SOGEDIS BANDEAU HP F2 User manual

SECHE ‐ LINGE

MANUEL DE SERVICE

BANDEAU HP F2

SERVICE MANUAL

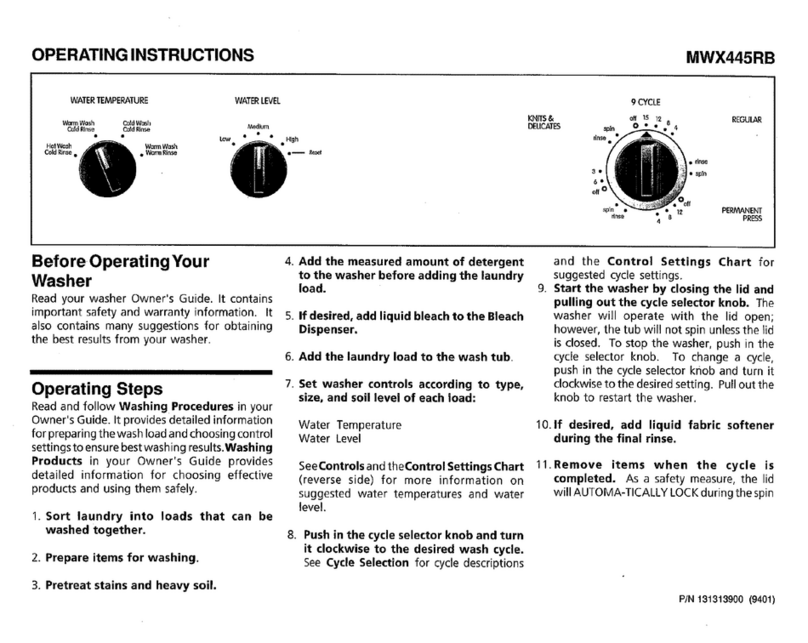

4. CONTROL PANEL AND PROGRAM SELECTION TABLE

4.1. Control Panel

Display Symbols Drying Stages Indicator

4.2.Program List

KNOB POSITION

PROGRAM

1

Cotton Extra Dry

2

Cotton Cupboard Dry

3

Cotton Iron Dry

4

Synthetics Cupboard Dry

5

Synthetics Iron Dry

6

Delicate

7

Mix

8

Baby Care

9

Jeans

10

60 min

11

40 min

12

20 min

13

Refresh

14

Express 45 ’

15

Shirts 30 ‘

16

OFF

BANDEAU HP F2

SERVICE MANUAL

***The machine has humidity sensor that detects whether the laundry dry or not. At the programs

that work with humidity sensor laundry does not dry in fixed time. Duration is constantly updates

according to humidity data taking from laundry

***Time Drying Program: 60min /40min / 20min Humidity sensor is deactivated. The program ends

when the time is up, without checking the humidity of the laundry.

***Express 45’/ Shirts 30 ‘: Humidity sensor is activated. The program time may extend, if the

customer use different laundry according to the load in the program description.

Express 45' : 2 kg of cotton shirts spun at a high speed in the washing machine are dried in 45

minutes.

Shirts 30' : 2 to 3 shirts are ready for to be ironed in 30 minutes.

***Delicate: Delicate fabrics are dried for a longer time at a low temperature.

4.3. Children’s Safety

There is a child lock option to avoid changes in the program flow

when keys are pressed during the program.

There is a child lock option to avoid changes in the programme

flow when keys are pressed during the programme. To activate the

child lock, press and hold the "Anti-Crease" and "Delicate Drying"

keys simultaneously for 3 seconds. When the child lock is active, all keys will be deactivated. Child

lock will be deactivated automatically at the end of the programme.

When activating/deactivating the child lock, the LEDs of the "Anti-Crease" and "Delicate Drying"

options will flash and an audible warning will be heard.

BANDEAU HP F2

SERVICE MANUAL

5.FAILURE MODES AND SERVICE AUTOTEST

***Service auto test must be run for every service call.

The case in the photo don’t show us a failure code. Normally, when the drying program ends, the

filter, water tank and end led are flashing. In addition, heat exchanger cleaning warning led is on

every 30 cycles.

BANDEAU HP F2

SERVICE MANUAL

5.1. Failure Modes and Warning Leds

Notes For Service autotest:

*Service can not pass the current step before completing the minimum duration

*When minimum duration for each step (5 sec) is completed, filter led makes slow blink to indicate

that service can pass the next step

*For error codes, leds must make fast blink

ERROR CODE REASON

E03

Aquaswitch connector is disconnected

E04 Compressor connector is disconnected

E05 Compressor NTC connector is disconnected

E06 Door NTC connector is disconnected

E07 Motor connector is disconnected, motor is locked

E08

Voltage fluctuation

F2 HEAT PUMP MODEL ERROR CODES

BANDEAU HP F2

SERVICE MANUAL

5.2.Service Auto Test Steps

STEPS

Control

Possible Errors

While pushing SW2 button for 5 sec, position knob to

Program 1. Then press Start/Pause button. Machine enters

to service autotest.

F2: All warning leds makes fast blink for 2 sec and then

becomes fix off.

Machine shows the last error saved by machine. When

knob positioned to program 2, control steps starts.

The

Routine to

Enter

Servis

Autotest

Step 2

Dryer check Aquaswitch, if aquaswitch ON go

*Aquaswitch connector is taken out

(Knob

to next step (pump activation), if aquaswitch

LD6

*Aquaswitch connector is short circuit

Position 2)

OFF give water tank full error

*Styrofoam is borken or not

Step 3

Service must pour water to pump reservoir and

check whether water is pumped to tank.

(Knob

Pump is on

-

If water is not pumped to water tank;

Position 3)

*Pump connector is taken out

Service must check whether tumble is moving to CW.

Step 4

If not;

(Knob

Motor CCW (Tumble CW)-Motor stops

-

*Motor connector is taken out

Position 4)

*Motor might be locked

*Motor belt might be dislocated

Step 5

Service must check whether tumble is moving to

CCW

(Knob

Motor CW (Tumble CCW) -Motor stops

-

*If tumble is moving to CW again, then motor relay

Position 5)

short circuit CCW

Step 6

Check Compressor NTC if heater NTC

*Compressor NTC connector is taken out or short

(Knob

LD3

Position 6)

T=255

LD5

circuit

Step 7

(Knob

Check Door NTC if heater NTC T=255

LD2

*Door NTC connector is taken out or short circuit

Position 7)

LD3

Step 8

Compressor OFF- Motor CCW (Tumble

Service must check power of at the home voltage

(Knob

-

and fan will be controlled manually by technical

CW) OFF- Cooling fan ON

Position 8)

service.

Step 9

Compressor ON- Motor CCW (Tumble CW)

(Knob

-

Service must check power of at the home voltage.

Motor OFF

Position 9)

Step 10

Service puts his hand on the humidity sensor plates

Check conductivity sensor when door is

and software checks sensor data

(Knob

LD2

opened and motor is off

*If sensor data=0, humidity sensor connector is taken

Position 10)

LD5

out

BANDEAU HP F2

SERVICE MANUAL

7. 7. COMPONENT SPECIFICATIONS AND MEASUREMENTS

7.1. Motor

The dryer has an asynchronous motor. In

the photo on the right, the socket on the

motor are shown to be measured by

multiple counters. It is driven with triac via

the electronic card (to give energy) and

relay (for direction control).

Technical Features

Type: single-phase asynchronous motor

Power: 200 W (Unloaded drum)

Main windings: 21.5±7% (20 °C temp.)

Aux windings: 19.5±7% (20 °C temp.)

Motor speed : 2750 rpm (Unloaded drum)

Drum speed : 52 ± 2

Capacitor value : 11 µF ± %5

Component Test

Check whether the motor cable is connected to the motor connector.

Check the connection of the capacitor cables

Measure the resistance values and check the capacitor values

Check whether it is working by connecting via the terminals 1 and 2 (Blue-White)

connection

If it is working, revolution of the drum is measured in unloaded state.

The terminals 1-3 of the motor should be connected with capacitor

Resistance measurement of main winding: Terminal 1 -2 (Blue-White) is measured.

Resistance measurement of aux winding: Terminal 3 -2 (Red-White) is measured.

BANDEAU HP F2

SERVICE MANUAL

7.1.1. Motor Measurements

1

2

3

2

1

3

3

1

2

BANDEAU HP F2

SERVICE MANUAL

7.2. Pump

In Tumble Dryer models, the pump is used

to transport the water that accumulates in

the condensation chamber to tank in the

drawer area. One triac is measured on the

electronic card.

Technical Features

Resistance : 764±10% ohm

Voltage: 220-240 Volt

Frequency: 50 Hz

Input Power : 13W max

Component Test

Check the connection of the pump connector

Check the pump resistances

Check whether pump is working, by feeding externally

If the pump is working, the water in the tank is unloaded by running the pump Then,

Unload 500 ml of water from water tank to pump reservoir and check whether water is

pumping.

While pump is working, if water is not reached into water tank, hoses should be checked.

BANDEAU HP F2

SERVICE MANUAL

7.2.1 Pump Measurements

2

1

1

BANDEAU HP F2

SERVICE MANUAL

7.3. Electronic Card

Technical Features

Electronic card is single sided printed circuit board and CEM-1 material

The upper picture shows where the components sockets are inserted.

7.4. Door/Compressor NTC Sensor

Two NTC sensors are used. The NTC

resistance decreases when the temperature

rises.

Technical Features

Door NTC Resistance : 12 kΩ (Measured from IDC connected to electronic card )

Compressor NTC Resistance : 12 kΩ (Measured from IDC connected to electronic card )

Component Test

Resistance is measured from IDC connected to electronic card

BANDEAU HP F2

SERVICE MANUAL

7.4.1. Door NTC Sensor Measurements

7.5. Compressor

The dryer has an compressor with

an asynchronous motor. In the

photo on the right, the terminal on

the compressor are shown to be

measured by multiple counters. It is

driven with relay via the electronic

card (to give energy) and relay drive

the compressor only one direction.

Technical Features

Type: single-phase asynchronous motor

Power: 350 W (Unloaded drum)

Main windings: 9.3±7%(25 °C temp.)

2

1

1

BANDEAU HP F2

SERVICE MANUAL

Aux windings: 8.75±7% (25 °C temp.)

Motor speed : 2928 rpm (Unloaded)

Gas Type: R290

Capacitor value : 20 µF ± %5

Compressor Capacity: 7.8 cm³/rev

Component Test

Check whether the compressor cable is connected to the compressor terminal.

Check the connection of the capacitor cables

Measure the resistance values and check the capacitor values

Check whether it is working by connecting via the terminals S,R and C connection

If it is working, start the machine and check the drum temperature.

The terminals S and R of the motor should be connected with capacitor.

Resistance measurement of main winding: Terminal C-R is measured.

Resistance measurement of aux winding: Terminal C-S is measured.

BANDEAU HP F2

SERVICE MANUAL

7.5.1. Compressor Measurements

2

1

3

c

r

s

r

c

s

c

s

r

BANDEAU HP F2

SERVICE MANUAL

7.6. Door Latch

Door latch locks when the door is closed.

It’s designed to be opened from inside, in

case of children are in the drum

Component Test

When the door is closed, check whether there is electrical transmission from IDC

connected to electronic card

Check the connection of the component connector

7.6.1 Door Latch Measurements

2

1

BANDEAU HP F2

SERVICE MANUAL

7.7. Humidity Sensor

The Humidity Sensor measures the amount

of dryness of the laundry in the drum.

Component Test

Each humidity sensor plate is checked whether there is electrical transmission from IDC

connected to electronic card.

Check the connection of the component connector

7.7.1 Humidity Sensor Measurements

2

1

BANDEAU HP F2

SERVICE MANUAL

7.8. Cooling Fan

The dryer has an cooling fan with an

asynchronous motor. In the photo on the

right, the terminal on the compressor are

shown to be measured by multiple

counters. It is driven with triac via the

electronic card (to give energy)

Technical Features

Type: single-phase AC fan

Power: 28 W

Main windings: 600±7%

Motor speed : 2600/3000 ±10%

Component Test

Check whether the cooling fan cable is connected to the fan terminal.

Measure the resistance values

BANDEAU HP F2

SERVICE MANUAL

7.8.1. Cooling Fan Measurements

7.9. Drumlight

Drumlight lights inside of the drum

Component Test

Check whether there is electrical transmission from IDC connected to electronic card.

2

1

1

BANDEAU HP F2

SERVICE MANUAL

8. TROUBLESHOOTING

If Machine has no power

Is there power

on power

sockets(outlet) ?

(220V-50 Hz)

Change The Main Board

MACHINE IS NOT WORKING

Is Electricity

Reaching To

Main Board?

YES

YES

Change the cable tree

NO

NO

Machine has not a failure

Is The Supply

Cord Plugged

Into The EMI

Filter?

NO

Make Electrical Connection

YES

Is the current

transmitted

on supply

cord plug ?

YES

NO

Change the supply cord and plug

BANDEAU HP F2

SERVICE MANUAL

If machine has power

Is the door

closed?

Change the electronic card

MACHINE IS NOT WORKING

Is the position

of door latch

switch

correct?

YES

YES

Fix the position of the switch

NO

NO

YES

Close / Repair the door

Is the door latch

socket connection

correct ?

NO

Make Electrical Connection

YES

Check the door

latch with

multimeter for

short circuit

YES

NO

Change the door latch

Is the door latch

cable transmitted

the current ?

Change the door latch cable

NO

YES

BANDEAU HP F2

Table of contents

Other SOGEDIS Washer manuals