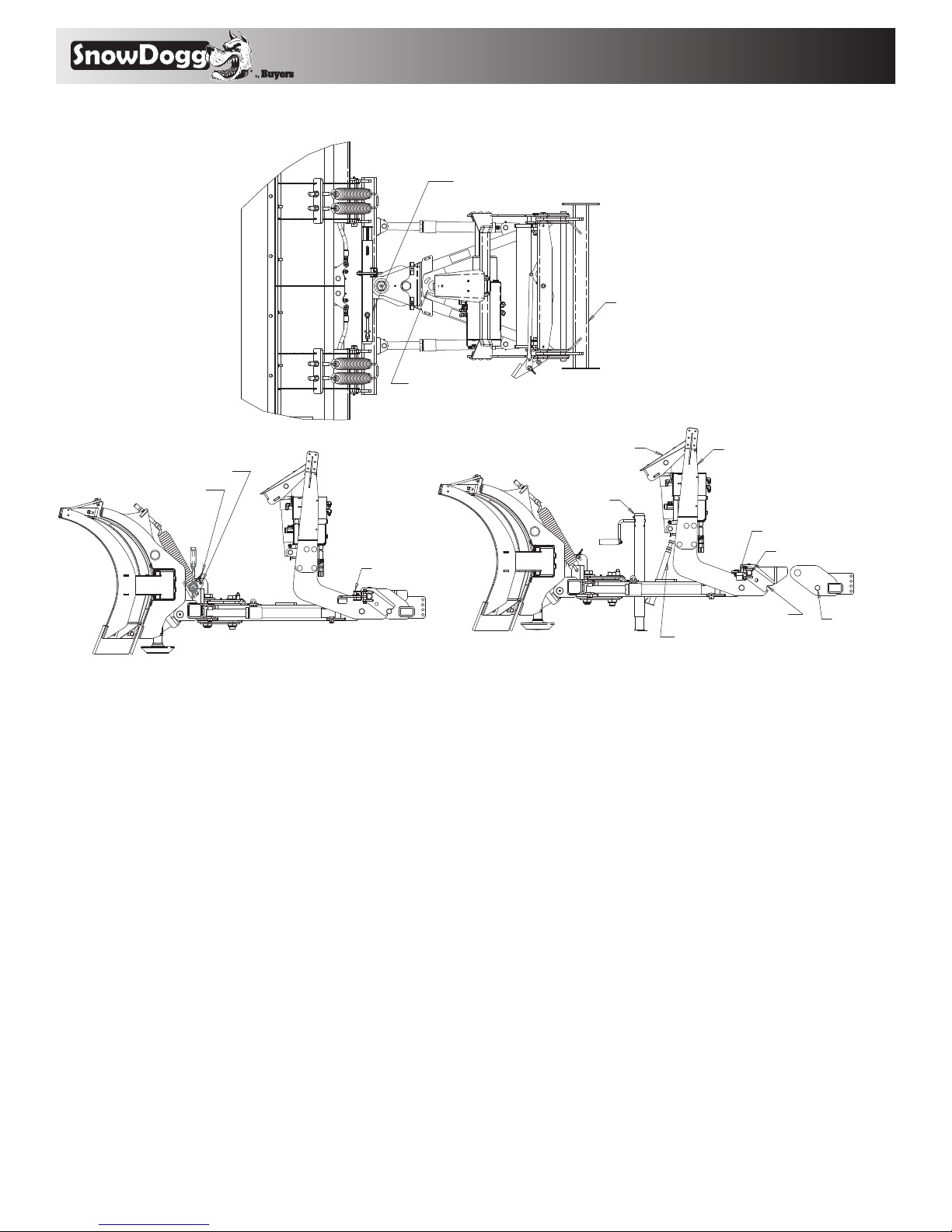

Snowplow Mounting (fig. above)

1. Check that the pins are fully retracted. The foot

pedal should be pushed towards the truck and will

lock in the retracted position.

2. Drive in to the plow so that the cross bar on

the mount engages with the receiver notch on the

plow. Depending on the plow height the jack many

need to lowered or raised to fully engage.

3. Pull the foot pedal away from the truck to release

the pins.

4. Push up on the lift frame to engage the pins. To

verify the lift frame is fully connected, check to see

that the gold pins are visible from each side. Insert

the lock pin (or padlock) through the foot pedal and

pedal linkage.

5. Retract the jack enough to allow its removal.

Rotate the jack to disengage from the jack mount

plate.

6. Stow the jack on the stow plate located on the

driver’s side moldboard and insert the lock pin. The

jack may also be stored in the truck for added theft

prevention.

7. Connect both the lighting & hydraulic control

connectors.

Snowplow Dismount (fig. above)

1. Put the plow in float by holding the down button

for 1 second.

2. Press down on the chain lift to retract the lift

cylinder. The chain must have slack for ease of

plow removal.

3. Install the jack into the jack mount plate. This

will raise the lift frame prop.

4. Extend the jack enough to remove weight from

the plow mount pins.

5. Push on the foot pedal and the lift frame

towards the vehicle simultaneously. The pins will

retract and the lift frame will rotate forward to rest

on the lift frame prop.

6. Disconnect the lighting and hydraulic connectors

7. Back away from the snowplow

MOUNTED PLOW

STOWED JACK

LOCK PIN

LOCK PIN

DISMOUNTED PLOW

CROSS BAR

MOUNT PIN

FOOT PEDAL

RECIEVER HITCH

LIFT FRAME PROP

JACK

CHAIN LIFT LIFT FRAME

<---

MOUNT PUSH BAR

JACK PLATE

STOWED JACK

516992140 Rev C

INSTALLATION

SnowDogg snowplows are shipped almost completely assembled to minimize the amount of time from

box to plowing. The illustrations are representative only and may differ from your hardware. Please see the

parts diagrams for specific part numbers.

ITEM QTY. PART NO. DESCRIPTION ITEM QTY. PART NO. DESCRIPTION

1 1 LIFT FRAME ASSEMBLY

16019000 XP Lift Frame

2 1 MOLDBOARD ASSEMBLY

16020920 XP810 Moldboard Assembly

3 1 16101100 TRIP PIN HARDWARE KIT

3a 2 Trip Pin

3b 2 Grease Fitting, 1/4-28

3c 2 Washer, Flat, 1", Zn

3d 2 Pin, Cotter, 1/4 x 2, Zn

4 4 16101200 TRIP SPRING

5 1 16101210 TRIP SPRING HARDWARE KIT

5a 4 Eyebolt, 5/8-11 x 8, SST

5b 8 Nut, 5/8-11, SST

5c 4 Washer, Lock, 5/8, SST

5d 4 Cap, Black Vinyl

6 1 16122100 BLADE GUIDE KIT

6a 2 Blade Guide, Orange, 24"

6b 4 Screw, Cap Hex 5/16-18 x 1, Zn

6c 4 Washer, 5/16 Flat, Zn

6d 4 Nut, Nylock, 5/16-18, Zn

7 2 16111510 LIGHT BRACKETS

8 1 16111512 LIGHT BRACKET HARDWARE KIT

8a 8 Screw, Cap Hex 1/4-20 x 1-1/4 Zn

8b 16 Washer, Flat 1/4 Zn

8c 8 Nut, Nylock, 1/4-20 Zn

9 1 16160700 LIGHT KIT

9a 1 Ps Side Light

9b 1 Ds Side Light

9c 4 Bolt, Plow Flathead, 1/2-13 x 2.5 Zy

9d 4 Washer, Spherical, Zy

9e 4 Washer, Flat, 1/2 Zy

9f 4 Washer, Lock, 1/2 Zy

9g 4 Nut, 1/2-13 Zy

10 1 16101102 LIFT FRAME HARDWARE KIT

10a 2 Clevis Pin, 7/8" x 4"

10b 2 Cotter Pin, 3/16 x 2"

10c 8 Carriage Bolt, 1/2-13 x 1.5 SS

10d 8 Washer, Flat, 7/16 SS

10e 8 Nut, Nylock, 1/2-13 SS

11 1 16111400 CHAIN LIFT

12 1 16122412 DEFLECTOR BRACKET KIT

12a 1 Bracket, PS, Deflector Mount

12b 1 Bracket, DS, Deflector Mount

12c 2 Clamp Strip, XP Deflector

12d 8

Screw, Socket Button, 3/8-16 x 1.25, SST

12e 8 Nut, Nylock, 3/8-16, SST

13 1 16120157 DEFLECTOR, RUBBER, 90"

2

1

3a

3b

3c 3d

4

5a

5b

5c

5d

6a

6b

6c 6d

7

8a

8b

8c

9c

9d

9e

9f

9g

10c

10d

10e

11

10a 10b

12a

12b

12c

12d

13 9a

9b

12e

616992140 Rev C

SNOWPLOW ASSEMBLY

1. Flip up the upper lift frame and secure using eight 1/2" x 1-1/2" stainless steel hex cap screws, nuts and

washers (10c/d/e).

2. Attach the chain lift to the upper lift frame and lift cylinder using two 7/8" x 4" clevis pins and cotter

pins (10a/b).

3. Attach the moldboards to the lift frame kit using the hinge pin, washer, and cotter pin as shown. Check

that the moldboards rotate freely around the hinge pin.

4.

Install the two cylinder rods to each moldboard half with the clevis pins, washers and cotter pins as shown.

5. Install the snow deflectors (if desired) by loosening the fasteners on the top of the moldboard. The end

two fasteners will need to be removed to slide the deflector between the black painted retainer strip & the

stainless steel skin. It may be necessary to clamp the skin in place to allow insertion of the deflector. After

the deflectors are in place replace and tighten all fasteners.

6. Install deflector as shown.

7. Connect hoses to mold board fittings. The hoses and fitting are color coded - verify that each hose is

connected to the correct fitting. Finger tighten the swivels and turn an additional 1/4 turn with a wrench.

This will correspond to a torque of ~20ft-lbs. DO NOT OVERTIGHTEN THE SWIVELS.

8. Install the blade guides using the included hardware kit.

9. Install the lights with the light kit hardware. Do not route the plow side light harness yet as the

Passenger and Driver side light connection will vary depending on the truck side installation. Do not tight-

en the light hardware yet, as they will need to be aimed.

10. The plow may now be set into mounting configuration – install the jack and level the plow to the prop-

er height for mounting to the truck.

VEHICLE SPECIFIC MOUNT INSTALLATION

1. Mount the truck undercarriage as shown in the undercarriage installation instructions. As with the

plow, all the fasteners should be checked on a regular basis.

VEHICLE SPECIFIC HEADLIGHT ADAPTER INSTALLATION

1. It may be necessary to remove vehicle headlights to access the truck light harness connectors.

2. Install the vehicle specific headlight adapters per included installation instructions.

3. Be sure to route wires and harnesses away from hot surfaces or moving parts.

CAUTION

For safety reasons, the blade drops very slowly on the plow as shipped. To adjust the drop speed of the blade use a flat

blade screwdriver and turn the lowering speed adjustment on the front of the hydraulic power unit counter clockwise. Turn it

clockwise to slow the blade drop speed. Do this only while the blade is dropped, and tighten the jam nut after adjusting.

716992140 Rev C

HARNESS INSTALLATION

The SnowDogg has two separate harnesses for ease of installation and troubleshooting – a control harness

and a light harness. They can be mounted separately. In the case of trucks with central hydraulics or

existing auxiliary lights, either harness can be omitted without affecting the functionality of the other system.

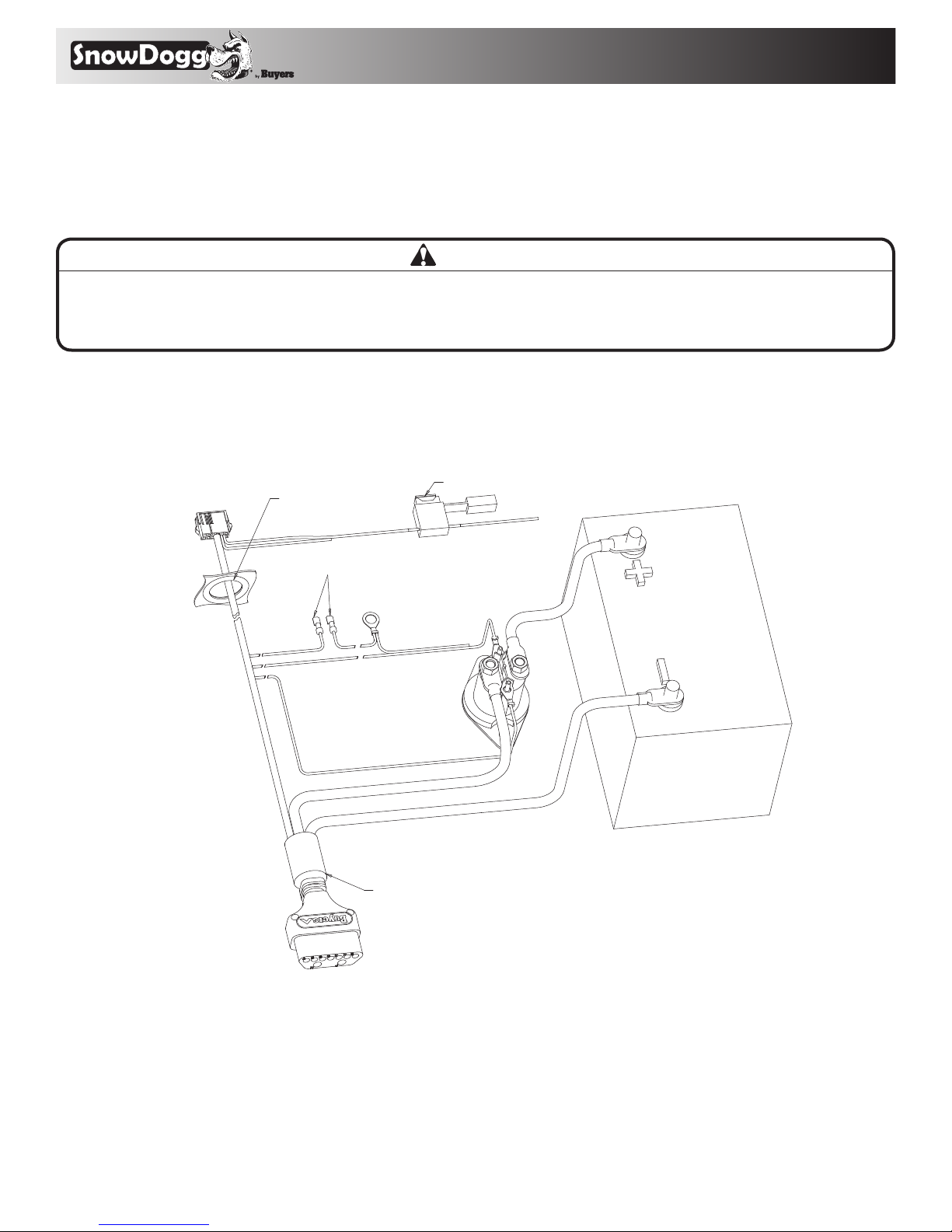

Control Harness

The plow side control harness has been preinstalled. The truck side control harness is routed through the

grill, by the battery, and through the firewall to the controller. It is preferable when possible to keep the

plow connector on the drivers side to make mount/dismount easier and faster.

Control Harness Diagram

CAUTION

Keep all connectors greased with dielectric grease on a regular basis to minimize corrosion & potential damage or wear to the pins.

It is critical that all electrical connections be tight and secure. Loose connections on the plow circuit can cause overheating,

component failure, or intermittent operation.

1. Route the CONTROL HARNESS through the truck grill, by the battery, and through the firewall. Some

trucks will require drilling a ø1.50" hole through the firewall, while some will have holes provided (usually

plugged). Check your truck Owner’s Manual for details. If the hole is drilled it is critical that a grommet be

used to prevent damage to the wire harness.

2. Mount the MOTOR RELAY in a convenient and secure location on the battery side of the vehicle using

the included self tapping screws.

3.

The small RED WIRE from the CONTROL HARNESS is connected to a small terminal of the MOTOR RELAY.

4. The small BLACK WIRE from the CONTROL HARNESS has two leads – one is connected to the other

POSITIVE (+)

TERMINAL

NEGATIVE (-)

TERMINAL

TO ACC POWER (+12V)

BLACK

RED/WHITE

BLACK

RED

RED 4GA

BLACK 4GA

TO CHASSIS OR

BATTERY GROUND

TO CONTROLLER

THROUGH GRILL

SEE INSTRUCTIONS

10A FUSE

TRUCK FIREWALL

DRILL Ø1.5" HOLE AND

PROTECT WITH GROMMET

16160300 CONTROL HARNESS

816992140 Rev C

small terminal of the MOTOR RELAY. The other is connected directly to vehicle/chassis ground.

5. The large (4 gage) BLACK WIRE on the CONTROL HARNESS must be connected directly to the

NEGATIVE (-) battery terminal. A BATTERY TERMINAL ADAPTER may be required.

6. The large (4 gage) RED WIRE on the CONTROL HARNESS is connected to one of the large terminals on

the MOTOR RELAY.

7. The shorter red BATTERY CABLE is used to connect the other large terminal of the MOTOR RELAY

with the POSITIVE (+) terminal on the battery. A BATTERY TERMINAL ADAPTER may be required.

8. The CONTROLLER CONNECTOR is routed through the firewall. Wait to complete RELAY HARNESS

installation before further steps.

9. Connect the handheld controller and locate in a convenient location for the operator using the included

mounting bracket or Velcro.

10. Male spade connectors on the BLACK and RED/WHITE wires will be connected to the LIGHT

HARNESS in the next step.

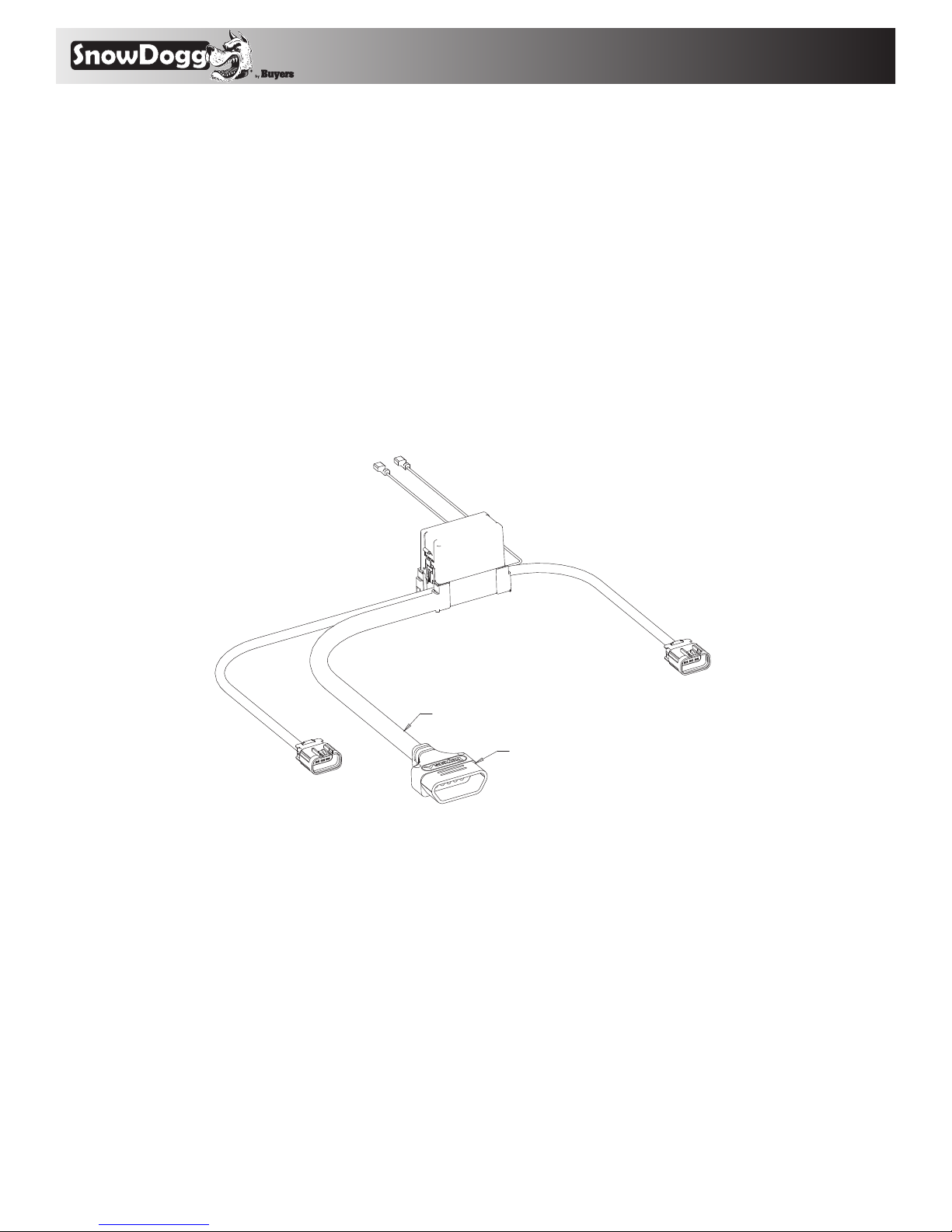

Light Harness

1. Route the RELAY HARNESS through the grill (drivers side preferably) and place the RELAY MODULE

close to either the drivers or passenger side headlight (whichever is convenient).

2. A VEHICLE SPECIFIC HEADLIGHT ADAPTER for your plow should be installed between the OEM

HARNESS and HEADLIGHT on both the passenger and driver sides. The BROWN wire from the adapter

should be spliced into the PARKING light circuit. The PURPLE wire from your adapter should be spliced

into the TURN signal circuit.

3. Route and connect the 8-pin connectors on the RELAY HARNESS to the VEHICLE SPECIFIC

HEADLIGHT ADAPTERS. There is a LONG and SHORT cable on the RELAY HARNESS. The LONG

cable is for the far side of the vehicle. Both CABLES are identical. LEFT and RIGHT turn signals will be

determined prior to routing the LIGHT HARNESS on the plow.

4.

The ORANGE and BLACK/WHITE wires on the RELAY HARNESS are connected to the RED/WHITE and

BLACK wires on the CONTROL HARNESS. Connect them as shown below – see the application guide for spe-

cific information on your vehicle. In the case of a standard ground vehicle (switched hot), connect the wires as

shown below for standard configuration. In the case of a switched ground vehicle, locate the gray wire with male/

female disconnected fittings (already connected). Disconnect the two halves. The male quick connect end of the

wire will not be used and may be taped off. The female end will be connected to the RED/WHITE wire from the

BLACK/WHITE WIRE

ORANGE WIRE

TO HEADLIGHT

ADAPTER (1607XXXX)

TO HEADLIGHT

ADAPTER (1607XXXX)

16160100 RELAY HARNESS

THROUGH TRUCK GRILL

Light Harness Diagram

916992140 Rev C

16160300 harness. Connect the other wires as shown. It is recommended that heat shrink tubing be put over

these connections once complete to seal against corrosion.

Light Aiming

1. Place the vehicle on a level surface 25 feet in front of a matte-white screen, such as a white wall or

garage door.

2. The snowplow should be mounted, with the blade raised in transport position.

3. Check that the truck is in normal operating condition with no flat tires, failed suspension components,

and no passengers.

4. Mark the vertical centerline of the vehicle headlights on the screen (a line matching the height the of

headlights from the ground). Mark the horizontal centerline of the vehicle headlights on the screen (lines

matching the headlight center to center distance).

5. The high intensity zone of the low beams should be just below the horizontal line and the right of the

vertical lines (see diagram below). Adjust the headlight aim as required.

NOTE: Snowplow installers must certify that installation conforms to federal motor vehicle safety standards.

STANDARD HEADLIGHTS

SWITCHED GROUND HEADLIGHTS

(SEE APP GUIDE FOR ASSISTANCE)

WHITE/BLK

ORANGE RED/WHITE

BLACK

RELAY HARNESS CONTROL HARNESS

GRAY GRAY

ALREADY CONNECTED

IN RELAY MODULE

WHITE/BLK

ORANGE RED/WHITE

BLACK

RELAY HARNESS CONTROL HARNESS

GRAY GRAY

NOT USED - COVER END

WITH TAPE OR HEAT SHRINK

5.Connect the FUSED POWER LINE to an OEM approved +12V IGNITION SWITCHED source (10A)

Screen Located

25' from Headlights

Align with Vehicle

Centerline

Distance Between

Headlight Centers

High Intensity Zones

For Type 2 (Sealed Beam)

Headlights on Low Beam

Vertical Centerline

Ahead of Right Headlight

Light Aiming Diagram

10 16992140 Rev C

Your plow and truck are now ready for operation. The hydraulic system has been filled at the factory and

should be fully operational. It is possible that agitation due to the shipping has introduce some air into the

oil. When operating the plow for the first time some oil may exit the vent (by the coils). This should stop

once the plow is cycled and operational. Check all plow and light functions. If something is not working

correctly, reread the installation directions to make sure a step was not missed and check the schematics.

STORAGE

1. Before disconnecting the plow from your vehicle, fully compress the lift cylinder

2. Disconnect the plow from your vehicle

3. Coat all electrical connection points with dielectric grease

4. Repair/touch up any chipped paint or rusted areas

5. Apply a coat of oil or grease to all exposed chrome (on angle and lift cylinders)

6. Grease all grease fittings on trip pins and king pin

REMOVAL FROM STORAGE

1. Check all fasteners and hydraulic fittings for tightness.

2. Replace any cracked hydraulic hoses

3. Coat all electrical connection points with dielectric grease

4. Connect plow to vehicle

MAINTENANCE

The SnowDogg line of plows has been simply designed for reliable service. In order to ensure the

reliability of your plow, observe the following maintenance items and regularly inspect:

• Fasteners and retaining devices for proper installation and tightness.

• Hydraulic cylinders for damage, pitting or leakage

• Hydraulic hoses for wear, damage or leakage. Replace any damaged hose.

• All electrical connections for corrosion – apply dielectric grease as required

• Cutting edge wear

• Plow shoe wear

• Greasable fittings (2x trip pins and king pin)

HYDRAULIC SYSTEM

• All SnowDogg plows use SnowDogg brand Low-Temperature Hydraulic Fluid (P/N 16150010) available

from SnowDogg dealers.

• The reservoir should be filled through to top port until oil reaches the top port.

• Recheck and tighten all fittings and valves every season or as necessary. Vibration due to normal use

can cause fittings to loosen.

• Loctite or Teflon tape should not be used on any fittings or hoses. The only plugs where pipe sealant

may be used are the reservoir plugs.

• The reservoir should be drained and refilled every season to ensure that the oil remains free of water

and contanimants. If contaminants are known to be present, it is recommended that the reservoir be

removed and cleaned.

With proper maintenance and care your SnowDogg plow will provide years of trouble free service!

11 16992140 Rev C

Figure A - Lift Frame Diagram Figure B - Linkage Detail Diagram

22a 103 106 107

101 106 107

32a

23a

112

17

18

18a

112

8

10

9

11

9

10

16a

8 67a

72

16b

111

30

11

11

33

75

193

191

194

192

97

97

110

38

35

34a

41

1

13

35

12

11

69

74

26

73

31

32

27

28

24

104

105

29 15

5

3 14

37

37

7

4 6

190

74a

190

25

43

36b

34b

44

36c

39

42

46

36a

45

45a

11

70

71

95 197

99

2

Figure C - Moldboard Diagram

12 16992140 Rev C

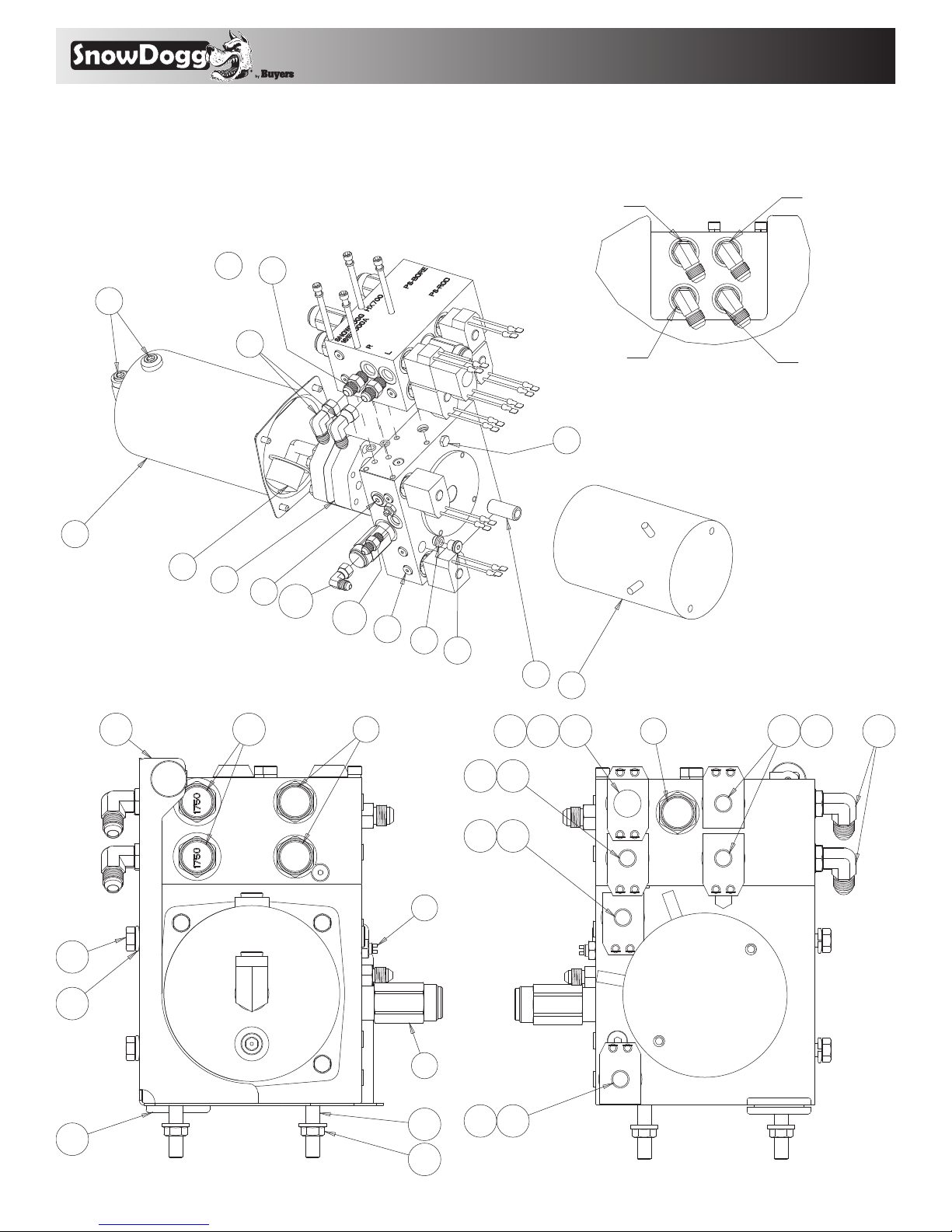

Figure D - Hydraulic Power Unit Diagram

PS-ROD PS-BORE

DS-ROD DS-BORE

WING HOSE POSITIONS

196

114

115

195

116

113

58

62

58180 190

183 185

183 185

184 185

65 185

186 185 185 59

50

55

54

51

189

64

63

67a

61 79

76

56

68

53

52

69

13 16992140 Rev C

Figure E - Harness Diagram

Figure D - Hydraulic Power Unit Wiring Diagram

80

83

85 88

89

98

84

87

S5

S6

S2

S3

S4

S1B

S1A

BLU

GRN

ORG

BLU/WHT

GRN/WHT

ORG/WHT

PUR

TO

MOTOR

14 16992140 Rev C

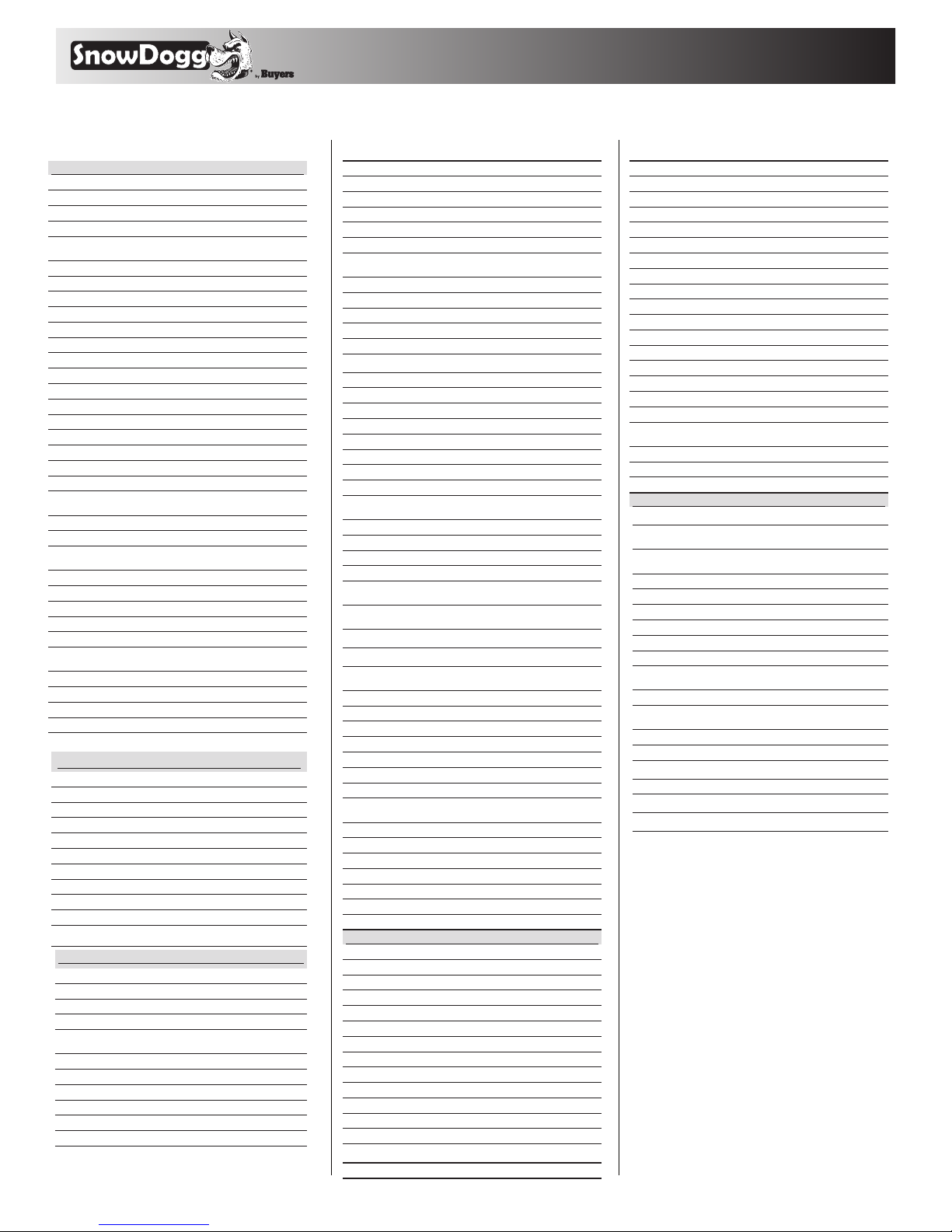

Parts List

ITEM PART NO. QTY DESCRIPTION

FIGURE A - LIFT FRAME DIAGRAM

816102100 2Clevis Pin, 1"x4"

916102102 Cotter Pin, 3/16"x2"

10 16102104 2Washer, 1"

11 16102122 3 Clevis Pin Kit, 7/8" x 4"

16a 16110100 1 Lower Lift Frame, Assembled w/

Linkages

16a 16111612 1Lift Frame, Lower Weldment

16b 1611162 0 1 Lift Frame, Upper Weldment

30 161114 0 0 1 Chain Lift Arm (assembled)

30 161114 0 2 1 Chain Lift Cover, w/screws

30 161114 0 6 1 Chain Lift Fastener Kit

32 1611112 0 1Snapper Pin, 1-5/8in

32a 16111124 2Snapper Pin, 2-1/2in

33 16111510 2Bracket, Light

67a 16151325 1 Fitting, Cyl Lift Port

72 16153100 1 Hose, Lift (1/4"x18")

75 16154200 1Cylinder, Lift (2"x6")

75 16154202 1 Packing Kit, 2" w/Wiper Seal

75 16154204 1 Gland Nut, 2", w/Wiper Seal

97 16160700 1 Light, Plow, Pair

97 16160710 1 Light, Plow, DS

97 16160712 1 Light Housing Only, DS

97 16160720 1 Light, Plow, PS

97 16160722 1 Light Housing Only, PS

97 16160730 2 Hardware Kit, Light Mounting

(1 set)

97 16160732 2 Seal, Light Lens to Housing

97 16160734 2Harness, Light Internal

97 16160740 2 Bulb, H1 High Beam

97 16160742 2 Bulb, H7 Low Beam

97 16160744 2Bulb, Park/Turn, Amber

110 16111512 1 Light Bracket Fastener Kit (8

Screws/Washers/Nuts)

111 16101014 1Lift Frame Upper/Lower Fastener Kit

191 16152120 1 Cover, Top, HV600 HPU

192 16152125 Cover, DS Front, XP

193 16152124 1 Cover, PS Front, V

194 16152126 3 Screw, Thumb, HPU Cover

FIGURE B - LINKAGE DETAIL DIAGRAM

17 16111102 2Pin, Mount Locking

18 16111104 2 Spring, Mount Locking Pin

18a 16111116 2Washer, Flat

22a 16111117 2Foot Pedal, Dual

23a 16111115 2Linkage, Dual Pedal

32a 16111124 2Snapper Pin, 2-1/2in

101 16101001 2 Screw, Cap, 3/8-16 x 1.00 SST

103 16101003 2 Screw, Cap, 3/8-16 x 3.00 ZN

106 16101006 4 Nut, Nylock 3/8-16 SST

107 16101007 6 Washer, Flat 3/8 SST

112 16111118 4Roll Pin, 1/4x2.00

FIGURE C - A-FRAME & MOLDBOARD DIAGRAMS

116101100 1 Pin, Trip, HD/EX/XP (Pair)

116101516 1 Grease Fitting, 1/4-28 Threaded

216101200 4Spring, Trip

316101210 2 Spring Mount Eye Bolt Kit (set of 4)

416101120 1 Bolt, Pivot w/grease fitting, HD/

EX/TE/XP

416101515 1 Grease Fitting, Press

416101516 1 Grease Fitting, 1/4-28 Threaded

516101122 2Nut, Pivot/Angle Stop Bolt

616101124 4Washer, Pivot/Angle Stop Bolt

716101140 1 Bolt, Angle Stop

916102102 Cotter Pin, 3/16"x2"

11 16102142 4 Clevis Pin Kit, 7/8" X 3-1/4"

ITEM PART NO. QTY DESCRIPTION

13 16122100 1Blade Guide Assembly (pr)

14 16103000 2Chain, Lift

15 16103020 2 U-Bolt Kit, Lift Chain w/nuts

24 16101515 1 Grease Fitting, Press

24 161112 0 0 1 A-Frame, HD/EX/TE/XP

25 16102199 2 Clevis Pin Kit, 7/8 X 4-1/2, W/cotter

26 16111210 1 Prop Stand Assembly (with lift

bolt/nut)

27 16111212 1Bolt, Prop Stand

28 16111214 1 Nut, Jam 5/8-11

29 161113 0 0 1Sector, HD/EX/XP

31 16111310 1Jack, A-frame

31 16111312 1Cap for Jack

32 1611112 0 Snapper Pin, 1-5/8in

34a 16120920 1 Cutting Edge, XP810 Center

34b 16120922 2 Cutting Edge, XP810 Wing

35 16120114 1 Cutting Edge Fastener Kit (set of 10)

36a 16121920 1 Skin, XP810 Center, SST

36b 16121922 1 Skin, XP810 DS Wing, SST

36c 16121924 1 Skin, XP810 PS Wing, SST

37 16120110 1 Skin Fastener Kit (set of 10)

38 16120120 2Cap, Crosstube

39 16120157 1Deflector, Rubber, MD/HD/TE/

EX75, XP810

41 1612110 0 2 Shoe Assembly

41 16121120 16 Shoe, Washer (1/8")

41 16121140 2 Shoe, Linch Pin

42 16120266 2 Clamp Strip, XP810

43 16122420 1 Moldboard Weldment, XP810

DS Wing

44 16122430 1 Moldboard Weldment, XP810

PS Wing

45 16122412 Deflector Bracket Kit w/Hardware

45a 16122414 Deflector, Hardware Only

46 16122410 1 Moldboard Weldment, XP810

Center

69 16151324 2 Fitting, Mfd/Cyl Angle Straight

70 1611114 0 1 Bracket, Hose Anchor, SST

71 16111142 2 Clamp Kit, Hose

73 1615 3110 2 Hose, Angle (3/8"x36")

74 16154100 2Cylinder, Angle (1-1/2"x12")

74 16154212 2 Packing Kit, 1-1/2" w/Wiper Seal

74 16154214 2 Gland Nut, 1-1/2", w/Wiper Seal

74a 16154300 2Cylinder, Double Acting

(1-1/2"x12")

74a 16154302 2 Seal Kit for 16154300

95 16153140 2 Hose, Wing Retract, 3/8" X 13"

99 16153130 4 Hose, Wing Cylinder, 3/8" x 60"

104 16101004 1 Screw, Cap, 3/8-16 x 2.00 ZN

105 16101005 1Nut, Nylock 3/8-16

190 16152346 4 Fitting, Elbow, 3/8" JIC M/F

197 16151340 2 Fitting, Bulkhead Elbow, 3/8"

FIGURE D - HYDRAULIC POWER UNIT DIAGRAM

50 16152104 1Manifold O-ring/Fastener Kit

50 16153000 1Hydraulic Power Unit, XP

51 1615110 0 1Pump, Gear

51 16159116 1Seal, Shaft

52 16151102 1Inlet Strainer

53 16152004 1Spline Coupler

54 16151110 1 Reservoir Kit (Res/Bolts/Seal/Cap)

54 16159114 1O-ring, Reservoir

55 16151112 2 Plug, Reservoir, 3/8" NPT

56 16151200 1Motor, 1.6kW

58 16151302 3Valve, Main Relief

59 16151304 1 Valve, Angle Cross Over Relief

61 16151308 1 Valve, Lift Check

61 16900010 Tool, Lift Check Valve Removal

62 16151310 1Valve, Lowering Speed

ITEM PART NO. QTY DESCRIPTION

63 16152016 28 Plug, -2 SAE, (1/8")

64 16152018 1 Plug, -4 SAE, (1/4")

65 16151316 1 Valve, 4-WAY/2-POS Solenoid

67a 16151325 1 Fitting, Cyl Lift Port

68 16151322 2 Fitting, Mfd Angle/Lift Elbow

69 16151324 2 Fitting, Mfd/Cyl Angle Straight

76 16151326 1Breather, Vent

79 16152332 1 Plug, Lift Check Valve

113 16101016 2 Stud, 3/8-16 X 2, ZN

114 16101017 2 Screw, Cap, 3/8-16 x 3/4, ZN

115 16101018 2 Washer, Lock, 3/8, ZN

116 16101019 2 Nut, Serrated Flange, 3/8-16, ZN

180 16151336 2 Valve, Relief, 1750 PSI Differential

183 16151312 2 Valve, S1A/S1B Solenoid

184 16151332 2Valve, S5/S6 Solenoid

185 16152336 7Coil, w/flying leads

186 16151334 1 Valve, S2/S3 Solenoid

189 16151321 1 Fitting, Manifold Lift Port 90 Deg

Swivel

190 16152346 4 Fitting, Angle Port/Cyl 90°

195 16152128 1Grommet, HPU Tray

196 16152130 1 Fitting, Mfd Angle/Lift Elbow

FIGURE E - HARNESS DIAGRAM

80 16160100 1Harness, Truck Relay

80 16160110 1 Repair Connector, 16160100 Grill

Connector

80 16160112 2Repair Connector, 16160100

Adapter Connector

80 16160116 1Plate, Mounting, Relay Harness

80 16160510 1Cap, 16160100/16160300

83 16160114 6Relay, Light, Individual

84 16160200 1Harness, Plow Light

84 16160512 1Cap, 16160200/16160400

85 16160300 1Harness, Truck Control

85 16160310 1 Repair Connector, 16160300 Grill

Connector

85 16160510 1Cap, 16160100/16160300

87 16160402 1 Spring Cage (Kit of 2), Power

terminals

87 16160512 1Cap, 16160200/16160400

87 16162400 1 Harness, Plow Control XP

88 16160410 1Relay, Motor

89 16160500 1Cable, Battery

98 16160610 Harness, Controller Extension (36")

98 16160620 1Mount Kit, SnowDogg Controller

98 16162600 1Controller, Expanding Plow

15 16992140 Rev C

NOTE

Full schematics and pin out

information can be found online at

www.snowdoggplows.com under

Tech Support in the 16992930

service manual.

S6

S5

S2

S3

S4

S1B

S1A

RV1

RV2

BLU

GRN

ORG

BLU/WHT

GRN/WHT

ORG/WHT

PUR

TO

MOTOR

S1B

SOL

S1A

MOTOR

S2

S3

S4

S5

S6

UP

DOWN

LEFT

FLOAT

RIGHT

LEFT IN

LEFT OUT

RIGHT IN

RIGHT OUT

BOTH IN

BOTH OUT

MOTOR

1B

1A

DS

CYL PS

CYL

DS

WING PS

WING

3

24

1

3

1

4

2

3

1

4

2

3

42

1

S3

S4

S6S5 S2

RV1

RV2

WING HOSE POSITIONS

PS-ROD PS-BORE

DS-ROD DS-BORE

16 16992140 Rev C

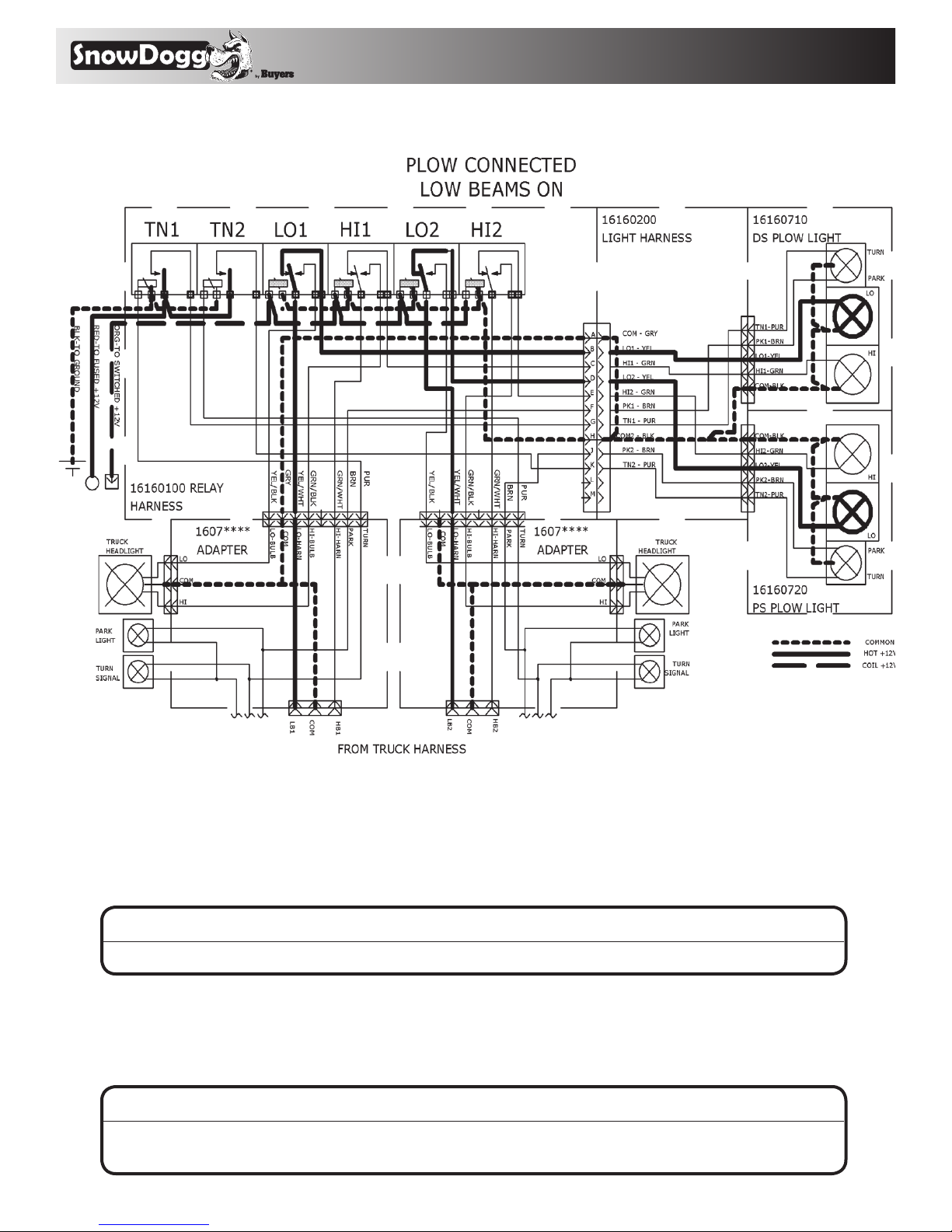

LIGHTING SCHEMATIC

PROPER OPERATION OF LIGHTS

Plow Parking Lights: On simultaneously with the Truck Parking Lights

Plow Turn Signals: On simultaneously with the Truck Turn signals / isolated by relays

Plow Headlights: On INSTEAD of Truck headlights. Truck and Plow headlights should NEVER be on at the same time.

NOTE

If the red/white wire is hooked straight to battery +12V, it will draw current at all times, draining the battery.

NOTE

Full schematics and pin out information can be found online at www.snowdoggplows.com

under Tech Support in the 16992900 service manual.

METHOD OF OPERATION

Headlights

The SnowDogg relay isolation module diverts switched power or ground for the plow high and low beams from the truck

harness to the snowplow lights when the plow is connected. There is no additional draw from the plow lights. The plow

headlights common uses the vehicle headlight harness common (+12V or ground) which is supplied through the light gray

wire. When the plow is disconnected power flows through the relay common to normally closed contacts to the truck headlights.

17 16992140 Rev C

TROUBLESHOOTING

Disconnect the RELAY MODULE CONNECTOR for the following steps.

The controller will not detect most electrical faults with the relay module connected.

SYMPTOM/DIAGNOSTIC RESULT FIX

PUMP MOTOR NOT RUNNING WHEN UP, LEFT OR RIGHT PRESSED

Status light blinks ONCE Continuity Problem Check RED WIRE/MOTOR RELAY

Check voltage at MOTOR terminals with UP, LEFT, or

RIGHT buttons pressed

If voltage present - MOTOR is bad Replace MOTOR

Check cable continuity between MOTOR RELAY and

MOTOR

If no continuity, check cable, connections, and

replace if necessary

Replace/repair cable or connections

Check control signal to MOTOR RELAY (small wires

to motor relay) with UP, LEFT, or RIGHT buttons

pressed

If voltage present and no click is heard when

buttons are pressed, MOTOR RELAY is bad

Replace MOTOR RELAY

Check ground continuity between between control

ground at MOTOR RELAY and battery ground

If no continuity, check cable, connections, and

replace if necessary

Replace/repair cable or connections

PLOW WON'T MOVE AT ALL, MOVES "JERKILY", VERY SLOWLY, OR CHATTERS

Check fluid level in reservoir Fluid should be visible in elbow fitting. Add fluid

Air in fluid Bleed air from system Slightly loosen fittings to angle cylinders and move

the plow wings. Tighten fittings while fluid is

escaping. Do this over an absorbent mat, or hold a

rag over fitting to absorb excess fluid.

OIL IS LEAKING FROM CYLINDERS

Packing is loose Tighten gland until leak stops

Rods are pitted Polish rods with fine steel wool

Replace cylinder

OIL SPRAYS OUT OF VENT PORT IN POWER UNIT

Air in Fluid Bleed air from system Slightly loosen fittings to angle cylinders and angle

the plow. Tighten fittings while fluid is escaping.

Do this over an absorbent mat, or hold a rag over

fitting to absorb excess fluid.

Check fluid level Fluid should be visible in elbow fitting. Remove fluid if necessary - in most cases the

problem will subside as entrapped air dissipates.

PLOW WON'T DROP

Status light blinks 8 times Continuity Problem Check PURPLE WIRE/S1B COIL

Check voltage at S1B VALVE coil If no voltage present, check cable and connections Replace/repair cable or connections

Check DROP SPEED control valve DROP SPEED valve should be several turns from

fully closed

Open DROP SPEED valve

Check S1B VALVE for contamination Poppet must move freely, and seat area must be

clear of any debris

Remove S1B VALVE and check free movement of

poppet, clean any chips/debris from poppet seat

Replace S1B VALVE

Check LIFT LOCK valve for contamination Poppet must move freely, and seat area must be

clear of any debris

Remove LIFT LOCK valve and check free movement

of poppet, clean any chips/debris from poppet seat

Replace LIFT LOCK valve

PLOW WON'T LIFT

Status light blinks 2 times Continuity Problem Check BLUE WIRE/S1A COIL

Check voltage at S1A VALVE coil If no voltage present, check cable and connections Replace/repair cable or connections

Check S1A VALVE for contamination Poppet must move freely, and seat area must be

clear of any debris

Remove S1A VALVE and check free movement of

poppet, clean any chips/debris from valve

Replace S1A VALVE

PLOW WON'T ANGLE

Status light blinks 3 times Continuity Problem Check GREEN WIRE/S2 COIL

18 16992140 Rev C

PLOWING TIPS

• Know the area you are plowing. Be aware of all hidden obstacles (pipes, drains, berms, etc.)

• Plow with the storm, do not let snow accumulate

• Always lower the plow blade when parking to minimize the risk of the plow dropping and to reduce the

load on the truck suspension.

• When transporting the plow – monitor coolant temperature. If the truck is running hot, adjust the plow

position to allow additional airflow to the radiator.

• Plowing at high speeds increases the potential for damage to your plow AND your truck

TROUBLESHOOTING, continued

SYMPTOM/DIAGNOSTIC RESULT FIX

Status light blinks 4 times Continuity Problem Check ORANGE WIRE/S3 COIL

Check voltage at S2 or S3 VALVE coils If no voltage present, check cable and connections Replace/repair cable or connections

Check S2/S3 VALVE for contamination Spool must move freely, and sleeve area must be

clear of any debris

Remove S2/S3 VALVE and check free movement of

spool, clean any chips/debris from valve

Replace S2/S3 VALVE

LEFT AND RIGHT WING WON'T RETRACT

Status light blinks 5 times Continuity Problem Check BLUE/WHT WIRE/S4 VALVE

Check voltage at S4 VALVE coil If no voltage present, check cable and connections Replace/repair cable or connections

Confirm BLUE/WHT wire at S4

Check S4 VALVE for contamination Spool must move freely, and sleeve area must be

clear of any debris

Remove S4 VALVE and check free movement of

spool, clean any chips/debris from valve

Replace S4 VALVE

LEFT WING WON'T EXTEND OR RETRACT

Status light blinks 7 times Continuity Problem Check ORANGE/WHT WIRE/S5 VALVE

Check voltage at S5 VALVE coil If no voltage present, check cable and connections Replace/repair cable or connections

Confirm ORANGE/WHITE wire at S5 VALVE

Check S5 VALVE for contamination Spool must move freely, and sleeve area must be

clear of any debris

Remove S5 VALVE and check free movement of

spool, clean any chips/debris from valve

Replace S5 VALVE

RIGHT WING WON'T EXTEND OR RETRACT

Status light blinks 6 times Continuity Problem Check GREEN/WHT WIRE/S6 VALVE

Check voltage at S6 VALVE coil If no voltage present, check cable and connections Replace/repair cable or connections

Confirm GREEN/WHITE wire at S6 VALVE

Check S6 VALVE for contamination Spool must move freely, and sleeve area must be

clear of any debris

Remove S6 VALVE and check free movement of

spool, clean any chips/debris from valve

Replace S6 VALVE

PLOW DRIFTS WHILE PLOWING SNOW

Air in Fluid Bleed air from system Slightly loosen fittings to angle cylinders and angle

the plow. Tighten fittings while fluid is escaping.

Do this over an absorbent mat, or hold a rag over

fitting to absorb excess fluid.

Check CHECK VALVES for contamination Poppet must move freely, and seat and piston area

must be clear of any debris

Remove CHECK valves and clean

Replace CHECK valve

Check RELIEF valves for contamination Poppet must move freely, and seat must be clear of

any debris

Remove RELIEF valves and clean

Replace RELIEF valves

19 16992140 Rev C

Limited Warranty

COVERAGE

Buyers Products Company warrants to the original purchaser of a Buyers Products SnowDogg®brand

snowplow that they will be free from defects in materials and workmanship for a period of two (2) years

after the date of original purchase. Buyers Products warrants accessories, service parts, and components

purchased separately to be free of defects in materials and workmanship for a period of one (1) year after

date of original purchase.

These warranties are exclusive and in lieu of all other express and, except to the extent prohibited

by applicable law, all implied warranties, including but not limited to the implied warranties or

merchantability and fitness for a particular purpose, are limited in duration to the duration of this

warranty.

Buyers Product’s Liability is expressly limited to repair or replacement of defective parts. Buyers Products

shall not be liable for consequential, incidental or contingent damages whatsoever, even if damages are

caused by the negligence or fault of Buyers Products.

This warranty gives you specific legal rights. Additional purchaser’s rights may vary from state to state.

WHAT IS NOT COVERED

The warranty does not apply to:

…parts not furnished by Buyers Products or damage resulting from same.

…parts modified without authorization or damage resulting from same.

…expendable parts (cutting edges, fluids, etc.).

…damage resulting from failure to install, maintain or operate the product per the owner’s manual,

installation instructions, or application guides.

…damage to vehicle and/or frame of vehicle resulting from plow attachment.

WARRANTY PROCEDURE

If any part is proven to be defective within that warranty period, Buyers Products will, at its sole

discretion, repair or replace said part at its expense FOB Cleveland, OH. Labor will be credited to

authorized dealers as determined by published rate charts.

Buyers Products obligation shall be limited to such repair or replacement and shall be further contingent

on Buyers Products receiving written notice of the alleged defect and proof of original purchase within ten

(10) days of its discovery as well as the return of the allegedly defective part to Buyers Products.

To obtain service, the purchaser must return the defective snowplow to an authorized SnowDogg Dealer

with proof of purchase and applicable maintenance records. All transportation costs to and from the dealer

will be the responsibility of the purchaser. SnowDogg dealers may be located on-line at

www.snowdoggplows.com.

Buyers Products

9049 Tyler Blvd.

Mentor, OH 44060

Contact Your Dealer for Service and Technical Support

20 16992140 Rev C

Buyer Products Co.

9049 Tyler Blvd.

Mentor, Ohio 44060

Table of contents

Other SnowDogg Snow Blower manuals