Solair 11EER Series User manual

Page 1 of 39

11EER Series

Wall Mount Air Conditioner

Models:

INSTALLATION INSTRUCTIONS

J42AC-A

J42AC-B

J42AC-C

J48AC-A

J48AC-B

J48AC-C

J60AC-A

J60AC-B

J60AC-C

J72AC-A

J72AC-B

J72AC-C

Manual: 2100-723C

Supersedes: 2100-723B

Date: 4-15-21

Manual 2100-723C

Page 2 of 39

CONTENTS

Getting Other Information and Publications .... 3

Wall Mount General Information ......................... 4

Air Conditioner Wall Mount Model Nomenclature..... 4

Shipping Damage ................................................. 4

General ............................................................... 4

Duct Work ........................................................... 5

Filters ................................................................. 5

Filter Removal/Installation................................. 5

Switching Filter Sizes ....................................... 5

Fresh Air Intake ................................................... 7

Installation ............................................................... 8

Basic Installation Design and Application Planning.. 8

Wall Construction ............................................. 8

Outdoor Area Inspection.................................... 8

Condensate Water Drainage ............................... 8

Indoor Ducted and Non-Ducted Applications........... 8

Indoor Supply Airow........................................ 8

Indoor Return Airow........................................ 8

Ducted Applications ......................................... 8

Free Blow Applications...................................... 9

Thermostat or Indoor Temperature Sensor

Placement ....................................................... 9

Unit Installation ................................................... 9

Materials/Tool List ............................................ 9

Wall Preparation............................................. 10

Wall Mount Installation to Wall Surface ............ 10

Wiring – Main Power........................................... 17

High Voltage Connections................................ 17

Wiring – Low Voltage........................................... 18

Low Voltage (24VAC) Connections .................... 18

Unit Shutdown Feature ................................... 18

Balanced ClimateTM Feature............................. 18

Ventilation Features ........................................ 18

Low Ambient Control (LAC) ............................. 18

Outdoor Temperature Switch and Freeze

Protection Thermostat................................. 18

Alarm Relay Feature ....................................... 18

Start Up ................................................................... 22

General ............................................................. 22

Topping Off System Charge ................................. 22

Safety Practices ................................................. 22

Important Installer Note...................................... 22

High Pressure Switch.......................................... 22

Three Phase Scroll Compressor Start Up

Information........................................................ 22

Phase Monitor.................................................... 23

Condenser Fan Operation .................................... 23

Service Hints ..................................................... 23

Sequence of Operation........................................ 23

Balanced ClimateTM Mode................................ 23

Vent Connection Plug.......................................... 24

Compressor Control Module................................. 24

Features ........................................................ 24

Delay-on-Make Timer ...................................... 24

Short Cycle/Delay-on-Break ............................. 25

Low Pressure Detection................................... 25

High Pressure Detection.................................. 25

Test Mode...................................................... 25

Brownout Protection with Adjustment............... 25

Pressure Service Ports ........................................ 25

Service ..................................................................... 26

Troubleshooting Nidec SelecTech Series ECM

Motors............................................................... 26

If the Motor is Running ................................... 26

If the Motor is Not Running............................. 26

Model SelecTech Communication Diagnostics ... 27

Fan Blade Setting Dimensions ............................. 28

R-410A Refrigerant Charge ................................. 28

Removal of Fan Shroud....................................... 28

Setting Unit Airow ............................................ 32

Blower Speeds ............................................... 32

Speed Tap 1 – Vent/Blower Only .................. 33

Speed Tap 2 – Balanced Climate ................. 33

Speed Tap 3 – Default LO Cooling &

Heating ............................... 33

Speed Tap 4 – Optional MED Cooling &

Heating ............................... 33

Speed Tap 5 – Optional HI Cooling &

Heating ............................... 33

FIGURES

Figure 1 Front Control Panel Cover ...................... 5

Figure 2 Removing Left Filter.............................. 5

Figure 3 Removing Second Filter......................... 5

Figure 4 Filter Tabs in Down Position ................... 6

Figure 5 Bend FIlter Tabs to Up Position .............. 6

Figure 6 Remove Four Screws ............................. 6

Figure 7 Re-Install Filter Support Brackets into

Upper Slots .......................................... 6

Figure 8 Install Right 1" Filter............................. 6

Figure 9 Install Left 1" Filter............................... 6

Figure 10 Fresh Air Damper .................................. 7

Figure 11 Vent Installation/Removal Clearance

Required ............................................ 11

Figure 12 Unit Dimensions ................................. 12

Figure 13 Mounting Instructions.......................... 13

Figure 14 Electric Heat Clearance ....................... 14

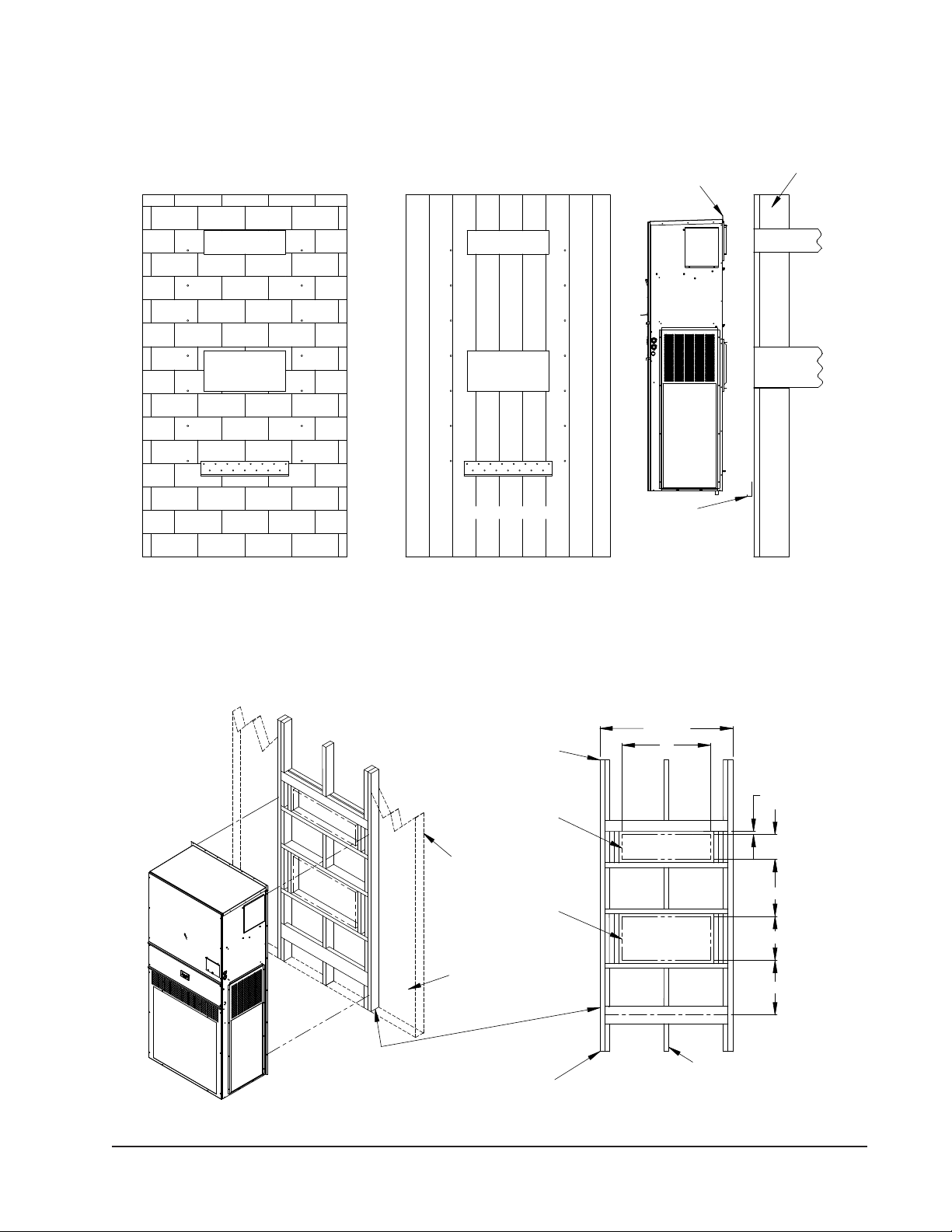

Figure 15 Wall Mounting Instructions .................. 15

Figure 16 Wall Mounting Instructions .................. 15

Figure 17 Common Wall Mounting Installations .... 16

Figure 18 High Voltage Connections .................... 17

Figure 19 Programmable Thermostat

Connections ....................................... 20

Figure 20 Non-Programmable Thermostat

Connections ....................................... 21

Figure 21

8201-164 Compressor Control Module ...

24

Figure 22 Motor Connections .............................. 26

Figure 23 Motor Connections .............................. 27

Figure 24 Fan Blade Setting ............................... 28

Figure 25 Fan Shroud Removal ........................... 28

Figure 26 Speed Taps......................................... 32

Figure 27 Speed Taps......................................... 33

Manual 2100-723C

Page 3 of 39

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help when installing the air

conditioner. They can usually be found at the local

library or purchased directly from the publisher. Be

sure to consult the current edition of each standard.

National Electrical Code ......................ANSI/NFPA 70

Standard for the Installation of Air Conditioning and

Ventilating Systems

.......................................................ANSI/NFPA 90A

Standard for Warm Air Heating and Air Conditioning

Systems

.......................................................ANSI/NFPA 90B

Load Calculation for Winter and Summer Air

Conditioning

....................................... ACCA Manual J Residential

Duct Design for Residential Winter and Summer Air

Conditioning and Equipment Selection

....................................................... ACCA Manual D

For more information, contact these publishers:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating, Refrigeration

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

TABLES

Table 1 Clearance Required for Service Access

and Adequate Condenser Airow........... 11

Table 2 Minimum Clearances Required to

Combustible Materials ......................... 11

Table 3 Wall Thermostats ................................ 19

Table 4 Humidity Controls ............................... 19

Table 5 CO2Controllers ................................... 19

Table 6 Thermostat Wire Size........................... 19

Table 7 Fan Blade Dimensions......................... 28

Table 8 Cooling Pressure – Standard Airow ...... 29

Table 9 Cooling Pressure – Balanced Climate

Airow ............................................... 30

Table 10 Electrical Specications J**AC............. 31

Table 11 Recommended Airow ......................... 32

Table 12 Blower Speeds for Unit Operational

Modes................................................ 32

Table 13 Indoor Blower Performance .................. 34

Table 14 Maximum ESP Electric Heat Only......... 35

Table 15 Electric Heat ...................................... 35

Table 16 Vent and Control Options ..................... 36

Table 17 Optional Accessories ........................... 37

GRAPHS

Graph 1 J42AC FAD-NE5 W/O Exhaust

Ventilation Delivery ............................. 38

Graph 2 J48AC FAD-NE5 W/O Exhaust

Ventilation Delivery ............................. 38

Graph 3 J60AC FAD-NE5 W/O Exhaust

Ventilation Delivery ............................. 39

Graph 4 J72AC FAD-NE5 W/O Exhaust

Ventilation Delivery ............................. 39

Manual 2100-723C

Page 4 of 39

WALL MOUNT GENERAL INFORMATION

Shipping Damage

Upon receipt of equipment, the carton should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

General

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do

not play with the appliance.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and

return ducts.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly “Starting

Procedure” and any tags and/or labels attached to the

equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any

national and/or local codes in any way. Authorities

having jurisdiction should be consulted before the

installation is made. See page 3 for information on

codes and standards.

Size of unit for a proposed installation should be based

on heat loss calculation made according to methods of

Air Conditioning Contractors of America (ACCA). The

air duct should be installed in accordance with the

Standards of the National Fire Protection Association

for the Installation of Air Conditioning and Ventilating

Systems of Other Than Residence Type, NFPA No.

90A, and Residence Type Warm Air Heating and Air

Conditioning Systems, NFPA No. 90B. Where local

regulations are at a variance with instructions, installer

should adhere to local codes.

AIR CONDITIONER WALL MOUNT MODEL NOMENCLATURE

NOTE: Vent options X is without exhaust capability. May require separate field-supplied barometric relief in building.

CONTROL MODULES

J – LAC and Alarm Relay (ALR)

COIL OPTIONS

X–Standard

J 42 A C –A 00 X P X X X J

MODEL SERIES

REVISION

KW

FILTER OPTIONS

P–2" MERV8 Disposable

PLACEHOLDER

X–Future Use

COLOR OPTIONS

X–Beige (Standard)

CAPACITY

42 –3½ Ton

48 –4 Ton

60 –5 Ton

72 –6 Ton

VENTILATION OPTIONS

X–Fresh Air Damper - No Exhaust (Standard)

Z – Full Flow Economizer, JADE

VOLTS & PHASE

A–230/208/60/1

B–230/208/60/3

C–460/60/3

A – Air Conditioner

Manual 2100-723C

Page 5 of 39

Duct Work

All duct work, supply and return, must be properly

sized for the design airow requirement of the

equipment. Air Conditioning Contractors of America

(ACCA) is an excellent guide to proper sizing. All duct

work or portions thereof not in the conditioned space

should be properly insulated in order to both conserve

energy and prevent condensation or moisture damage.

Refer to the Maximum External Static Pressure (ESP)

of Operation – Electric Heat Only table on page 35.

Design the duct work according to methods given by

the Air Conditioning Contractors of America (ACCA).

When duct runs through unheated spaces, it should

be insulated with a minimum of 1" of insulation. Use

insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect the

duct work to the equipment in order to keep the noise

transmission to a minimum.

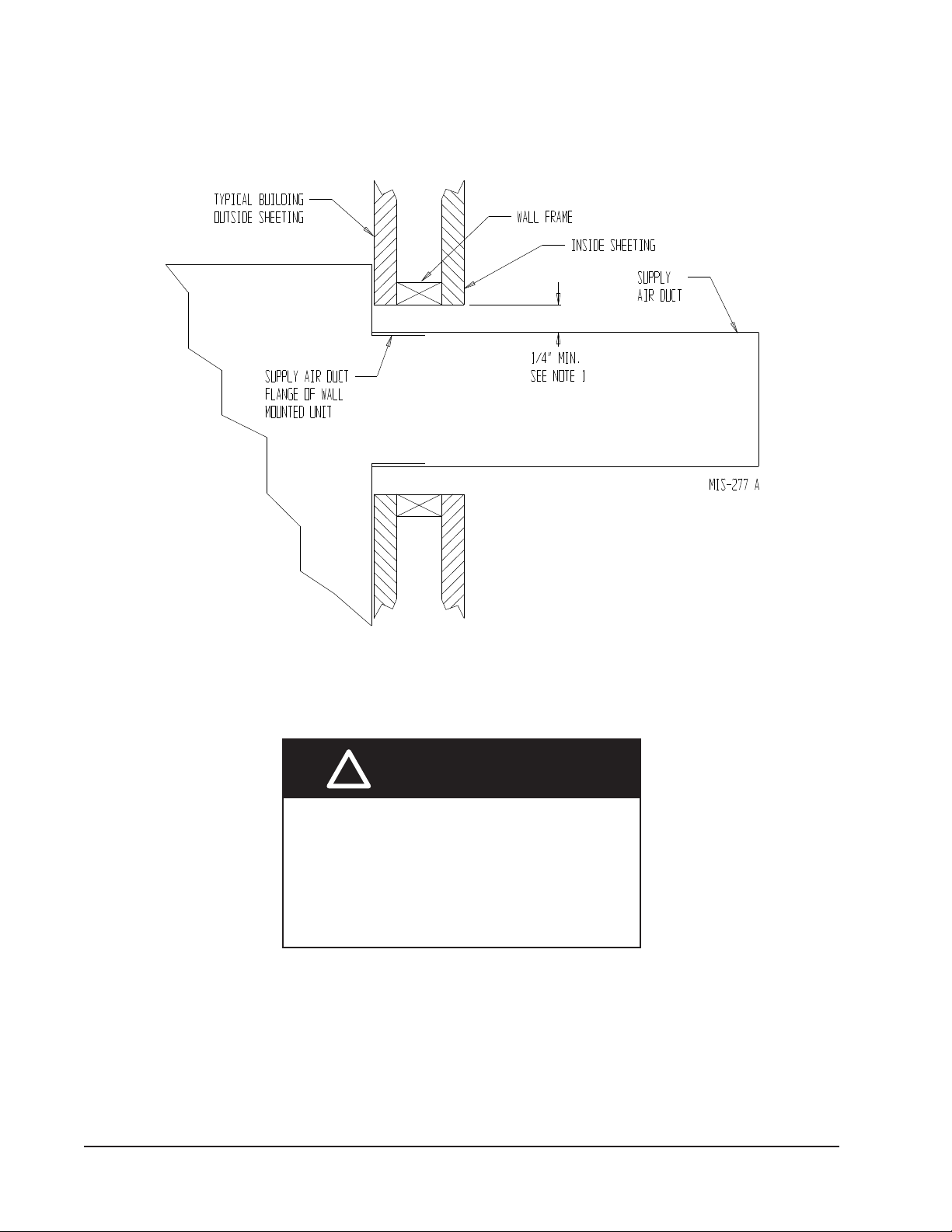

All model series require a 1/4" clearance to

combustible material for the rst 3' of duct attached to

the outlet air frame. See instructions on page 10 and

Figures 13 − 17 (pages 13 – 16) for further details.

Ducts through the walls must be insulated and all joints

taped or sealed to prevent air or moisture entering the

wall cavity.

Some installations may not require a return air duct. A

metallic return air grille is required with installations

not requiring a return air duct. The spacing between

louvers on the grille shall not be larger than 5/8".

Any grille that meets with 5/8" louver criteria may be

used. It is recommended that Bard Return Air Grille

Kits RG5 or RFG5 be installed when no return duct

is used. Contact distributor or factory for ordering

information. If using a return air lter grille, lters must

be of sufcient size to allow a maximum velocity of

400 fpm.

NOTE: If no return air duct is used, applicable

installation codes may limit this cabinet to

installation only in a single story structure.

Filters

The lters can be serviced from the outside by

removing the front control panel cover (see Figure 1).

Two (2) 20" x 20" x 2" disposable lters come standard

with each unit.

Filter Removal/Installation

1. Remove left lter rst by pulling on lter removal

slide (see Figure 2).

2. Slide second lter to the left around the wires and

pull the lter out (see Figure 3).

3. Reverse the order for new lter installation.

NOTE: When installing new filters, make sure that

airflow arrows on filters point up.

FIGURE 1

Front Control Panel Cover

Front

Control Panel

Cover

FIGURE 3

Removing Second Filter

Switching Filter Sizes

1. To switch from 2" to 1" lters, start by removing

the lter slide and bend the tabs up (see Figures 4

and 5 on page 6).

2. Locate the lter support brackets and remove the

four (4) screws holding them to the top of the

control panel (see Figure 6 on page 6).

Filter

Removal Slide

FIGURE 2

Removing Left Filter

Manual 2100-723C

Page 6 of 39

NOTE: When installing new filters, make sure that

airflow arrows on filters point up.

7. Reverse the steps above to switch from 1" to 2"

lters.

FIGURE 6

Remove Four Screws

FIGURE 7

Re-Install Filter Support Brackets into Upper Slots

3. Pull the brackets out towards the front of the unit.

The back of the bracket will slip out of the lower

slots at the back of the lter tray.

4. Re-install the lter support brackets into the upper

slots at the back of the lter tray (see Figure 7).

5. Re-install the four (4) screws into the lower

screw holes on the lter support brackets. If the

tabs have been bent down, they will need to be

straightened out to be used.

6. Install the right 1" lter rst followed by the left

lter (see Figures 8 and 9).

Upper slots for

1" lters

Lower slots for

2" lters

FIGURE 8

Install Right 1" Filter

FIGURE 9

Install Left 1" Filter

FIGURE 4

Filter Tabs in Down Position

FIGURE 5

Bend Filter Tabs to Up Position

Manual 2100-723C

Page 7 of 39

Fresh Air Intake

All units are built with fresh air inlet louvers punched

in the side grilles.

If the unit is equipped with a fresh air damper assembly,

the assembly is shipped already attached to the unit.

The damper blade is locked in the closed position. To

allow the damper to operate, remove the two (2) screws

in the bottom of the blade (see Figure 10). Remove right

side grille to access the damper blade.

There is an adjustable slide on the side of the fresh air

intake that can be adjusted to limit how far the damper

opens so that the amount of fresh air that enters the

structure is regulated.

Graphs found on pages 38 and 39 give approximate

fresh air amounts based on the slide adjustment

setting.

All capacity, efciency and cost of operation

information is based upon the fresh air blank-off plate

in place.

The blank-off plate is available upon request from the

factory and is installed in place of the fresh air damper

shipped with each unit.

MIS-3977

MIS-3977

BLADE IS SCREWED CLO

SED

FOR SHIPPING. REMOVE

(2)

SCREWS FOR FRESH AIR IN

TAKE

DURING UNIT OPERA

TION.

Blade is screwed closed for

shipping. Remove two (2)

screws for fresh air intake

during unit operation.

FIGURE 10

Fresh Air Damper

Manual 2100-723C

Page 8 of 39

INSTALLATION

Basic Installation Design and

Application Planning

Successful unit installations require proper planning

and site inspection before installation begins. Before

installing the wall mount unit, make sure that all

service and airow clearances are met and that the

unit can meet all applicable code and regulation

requirements. Provide an inspection of both the inside

and outside of the structure by reviewing oorplans

and/or visiting the installation site.

Wall Construction

The wall must be inspected to ensure that the weight

of the unit can be supported. Be sure to review all

applicable construction codes and regulations including

seismic requirements. When inspecting wood frame

walls, the wall construction must be strong and

rigid enough to carry the weight of the unit without

transmitting any unit vibration. It is important that

the side unit wall mounting lags and optional bottom

bracket are supported by structural members inside

the wall cavity. Concrete block and brick walls must be

thoroughly inspected to ensure that they are capable of

carrying the weight of the installed unit. Metal buildings

must contain structural components to support the unit

weight. If heavily corrugated siding is present, it may

need to be trimmed and ashed similar to a window

to provide a at, even surface to attach and seal the

unit to the wall. Heavy gauge corrugations that would

be present on shipping containers and blast-proof

structures may require the installation of a metal plate

over the corrugated area. It is important that the unit

area is weatherized and sealed to avoid air and water

inltration into the area between the unit and the wall.

Outdoor Area Inspection

Inspect the outdoor area of the jobsite or review

construction plans and locate the area where the wall

mount is to be installed. The outdoor area must be

free from obstructions including fences, bushes and

walls that will hinder unit operation regarding outdoor

condenser airow and unit serviceability. Do not

install units in enclosed areas that limit the amount

of ambient temperature airow. Warm air will exit

the front condenser section of the unit, and outdoor

ambient temperature air must be able to enter side

intake condenser openings of the unit. Portable or

modular building placement must be in a way that the

wall mount units have a constant supply of outdoor air

for proper unit operation. Make sure that the service

panels of the unit are accessible. Inspect wall surfaces

for obstructions that could hinder unit installation

and servicing including outdoor electrical conduits,

junction boxes, wall drains, vent hoods, windows, doors,

overhangs and posts.

Condensate Water Drainage

Review all codes and requirements for unit condensate

drainage. A clear, exible PVC drain hose (3/4" ID, 1"

OD) extends from the drain pan in the upper section of

the unit and extends down to the unit base. An opening

is supplied towards the back of the unit base for the

drain hose to pass through, and the hose extends 1"

to 2" below the unit base. Water removed from the

indoor air (condensate) will be expelled from the unit

in large amounts during cooling operation through the

hose. Units running in cooling operation in cold outdoor

below freezing conditions can cause the condensate

to freeze after leaving the drain hose. In the event the

drain hose is connected to a drain system of some type,

it must be an open or vented type system to ensure

proper drainage throughout seasonal use.

Indoor Ducted and Non-Ducted

Applications

Air distribution inside the structure being conditioned

plays an important role in making sure the area is

a consistent temperature. Improper air distribution

can result in areas being cooler or warmer, electrical

equipment not receiving sufcient airow or occupancy

discomfort felt inside an area. Thermostat or indoor

temperature sensor placement inside the area being

conditioned also plays an important role in indoor

climate control.

Indoor Supply Airow

Indoor installation areas must provide a non-restrictive

path for the conditioned supply air to leave supply

grilles and registers. Inspect the area to ensure that all

indoor portions of the room or rooms will have access

to supply air. Ductwork may be used to ensure proper

air circulation and all provided ductwork guidelines and

clearances must be followed. Non-ducted applications

must use a supply louver grille installed over the supply

opening inside the room. Be sure to adjust supply

deectors to properly disperse the conditioned supply

air to all parts of the room. Avoid closing sections of

the supply grilles which would cause unneeded supply

duct pressurization.

Indoor Return Airow

A non-restrictive path for room air returning to the

center section of the unit must be provided inside

the room. Avoid placing objects including furniture,

electronics equipment, equipment racks and cabinets

directly in front of the unit return grilles and registers.

Bard recommends at least 2' between solid objects

and return grilles or registers. Ductwork may be used to

ensure proper air circulation and all provided ductwork

guidelines and clearances must be followed. Non-

ducted applications must use a return louver grille

installed over the return opening inside the room.

Manual 2100-723C

Page 9 of 39

Ducted Applications

Field fabricated supply and return duct work may be

installed inside the structure being conditioned. A short

supply and/or return stub duct may be connected to the

unit supply and return anges before unit installation to

help with duct connections inside the structure. Supply

and return ducts must be properly sized for the design

airow requirement of the equipment. Air Conditioning

Contractors of America (ACCA) is an excellent guide

to proper sizing. All duct work or portions thereof not

in the conditioned space should be properly insulated

in order to conserve energy, reduce heat conductivity,

and prevent condensation or moisture damage. Refer

to the Maximum External Static Pressure (ESP) of

Operation – Electric Heat Only table on page 35.

Design the duct work according to methods given by

the Air Conditioning Contractors of America (ACCA).

When duct work is installed in unheated spaces, it

should be insulated with a minimum of 1" of insulation.

Use insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect

the duct work to the equipment in order to keep the

noise transmission to a minimum. Ducts through the

walls must be insulated and all joints taped or sealed to

prevent air or moisture from entering the wall cavity.

All model series require a 1/4" clearance to

combustible material for the rst 3' of duct attached to

the outlet air frame. See instructions on page 10 and

Figures 13 − 17 (pages 13 – 16) for further details.

A non-restrictive metallic supply air grille with

deectors is required for free blow applications. Contact

the local Bard distributor or visit www.bardhvac.com for

ordering information.

A metallic return air grille is required for non-ducted

applications. The spacing between louvers on the grille

shall not be larger than 5/8". It is recommended that a

Bard Return Air Grille Kit is installed that is designed

specically for the wall mount product. Contact the

local Bard distributor or visit www.bardhvac.com for

ordering information. A eld-supplied return grille

that meets the 5/8" louver criteria and does not cause

the unit to exceed the maximum specied external

static pressure (ESP) may be used. If using a return

air lter grille, lters must be of sufcient size to

allow a maximum velocity of 400 fpm. Filter return

air grilles do not lter air being brought into the

structure through ventilation options including fresh air

dampers, ventilators, economizers and energy recovery

ventilators. Be sure to install the return grille with the

louvers pointed downward towards the oor. This will

help ensure return air is drawn upward from the oor

and improve air circulation in the room.

NOTE: If no return air duct is used, applicable

installation codes may limit this cabinet to

installation only in a single story structure.

Thermostat or Indoor Temperature Sensor Placement

The location and installation of the thermostat or

temperature sensor that monitors indoor temperature is

very important regarding unit operation. Avoid placing

the thermostat in an area exposed to direct sunlight

or air from doorways leading outdoors. Use a piece

of insulating material to close off conduit openings

or holes in the wall surface for wire entry into the

thermostat or temperature sensor. This will help avoid

non-conditioned air from entering the thermostat

and effecting temperature and/or humidity readings.

As common practice, the thermostat or temperature

sensor should measure the temperature of the air

being returned to the unit, and not the conditioned

air being supplied by the unit. Placing the thermostat

or temperature sensor near a return air opening will

normally result in optimal unit performance.

Unit Installation

Make sure to have the proper tools at the work site that

are needed for unit installation. The following steps

are provided to ensure the unit is installed properly to

the wall surface, and that the unit will provide years of

service with minimal service requirements.

Materials/Tools List

Additional hardware and miscellaneous supplies are

needed for installation. These items are eld supplied

and must be sourced before installation. This list also

includes tools needed for installation.

Fire hazard.

Maintain minimum 1/4" clearance between the

supply air duct and combustible materials in

the rst 3' of ducting.

Failure to do so could result in re causing

damage, injury or death.

!WARNING

Free Blow Applications

Some installations may not require extensive supply

duct work throughout the structure and are referred

to as free blow applications. A short eld-fabricated

supply duct must be used in the wall cavity to

transition between the supply collar on the unit and

the supply louver grille in the room. The duct must

be properly insulated in order to conserve energy,

reduce heat conductivity and prevent condensation or

moisture damage. All joints must be taped or sealed to

prevent air or moisture entering the wall cavity. Follow

all clearances including distances to combustible

materials and all instructions provided in this manual.

Manual 2100-723C

Page 10 of 39

• Appropriate safety gear including gloves and safety

glasses

• 5/16" hex bit with drill driver

• Phillips head screwdriver

• Small straight (thermostat) screwdriver

• Tape measure

• Leveling device

• Two (2) tubes of caulk and caulk gun

• Utility knife

• Tools for cutting holes in the wall surface (if

needed)

• Electrical components and wiring along with

electrical tools

• Multimeter

• Wall fasteners for side anges, bottom mounting

bracket and top rain ashing.

• Duct tape and/or other duct sealing materials.

Wall Preparation

1. Two holes for the supply and return air openings

must be cut through the wall as shown in Figure

13 on page 13. Be sure the openings are square

and level. Follow all clearances including distances

to combustible materials and all instructions

provided in this manual.

2. Review all electrical requirements provided in this

manual and plan out electrical entrances into the

building. Also plan electrical conduit routing and

thermostat placement, if necessary.

3. Install necessary duct work and prepare the

openings for unit installation.

4. Clean the exterior wall where the unit is to be

installed and make sure it is able to provide a

smooth, level, debris-free surface. Remove all

construction debris from the supply, return and

electrical hole cutting process.

Wall Mount Installation to Wall Surface

1. Remove packaging from unit and make sure the

unit is not damaged before installation. A top rain

ashing is supplied for eld use and is mounted to

the back of the unit for shipping. Remove the rain

ashing before locating the unit against the wall.

Top rain ashing is required to avoid water entering

the area behind the unit that is against the wall. A

bottom mounting bracket, attached to the skid for

shipping, is provided for ease of installation but

is not required. Review all requirements listed on

unit labels and on serial plate located on the side

of the unit.

2. Locate and mark bolt hole locations and bottom

mounting bracket location. Install bottom

mounting bracket with eld-supplied fasteners to

wall if it is to be used (optional). Bracket must be

level and installed in the correct location to help

support the unit during the installation process

(see Figure 13).

3. Position the wall mount unit close to the wall

surface where it will be installed. Install rain

ashing at the top of the unit facing the wall by

hooking the hem bend into the rear bend of the

unit top (see Figure 13).

4. Apply a liberal amount of caulk on left and right

cabinet side wall mount brackets and back of

top rain ashing. Place unit back surface ush

against wall. Unit must be level to ensure proper

condensate drainage. Optional bottom bracket may

be used to help support the unit.

5. Units are secured to the wall by using eld-

supplied fasteners along each side of the wall

mount through the built-in wall mounting brackets.

It is the responsibility of the installer to select

the proper fastener to secure the unit to the wall

based on wall construction and applicable building

codes. Typical installations may include 5/16"

fasteners with 7/8" diameter at washers. Be sure

unit is securely mounted and all weight-bearing

fasteners are attached to the weight supporting

structural members of the wall.

6. Apply a bead of caulk between the back of the unit

top and the front surface of the top rain ashing

(see Figure 13).

7. Connect unit duct work from the inside of the

building following all clearances and instructions

provided. For additional mounting rigidity, the

return air and supply air frames or collars can be

drilled and screwed or welded to the structural wall

itself (depending upon wall construction). Be sure

to use code approved duct tape or other sealing

materials to seal the duct work to the unit.

8. On side-by-side installations, maintain a minimum

of 20" clearance on both sides to allow access to

heat strips and to provide proper airow to the

outdoor coil. Additional clearance may be required

to meet local or national codes.

Manual 2100-723C

Page 11 of 39

* For vent installation and removal, one side of the unit

requires 45" clearance in the vent area. See Figure

11 for clarity.

See Specications Sheet S3590.

TABLE 1

Clearance Required for Service Access and

Adequate Condenser Airow

Model Left

Side

Right

Side

Discharge –

Front

J42AC

J48AC

J60AC

J72AC

20" 20" 10'

TABLE 2

Minimum Clearances Required

to Combustible Materials

Model Supply Air Duct (1st 3') Cabinet

J42AC

J48AC

J60AC

J72AC

1/4" 0"

FIGURE 11

Vent Installation/Removal Clearance Required

2034"

2"

3714"

1734"

45"

MIS-4042

KEEP AREA

CLEAR FOR 45"

IN FRONT OF

SIDE PANEL

OBJECT OR WALL

IN THIS SECTION OR ANY

OTHER OBSTRUCTION

OF UNIT

OR RIGHT SIDE OF UNIT

CLEARANCE NEEDED ON LEFT

VENT ASSEMBLY

SHOWN OUTSIDE

AVOID LOCATING UNIT DISCONNECT

VENTS CAN BE INSTALLED

FROM EITHER SIDE OF UNIT.

45"

Manual 2100-723C

Page 12 of 39

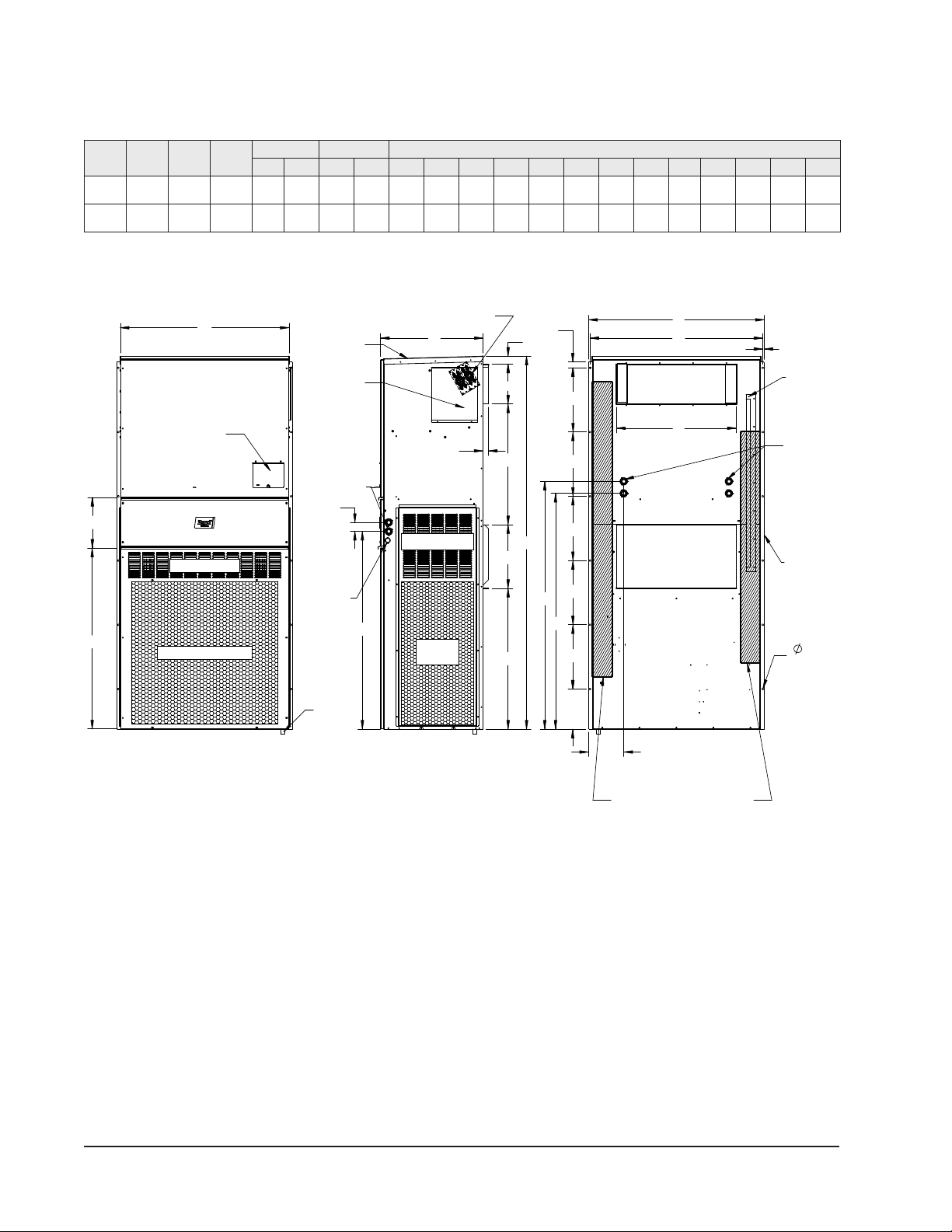

FIGURE 12

Unit Dimensions

Width

(W)

Depth

(D)

Height

(H)

Supply Return

A B C B E F G I J K L M N O R S T

J42AC

J48AC 42.00 25.52 84.75 9.88 29.88 15.88 25.52 43.88 12.63 39.06 30.06 43.25 26.94 55.59 52.59 8.82 43.00 1.44 16.00 1.88

J60AC

J72AC 42.00 25.52 92.88 9.88 29.88 15.88 25.52 43.88 12.63 45.00 30.06 49.25 35.06 61.72 58.72 8.82 43.00 1.44 16.00 10.00

All dimensions are in inches. Dimensional drawings are not to scale.

2.000

Return Air Opening

Supply Air Opening

MIS-3978 A

Condenser Air Outlet

Ventilation Air

Inlet

Cond. Air

Exhaust Air

Brackets

(Built In)

Mounting

Side Wall

Location

Shipping

Flashing

Top Rain

DO NOT PLACE ELECTRICAL

ENTRANCES IN SHADED AREAS

ABOVE DUE TO POTENTIAL

INTERFERENCE WITH COPPER TUBING

L

O

B

E

.375

M

N

T

S

S

S

S

S

R

.375

TYP.

Access Panel

(Lockable)

Disconnect

C. Breaker/

Filter Behind Control Panel Door

Optional

Electrical

Entrance

Drain

W

G

F

4° Pitch

Rain Hood

Electrical

Panel

High Voltage

Built In

Entrance

Heater Access

Electric Heat

Low Voltage

Electrical

Entrance

1.375

A

K

H

D

C

I

2.250

J

Manual 2100-723C

Page 13 of 39

FIGURE 13

Mounting Instructions

13

4"4"

D

16"

16"

16"

16"

16"

61

2"61

2"

1" 3"

4"

Typ.

4"

Typ.

61

2"30"

E

F

A CC

B

G

SEAL WITH BEAD

OF CAULKING ALONG

ENTIRE LENGTH OF

TOP.

WALL

WALL STRUCTURE

1/4" CLEARANCE ONALL

FOUR SIDES OFSUPPLY

AIRDUCTIS REQUIRED

FROM COMBUSTABLE

MATERIALS

HEATER ACCESS

PANEL

FOAMAIRSEAL

RAIN FLASHING

SUPPLIED

TOP

Right Side ViewWall Opening and Hole Location View

Supply Opening

Return Opening

UNITS REQUIRED DIMESIONS A B C D E F G

J42AC-J48AC

UNITS

REQUIRED DIMESIONS TO

MAINTAIN 1/4" MIN. CLEARANCE

FROM COMBUSTIBLE

MATERIALS 30 1/2 10 1/2 6 1/4 1 1/4 29 3/4 16 1 7/8

REQUIRED DIMENSIONS TO

MAINTAIN RECOMMENDED 1"

CLEARANCE FROM

COMBUSTIBLE MATERIALS 32 12 5 1/2 2 29 16 1 7/8

J60AC-J72AC

UNITS

REQUIRED DIMESIONS TO

MAINTAIN 1/4" MIN. CLEARANCE

FROM COMBUSTIBLE

MATERIALS 30 1/2 10 1/2 6 1/4 1 1/4 29 3/4 16 10

REQUIRED DIMENSIONS TO

MAINTAIN RECOMMENDED 1"

CLEARANCE FROM

COMBUSTIBLE MATERIALS 32 12 5 1/2 2 29 16 10

MIS-4069 A

Manual 2100-723C

Page 14 of 39

FIGURE 14

Electric Heat Clearance

NOTE 1: SIDE SECTION VIEW OF SUPPLY AIR

DUCT FOR WALL MOUNTED UNIT SHOWING 1/4"

CLEARANCE TO COMBUSTIBLE SURFACES.

Fire hazard.

Maintain minimum 1/4" clearance between the

supply air duct and combustible materials in

the rst 3' of ducting.

Failure to do so could result in re causing

damage, injury or death.

!WARNING

Manual 2100-723C

Page 15 of 39

FIGURE 15

Wall Mounting Instructions

FIGURE 16

Wall Mounting Instructions

I

A

C

K

E + 1.000

B

1.000

L

C

STRUCTURAL STEEL

2 x 6

SEE UNIT DIMENSIONS, FIGURE 2,

FOR ACTUAL DIMENSIONS.

SUPPLY DUCT

OPENING

FRAMING MATERIAL

ALL AROUND DUCT

1.000" CLEARANCE

2 x 4'S, 2 x 6'S &/OR

OPENING

RETURN DUCT

INTERIOR FINISHED WALL

OVER FRAME

EXTERIOR FINISH WALL

OVER FRAME

ATTACH TO BOTTOM

PLATE OF WALL

1.000" CLEARANCE

ALL AROUND DUCT

ATTACH TO TOP

PLATE OF WALL

THIS STRUCTURAL MEMBER

LOCATED TO MATCH STUD

SPACING FOR REST OF WALL.

ASECOND MEMBER MAY BE

REQUIRED FOR SOME WALLS.

MIS-3982

SEE UNIT DIMENSIONS, FIGURE 12,

FOR ACTUAL DIMENSIONS

See Figure 13 Mounting Instructions

WALL BEFORE

CONCRETE BLOCK WALL INSTALLATION

OPENING

RETURN AIR

WALL STRUCTURE

INSTALLING UNIT.

OPENING

WOOD OR STEEL SIDING

MOUNT ON UNIT

BOTTOM MOUNTING

WOOD FRAME WALL INSTALLATION

BRACKET. MOUNT ON

BEFORE INSTALLATION

SIDE VIEW

FACTORY SUPPLIED

RAIN FLASHING.

SUPPLY AIR

MIS-3981 A

Manual 2100-723C

Page 16 of 39

FIGURE 17

Common Wall Mounting Installations

FLASHING

RECOMMEND WALL SLEEVE

WALL

RAIN

SUPPLY DUCT MAYBE LOCATED IN AN ATTIC

SUPPLY AIR DUCT

FINISHED CEILING

RAFTERS

WALL

OPENING WITH

CEILING SURFACE

OUTSIDE

WALL

WALL

WALL SLEEVE

SUPPLY DUCT MAY BE LOCATED IN AN ATTIC

FINISHED CEILING SURFACE

RAIN

CLOSET WALL

FINISHED CEILING SURFACE

RAIN

RECOMMEND WALL SLEEVE

RAFTERS

GRILLE

FLASHING

OR BELOW CEILING RAFTERS AS SHOWN

OR BELOW CEILING RAFTERS AS SHOWN

FLASHING

OUTSIDE

SURFACE

RAIN

FLASHING

SLEEVE

FINISHED

SUPPLY DUCT MAYBE LOCATED IN AN ATTIC

GRILLE

OUTSIDE

OR BELOW CEILING RAFTERS AS SHOWN

SUPPLY AIR DUCT

RAFTERS

RETURN AIR

RETURN AIR

RETURN AIR

OPENING WITH

GRILLE

FALSE WALL

SUPPLY AIR DUCT

OPENING WITH GRILLE

FALSE WALL INSTALLATION CLOSETINSTALLATION

DUCTED SUPPLY

RETURN AT UNIT

FREE AIR

NO DUCT

MIS-4043 A

RAISED FLOOR

RETURN AIR

RETURN AIR

GRILLE

SUPPLY AIR

GRILLE

SUPPLY AIR DUCT

LOWERD

CEILING

OUTSIDE

WALL

RAFTERS

RETURN AIR

SPACE

Manual 2100-723C

Page 17 of 39

Wiring – Main Power All models are suitable only for connection with copper

wire. Each unit and/or wiring diagram will be marked

“Use Copper Conductors Only”. These instructions

must be adhered to. Refer to the National Electrical

Code (NEC) for complete current carrying capacity data

on the various insulation grades of wiring material. All

wiring must conform to NEC and all local codes.

The electrical data on the serial plate, in the unit

specications and also in Table 10 on page 31 list fuse

and wire sizes (75°C copper) for all models including

the most commonly used heater sizes. Also shown are

the number of eld power circuits required for the

various models with heaters. The unit rating plate lists

a “Maximum Time Delay Relay Fuse” or circuit breaker

that is to be used with the equipment. The correct type

and size must be used for proper circuit protection and

also to ensure that there will be no nuisance tripping

due to the momentary high starting current of the

compressor motor.

Three phase models must have proper phasing. A phase

monitor is included in all three phase models, and will

indicate improper phasing during a call for cooling

(24VAC at Y1 terminal). See provided information

included in this document regarding the phase monitor.

High Voltage Connections

Route eld wires under the eld wire shield shown in

Figure 18. (The eld wire shield can be removed for

wire installation.) If eld power is supplied to the left

side of the unit, run the high voltage wires under the

shield and to the right of the wire shield next to the

compressor contactor and up into the upper control

FIGURE 18

High Voltage Connections

MIS-4044

MIS-4044

USE CONDUIT

WHEN FIELD WIRES

COME IN THROUGH

THE BACK

RIGHT SIDE VIEW

WIRE SHIELD

FIELD HIGH OR LOW

VOLTAGE WIRE SHIELD

FRONT VIEW

MIS-4044

USE CONDUIT

WHEN FIELD WIRES

COME IN THROUGH

THE BACK

RIGHT SIDE VIEW

WIRE SHIELD

FIELD HIGH OR LOW

VOLTAGE WIRE SHIELD

FRONT VIEW

Electrical shock hazard.

Do not operate this equipment without an

earth ground attached and always disconnect

the remote electric power supplies before

servicing.

Electrical shock can result in serious injury or

death.

!WARNING

Main electrical power must be supplied to the unit

from a clean, reliable power source. Verify voltage being

supplied to the unit is consistent during all times of the

day and within the range specied for the unit in the

unit specications and on the unit serial plate. Voltage

must be measured at the eld power connection point

in the unit and while the unit is operating at full load

(maximum amperage operating condition).

Refer to the unit serial plate and unit specications

for wire sizing information and maximum fuse or

circuit breaker size. Each outdoor unit is marked with

a “Minimum Circuit Ampacity”. This means that the

eld wiring used must be sized to carry that amount

of current. Depending on the installed KW of electric

heat, there may be two eld power circuits required. If

this is the case, the unit serial plate will so indicate.

Manual 2100-723C

Page 18 of 39

panel where the connections are made. If eld power is

supplied to the right of side of the unit, the low voltage

wires can be run under the eld wire shield to access

the low voltage terminal strip.

When eld wires are supplied through the back of the

unit, exible conduit must be extended through the

back of the unit and terminate into the knock-outs on

the upper control panel (see Figure 18).

Wiring – Low Voltage

All 230/208V 1 phase and 3 phase equipment have

dual primary voltage transformers. All equipment leaves

the factory wired on 240V tap. For 208V operation,

reconnect from 240V to 208V tap. The acceptable

operating voltage range for the 240 and 208V taps are:

Tap: 240 Range: 253 – 216

Tap: 208 Range: 220 – 187

NOTE: The voltage should be measured at the field

power connection point in the unit and while

the unit is operating at full load (maximum

amperage operating condition).

For low voltage wiring, an 18 gauge copper, color-

coded cable is recommended. See Table 6 for more

information.

Low Voltage (24VAC) Connections

These units use a 24-volt AC low voltage circuit.

Cterminal is the 24VAC common and is grounded.

Gterminal is the indoor blower input.

Y1 terminal is the 1st Stage input for cooling.

Y2 terminal is the 2nd Stage compressor input for cooling

(if equipped with an economizer) or Y2 disables Balanced

Climate mode if the Y1-Y2 jumper is removed (see page

24).

B/W1 terminal is the 1st stage electric heat.

W2 terminal is the 2nd stage heat (if equipped).

Aterminal is the ventilation input. This terminal

energizes any factory-installed ventilation option and

indoor blower.

Lterminal is 24 volt alarm active output.

For units equipped with an alarm relay:

1 terminal is the normally closed contact on the relay.

2 terminal is the normally open contact on the relay.

3 terminal is the common contact on the relay.

Unit Shutdown Feature (Standard on All Models)

The RT terminal is the 24VAC transformer output,

and the R terminal is the 24VAC hot terminal for the

operation of the equipment. RT and R are connected

with a brass jumper bar which can be removed and RT

and R connected to an external NC (normally closed)

contact such as a re/smoke detector that will cause

shutdown of the equipment upon activation.

Balanced Climate™ Feature (Standard on All Models)

All units are equipped with the capability of running

in Balanced Climate mode. This mode is designed to

enhance the comfort level by reducing the indoor airow

amount and extending the run time to help extract more

humidity during cooling operation. The Y1 terminal

is the 24VAC input for Balanced Climate compressor

cooling operation. The Y2 terminal is the 24VAC input

for compressor cooling standard operation. Y1 and Y2

are connected with a brass jumper bar which can be

removed to enable Balanced Climate mode. Units with

an economizer will not have the brass jumper installed.

Refer to vent manuals for instructions on how Balanced

Climate works with each vent.

To operate in Balanced Climate mode, a 2-stage

cooling thermostat is required. The lower indoor airow

operation is overridden by utilizing a 2-stage thermostat.

If the call for cooling is not satised within a given

time frame or temperature differential (specied by

the thermostat), the thermostat will send a signal to

Y2 which then increases the blower speed back to the

selected speed. See pages 32

– 34

for blower speed

selection options.

Refer to page 23 for additional Balanced Climate

requirements and limitations.

Ventilation Features (Optional)

See ventilation instructions provided with unit for low

voltage wiring.

Low Ambient Control (LAC)

The low ambient control is a pressure switch that is

attached to the liquid line of the system and monitors

high side pressure. Operation of the LAC occurs as

outdoor temperatures drop below 60°F. LAC operation

cycles the condenser fan on/off based on pressure

changes caused by outdoor temperature changes.

Outdoor Temperature Switch and Freeze Protection

Thermostat

An outdoor temperature switch and an evaporator

freeze protection thermostat is supplied with all units

that have a low ambient control. The outdoor switch

disables Balanced Climate mode (if enabled) when

the temperature drops below 50°F. This prevents

potential evaporator coil freeze up issues. For units

with mechanical dehumidication, this switch must

remain disconnected when Balanced Climate mode

is not being used. Refer to unit wiring diagram. The

freeze thermostat cuts out compressor operation if the

evaporator begins to freeze up.

Alarm Relay Feature (Controls Option)

The alarm relay provides a set of NO (normally open)

and NC (normally closed) pilot duty contacts that

operate when the compressor control module locks out

compressor operation because of a high or low system

refrigerant pressure event.

Manual 2100-723C

Page 19 of 39

TABLE 4

Humidity Controls

Part Number Predominate Features

8403-038

(H600A1014)

SPDT switching, pilot duty 50VA @ 24V;

Humidity range 20-80% RH

8403-047

(H200-10-21-10)

Electronic dehumidstat SPST closes-

on-rise; Humidity range 10-90% with

adjustable stops

TABLE 5

CO2Controllers

Part Number Predominate Features

8403-056

CO2ventilation control with digital display.

Normally Open SPST (Default: Close at

800ppm)

8403-067

Normally Open SPST relay closes-on-rise

24V dual wave length sensor. Default setting

950ppm, adjustable to 0-2000ppm

Default off setting 1000ppm, adjustable to

0-200 ppm can be calibrated

TABLE 6

Thermostat Wire Size

Transformer

VA FLA Wire Gauge

Maximum

Distance

In Feet

55 2.3

18 gauge

16 gauge

14 gauge

12 gauge

60

100

160

250

TABLE 3

Wall Thermostats

Part Number Predominate Features

8403-057

(TH3110D1040)

1 stage Cool, 1 stage Heat; Electronic Non-Programmable; Auto or Manual changeover

8403-059

(TH5220D1219/U)

2 stage Cool, 2 stage Heat; Electronic Non-Programmable; HP or Conventional (Default: AC); Auto or Manual

changeover

8403-060

(1120-445)

3 stage Cool; 3 stage Heat; Electronic Programmable/Non-Programmable; HP or Conventional; Auto or Manual

changeover; Dehumidication Output

CS9B-THO

3 stage Cool, 3 stage Heat; Programmable/Non-Programmable; HP or Conventional; Auto or Manual Changeover;

Humidity Sensor w/ dehumidication; Motion Sensor w/Intelligent Learning Control; BACnet-compatible

CS9B-THOC

3 stage Cool, 3 stage Heat; Programmable/Non-Programmable; HP or Conventional; Auto or Manual Changeover;

Humidity Sensor w/ dehumidication; CO2Sensor; Motion Sensor w/Intelligent Learning Control; BACnet-compatible

CS9BE-THO

3 stage Cool, 3 stage Heat; Programmable/Non-Programmable; HP or Conventional; Auto or Manual Changeover; Humidity

Sensor w/ dehumidication; Motion Sensor w/Intelligent Learning Control; BACnet-compatible; Ethernet-compatible

CS9BE-THOC

3 stage Cool, 3 stage Heat; Programmable/Non-Programmable; HP or Conventional; Auto or Manual Changeover;

Humidity Sensor w/dehumidication; CO2Sensor; Motion Sensor w/Intelligent Learning Control; BACnet-compatible;

Ethernet-compatible

8403-089

(T4 Pro)

1 stage Cool, 1 stage Heat – Heat Pump; 1 stage Cool, 1 stage Heat – Conventional; Programmable/Non-

Programmable Electronic; Auto or Manual changeover

8403-090

(T6 Pro)

2 stage Cool, 3 stage Heat – Heat Pump; 2 stage Cool, 2 stage Heat – Conventional; Programmable/Non-

Programmable Electronic; Auto or Manual changeover

8403-091

1 stage Cool, 1 stage Heat; Non-Programmable; FEMA use

8403-092

(T6 Pro Wi-Fi)

2 stage Cool, 3 stage Heat – Heat Pump; 2 stage Cool, 2 stage Heat – Conventional; Programmable/Non-

Programmable Electronic; Auto or Manual changeover; Wi-Fi

Manual 2100-723C

Page 20 of 39

FIGURE 19

Programmable Thermostat Connections

Thermostat W1/E AYO/D

LO/BY2Y1R GC W2

Bard #8403-060

61012

119 4

12-Pin

Vent Plug 23 5 7

CO2 OUT

Optional CO2 Controller

Bard Part #8403-096

6

5

4

3

2

1

TEMP-OUT

24VAC

W3 65421R

Unit Low

Voltage

Term. Strip W2C GRT Y1 Y2 B/W1 L DA 3

not present if economizer is factory installed. Units with economizers have balanced

Install jumper for 1 stage electric heat on units with more than 10KW

Y1 Y2 jumper

climate jumper in economizer, refer to economizer manual.

Factory installed jumper. Remove jumper to activate Balanced Climate™ mode.

8

7

6

Do not connect "A" from thermostat if optional CO2 controller is used

0-10 VDC modulating C02 control signal for modulating ventilation

control (optional for ECON only - see vent instruction manuals)

5

Change model configuration from heat pump to heat/cool. Must be configured to programmable

and fan set to be programmed fan for the "A" output tofunction during scheduled occupied

periods. Must be configured for multi-stage for Y1 output to be active 1st stage cooling. For

dehumidification, must be configured for "No Economizer" for YO/D to be active for humidity

control.

4

Factory installed jumper. Remove jumper and connect

to N.C fire alarm circuit if emergency shutdown required.

3

Wire not needed below 15KW.2Wire required for dehumidification models only.

1

Do not add these wires if setting up for modulating control. See note 5.

9A 2-stage thermostat is recommended for Balanced Climate mode.

W1/E

SC SC

SC

Completestat

Model #CS9B-THOA or

Model #CS9BE-THOA

W2

COM G

24V Y1 Y2 O/B L DA GND

MIS-3974

ALL VENT OPTIONS PLUG IN HERE

2

3

3

1

6

D

4

5

7

If notequipped withaventilation option to plug in, a jumper plug mustbe installed.

4

2

8

9

Other manuals for 11EER Series

1

This manual suits for next models

12

Table of contents

Other Solair Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu ART45L operating manual

Technibel

Technibel KPAFP125R5IA Series instruction manual

Midea

Midea BREEZELESS Technical manual

Sharp

Sharp CVP12PX - Ha Sh 11500 Btu Portable Air... Installation and operation manual

LG

LG A2UN186FA0 Service manual

Frigidaire

Frigidaire FFMS121CQ10 installation manual