SOGEDIS T0 Series User manual

Série T0

CODES PANNES

et

AUTOTEST

5

3. Operating Instructions

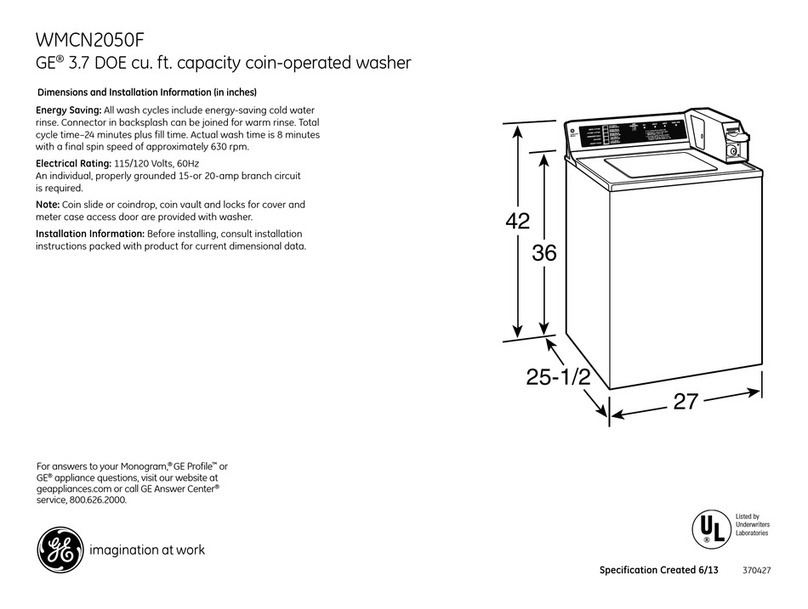

3.1. LCD Screen, Function Buttons & Knobs

3.2. Program List

KNOB

POSITION

PROGRAM

1

Cotton 60°C

2

Cotton 40°C

3

Cotton Prewash

4

Eco 20°C

5

Easy Care

6

Wool

7

Rinse

8

Allergy Safe

9

Spin

10

Delicate / Hand Wash

11

Sports Wear

12

Mix/Duvet*

13

Jeans

14

Daily 60'

15

Rapid 15'**

16

OFF

*Mix algoritm is available for 32, 40, 41+, 42, 44, 44+, 47, 49, 50, 54, 59lts. Duvet algorithm is

available for 55, 60, 61, 62 lts.

**Rapid 15 is available for without twinjet model, Rapid 12 is available for with twinjet model.

PR

Program Selector with ON/OFF

SW1

Start / Pause

SW2

Option Selection

SW3

Spin Speed Selection

SW4

Temperature Selection

LD1

Start / Pause Led

LD2

Option Led

D1

7-segment display 1

D2

7-segment display 2

PR

SW1

SW2

SW3

SW4

6

3.3.

Child Lock

Activation

1. Press the SW2 and SW3 buttons simultaneously for 3 sec.

Deactivation

1. Press the SW2 and SW3 buttons simulaneously for 3 sec.

Child lock during selection:

Machine does not respond to any pressing of buttons or

changing position of program knob. CL at 7 segment display will

make fast blink for 2 sec to

indicate child lock is activated.

Child lock during the program:

Machine does not respond to any pressing of buttons or

changing position of program knob. “CL” is visualized on display for

2 sec to indicate child lock activation with tone D buzzer in models

having buzzer option. After 2 sec “CL” indication if fixed off and

remaining time is visualized on display.

In end condition

When cycle is finished child lock is automatically

deactivated. It is not possible to activate child lock during End mode.

In Error Mode

Child lock will be automatically deactivated when error is

detected

Child lock during delay mode:

Child lock can be activated / deactivated during delay

mode. If child lock is active during delay mode, it will be kept locked

until the end of washing (unless user deactivates by pressing SW2

and SW3 buttons simultaneously for 3 sec.)

7

4. Test Mode

4.1. Autotest

* This test is for quick checking of the product. You can not see the

failure codes.

1. Push SW4 button. Keeping SW4 button pushed, turn

program knob to position 1.

2. After 3 sec, door will be locked and machine enters

autotest mode. Release SW4 button. "AU" will be

visualized on LCD.

The test steps are as below;

Step1: The pump is activated for 3 seconds and there is EPS

check , the frequency value should be between the 46.04Hz and

43.40Hz. It checks the EPS and if it is OK it continues the autotest; if

it is NOK then it should give E10 ERROR & cancels the autotest (

goes to the selection mode ). Also if any frequency can not be

detected, then it means there is problem with connection or EPS, so

it gives E10 which is EPS error and cancels the autotest.

Step2: The motor ramps to max spin for 15 seconds. While its

speed rising up to the maximum speed the EV1 (prewash valve) is

activated for 5 seconds and then the EV2 (wash valve) is activated

for 5 seconds.

Step3: The motor reduces speed to stop (depends on the motor

stop time) for 5 seconds. While it is slowing down it activates EV1

and EV2 valve, concurrently.

Step4: The motor turns to right.

Step5: The motor turns to left for 5 seconds.

Step6: The option 1 button is pushed

The EV1 and EV2 are activated concurrently until it reaches

pressure sensor's first level frequency ( Hz ) for 5 seconds.

Step7: Software will detect NTC's resistance value and will check

if the temperature is between 5°C < Tdetected < 40°C . If it is inside

the range, heating step will be done. If temperature value is outside

the range, then it means NTC is detecting the temperature in a

wrong way and heating step will be skipped.

Step8: Autotest ends and "--" is visualized (T0).

Autotest ends and "End" is visualized on LCD (In the rest of the

models).

8

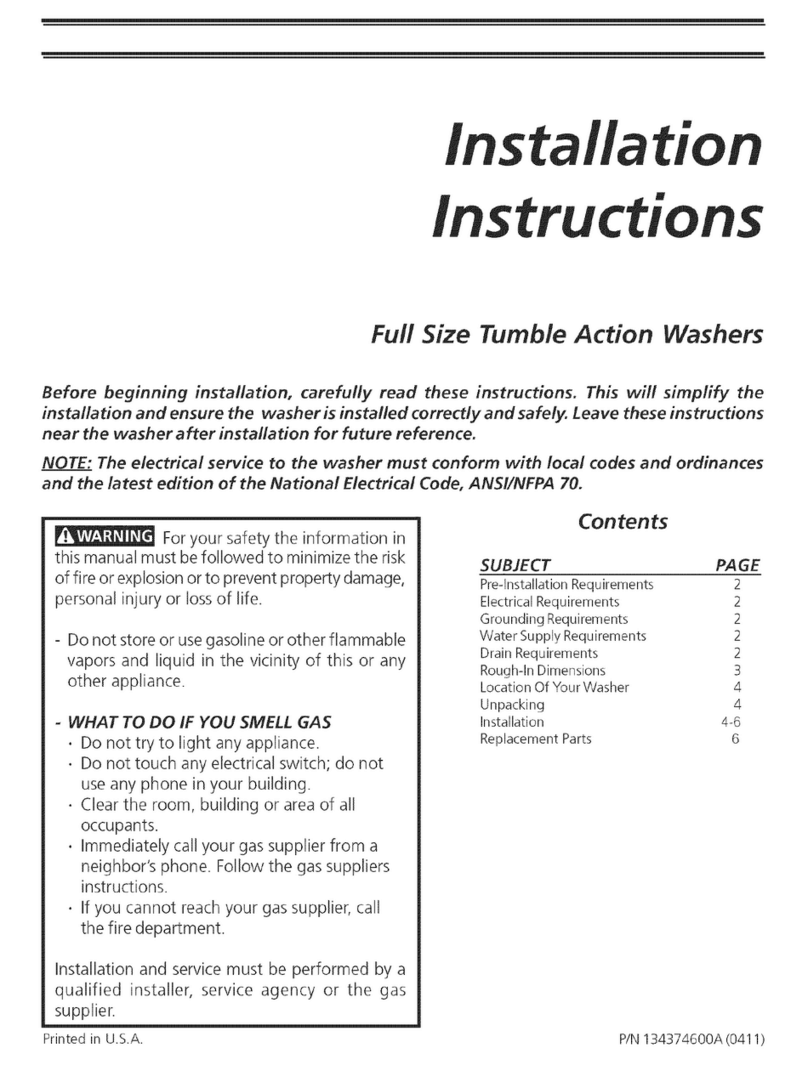

Flow chart of the autotest:

During test “AU” is visualized on display, at the end of the test “--” is visualized and door is unlocked. During test, pressing other buttons makes no change on display.

9

5. Service Mode

5.1. Service Autotest

End users can only see E1-E2-E3-E4. During service autotest, other failures can be seen.

1. To activate service autotest, Press SW3 button and simultaneously position program knob to 1.

2. After 3 sec, door will be locked, and machine enters service autotest mode. Release SW3 button.

In T0 "SA" will be visualized on LCD. In rest of the models "SAU" will be visualized on LCD.

Selector

Position 1

Selector

Position 2

Selector

Position 3

Result

Result

Result

HEATER ON

PUMP ON

RAPID 15' PROGRAM

Comments :

When entering in service

test, door will be locked.

TEST IS OVER Door will be

unlocked, machine will go to

END state.

The test steps are as below ;

Step 1 :

Selector position 1 will be “HEATER ON”

Before heating it should take water till first level frequency then start

heating.

Heater will be on max. 8 minutes.If temperature doesn’t increase 2°C

in 8 minutes,machine will give NTC failure. ( E05 ).

Or if the NTC connection is broken then it should give again E05 NTC

failure.

At the end of heating, "SA" or “SAU” visualization should make slow

blink to indicate that the step is over.

Note : If user changes the selector position, machine will do what is

defined for the new selected position.

Step 2 :

Selector position 2 will be “PUMP ON”

Temperature will be measured, if it is higher than 50°C, it should take

80sec. cooling water and then make "Drain+ 5sec.)

At the end of pump activation, "SA" or "SAU" visualization should

make slow blink to indicate that the step is over.

Step 3 :

Selector position 3 will be “RAPID 15' ”

So machine will make exactly the same algorithm of Rapid 15'.

So, time for selector position 1 is 15 minutes.

At the end of Rapid 15' the door will be unlocked and machine will go

to END mode.

10

5.2. Failure Codes

*Some of the error codes can not be seen based on changing the product types

6. Troubleshooting Guide

All repairs which must be done on the machine should be done by authorized agents only. When a repair is required for machine or you are unable

to eliminate the failure with the help of the information given below:

Unplug the machine.

Close the water tap.

FAILURE

PROBABLE CAUSE

METHODS OF ELIMINATION

Machine does not

operate.

It is unplugged.

Insert the plug into the socket.

Fuse is defective.

Change fuse.

Start / Pause button has not been

pressed.

Press the start / pause button.

The program knob is in 0 (off)

status.

Bring the program knob on the desired status.

The door is not shut properly.

Shut the door properly. You should hear the

click.

Child lock is active.

See page 9.

Error Indication

Error Number

Indication For User

Indication For Service

Yes/No

Yes/No

Door is not locked

E01

Yes

Yes

Door is unlocked during programme

E01

Yes

Yes

Lack of water

E02

Yes

Yes

Pump failure

E03

Yes

Yes

Overflow

E04

Yes

Yes

NTC or Heater Failure

E05

No

Yes

Motor Failure - 1 (Tachometer open-short circuit or motor

connector is disconnected)

E06

No

Yes

Configuration Failure

E07

No

Yes

Motor Triac Failure

E08

No

Yes

Voltage Error

E09

Yes

Yes

Electronic Pressure Sensor

E10

No

Yes

Dryer Card Communication Error

E11

No

Yes

3D Communication Error

E12

No

Yes

LCD Communication Error

E13

No

No

Dryer Resistance Failure

E14

No

Yes

Twinjet Failure

E15

No

No

High Temperature Error

E16

No

Yes

Flowmeter Failure

E17

No

Yes

Dryer NTC Failure

E18

No

Yes

BLDC Failure

E19

No

Yes

Pyrojet Failure

E20

No

Yes

Detergent Dosage Pump Failure

E21

No

Yes

Softener Dosage Pump Failure

E22

No

Yes

Communication Failure Between PCB and BLDC Card

E23

No

Yes

Wrong LCD Software

E50

No

Yes

Wrong BLDC Software

E51

No

Yes

11

Machine does not

receive water.

Water tap is closed.

Open water tap.

The water inlet hose may be bent.

Check the water inlet hose.

The water inlet hose is obstructed.

Clean the filters of water inlet hose.

The water inlet filter is obstructed.

Clean the valve inlet filters.

The door is not shut properly.

Shut the door properly. You should hear the

click.

Machine is not

draining water.

The drain hose is obstructed or

bent.

Check the drain hose.

The pump filter is obstructed.

Clean the pump filter.

The clothes are not placed inside

the machine in a well-balanced

manner.

Spread the clothes inside the machine in an

orderly and well-balanced manner.

Machine is

vibrating.

The feet of machine are not

adjusted.

Adjust the feet.

Transportation screws are not

removed.

Remove transportation screws.

There is a small amount of clothes

in the device.

It does not prevent operation of the machine.

Excessive amount of clothes are

filled in the machine or the clothes

are not placed in a well-balanced

manner.

Do not exceed the recommended quantity of

clothes and spared clothes in the machine in a

well-balanced manner.

FAILURE

PROBABLE CAUSE

METHODS OF ELIMINATION

Excessive foam in

the detergent

drawer

Too much detergent has been

used.

Press the start/pause button. In order to stop

the foam, dilute one table-spoon of softener in

half liter of water and pour it in the detergent

drawer. Press the start/pause button after 5-10

minutes. Arrange the amount of the detergent

properly in the next washing process.

Wrong detergent has been used.

Use only the detergents produced for full

automatic machines.

The washing result

is bad.

Laundry too dirty for the program

you have selected.

Select a suitable program.

The amount of detergent used is

not sufficient.

Use more detergent according to the

detergent.

The washing result

is not good.

Clothes exceeding the maximum

capacity has been filled in machine.

Put the clothes in machine in a manner not to

exceed its maximum capacity.

Water may be hard.

Use the amount of detergent according to the

declaration of the detergent producer.

Distribution of the clothes in

machine is not well-balanced.

Spread the clothes inside the machine in an

orderly and well-balanced manner.

The water is seen

in the drum during

washing.

No failure. The water is at the lower

part of the drum.

There are residues

of detergent on the

clothes.

The pieces of some detergents

which do not dissolve in water may

stick to clothes as white stains.

By calibrating machine for “Rinsing” program,

make an additional rinsing or eliminate the

stains After drying with the help of a brush.

There are grey

stains on the

clothes.

These stains may be caused by oil,

cream or ointment.

In the next washing operation, use the

maximum detergent amount declared by the

detergent producer.

The spinning

process is not done

or starts with delay.

No failure. The unbalanced load

control works in that way.

The unbalanced load control system will try to

distribute clothes in a homogenous manner.

After clothes are distributed, passage to

spinning process will be realized. In the next

washing process, place clothes into the

machine in a well-balanced manner.

25

8. Component Specifications

8.1. Drain Pump

Drain pump is both a mechanical and elektrical component which is used to drain

water inside the washing machine. It has an synchronous motor inside. For

better performance maintanance, pump filter should be cleaned regularly.

8.1.1. Technical Features

Nominal voltage 220 - 240 V

Nominal current 0.28 A (±10 %)

Nominal power 37 W

Frequency 50 Hz

Resistor (coil) 130 Ω (±5%)

Water flow: 17 L/min(to 1 m height)

Thermal protector YES

8.1.2. Checking of Component

Check the resistance value on the component with multimeter as shown in belows figures.

Resistance value should be between 125- 140 Ω

Checking the component

26

8.2. Resistance

Heating element (Resistance) is a component which is desingned to regulate

temperature of water inside the drum. It has three connections: Phase, notral and

ground connections.

8.2.1. Technical Features

Kind of heating Tubular heating element with NTC –sensor

Nominal voltage 230 V

Nominal power 2000 W (±5%)

Resistance 24,8 ±5% Ω

Thermal fuse 2 –sided

8.2.2. Checking of Component

Check the resistance value on the component with multimeter as shown in below pictures.

Checking the component

27

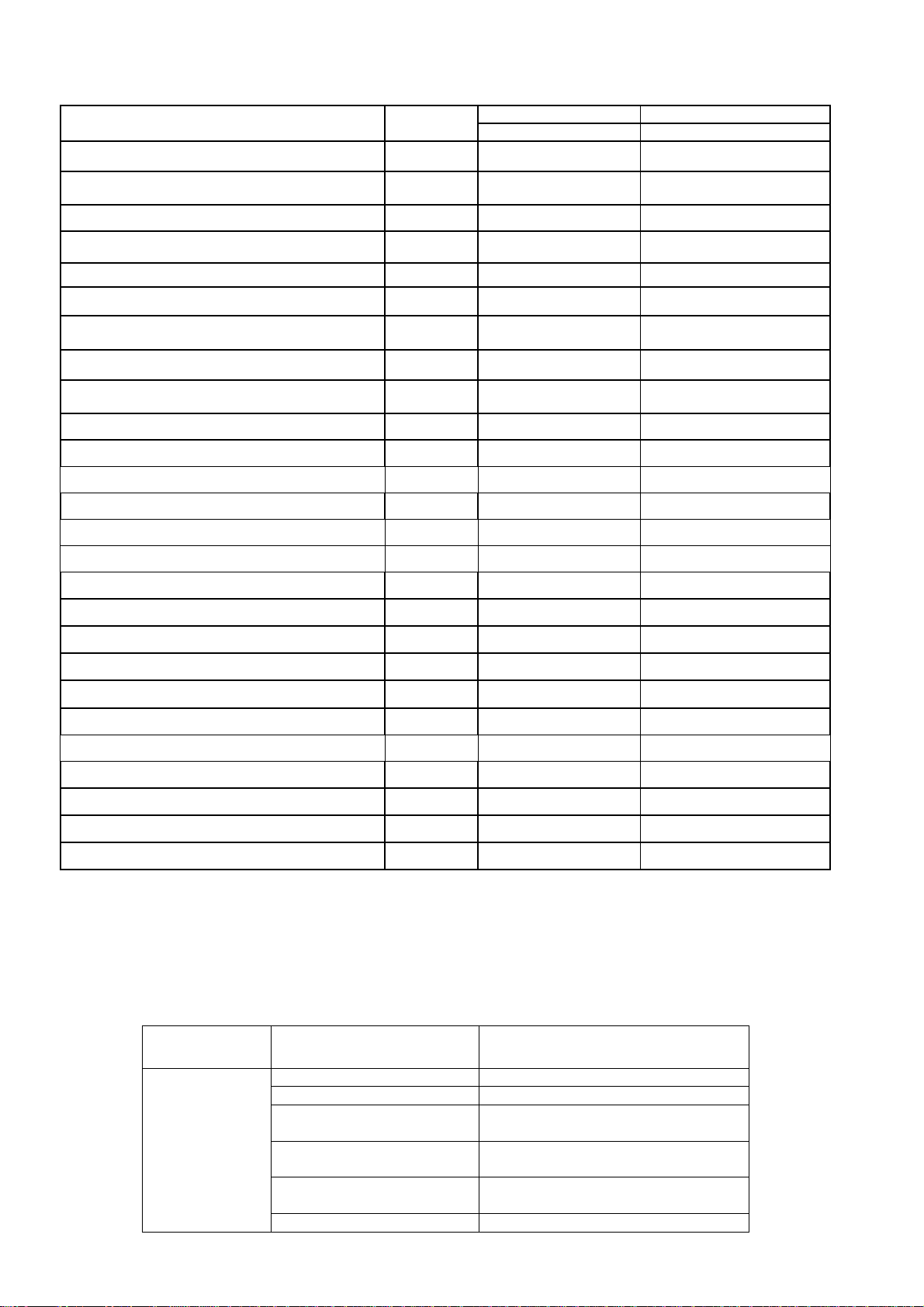

8.3. NTC

Component which sends signals to PCB about the water temperature inside the tub.

The Resistance (Ohm) value of the NTC decreases as the temperature increases.

8.3.1. Technical Features

Tem (°C)

R min (kΩ)

R max (kΩ)

-10

54,9

62,6

-5

43,0

48,6

0

33,9

38,1

5

27,0

30,1

10

21,6

23,9

15

17,4

19,1

20

14,1

15,4

25

11,5

12,5

30

9,4

10,2

35

7,8

8,3

40

6,4

6,9

45

5,4

5,7

50

4,5

4,7

55

3,8

3,9

60

3,2

3,3

65

2,7

2,8

70

2,3

2,4

75

1,9

2,0

80

1,7

1,8

85

1,4

1,5

90

1,2

1,3

95

1,1

1,1

100

0,9

1,0

NTC Tempure –Resistance Values

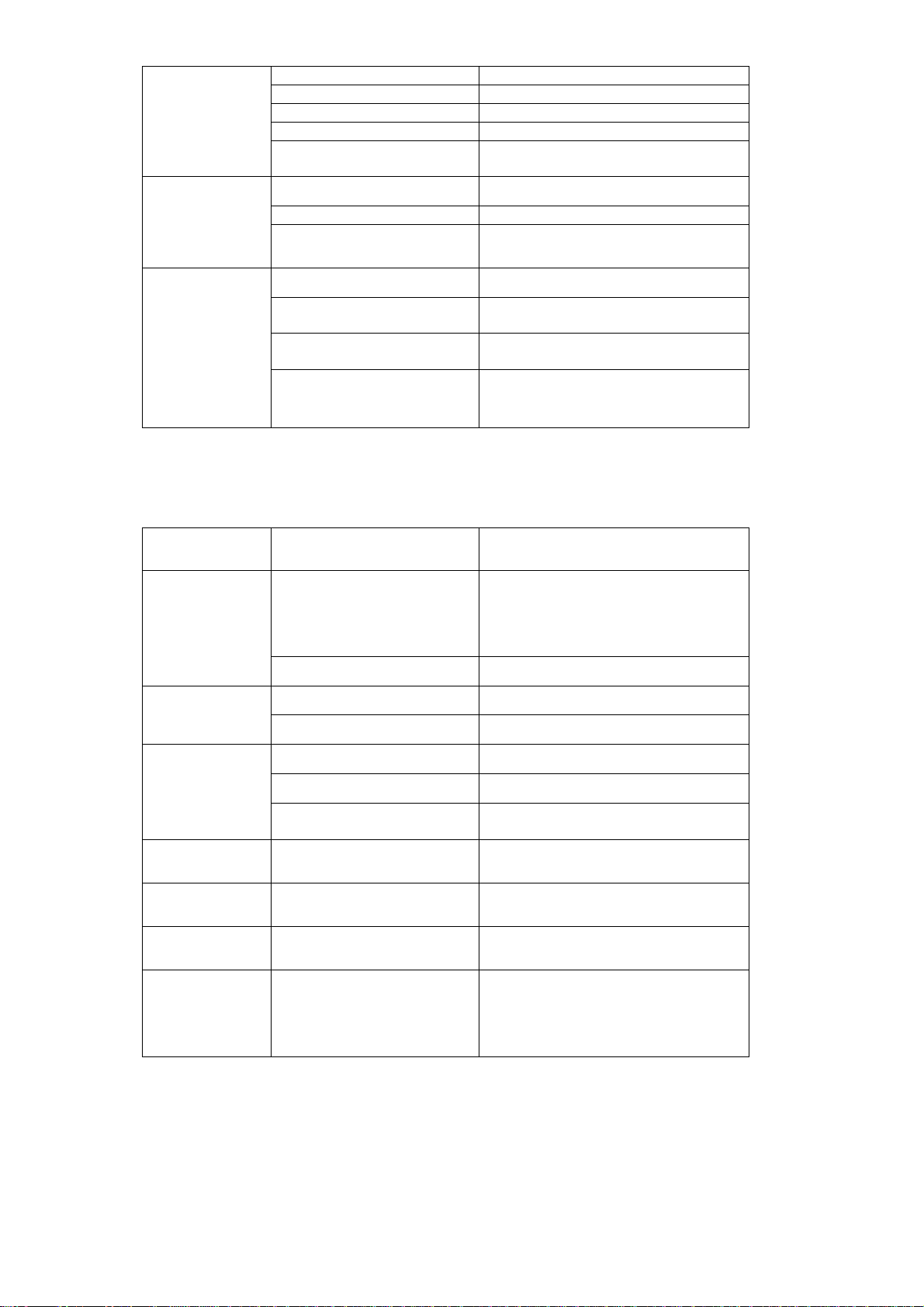

8.3.2. Checking of Component

Check the resistance value on the component with multimeter as shown in below pictures.

Checking the component

28

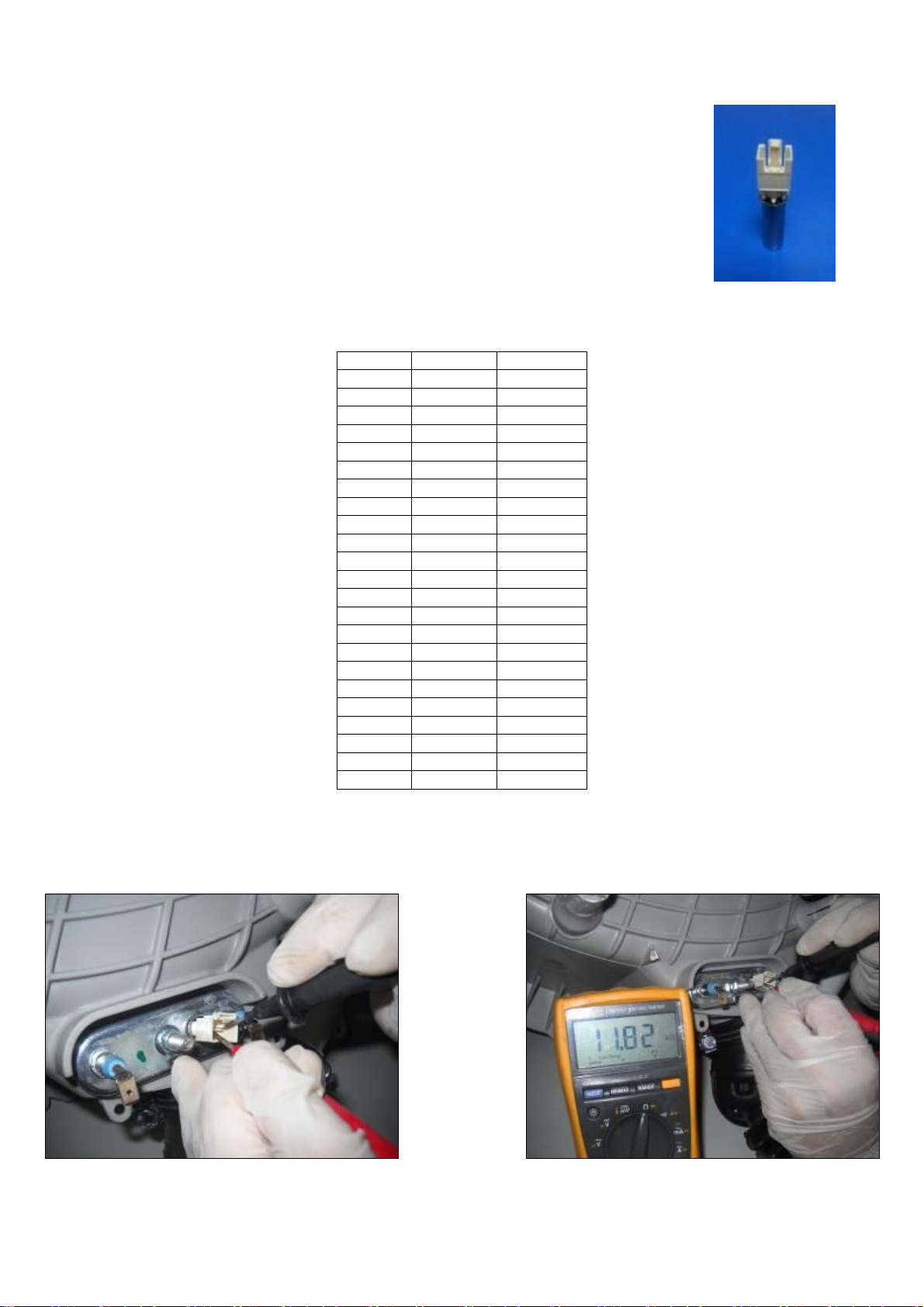

8.4. Valve

Valve is an electrical and mechanical component which is designed to take water from the network

system into the washine machine. It is operated by PCB card.

8.4.1. Technical Features

Nominal voltage 220 –240 V

Nominal power 8 VA

Frequency 50-60 Hz

Rated flow: 7 lt/min (±15 %)

Operating water pressure 0.0,3 –1 Mpa

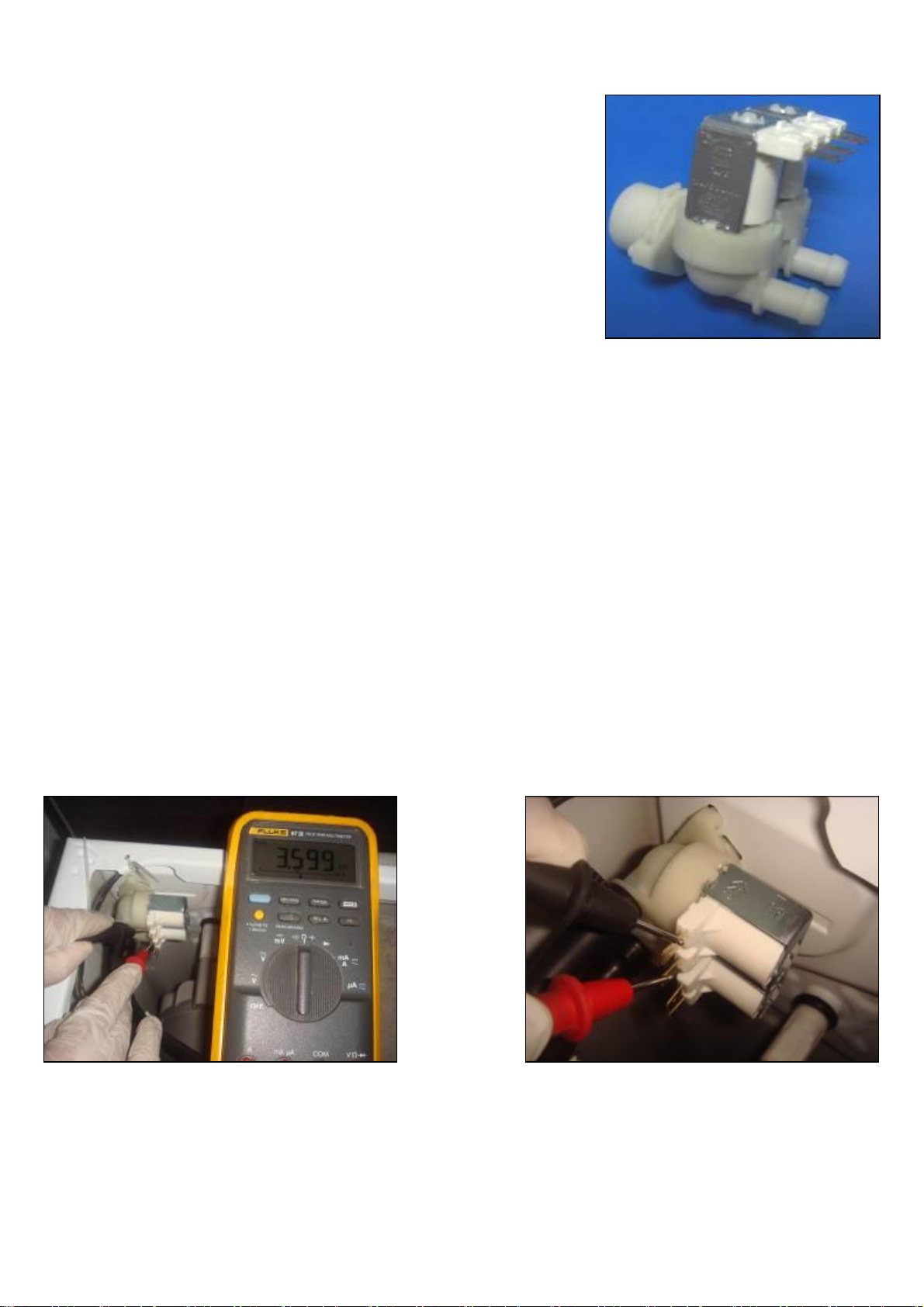

8.4.2. Checking of Component

Check the resistance value on the component with multimeter as shown in below pictures.

Valve water flow rate should be between 6 lt/min - 8 lt/min.

Each valve bobbin resistance values should be between 3,3 - 4.2 kohm .

Checking the component

29

8.5. Electronic Pressure Switch (EPS)

8.5.1. Technical Features

Electromagnetic field occurs as a result of the vibration of the membrane which is under pressure in the coil. The nucleus part is moved up and down by

the electromagnetic field. The water level is regulated by the frequency which is controlled by the PCB and changes according to the movement of the

nucleus part.

8.5.2. Checking of Component

1. Make sure there are no laundry in washing machine, tap is connected and opened, power cord is plugged. Put no detergent in drawer.

2. Bring porgram knob to position 1 (Cotton 90°C program)

3. Press start button.

4. Wait for water intake step to finish. You can recognise it by listening the water sound or slightly opening and observing detergent drawer.

5. As soon as water intake is over turn program knoc to position 0 (Off position)

6. Check water level from door glass. The water level should be just below door glass as seen in the picture below: (There is a %10 tolerance

with this level)

30

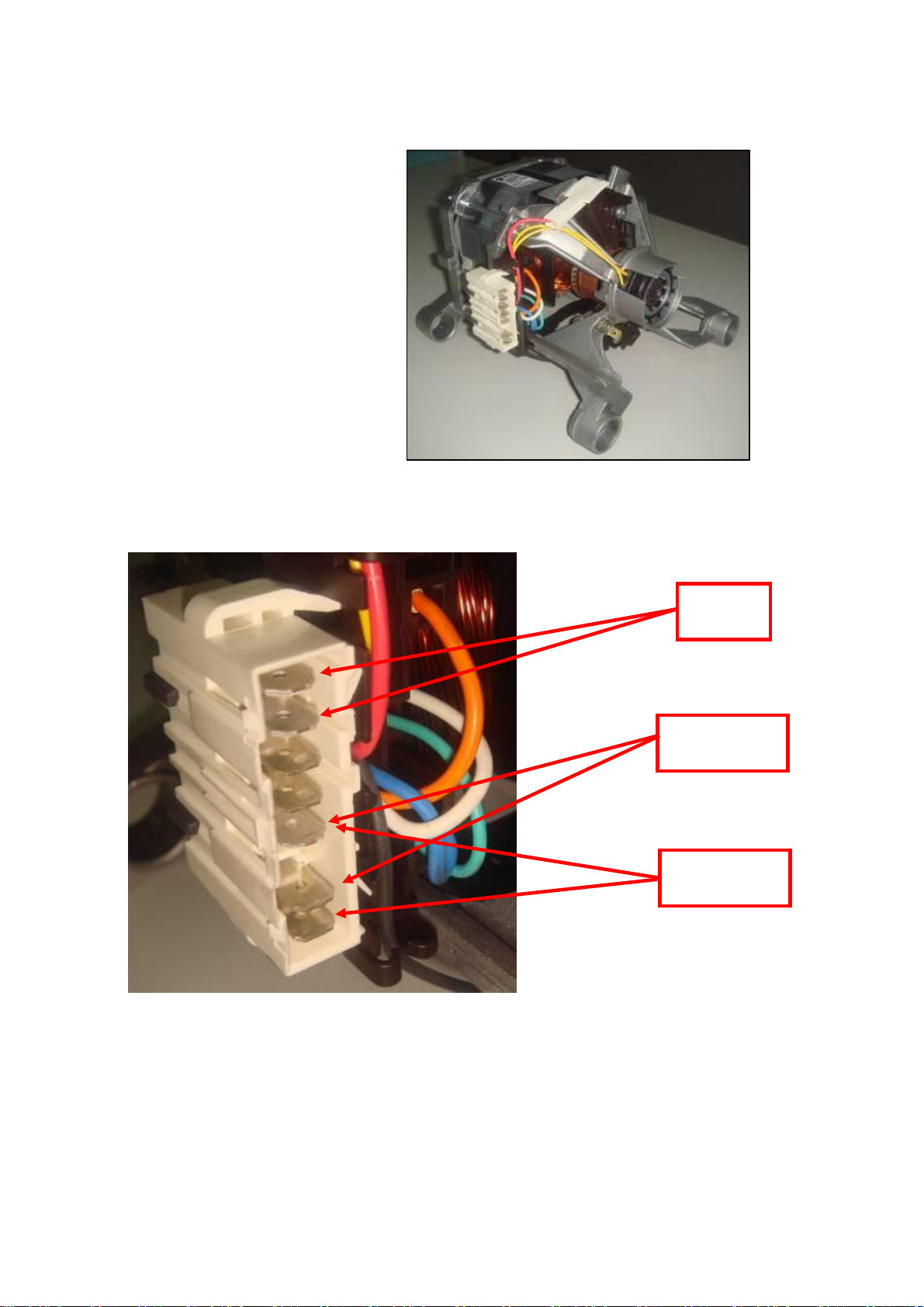

8.6. Motor

The washing machine has an asynchronous motor. t is controlled by the

PCB.

It is essential to check the motor for correct diagnosis and quick servicing.

In the below picture, socket points on the motor is shown to measure with

multimeter.

Motor Socket Terminals

Tacho

Socket

Terminal

Stator Full Field

Coil Socket

Terminal

Stator Half Field

Coil Socket

Terminal

31

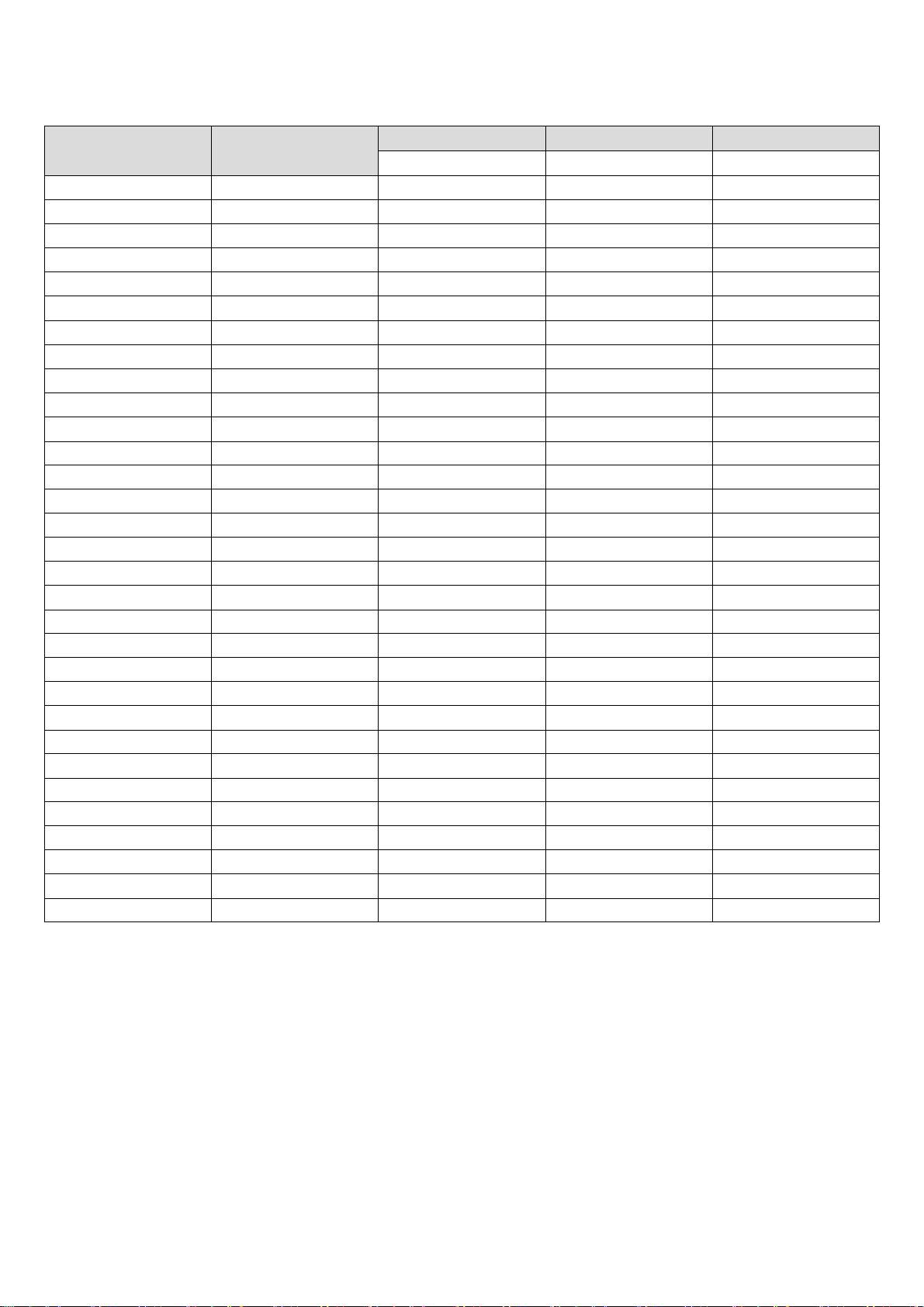

Tacho and stator (full field-half field) ohm resistance values for the motor types are listed in the below table.

MOTOR CODE

SUPPLIER

STATOR

AUXILIARY WINDING

TAKO

Resistance

Resistance

Resistance

32016268

WELLING

2,00 ± %7 Ω

NA

66,6± %7 Ω

32030654

G&J

1,86-2,14 Ω

NA

60,69-69,83 Ω

32016267

WELLING

1,45 ± %7 Ω

NA

66,6± %7 Ω

32031898

G&J

2,10-2,42 Ω

NA

60,69-69,83 Ω

32030127

WELLING

1,68 ± %7 Ω

NA

66,6± %7 Ω

32028497

NIDEC

1,63 ± %7 Ω

0,82 ± %7 Ω

184 ± %7 Ω

32028498

WELLING

1,377 ± %7 Ω

0,785 ± %7 Ω

66,6 ± %7 Ω

32030432

WELLING

1,68 ± %7 Ω

1,55 ± %7 Ω

66,6± %7 Ω

32017283

WELLING

1,93 ± %7 Ω (AL)

NA

66,6± %7 Ω

32013652

HAIER

2,65 ± %7 Ω

NA

68,8 ± %7 Ω

32032079

TONLON

2,28 ± %7 Ω

NA

70,2± %7 Ω

32030653

G&J

2,28-2,63 Ω

NA

60,69 - 69,83 Ω

32037679

KENING

2,10 ± %7 Ω

NA

63,6± %7 Ω

32031043

G&J

2,03-2,34 Ω

NA

60,69 - 69,83Ω

32027577

WELLING

2.39±7%Ω

NA

66,6±7%Ω

32027576

HAIER

2.36±7%

NA

68,8± %7 Ω

32019342

WELLING

2,00 ± %7 Ω

NA

66,6± %7 Ω

32034697

G&J

1,82 ± %7 Ω

NA

65,26± %7 Ω

32032630

HAIER

1,27 ± %7 Ω

NA

68,8± %7 Ω

32019343

WELLING

1,67 ± %7 Ω

NA

66,6± %7 Ω

32034698

G&J

1,82 ± %7 Ω

NA

65,26± %7 Ω

32031529

HAIER

1,27 ± %7 Ω

NA

68,8± %7 Ω

32004905

NIDEC

2,70 ± %7 Ω

1,04 ± %7 Ω

184 ± %7 Ω

32027578

WELLING

1,21 ± %7 Ω

NA

66.6 ± %7 Ω

32025348

NIDEC

1,72 ± %7 Ω

0,70 ± %7 Ω

184 ± %7 Ω

32028496

ANAIMEP

1,36 ± %7 Ω

0,70 ± %7 Ω

180 ± %7 Ω

32030431

NIDEC

1,50 ± %7 Ω

0,75 ± %7 Ω

184 ± %7 Ω

32033330

WELLING

1,38 ± %7 Ω

0,761 ± %7 Ω

66,6± %7 Ω

32030003

NIDEC

2,25 ± %7 Ω

1,03 ± %7 Ω

184 ± %7 Ω

32028925

NIDEC

2,70 ± %7 Ω

1,14 ± %7 Ω

184 ± %7 Ω

32033617

WELLING

2,04 ± %7 Ω

0,99± %7 Ω

66,6 ± %7 Ω

Resistance values for the motor types

32

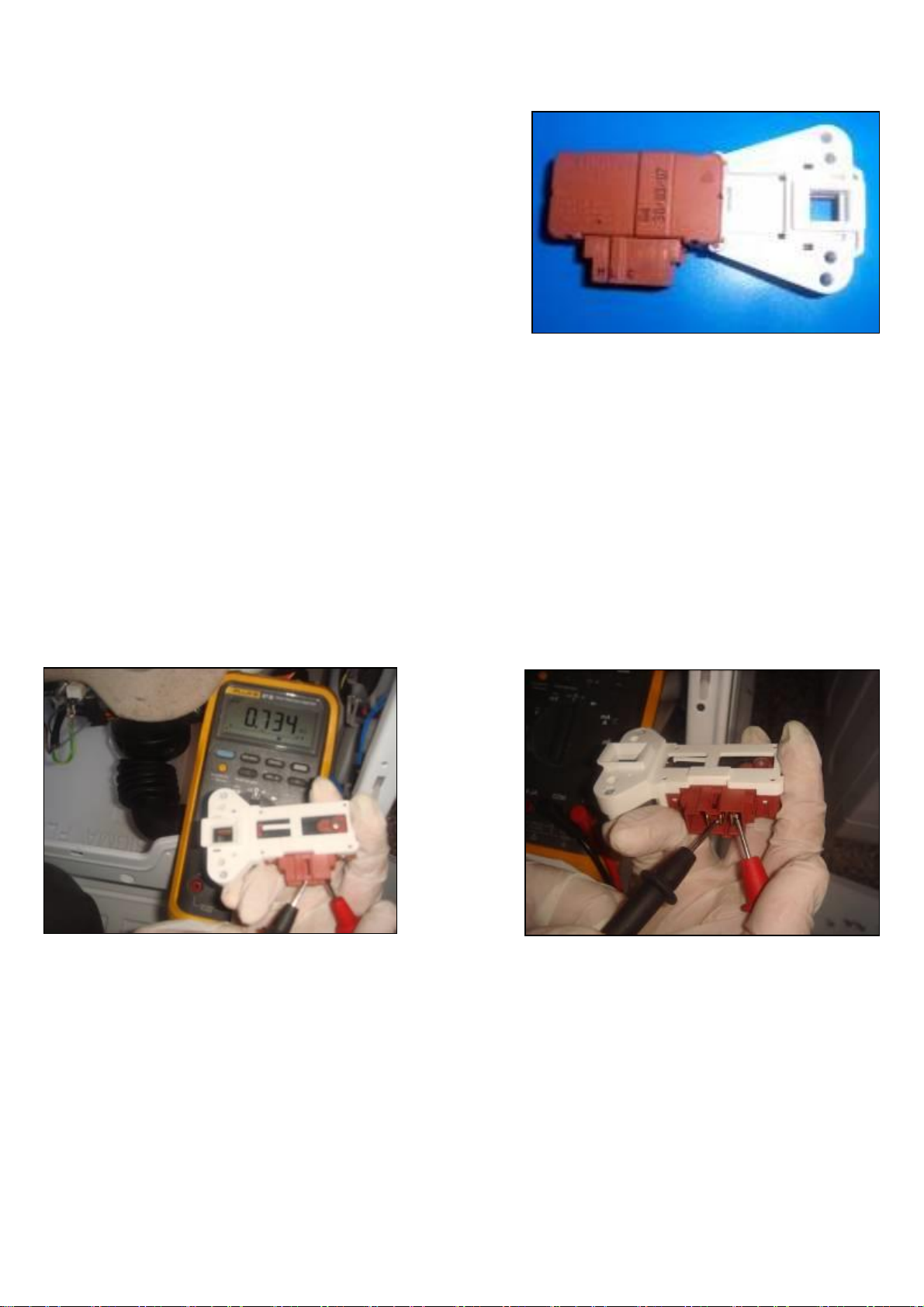

8.7. Door Lock

Door lock is activated at the beginning of the program in order to prevent the door

from opening. It can be unlocked approximately after 2 minutes of the program end.

This time delay is caused by the PTC which is assambled in the door lock.

8.7.1. Technical Features

Lock Time (20 °C) 2” – 6”

Unlock Time (20 °C) 35” – 75”

Nominal voltage 220 V

Nominal current 16 (4) A

8.7.2. Checking of Component

Check the resistance value on the component with multi-meter as shown in below figures.

Resistance value on the PTC should be 1000 Ω ±50% at 25 °C. That resistance value can be measured from terminal 3-4 (See wiring diagram page 51

below).

2

3

4

5

Table of contents

Other SOGEDIS Washer manuals