SnoWizard SnoBall Operating manual

SnoWizard, Inc. * 101 River Road * New Orleans, LA 70121 * 1-800-366-9766 * www.SnoWizard.com

®

Another SnoBall season will soon be coming to a close for most operators. This is the

time to perform the annual maintenance on the SnoWizard SnoBall Machine®. A little

preventative maintenance now will prevent costly repairs later and your machine will be

ready to go at the start of the next season.

First, unplug the power cord to your machine.If your machine is like most, there will

be water spots and dried syrup on the exterior surfaces. Take a look at the underside and

you probably have a buildup of mold under the right side where water drips out of the

cabinet below the cutter head. There is probably a buildup of mineral or calcium deposits

on the interior of the machine and especially in the cavity where the cutter assembly fits.

Let’s start the cleaning by removing the belt guard and the cutter

assembly. To remove the belt guard, loosen the four wing nuts that

attach it to the cabinet. These should be finger tight only with no tools

needed to loosen and remove them. Slip off the belt as you would a

bicycle chain off a sprocket.

Next, remove the entire cutter assembly from the cabinet.

Check the opening on the right side where the cutter

assembly fits for calcium build up and mold. Make a cleaning

solution of hot water, dishwashing detergent with 1

tablespoon of bleach per gallon. Wet all of the interior

surfaces with the solution to sanitize the interior. Use a soft to

mild stiffness brush to scrub away any mold. The bottlebrush

works great for cleaning the interior where the cutter

assembly fits. Be certain to check the topside of the interior as

well. Carefully tilt the machine back on its legs and scrub the

underside with a utility brush. Once everything has been

scrubbed, thoroughly rinse the cabinet clean. Look it over to

see if any areas need to be redone.

Now that everything has been cleaned, it is time to apply a calcium deposit remover if

you have any buildup. Lime or calcium deposit removers can be purchased at most

hardware and drug stores. Follow the mixing and application instructions on the bottle and

apply the solution to all parts of the cabinet that have buildup. Depending upon the brand

purchased, a waiting period may be necessary in order for the solution to dissolve the

deposits. A Scotchbrite®pad may be necessary to get heavy deposits off. If a

Scotchbrite®pad or other type of scrubbing pad is required, be certain to move the pad

back and forth in the same direction as the grain of the stainless steel. When all of the

deposits have been removed, thoroughly rinse the surfaces to remove all cleaner. A hose

works really well here.

With the wing nuts and belt

removed a firm tug will separate

the cutter head from the cabinet. It

is not necessary to remove any

additional nuts or bolts from the

cutter assembly.

SnoWizard, Inc. * 101 River Road * New Orleans, LA 70121 * 1-800-366-9766 * www.SnoWizard.com

Cutter shown with 3 bent

fins. This occurred at our

own SnoWizard ® SnoBall

Shoppe when the operator

inserted an ice pick in the

chute to remove clogged

snow. Ironically, a water

sprayer mounted on the drip

pan, specifically for this

purpose, was not used by

the employee.

Now wet all of the surfaces again with the dishwashing liquid solution to sanitize it

once more. Let the solution set for about 3 minutes to do its work. Thoroughly rinse the

cabinet again with the hose and be sure to get the underside as well. When done, dry off

all the surfaces, inside and out. When finished, leave the door to the machine open to let it

air out and completely dry.

It is now time to service the cutter assembly. Let’s start by

removing the large pulley from the shaft. This is done by loosening

the set screw from the pulley with a 5/32” Allen wrench. Make sure

the stainless steel key is put in a secure place with the pulley for

installation later.

Next, slip the cutter out of the cylinder housing. If you have

performed regular maintenance and greasing of the shaft and

bearings, the cutter and shaft will easily slide out of the bearings

of the cylinder housing. If there is any resistance or the shaft

does not easily slide out of the bearings, do not use a hammer

or other object to tap or hit on the shaft. This can result in

damage to the shaft and cutter. Use a lubricant such as WD-40

and apply to the area where the shaft meets the bearings. Wipe

the shaft clean of any dirt or grit. Slowly work the cutter and shaft in and out of the

bearings with your hands. Apply more lubricant if necessary and wipe clean. Under no

circumstances should you hit on the shaft with a hammer or other object. If you need

assistance, please call us and we give you further instructions to safely remove the shaft.

Look at the fins and make certain that they are straight and not bent or damaged in

any way. Older machines built prior to 1983 will have a curved fin design. If the fins are

bent, then something was inserted into the snow spout while the machine was in

operation. Not to worry, though! If this occurs the SnoWizard SnoBall Machine®fins were

designed to bend, not break. This ensures that you will never be put out of business if an

object is inserted in the chute.

The fins can be straightened to their original shape with a pair of pliers (See picture

below). However, as the owner of the business, I’d want to find out who did it so that it

does not happen again.

SnoWizard, Inc. * 101 River Road * New Orleans, LA 70121 * 1-800-366-9766 * www.SnoWizard.com

Cutter has been neglected and shows severe mineral

deposit buildup. Regular cleaning and maintenance

would have prevented this.

This blade has cracked as a result of

calcium deposits which formed on the

underside. Water trapped between

the blade and the cutter caused a

catalytic reaction to occur. Calcium

crystals formed and pushed up

against the blade, cracking it at its

weakest point; the screw slot.

Remove the blades with a No. 2 Philips

head screw driver.

Next, remove the blade screws and all of the blades from

the cutter and set them aside. Then remove the 6 screws

that hold the fins in place and set the screws and fins

aside. Look at the cutter and cylinder for any mineral

deposit buildup. If there is any, clean these parts in the

same manner that the cabinet was cleaned. Make certain

to remove all buildup from the flat surfaces where the

blades fit. This is critical! If mineral deposits are left on

these surfaces, calcium crystals will form underneath the

blades. Since the blades are held firmly in place with

screws, the crystals will push up against the blades

cracking them at their weakest point - the blade slots.

At the start of each season, we have several customers who

bring their cracked blades in wondering what happened.

After an examination of the backside of their blades we saw

that they were coated with calcium deposits. What

happened? They simply turned off their machine at the end

of the season without performing any end of year

maintenance. The water trapped between the blades and

the cutter formed calcium deposits and when the deposits

formed crystals, which grew –they cracked the blades. Then

at the beginning of the next season when they went to

remove the blades to put in a fresh set, they found that their

blades had cracked. So it is very important to remove any

calcium deposit buildup from the blade slots.

Now let’s go back to the cutter. Once the cutter has been cleaned of mineral deposits,

thoroughly wash it with soapy water and then rinse it in very hot water.Let the water

run over the cutter until it heats up the metal. Dry the cutter off well with a towel. As best

as possible, blow through the screw holes to remove any water. Set the cutter down and

let it rest for a while so that all water can evaporate from the screw holes.

Cutter has been cleaned regularly and is well maintained.

SnoWizard, Inc. * 101 River Road * New Orleans, LA 70121 * 1-800-366-9766 * www.SnoWizard.com

Now it is time to start putting it all back together. Squirt a small amount of foodservice

grease into all of the screw holes. This is the Petro Gel grease that comes with your

machine. Use your finger to push the grease down into the holes. Attach the fins first.

Insert a screw into the tab of a fin. This is the part that screws into the hub of the cutter.

Turn the screw until it’s held in place by the threads, but not all the way. Then while

holding the fin up a little, insert the other screw into the tab on the fin and screw it into the

cutter. Turn the screws back and forth a couple of times. This will work the grease into all

the threads to thoroughly lubricate them. This is very important. If these screws are never

removed, then water seeps into the threads and calcium deposits form, locking the screws

in place over a period of time. If a fin ever needs to be replaced, the screws may not come

out since they were never lubricated. Finish attaching the remaining fins and thoroughly

tighten all of the screws when done.

The last thing to do is to install the blades. We highly recommend installing a newly

sharpened set of blades, so before you re-install the set that you took out, check to see if

they are sharp; really sharp. If they are, they will be able to shave the hair off of your arm.

Spread a thin film of grease on the blade slots of the cutter. Work the screws back and

forth to spread the grease throughout the threads. Install a sharpened or new set of

blades. Do not put the old set back in that were just removed if they are dull and need

sharpening. However, if they are sharp and you put them back on the cutter, check the

backside of the blades to make certain that there are no calcium deposits. If there is, then

remove the calcium deposits, and spread a thin film of grease on the backsides of all the

blades before installing them onto the cutter.

Now, take a look at the shaft and check to see if there is any buildup of any kind.

Also check the surface of the shaft for any small scratches or burrs that might scar the

bearing. Wipe the shaft off with a rag or paper towel to remove any dirt and grit. If there is

anything built up on the surface, remove it with a fine piece of steel wool or 400 grit

sandpaper by wrapping the polishing material around the shaft and turning it back and

forth with the palm of your hand. Wipe the shaft off when done and spread a thin film of

grease over the surface. Place a dab of grease on each of the sealed bearings and

spread it over the surfaces.

SnoWizard®machines built prior to 1983 have bushings and thrust bearings that require other maintenance. The shaft and

bushings must be checked for wear. To check this, the cutter housing must be assembled. Check this by alternately pushing

on either side of the cutter attempting to rock the cutter back and forth inside the cylinder housing. If the cutter can be

rocked substantially, then the shaft and/or bushings are worn and need to be replaced. This is the time to replace them so

don’t assemble the cutter and put it back on the machine. Order the parts and replace them now, before the start of next

season.

Reassemble the cutter according to the instructions in your

manual. Make certain that the pulley and cutter are kept

pressed together when tightening the setscrew on the pulley.

To do so, form a ball with a rag and place it on the face of

the cutter, up against the blades, at the same time turning

the cutter down towards the working surface (see picture).

This will keep the cutter recessed inside the cylinder. Place

the pulley on the end of the shaft and insert the machine key

into the slot. Press down on the pulley firmly while tightening

the setscrew. Assembly is now complete.

Install the complete cutter assembly back onto the machine with the v-belt and belt

guard. Turn the motor on and run it for a few seconds to make certain that everything

sounds normal and was assembled correctly so you don’t have any surprises on opening

day next season.

SnoWizard, Inc. * 101 River Road * New Orleans, LA 70121 * 1-800-366-9766 * www.SnoWizard.com

The threaded rod should also be cleaned and re-greased. This is

the part on top of the machine that is attached to the hand wheel and

pressure plate. Turn the hand wheel counter-clockwise to fully expose

all of the threads on the threaded rod. Wrap a small piece of rag around

the threads and turn the hand wheel back and forth to remove any dirt

and old grease. Place a small dab of foodservice grease on the threads

and turn the hand wheel back and forth to spread the grease

throughout the threads.

You should also inspect the legs of the machine for any mold, dried syrup or

calcium deposit buildup. Since the legs sit in the drip pan where water accumulates,

there’s a good chance that calcium deposits are present on them. Treat the legs in the

same manner as all other pieces to remove the deposits. Since you’re working on

cleaning the legs, why not give the drip pan a good scrubbing. Use the same solution of

dishwashing liquid and bleach to scrub the sides and bottom. You might want to plug up

the drain hole and pour in some extra sanitizing solution so that the entire bottom surface

of the pan is filled with water. Add a little extra bleach if needed and let the solution stand

for a while. The bleach should remove any syrup stains. Give the pan a good scrubbing

with the utility brush and thoroughly rinse the legs and pan with clean water. It should look

like new when you’re done. Dry the pan and be sure to get underneath the legs.

The last thing that you should do is to wipe down the entire exterior of the machine

with a polish. Furniture polish will do or you can use a lubricant such as WD-40 on a rag.

Rub the machine with a polish to remove any water spots or stains. The lubricant also

protects the cabinet from any surface moisture during the off-season.

O.K., you’re done! At the beginning of next season your machine will be in tip-top shape

and ready to shave fine fluffy snow. You won’t have any surprises on your opening day of

business. However, you should rinse out the machine with water and run a piece of ice

through the cutter before opening day to insure that everything is fine and that no critters

have used the machine as their home during the off-season.

Performing this maintenance at the close of every season takes only 30 to 45 minutes.

However, it is time well spent and needed if you want to keep your SnoWizard SnoBall

Machine®is top condition without requiring unnecessary service.

Place the cutter assembly on the cabinet

and hold it in place with one hand. Do

not put the wings nuts on.

Next, place the belt and pulley guard on

the threaded studs and screw on the

four wing nuts. No tools should be used;

finger tighten only.

While holding the cutter assembly

to the cabinet, place the V-belt on

the small motor pulley and rotate

around the large cutter pulley.

Table of contents

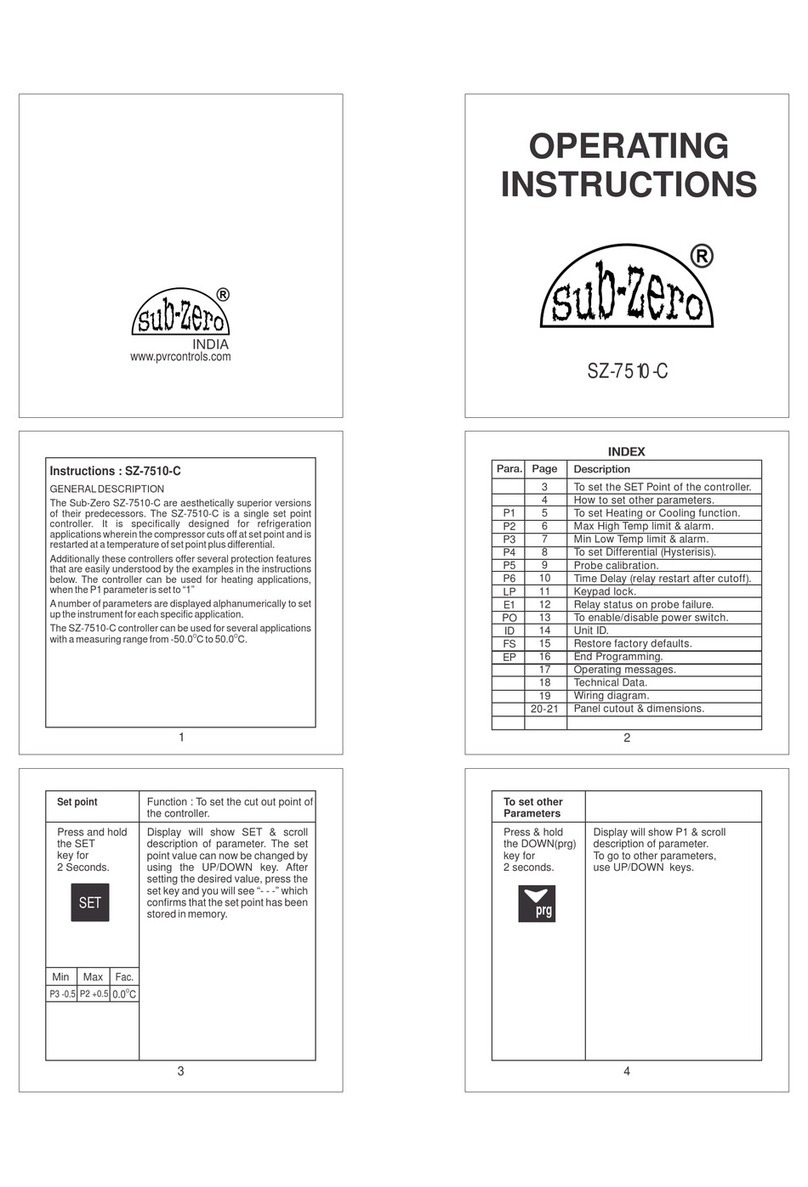

Popular Ice Maker manuals by other brands

Tramontina

Tramontina 80901/106 Use & care instructions

Ice-O-Matic

Ice-O-Matic MFI0800 Specifications

ITV ICE MAKERS

ITV ICE MAKERS IQF FLAKER user manual

CombiSteel

CombiSteel 7453 Series Cleaning and sanitizing manual

Hoshizaki

Hoshizaki KM-500MAH-E parts list

U-Line

U-Line UMCR014-D01A User guide & service manual