SolarAttic PCS4 User manual

Installation

and

Operating Instructions

SolarAttic®

Solar Pool Heater

Pool Convection System 4™

U.S. Patents 5,014,770 5,452,710 5,746,653

SolarAttic Model PCS4™

This page intentionally left blank.

- 1 -

Table of Contents

Table of Contents.....................................................................................................................1

1. Introduction to SolarAttic........................................................................................ 2

•Solar Without Panels...................................................................................................2

•Basic Operation ...........................................................................................................2

•Description of Technology..........................................................................................2

•Automation..................................................................................................................2

2. Consider Before Installation ................................................................................ 2-3

3. Cautions & Warnings........................................................................................... 4-6

4. Installation........................................................................................................... 6-15

•ABC’s of Installation...................................................................................................6

•Locate the SolarAttic PCS4.........................................................................................6

•Retrofit Support System .......................................................................................... 6-7

•Basic Plumbing Diagram............................................................................................ 8

•Power The PCS4..........................................................................................................9

•Internal Wiring Diagram............................................................................................10

•Float Wiring Diagram................................................................................................11

•Goldline GL235 Solar Control ................................................................................. 12

•Goldline GL235 Circuit Board................................................................................. 13

•Automation Wiring Diagram.....................................................................................14

•Goldline GL235 Wiring Option................................................................................ 15

5. Operation.................................................................................................................16

6. General Service Notes.............................................................................................17

7. Spring Start Up .......................................................................................................17

8. Winterization..................................................................................................... 18-19

9. Winter Freeze Warnings........................................................................................19

10. Unattended Pools ................................................................................................ 19-20

11. Repairs.......................................................................................................................20

12. System Troubleshooting...........................................................................................20

•Troubleshooting Guide......................................................................................... 21-25

13. Safety Certification Label.........................................................................................26

14. Specifications.............................................................................................................27

15. Warranty ...................................................................................................................28

- 2 -

1. Introduction to SolarAttic

SOLAR Without PANELS: SolarAttic has

engineered the Pool Convection System to

heat your swimming pool, using your

attic and roof as a source of free energy.

When your attic gets hot, the SolarAttic

Swimming Pool Heater can add six

weeks on to each end of your

swimming season and

can raise your pool temperature 10-15

degrees over non-heated state. That

means your

family can enjoy the swimming

pool without having to pay high

heating bills. You get the

benefits of solar pool heating

withoutroof mounted solar

panels.

BASIC

OPERATION:

The simplified

graphic diagram

to the right shows

how the PCS4

works. When the

sun shines, the roof

acts as a large solar collec-

Cools your home,

as it heats the pool!

tor. Heat accumulates inside the attic. The PCS4 safely uses this attic heat to warm your pool. It elimi-

nates the need for solar roof panels. AND, as it heats your pool, it cools your home! This house cooling

effect can lower air conditioning costs 25-30% or more.

DESCRIPTION OF TECHNOLOGY: Solar radiation strikes the roof and reaches the attic through a

process called “conduction.” The SolarAttic pool heater is physically located inside the attic and then

transfers this solar radiation from the attic air into the swimming pool’s water through a process called

“forced air convection.”

AUTOMATION: Full automation is achieved by using an optional solar controller. When the attic is

4F warmer than the pool and the pool needs heat, the GL235 solar control automatically routes water

up to the PCS4 and turns it on. The solar control can also synchronize the pool pump--turning it on at

the same time--when an external relay is used in conjunction with the GL235. Temperature sensors

sense the pool and attic temperatures. The pool owner sets the desired pool temperature setting and

maximum heat extraction in the attic occurs automatically. Note: The pool pump must be turned on

during the time the PCS4 is turned on to effect heat transfer. And, water and air flow must be in sync.

2. Consider Before Installation

The following items should be considered prior to any installation.

1. Heat rises in a hot attic. Locate the PCS4 as high in the attic as is practical.

- 3 -

2. Airflow through the PCS4 is important. Do not obstruct air going in or out of the unit.

3. Recirculating the air within the attic works well for heat transfer. Locate the PCS4 within

the middle 1/3 of the attic. Do not locate near an end wall where the unit’s airflow will

become obstructed [finned intake side] or short circuited [air discharge side]. Short

circuiting means that discharged cooler air reflects back into the finned intake side of

unit.

4. Heat is drawn into the coil or finned side and cooler air is discharged from the fan side

[the two blower openings]. If the PCS4 is located off to one side the attic’s center 1/3rd,

make sure the coil side of the unit is facing the longest portion of the attic.

5. You can suspend the PCS4 on a platform using cargo straps or small chains. You can also

allow the PCS4 to sit on a platform that is connected to the attic structure. We

recommend that a one inch piece of foam be placed under the PCS4 and that a smitty pan

be used as a second layer of leak protection. This is actual plumbing code in some

locations.

6. The attic sensor can be cooled by the air discharge of the PCS4. Locate the attic sensor at

the peak of the attic and out of the airflow of the unit. This prevents erratic on and off

cycling caused by the cooling effect of the discharge air. Note: The discharge air of the

PCS4 [blower side of unit] can run 20-30 degrees Fahrenheit cooler than the intake air

[coil finned side of unit]. All performance criteria was developed on the basis that the

attic temperature sensor would sense the PEAK attic temperature. That is the temperature

at the very apex of the attic where the roof sections join. If this sensor is lowered from the

actual attic peak, heat transfer performance can be dramatically reduced.

7. The pool water sensor can be influenced by the sun and rain. Shelter the pool water

sensor as much as possible. It can even be insulated if necessary with fiberglass or

other materials. Midnight rain “cooling” the pool sensor can fake the solar control into

thinking the pool needs heat when it doesn’t. An exposed pool sensor might also cause

erratic on and off conditions if not protected (sheltered or insulated) properly.

8. The ground can “SINK” heat away from pipes going to and from the PCS4. Insulate or

wrap all underground pipes so the ground does not contact the pipes directly. Bubble

wrap over the pipes that prevents the wet ground from coming into direct contact with

the horizontal buried pipes is usually sufficient. It is not necessary to insulate vertical

above-ground pipes.

9. Use 2" PVC pipe to reduce friction losses and on all pools with a pool pump greater

than one horsepower in size. This is especially important for long pipe runs and large

pumps.

10. If you use the recirculating freeze protection in the GL235, it will disable the optional

leak detection float of the PCS4 and prevent the pump and/or the PCS4 from turning off.

11. The mechanical stress caused by unsupported pipes can crack glued PVC joints.

Support all pipes in and outside of the attic with straps or C-clamps that keep the

weight of the pipes off of all joints and union connections. Do not allow the pipe to sag

in the attic.

12. If excessive attic heat is a local concern, CPVC pipe can be used instead of PVC pipe.

All external PVC piping should be painted to avoid deterioration from sunlight. Flex

PVC pipe can be used in the attic to avoid cementing joints in a closed and confined

- 4 -

area. This will provide a continuous length of pipe inside the attic without joints except

at the unit.

- 5 -

3. Cautions & Warnings

The following notes are CAUTIONS & WARNINGS designed to inform you of the existence of

areas of potential injury and hazard. These notes help to prevent personal injury and fatalities.

They will also help prevent damage to the SolarAttic Swimming Pool heater, swimming pool

systems or to the house.

MAKE SURE YOU READ AND UNDERSTAND THESE CAUTIONS & WARNINGS!

CHILDREN CAUTION: SHARP EDGES ON THE SOLARATTIC POOL HEATER CAN CAUSE

INJURY. **KEEP ALL CHILDREN AWAY FROM THIS PRODUCT TO PREVENT INJURIES OR

ACCIDENTS**

ELECTRICAL DANGER: THIS PRODUCT USES 115 VAC POWER AND CAN CAUSE A FATAL

INJURY IF SERVICED BY INEXPERIENCED PEOPLE. THIS MANUAL ASSUMES THAT AN

EXPERIENCED ELECTRICIAN IS BEING EMPLOYED. ALL ELECTRICAL WIRING MUST BE

DONE IN ACCORDANCE WITH LOCAL, STATE AND NATIONAL ELECTRICAL CODES.

PLUMBING CAUTION: THIS PRODUCT REQUIRES PVC CEMENT WELDING AND THIS

MANUAL ASSUMES AN EXPERIENCED PLUMBER IS BEING EMPLOYED. DO NOT ACCEPT

ANY LEAKING PVC JOINTS. DAMAGE TO THE VALVES FROM POOR PVC WELDING IS NOT

COVERED BY THE MANUFACTURERS WARRANTY. ASSEMBLE THE VALVES AND PIPES

BEFORE ACTUAL WELDING TO MAKE SURE THE JOINTS FIT PROPERLY. THIS ENSURES

YOUR PARTS ARE READY FOR PERMANENT CEMENTING.

PLUMBING CAUTION: DO NOT USE DRAIN-WASTE (HOUSE SINK OR DRAIN) PVC FITTINGS

(45OR 90ELBOWS, STRAIGHT SXS FITTINGS, ETC.) ON YOUR POOL’S SUPPORT SYSTEM

REASSEMBLY. USE SCHEDULE 40 PVC OR CPVC FITTINGS. THE DRAIN-WASTE PVC

FITTINGS DO NOT HAVE THE SAME DEPTH OF PVC PIPE PENETRATION, WHICH COULD

RESULT IN THE POOL’S PVC PIPE POPPING AWAY FROM THE SHORTER DRAIN-WASTE PVC

FITTING (ELBOW, ETC.).

FIN CAUTION: THE FINS ON THE WATER COIL ARE SHARP AND CAN CAUSE A RAZOR- LIKE

CUT IF YOUR HAND OR ARM COME INTO CONTACT WITH THEM. TAKE APPROPRIATE CARE

DURING INSTALLATION AND DO NOT COME INTO DIRECT CONTACT WITH THE FINS OF THE

COIL. IF THE COIL FINS ARE ACCIDENTALLY DAMAGED, THEY CAN BE “COMBED” STRAIGHT

WITH A FIN COMB [10 FINS PER INCH].

AIR MOVING ASSEMBLY CAUTION: THE PROTECTIVE GRILLE AND OTHER PARTS OF THE

AIR MOVING ASSEMBLY, INCLUDING THE BLOWER BLADES AND MOTOR, HAVE SHARP

EDGES WHICH CAN CUT YOUR FINGER OR HANDS. EXERCISE CAUTION WHEN HANDLING,

REMOVING OR INSTALLING ANY PART OF THE AIR MOVING ASSEMBLY.

BLOWER CAUTION: DO NOT OPERATE THE MOTOR WITH THE AIR MOVING ASSEMBLY

REMOVED. THE PROTECTIVE GRILLE IS TO PREVENT HARM WHILE THE BLOWER UNIT IS

OPERATING. UNPLUG THE SOLARATTIC POOL HEATER DURING SERVICE AND ENSURE

THAT THE BLOWER HAS STOPPED ROTATING.

- 6 -

MOTOR CAUTION: DO NOT OPERATE THE MOTOR FOR AN EXTENDED TIME WITHOUT THE

SQUIRREL CAGE ASSEMBLY ATTACHED. THE MOTOR IS A “TOTALLY ENCLOSED AIR OVER”

MOTOR [TEAO] AND THE AIRFLOW OVER THE MOTOR FROM THE CAGE PROVIDES MOTOR

COOLING. OPERATING THE MOTOR WITHOUT THE CAGE ASSEMBLY ATTACHED WILL LEAD

TO THE MOTOR OVERHEATING AND A THERMAL CUTOFF OF THE MOTOR [INTERNALLY].

TEKS SCREW CAUTION: DO NOT REPLACE ANY SELF-TAPPING #10-1/2 TEKS SCREW USED

ON THE REAR COIL SIDE WITH ANY SHEET METAL SCREW GREATER THAN ONE-HALF INCH

(1/2”) IN LENGTH. DOING SO CAN DAMAGE THE WATER COIL BY PUNCTURING ONE OF THE

COIL’S WATER PIPES OR MANIFOLDS. AS A GENERAL RULE, DO NOT USE ANY SHEET

METAL SCREW GREATER THAN 1/2 INCH IN LENGTH ON THE SOLARATTIC POOL HEATER.

WEIGHT CAUTION: THE PCS4 WEIGHS ABOUT 221 LBS CRATED AND 142 LBS UNCRATED.

THE PCS4 FILLED WITH WATER WEIGHS 163 LBS. IN ADDITION, THE UNIT IS BULKY.

CAUTION SHOULD BE TAKEN WHEN LIFTING THE UNIT SO AS NOT TO TWIST FROM THE

WAIST OR TO PLACE A BURDEN ON THE LOW BACK. NO ATTEMPT SHOULD BE MADE TO

LIFT THE UNIT ALONE. TWO OR MORE PEOPLE SHOULD BE PRESENT. ATTEMPTING TO

LIFT OR HANDLE THE PCS4 ALONE CAN LEAD TO PHYSICAL INJURY.

POOL CHEMISTRY CAUTION: AN IMPROPERLY MAINTAINED POOL WILL TURN ACIDIC

QUICKLY AND DAMAGE SUPPORT EQUIPMENT INCLUDING THIS HEATER. LOCATE ALL

CHEMICAL DISPENSERS DOWNSTREAM FROM THE PCS4.

BUILDING CODE CAUTION: INSTALL ALL EQUIPMENT IN ACCORDANCE WITH LOCAL, STATE

AND NATIONAL BUILDING CODES TO PREVENT ANY INJURY, FATALITIES OR DAMAGE TO

EQUIPMENT.

INSTALLATION DANGER: USE ADEQUATE VENTILATION WITHIN THE ATTIC IF YOU PLAN TO

CEMENT PVC JOINTS. PVC CEMENT FUMES CAN BE TOXIC IN THE ATTIC AND CAN LEAD TO

HEALTH PROBLEMS OR INJURY. COMPLETE ALL ATTIC INSTALLATION TASKS IN THE

MORNING WHEN HEAT BUILD UP IS MINIMAL TO PREVENT HEAT STROKE OR OTHER

INJURY. NOTE: A CONTINUOUS LENGTH OF FLEX PVC PIPE CAN BE USED IN THE ATTIC TO

MINIMIZE PVC CEMENTING IN THE CLOSED ATTIC ENVIRONMENT.

INSTALLATION CAUTION: SOME LOCAL BUILDING CODES REQUIRE THAT A SMITTY PAN BE

INSTALLED UNDER ANY ATTIC EQUIPMENT FOR ADDITIONAL PROTECTION FROM ATTIC

EQUIPMENT FAILURE. NOTE: A SMITTY PAN IS AN EXTRA WATER COLLECTION TRAY

PLACED UNDER ATTIC EQUIPMENT THAT IS TAPPED AND CONNECTED TO A HOSE TO

DRAIN EXCESS FLUIDS OUTSIDE.

NOTE: SMITTY PANS CAN USUALLY BE PICKED UP AT LOCAL PLUMBING SUPPLIERS. THEY

CAN ALSO BE BUILT BY ANY SHEET METAL FABRICATOR. A SMITTY PAN INSTALLATION IS

RECOMMENDED AS AN ADDED LAYER OF PROTECTION FOR ANY INSTALLATION WHERE

THERE IS A HIGH DEGREE OF CONCERN FOR MAXIMUM PROTECTION AGAINST POTENTIAL

FAILURE OF ATTIC EQUIPMENT. SMITTY PANS ARE A GOOD CONSTRUCTION PRACTICE.

SERVICE DANGER: UNPLUG THE SOLARATTIC POOL HEATER BEFORE ATTEMPTING ANY

SERVICE! FAILURE TO UNPLUG THE UNIT PRIOR TO ANY SERVICE CAN LEAD TO SERIOUS

INJURY OR DEATH. SERVICE SHOULD NOT BE ATTEMPTED BY AN INEXPERIENCED

TECHNICIAN WITHOUT FIRST READING THIS ENTIRE MANUAL!

- 7 -

SERVICE CAUTION: DO NOT CREATE A SITUATION THAT WOULD ALLOW POOL WATER TO

BE INADVERTENTLY ROUTED TO DISCONNECTED ATTIC PIPES. IF THE SOLARATTIC POOL

HEATER IS DISCONNECTED FROM THE ATTIC PIPES, DISCONNECT THE PUMP AND

REMOVE THE VALVE CONTROLS AND HANDLES DURING SERVICE. OR RECONNECT A

BYPASS PIPE IN PLACE OF THE SOLARATTIC POOL HEATER DURING ITS REMOVAL.

FAILURE TO OBSERVE THIS CAUTION CAN LEAD TO SUBSTANTIAL WATER DAMAGE.

4. Installation

Installation of the SolarAttic Pool Heater involves three basic steps:

A) Locate the SolarAttic Pool Heater in the attic.

B) Connect the SolarAttic Pool Heater to the pool’s support system.

C) Connect the SolarAttic Pool Heater to power or automation equipment.

LOCATE THE POOL HEATER IN THE ATTIC

The PCS4 is the fourth generation SolarAttic Pool Heater. It has been reduced in size and depth to

make installation in the attic easy. While physically reducing the size, SolarAttic has maintained the

60,000 Btu/hour nominal rating of the original PCS1 pool heater. The PCS4 is expected to fit directly

through 95% of all existing attic access panels.

Before physically locating the SolarAttic Pool Heater inside the attic, it is a good idea to install mating

female PVC union fittings to the 2 inch male pipe threads. When mating PVC female fittings to the

copper pipe threads, we recommend using silicone sealant and allowing the joints to properly cure for 24

hours before placing them into use. Do not use Teflon tape!

Locate the pool heater inside the attic. Use the supplied mounting bracket to hang the unit from the

roof truss structure. Some unit flexibility is needed for normal winterization of the system in areas

where the pool is winterized. Once the PCS4 is fully installed, there should be little or no noise or

vibration heard from within the house.

Remember to place the unit in the center 1/3rd of the attic and locate it as high as possible and practical

inside the attic. This completes the first step. The pool heater is now ready to be plumbed and powered.

RETROFIT SUPPORT SYSTEM

Connect the SolarAttic Pool Heater to the pool’s plumbing. The existing pool pump is sufficient to

move water to and from the pool in 99% of all installations.

- 8 -

If you have a PVC support system that needs to be retrofitted, plan on redoing the entire plumbing lay-

out. This should be done on paper first, before you actually start cutting PVC pipe in the support system.

CAUTION: If you are in an area that freezes, it is common to find a gate valve on all lines

going to the swimming pool. These are the pool’s main drain line, the pool’s return line and

the pool’s skimmer line. In some instances, there may be more than just these three lines

[such as two skimmer lines, etc.]. Do not remove these valves! They are needed to winterize

your swimming pool. In some cases, they may have to be removed and later reinstalled.

Plan on connecting the new valves and PCS4 to the valves and pipes leading to the swimming pool.

When it comes to the filter and pump, simply rearrange these as needed, as you reconstruct the pool’s

support system’s plumbing.

Copper pipes and brass valves can be reused. If copper or brass has been used, you will need to mate

these to PVC pipe which is generally done using a metal to rubber “mission” coupling that adapts

directly to the outside dimensions of both pipes involved. Example:

1 1/2 inch copper pipe has a different outside diameter than 1 1/2-inch PVC pipe. The appropriate

union to couple these pipes will have a rubber insert that matches the different size pipes.

The optional bypass valve is 2" PVC and can be reduced down to 1 1/2” by using a “reducing bushing.”

Some PVC valves accept both 1 1/2" and 2" PVC fittings directly. Some accept 2 1/2" pipes. NOTE: Be

sure to read the valve manufacturer’s instructions. Also, it may be easier to use sections of rigid 2” PVC

pipe for installing the valve shipped with the PCS4. This would include using some 2” PVC fittings.

The PCS4 inlet and outlet lines go to the attic. Having the support system located in a convenient spot

for easy attic access is a good strategy. Support systems located far away from the attic can be relocated

closer by extending the pool’s support piping. Extremely long pipe runs may require added horsepower

from the pool’s pump. If your pump is inadequate for the added lift to the attic, it will reduce the flow

of water and result in poorer filtration and may thermally cut itself off from overheating.

As a general rule, a 1 HP pump can handle a 250-foot round trip and up 25-30 feet in terms of vertical

lift. Each pump has a specific pressure and flow curve that can be referenced if needed to ensure your

pump is adequate.

NOTE: Do not upgrade your pump simply because it feels hot! Your pump will feel “too hot” to touch

by hand under normal operating conditions. If you are building a new pool and installing the PCS4 at

the same time, there is no expense associated with retrofitting the support system.

NOTE: Additional specialty plumbing and wiring diagrams are available at www.solarattic.com

The diagram on the next page is the basic plumbing diagram for the SolarAttic Pool Heater. Additional

plumbing diagrams and plumbing options may be found at www.solarattic.com/plumb.htm.

PLUMB THE POOL HEATER AS DESIRED.

- 9 -

PCS-1 ON

PCS-1 OFF

PCS1

Basic Plumbing Diagram

SKIIIMMER

SUCTIIION LIIINE

M

A

II

I

N

D

R

A

II

I

N

RETURN

LIIINES

VOR

Pool Water

Temp Sensor

Check

Valve

IIINTAKE

STRAIIINER

Chemical

Dispenser

PUMP

OUT

BYPASS

PCS4

IN

FIIILTER

- 10 -

POWER THE PCS4

The final step in the installation is supplying power to the SolarAttic Pool Heater. The PCS4 may be

fitted with a power cord that plugs into any standard 120 vac electrical outlet. In the simplest

installation, an outlet is wired to a manual switch and power is turned on as desired. The PCS4,

however, is capable of cooling as well as heating. Operating the system manually will not optimize the

heat for the pool and its resultant cooling for the home. If, for example, the manual system is turned on

when the pool is actually warmer than the attic, the attic will be warmed and the pool will be cooled.

Therefore, automation with the Goldline GL235 or other solar controller is highly recommended.

Following the use of a simple manual on/off switch is the use of an attic temperature switch wired in se-

ries with the PCS4 power and set to power the unit when the attic only reaches a set temperature. This

produces semi-automated operation. However, the heat extraction process will still not be optimized.

To optimize heat extraction requires full automation. This can be achieved with a variety of optional

solar control systems. Wiring diagrams for the Goldline GL235 solar control are illustrated in this man-

ual as an example. The Goldline GL235 is a simple solar control that does not require programming and

is the only solar control supported by SolarAttic’s technical staff.

Page 11 shows the “INTERNAL ELECTRICAL WIRING”. Please note the location of the motor

starting capacitor. If the motor fails to start, it might be a thermal overload or the starting capacitor.

However, failure of the capacitor is rare.

Page 12 shows the “AUTOMATION FLOAT WIRING DIAGRAM” and how to wire the optional

internal float switch in SERIES with the attic (solar) 10K ohm temperature sensor. Note: Place the

attic sensor above the PCS4, out of the air flow and at the apex or peak of the attic. The discharge air

of the PCS4 can cool the temperature sensor down, causing erratic cycling on & off of the unit.

Therefore do not locate the attic sensor where it can be influenced by the discharged cooler airflow of

the PCS4.

Page 13-14 shows the “GOLDLINE GL235 CONTROL and INTERNAL CIRCUIT BOARD” and how

to connect the sensors and plugs inside the GL235 controller. Important Notes: It may be necessary to

remove the top circuit board of the GL235 in order to wire the temperature sensors or to access the

jumper options as shown on the upper right graphic of page 12. Page 13 shows the board installed. Do

not wire 220vac power to the GL235 terminals used for 110vac. It will destroy the GL235.

Page 15 shows the “AUTOMATION WIRING DIAGRAM.” This diagram shows the full automation

wiring using the GL235 or a similar solar pool heater controller. Optional wiring diagrams are available

on SolarAttic’s website and include: 1) How to use an auxiliary relay to slave the pump [or other equip

ment] to the GL235 and ensure that water and air flow in the attic unit are synchronized; 2) How to use

a timer to enforce a minimal amount of filtration time when the sun does not shine. Important Note:

Heat transfer cannot occur unless both air flow and water flow are present at the PCS4 at the same time.

This is usually the problem when a system initially appears not to work. The attic should feel “cooler”

once the PCS4 has operated 20 minutes. If not, water and air are out ofsync.

Note: The additional wiring diagrams and wiring options, including how to slave other equipment like

the pump to the GL235 control may be found at http://www.solarattic.com/wiring.html.

Page 16 shows the “GOLDLINE GL235 WIRING OPTION FOR 220VAC TIMERS.”

Use the above pages and the automation instructions you received with your optional solar controller to

complete the wiring of the SolarAttic Pool Heater PCS4.

YOUR INSTALLATION SHOULD NOW BE COMPLETED.

- 11 -

Internal Electrical Wiring

The internal wiring of the PCS4 is located on the lower right of the front side (facing the

blower outlets.)

Inside on the left of the terminal block is a 5.0 microfarad 440 VAC motor starting capacitor.

If the blower just hums, this motor starting capacitor will have to be replaced. Turn the power

off, remove the electrical cover panel and replace the capacitor. Ensure the new capacitor is

wired as the original was and is as shown. The motor wiring diagram is shown on the inside of

the electrical cover panel. The ETL certification requires that the unit ship without a power

cord due to its location in the attic. Wire the power to the PCS4 in accordance with local

electrical codes.

- 12 -

PCS2

Right Panel on Face of PCS2 Unit

Float Wiring Diagram

An optional float for use with automation

controls can be installed in the PCS4. If

installed and the base pan has excess

condensate or water, the float will rise and

will open the attic 10K attic (solar) sensor

circuit. Solar controls in AUTO will interpret

the open circuit as a cold attic and shut down

the PCS4. An open float also results in a

flashing “check sensor” red light on the

Goldline GL235 solar control. The PCS4

must operate in the AUTO mode of the

GL235 for the internal float to work.

Attic 10K Ohm Thermistor

Temperature Sensor [at peak]. Wire

Nut

Note: When installed, the

two white float wires from

a normally closed micro

switch are wired in series

with the 10k attic or solar

sensor of the solarcontrol.

Caution: The float is only

for use with an attic 10K

thermistor.

Float Sensor's

White Wires

Photo shows float panel opened up with

the optional automation float installed.

Note: the float wires are routed through

the opening on the panel to the front.

NOTE: Not drawn to any scale

22 Gauge cable

from Solar Control

(18/2 recommended. 22/2 is min size)

**See optional float installation instructions**

Solar Sensor Wires

from Solar Control

- 13 -

Goldline GL235 Solar Control

- 14 -

Goldline GL235 Circuit Board

- 15 -

Automation Wiring Diagram - 115 VAC

GL-235 Terminal Wiring

1 - Ground from timer (green)

2 - No connection

3 - 115 vac Hot Side from timer (black)

4 - 115 vac Neutral from timer (white)

5 - 115 vac Hot Side from timer to GL-235 Relay (black)

6 - 115 vac Hot Side from Relay to SolarAtttic Outlet(black)

Neutral directly to SolarAttic Outlet (white)

Ground directly to SolarAttic Outlet (green)

- 16 -

Goldline Wiring Option - 220 VAC

- 17 -

5. Operation

MANUAL INSTALLATION

In this installation, a manual bypass valve is installed after the filter pump and is used in conjunction

with a manual power ON/OFF switch. To turn the pool heater ON, requires that the power be turned ON

and that water be routed to the PCS4 at the same time.

To turn the system OFF, you reverse the process turning the power switch off and the bypass valve to

bypass the pool heater. It is a good idea to limit water flow through the PCS4 to only when it is actually

being used. That is the reason for the bypass valve. It enables you to use the pump for filtration or

cleaning when you do not want to use the SolarAttic pool heater.

NOTE: In this type of installation, the owner decides when the attic is warmer than the pool. Use of a

temperature sensor in the attic can help make this an intelligent decision. Wireless digital thermometers

are relatively inexpensive at Radio Shack stores. Turning the pool heater ON when the pool is warmer

than the attic will warm the attic and cool the pool. This is the opposite of what is usually desired.

SEMI-AUTOMATED INSTALLATION

In this installation, an attic temperature switch is used in conjunction with the SolarAttic Pool Heater to

limit its ON time to only when the attic reaches a certain fixed temperature. One or more timers can be

used to control the pump and/or the attic power. However, the bypass valve must be either manually

turned on or otherwise automated. The exact nature of your semi-automated installation will determine

how you turn the PCS4 (system) ON and OFF.

AUTOMATED INSTALLATION

In both of the above installations, maximum heat extraction is limited by human intervention or semi

automated devices like switches or timers. However, heat extraction can be easily maximized and

automated by way of an optional solar controller like the Goldline GL235. Once installed, operation is

simple and straight forward.

SET the thermostat on the GL235 to its full clockwise location or maximum temperature setting. This

will ensure that maximum heat extraction will occur when the GL235 is in AUTO mode. While the dial

is calibrated in degrees F, there is a notorious difference between what the temperature dial reads and

what the typical pool thermometer at 18 inches of depth reads. Therefore, with the setting at maximum,

use the pool thermometer you have to determine when it is too warm. Simply back down the GL235

temperature setting to a position that “feels” comfortable to you in the pool and disregard the dial setting

itself. Your objective is to have an automatically warmed pool that is comfortable. Without a complex

temperature gauge installation throughout the pool and attic, it becomes a complex engineering task to

determine what the “real” temperature actually is. However, determining what is a very comfortable

temperature to you is an easy task.

To turn ON the SolarAttic PCS4, simply place the GL235 mode switch in either the AUTO or TEST

(ON) position. Note: The GL235 “ON mode” is a manual ON setting that is useful for testing or manual

operation of the system. However, this position does not use the pool and attic temperature sensors or

the internal float protection switch. For full automation and maximum heat extraction, ensure that the

GL235 mode switch is set to its AUTO mode position and the thermostat is set to maximum.

To turn OFF the SolarAttic PCS4, simply place the GL235 mode switch in the OFF position.

- 18 -

6. General Service Notes

The PCS4 is generally maintenance free and requires only occasional inspection to ensure

that everything is working properly. Here are some suggestions:

1. Inspect the PCS4 coil annually during spring startup or fall winterization for any accumulation of

dust or debris from attic environment. Vacuum any accumulated dust off of the coil fins. This is

not normally an issue to be concerned with. However, it is something to be aware of.

2. Any time service is performed inside the PCS4, disconnect power first.

3. If there is trouble with full automation, inspect to ensure proper installation of the optional float.

This is indicated by the float being free to move and being wired in series. If the float switch

was defective [open], the automatic mode of the GL235 will not work. Also, the “check sensor”

red light on the GL235 control panel will be ON and FLASHING. No debris or obstruction of

the float should be present during this examination. The float is accessed by removing one 5/16

hex screw on the right side of the front of the unit. See page 11 for float wiringdetails.

4. Do not lubricate the motor, as it is maintenance free.

5. During startup, listen to the blower and motor. There should be mostly airflow sound associated

with the blower unit. No bearing noise should be apparent. If so, the motor may need to be

changed. Note: This is also a very rare occurrence.

6. Some evidence of a small amount of condensate will be present in the form of a water stain in

the interior of the PCS4 base pan. This is normal.

7. CAUTION: When working on the PCS4 where the inlet and/or outlet union(s) will be

disconnected, ensure that (A) the bypass valve is in the “OFF” position bypassing

the PCS4; (B) the controller is “OFF”; (C) the valve operator ON1 | OFF | ON2

switch is in the OFF position; and, (D) the manual handle for the bypass valve is

removed. These precautions, along with disabling the pool pump, will prevent the

pool water from accidentally being routed up to the attic during service. When

finished, ensure that the VOR is returned to the same ON1 or ON2 position it was

in before you turned it to the OFF position for proper valve operation.

7. Spring Startup

1. Make a visual check of the plumbing for any deterioration or problems.

2. Manually inspect the blower cage for rotation on the motor. With the power off, the assembly

can be seen through the two front air outlets. The squirrel cage should not be loose orwobbly.

3. Check the PVC unions on the PCS4 inlet and outlet. They should be tight. Do not over tighten

as they could crack. Generally, a 1/4 turn past being hand tight should suffice.

4. Perform other pool startup chores and ensure pool chemistry is properly balanced before pump-

ing any water through the PCS4 heat exchanger.

5. Restart system and inspect attic for any sign of plumbing leaks.

6. System is ready to use for the season.

Table of contents

Other SolarAttic Swimming Pool Heater manuals

Popular Swimming Pool Heater manuals by other brands

Heat & Glo

Heat & Glo VRTIKL-AU Installation & operation instructions

Pennant

Pennant PNCP Installation and operation instructions

Holmes

Holmes HFH131 owner's guide

hurlcon

hurlcon HX Series Installation and operating instructions

Aqua Comfort

Aqua Comfort AC110 owner's manual

HydroTherm

HydroTherm 42 installation instructions

Pentair

Pentair 200K BTU/HR Installation and user guide

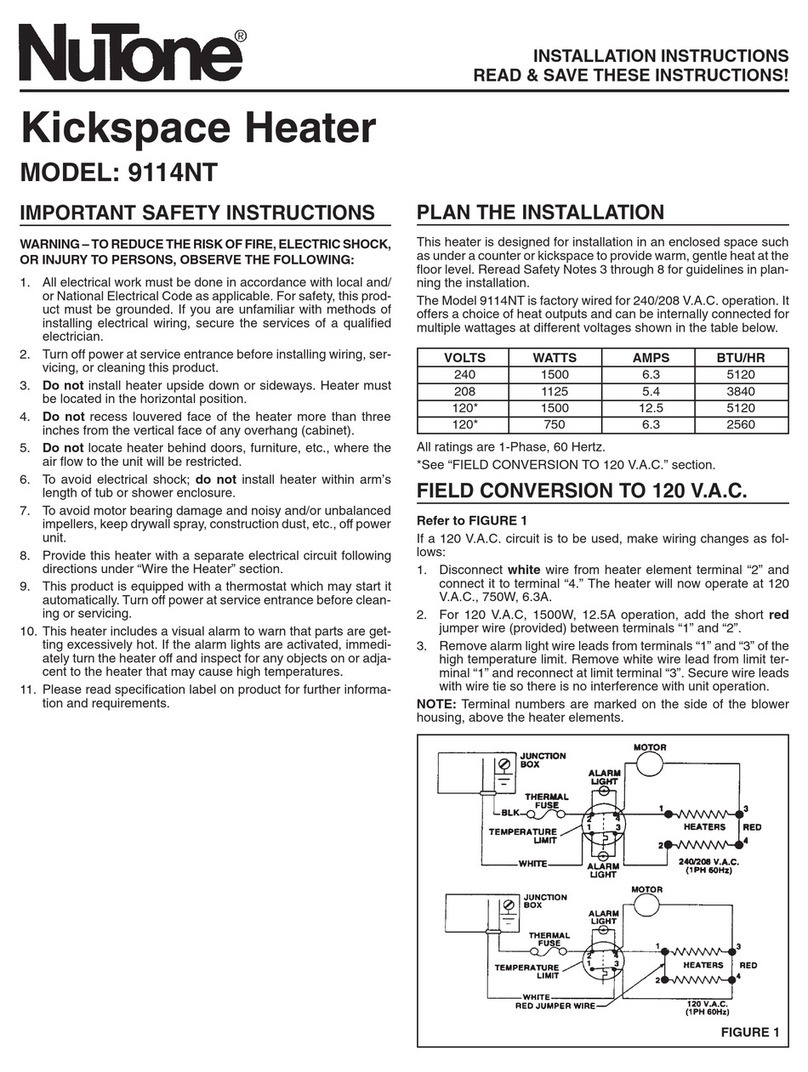

NuTone

NuTone 9114NT installation instructions

Nobel

Nobel PARASOL Installation, maintenance & use instructions

Consolidated

Consolidated K-STAR K-5 instruction manual

Lochinvar

Lochinvar SMART SYSTEM 502 - 2072 Installation & operation manual

Raypak

Raypak 6200.90 Limited warranty