SOGEDIS D4 Series User manual

Manuel de service

Séries D4

Table of Contents

1. Safety Precautions ..................................................................................................................................................4

2. Specifications..........................................................................................................................................................5

3. Control Panel and Acronyms ...................................................................................................................................6

4. Test Mode...............................................................................................................................................................7

4.1. Autotest.......................................................................................................................................................................... 7

5. Service Mode ..........................................................................................................................................................9

5.1. Service Autotest............................................................................................................................................................... 9

5.2. Failure Codes .....................................................................................................................................................10

6. Critical Torque Values ...........................................................................................................................................10

7. Disassembly and Assembly Instructions.................................................................................................................11

7.1. Top Plate ....................................................................................................................................................................... 11

7.2. Door.............................................................................................................................................................................. 11

7.3. Spring Wire.................................................................................................................................................................... 12

7.4. Detergent Drawer.......................................................................................................................................................... 12

7.5. Control Panel................................................................................................................................................................. 13

7.6. Electronic Card & Fuse ................................................................................................................................................... 14

7.7. Front Panel .................................................................................................................................................................... 15

7.8 Dryer Card ...................................................................................................................................................................... 16

7.9 Dryer Unit....................................................................................................................................................................... 16

7.10 Support Bracket............................................................................................................................................................ 18

7.11 Detergent Drawer Housing............................................................................................................................................ 18

7.12 Power Cable Group and EMI Filter................................................................................................................................. 18

7.13 Electronic Pressure Switch (EPS).................................................................................................................................... 19

7.14 Door Lock* ................................................................................................................................................................... 19

7.15 Drain Pump................................................................................................................................................................... 20

7.16 Front Counterweight*................................................................................................................................................... 20

7.17 Heater .......................................................................................................................................................................... 20

7.18 Tub Bellow Seal*........................................................................................................................................................... 21

7.19 Transport Screw............................................................................................................................................................ 21

7.20 Upper Counterweight* ................................................................................................................................................. 21

7.21 Washing Group............................................................................................................................................................. 22

7.22 Shock Absorber Pin....................................................................................................................................................... 22

7.23 Driven Pulley................................................................................................................................................................. 22

7.24 Driven Pulley................................................................................................................................................................. 22

7.25 Motor........................................................................................................................................................................... 23

7.26 Tub............................................................................................................................................................................... 23

8. Component Specifications.....................................................................................................................................24

8.1. Drain Pump.................................................................................................................................................................... 24

8.2. Heater ........................................................................................................................................................................... 25

8.3. Washer NTC................................................................................................................................................................... 26

8.4. Valve ............................................................................................................................................................................. 27

8.5. Electronic Pressure Sensor (EPS)* .................................................................................................................................. 28

8.6. Motor............................................................................................................................................................................ 29

8.7. Door Lock* .................................................................................................................................................................... 30

8.8. Fan Group...................................................................................................................................................................... 31

8.9. Dryer Heater.................................................................................................................................................................. 32

8.10. Dryer NTC .................................................................................................................................................................... 33

8.11 Component Control on PCB........................................................................................................................................... 34

9. Wiring Diagram* ...................................................................................................................................................37

10. Troubleshooting..................................................................................................................................................38

About Content

This service bulletin is prepared for all OEM products within D4 range. Therefore you may encounter information

about some optional components that may not exist in your product. As this is a generic service bulletin covering all

range, please ignore and skip extra/optional component information. Sections marked with asterisk (*) sign contain

information about optional components.

Information already exists in user manuals is not included in this service manual. Please refer to user manual of your

product for basic installation, operating, maintenance and troubleshooting issues.

Contact

For your inquiries please send an email to:

WashingMachineCustomerSupport@vestel.com.tr

You can also open a support ticket using Service Support Page:

https://www.vestelservice.com/VestelService/

Acronyms:

WM : Washing Machine

W&D : Washer & Dryer

WMCS : Washing Machine Customer Support

TJ : Twinjet

UI : User Interface

SI : Service Interface

A : Available

NA : Not Available

1. Safety Precautions

Important:

This service information is designed for experienced repair technicians only and is not designed

for use by the general public. It does not contain warnings or cautions to advise non-technical

individuals of potential dangers in attempting to service a product. Products powered by

electricity should be serviced or repaired only by experienced professional technicians. Any

attempt to service or repair the product or products dealt with in this service information by

anyone else could result in serious injury or death.

Warning:

Before any disassembly/repair operation make sure appliance is unlplugged water tap is closed

and heating elements are cooled down. There is electrical shock, burning and flood risk.

Warning:

Please replace whole cable group even in case there is any minor failure with cables / terminals /

sockets. Never try to repair nor to solder cable group. It may cause smoke, ignition and there is

major risk of electrical shock.

Important:

Always use insulator gloves to prevent injury by metal edges or to prevent electrical shock during

electrical tests.

Work with uniforms having long sleeves to protect your arms from metal edges.

Always use original spare parts. You may harm appliance, end user, environment or yourself

using untested and unapproved 3rd party spare parts.

Use right tools to prevent any wear or damage to components during assembly/disassembly.

2. Specifications

Here you will find descriptions of generic specifications for the range specified for this service manual. Please refer to

product fiche and user manual for detailed technical specifications.

*Twinjet System:

Twinjet system is designed to obtain a better washing performance by directly injecting water

with detergent using a recirculation system and two nozzles connected to it. With twinjet

system, water consumption is decreased by 30%, energy consumption is decreased by 10% and

washing time is decreased by 15%

Twinjet system is valid for all programs except spin and drain mode. The system dos not function

during Water inlet, heating, spinning, drain phases.

Even with a large load of 8 kg. the washing machine will have the minimum energy consumption

by the help of Twinjet system.

Washing machines with Twinjet system are very environment-friendly by having maximum

washing performance with minimum water consumption.

Eco-Logic System:

Half load detection system, thus using less water and power accordingly. This system is available

for cotton programs only.

Foam Protection System:

Foam Protection System is a safety algorithm that interrupts normal program flow and reduces

foam level by taking water and draining. This algorithm protects machine and environment

avoiding over foaming inside tub in case any customer misuse such as detergent overdose or use

of foamy cleaning agents.

Overflow Protection System:

Overflow protection is another safety algorithm in case of a flood risk. If there is more water in

tub than expected by algorithm, it will start to the drain routine giving E04 failure code. For

example this may happen in case of a valve failure and the machine constantly takes water. This

algorithm will keep drain routine, keeps water leveled and protects environment and machine

avoiding any flood risk.

Unbalanced Load Detection and Control System:

Unbalance Control System is another safety algorithm that protects the machine and

environment avoiding machine movement due to vibration during spinning profile. The

algorithm tries to balance load by a special balancing agitation, postponing spin profile till it is

balanced. This avoids spinning while load is unbalanced and prevents any possible physical harm

both to the appliance and to surroundings.

3. Control Panel and Acronyms

PR

Program selector 16 programs including off position

SW1

Switch 1, Start / Pause

SW2

Switch 2, Option 1 (Delay Timer)

SW3

Switch 3, Option 2 (Drying Level)

SW4

Switch 4, Spin Speed Selection

SW5

Switch 5, Temperature Selection

L1

LED 1, Start/Pause LED

L2

LED 2, Drying Level 1 LED

L3

LED 3, Drying Level 2 LED

L4

LED 4, Drying Level 3 LED

L5

LED 5, Drying Level Option LED

L6

LED 6, Delay Time LED

PR

SW5

SW4

SW3

SW2

SW1

4. Test Mode

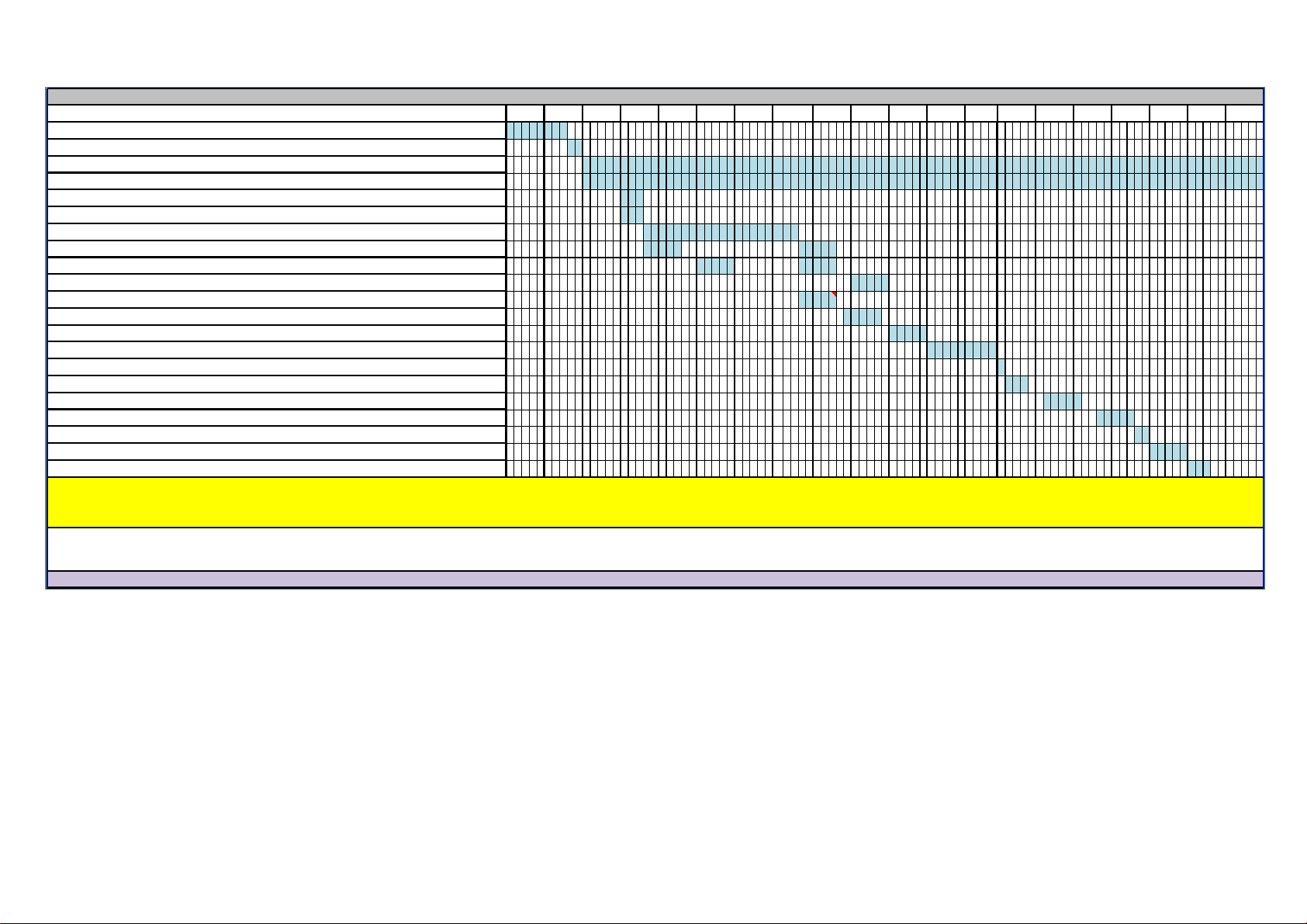

4.1. Autotest

4.1.1. Autotest Steps

1. Press and hold SW5.

Autotest follows a predefined flowchart in order. Unlike

service autotest, autotest automatically skips to next step

upon completing one. The steps of the test are as follows:

Step1:

The drain pump is checked.

Step2:

Motor ramps to max spin speed while valves are activated

in order.

Step3:

Motor stops, both valves are activated simultaneously.

Step4:

The motor turns to right. Also, dryer valve is activated.

Step5:

The motor turns to left.

Step6:

Both valves are activated. (Water intake for heating)

Step7:

Washer NTC is checked.

Step8:

Washer Heater is checked.

Step9:

Dryer resistance I and I&II are checked.

Step10:

Dryer NTC is checked for 2sec.

Step11:

Fan is checked.

In case of no failure test ends after this step and “End” is

displayed. In case of an error detection EXX and error

definition will pop up on display. (where XX is the error

number 1 to 10 )

Please see following autotest chart for details.

2. While pressing SW5, turn PR to 1st position

(Cotton). Wait 3 seconds and release SW5. During

test “AU” is visualized on display.

3. When autotest is finished, END screen is

visualized.

30

35

AUTOTEST

90

95

40

45

50

55

60

65

75

80

85

Time in seconds (to be adjusted)

5

10

15

20

25

EV1 + EV2 valves up to first level frequency (Depends on the water level)

Washer NTC check

Washer heater resistance

EPS measurement

Motor Ramp to max spin (max. is 20 sec.)

EV1 (flowrate dependent of washer)

EV2 (flowrate dependent of washer)

Dryer valve

Time until motor is stopped (Depends on the motor stop time)

Motor Preferred Run (Direction to Right)

Motor Inverse Run (Direction to Left)

100

Entering autotest

Changing power to 220 50Hz

Main Voltage 50 Hz

Door Lock Powered (Depends on door lock)

Pump

70

EPS measurement: It checks the EPS and if it OK, it continues the autotest; if it is NOK then cancel the Autotest and go to the selection mode. Also if any frequency can not be detected, then it means there is problem with connecion

or EPS, so it gives E10 which is EPS error and cancels the autotest & goes to the selection mode.

Dryer Ntc detection : Software will detect NTC's resistance value and will check if the temperature is between 0°C < Tdetected < 50°C. If it is inside the range, heating step will be done.

Washer Ntc detection : Software will detect NTC's resistance value and will check if the temperature is between 5°C < Tdetected < 40°C. If it is inside the range, heating step will be done.

If temperature value is outside the range, then it means NTC is detecting the temperature in a wrong way and heating step will be skipped. Additionally if NTC connector disconnected it should shows NTC failure code(E05) on display.

Dryer resistance I

Dryer resistance I + II

Dryer NTC

Fan

End Visualization

5. Service Mode

5.1. Service Autotest

5.1.1. Service Autotest Steps

1. Press and hold SW4.

If you turn knob position to other program between 1st to

3rd it will skip current test and start the selected one. It is

recommended not to skip any steps for a detailed

checkup. Unlike autotest, service autotest starts next test

step manually by rotating program selection knob.

Step1:

There will be a certain amount of water intake and then washer heater is

activated for 8 minutes. Washer NTC values are checked in this period.

In case of a washer heater/NTC failure, it pops up E05 error displaying

“E05” on SW3.

At the end of heating, "SAU" visualization should make slow blink to

indicate that the step is over. You can turn program knob to 2nd position

to continue with step2.

*During this step if EPS detects high water level, overflow algorithm is

applied and E04 is released.

Step2:

Drain pump is activated; in case of a pump failure it pops up E03 error.

At the end of pump activation, "SAU" visualization should make slow

blink to indicate that the step is over. You can turn program knob to 3rd

position to continue with step3.

Step3:

Dryer Heater I and fan is activated. After 3 mins if there will be no

temperature change (ΔT< 10°C), it will release E14 failure.

If temperature increases accordingly (ΔT > 10°C), "SAU" visualization

should make slow blink to indicate that the step is over. You can turn

program knob to 4th position to continue with step4.

Step4:

Dryer Heater II and fan is activated. After 3 mins if there will be no

temperature change (ΔT< 10°C), it will release E14 failure.

If temperature increases accordingly (ΔT > 10°C), "SAU" visualization

should make slow blink to indicate that the step is over. You can turn

program knob to 5th position to continue with step5.

Step5:

Rapid 15’program algorithms is run to test all washing components, the

only difference is error codes are displayed which normally are not

displayed to end user.

If no error found in test program ”SAU" visualization should make slow

blink to indicate that the step is over. You can turn program knob to 6th

position to continue with step6.

Step6:

A 5 mins drying program is run to test all drying components.

If case of no error service autotest ends and "End" is displayed.

*If user changes the selector position, machine will do what is defined

for the new selected position.

2. While pressing SW4, turn PR to 1st position

(Cotton). Wait 3 seconds and release SW4. Step 1 of

service autotest will start. During test “SAU” is

visualized on display. Please see details about steps

in right column.

3. When autotest is finished, END screen is

visualized.

5.2. Failure Codes

Error Indication

Error Number

Indication in UI

Indication in SI

Door/Door Lock Failure

E01

A

A

Lack of water

E02

A

A

Pump failure

E03

A

A

Overflow

E04

A

A

NTC or Heater Failure

E05

NA

A

Motor Failure

E06

NA

A

Configuration Failure

E07

NA

A

Motor Triac Failure

E08

NA

A

Voltage Error

E09

A

A

Electronic Pressure Sensor

E10

NA

A

Dryer Board Connection Failure

E11

NA

A

Dryer Thermostat Failure

E14

NA

A

Twinjet Failure

E15

NA

A

Dryer Overheated Failure

E16

NA

A

Flowmeter Failure

E17

NA

A

Dryer NTC Failure

E18

NA

A

6. Critical Torque Values

Assembly Locatıon

Bolt/Nut/Screw

Torque

Min. (Nm)

Torque

Nom. (Nm)

Torque

Max.

(Nm)

Air Pressure

Wrench

Speed (rpm)

*

Transport Screw Assembly

Transport Screws

6.50

6.50

7.00

1000

*

Motor Assembly

Motor Screws

6.00

6.50

7.50

800

*

Front Concrete Weight - Front

Tub Assembly

Front Counterweight

Screws

14.00

14.50

14.75

600

*

Upper Counter Weight

Assembly

Upper Counterweight

Screws

25.00

27.50

30.00

440

*

Pulley –Drive Shaft –

Washing Group Assembly

Pulley –Drive Shaft

Assembly Bolt

39.50

40.00

40.50

440

*

Washer Heater Assembly

Heater Assembly Nut

3.85

4.00

4.00

970

The bolts/nuts above are important for product safety purposes. Please tighten screw, bolts and nuts

according to the torque values given in table above.

7. Disassembly and Assembly Instructions

7.1. Top Plate

1

2

Remove two screws that fix the top-plate at

the back.

Push the top-plate back and pull it up.

7.2. Door

1

2

Remove two screws that fix the door. (by

using T25 tool)

Pull the door up.

3

4

Remove screws that fix the door group.

Put the door outside plastic with helping

screwdriver.

T25

5

6

Remove the door inside plastic.

Remove six screws that fix the door hinge.

7*

8*

Remove the door handle.

Remove the door handle pin.

7.3. Spring Wire

1

2

First, remove the spring wire fixing the tub

bellows seal by using the small size screw

driver. Pull the tub bellows seal.

Remove the tub bellows seal-body fixing

spring.

7.4. Detergent Drawer

1

2

Gently pull the detergent drawer.

While pressing siphon cover keep pulling

drawer to remove it.

7.5. Control Panel

1

2

Remove the screw which fixes the control

panel to the front panel.

Remove two screws fixing control panel.

3

4

Pull the control panel out.

Remove connectors.

5

6

Remove electronic card cover as it is shown

in the pictures by using small screw driver.

Remove the PCB card box from the control

panel.

7.6. Electronic Card & Fuse

1

2

Remove PCB box using a small screw driver.

3

4

Unplug display card connector.

Open fuse box and remove the fuse.

7.7. Front Panel

1

2

Remove the screw fixing the front panel at

the bottom

Remove two screws fixing the door lock

3

4

Remove the tub bellows seal.

5

6

Remove two screws fixing front panel to

body

Remove the screw fixing twinjet elbow

7

8

Pull front panel up

Remove front panel

9

10

Remove the screw that fixes the pump filter

cover.

Release the holder of the pump filter cover.

7.8 Dryer Card

1

2

Remove the screws that fixes the dryer card

Remove the sockets.

7.9 Dryer Unit

1

2

Remove the screws that fixes the heater unit

of the dryer

Remove the sockets of the heater unit

2

3

Remove the screws that fix the fan group.

Release the cable group by cutting the cable

connection.

4

5

Remove the Cable group of the dryer unit

Remove the sockets of the heater group

6

7

Remove the sockets of the fan group.

Remove the screws that fix the fan group.

8

9

Cut the connection plastic of the dryer unit.

Cut the cable connection of the dryer NTC

and remove the sockets.

7.10 Support Bracket

1

2

Remove two screws fixing the body group on

the upper part

Remove two clips fixing detergent drawer

housing to upper support bracket

7.11 Detergent Drawer Housing

1

2

Remove the tub bellow hose by releasing the

holder extensions of bellow hose

Unplug connectors from feed valve

3

4

Slightly turn the feed valve counter-

clockwise to remove

Remove the detergent drawer housing

assembly

7.12 Power Cable Group and EMI Filter

1

2

Remove the five conectors that is connected

to the EMI filter

Remove two screws fixing EMI filter.

3

4

Pull the power cable group up

Remove EMI filter

7.13 Electronic Pressure Switch (EPS)

1

2

Unplug EPS connector

Pull EPS up

3

Remove clamp from EPS hose

7.14 Door Lock*

1

Unplug door lock connector

7.15 Drain Pump

1

2

Remove clamp holding drain hose by using

a plier

Remove clamp fixing tub outlet hose

3

4

Unplug drain pump connector

Remove screws holding drain pump

7.16 Front Counterweight*

1

2

Remove three screws on the front

counterweight. (Wrench size 13 mm)

Gently pull counterweight out

7.17 Heater

1

2

Unplug heater connectors

Remove nut (8 mm) fixing the heater

Other manuals for D4 Series

1

Table of contents

Other SOGEDIS Washer manuals