7

4.7.The unit air-conditioning side and the hot water side which connect to running water must be

installed a one-way valve, filter and pressure relief devices (pressure relief devices used on

the closed water tank, water tank accessories in general, the parameter value 0.7MPa), in

accordance with the flow and valve arrow direction, to avoid flow be obstructed.

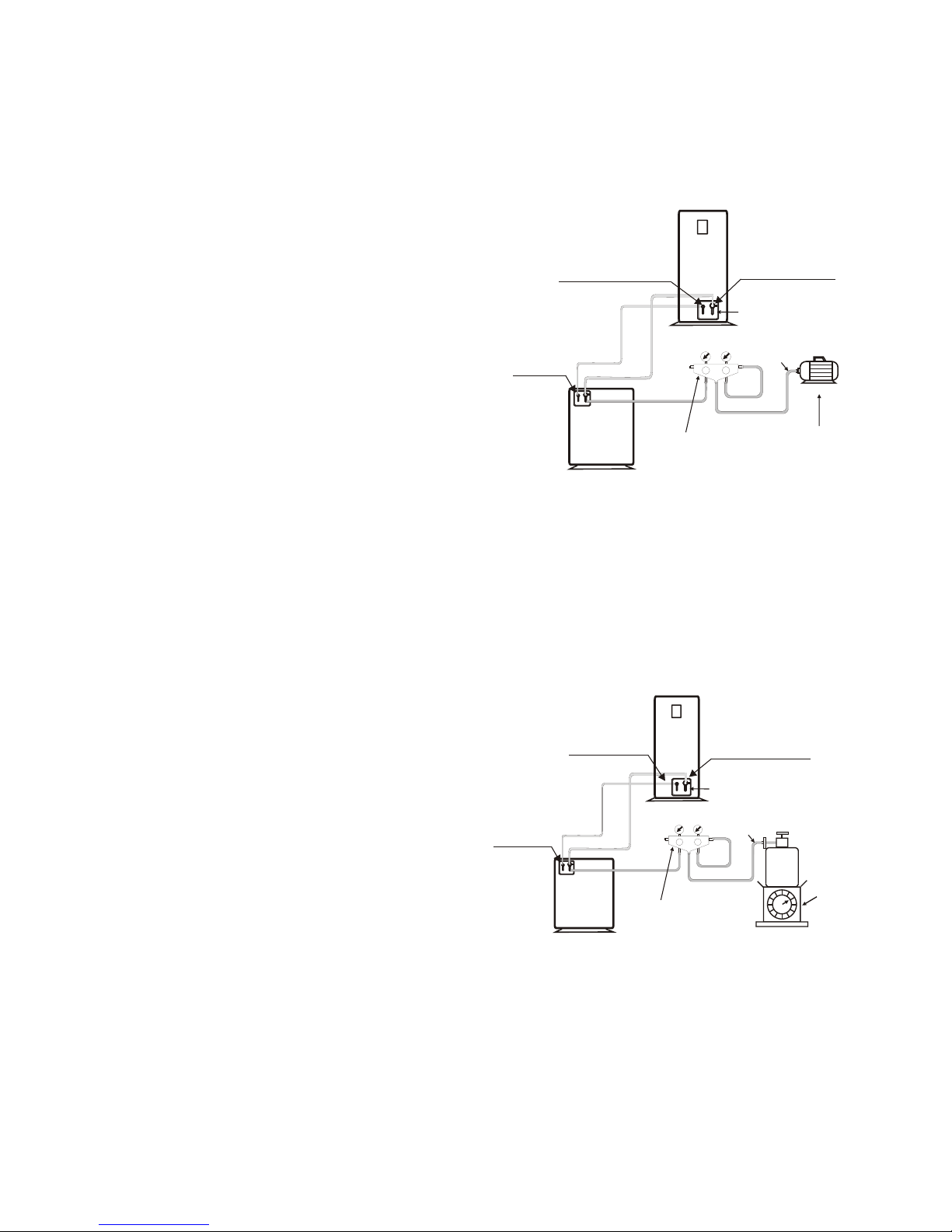

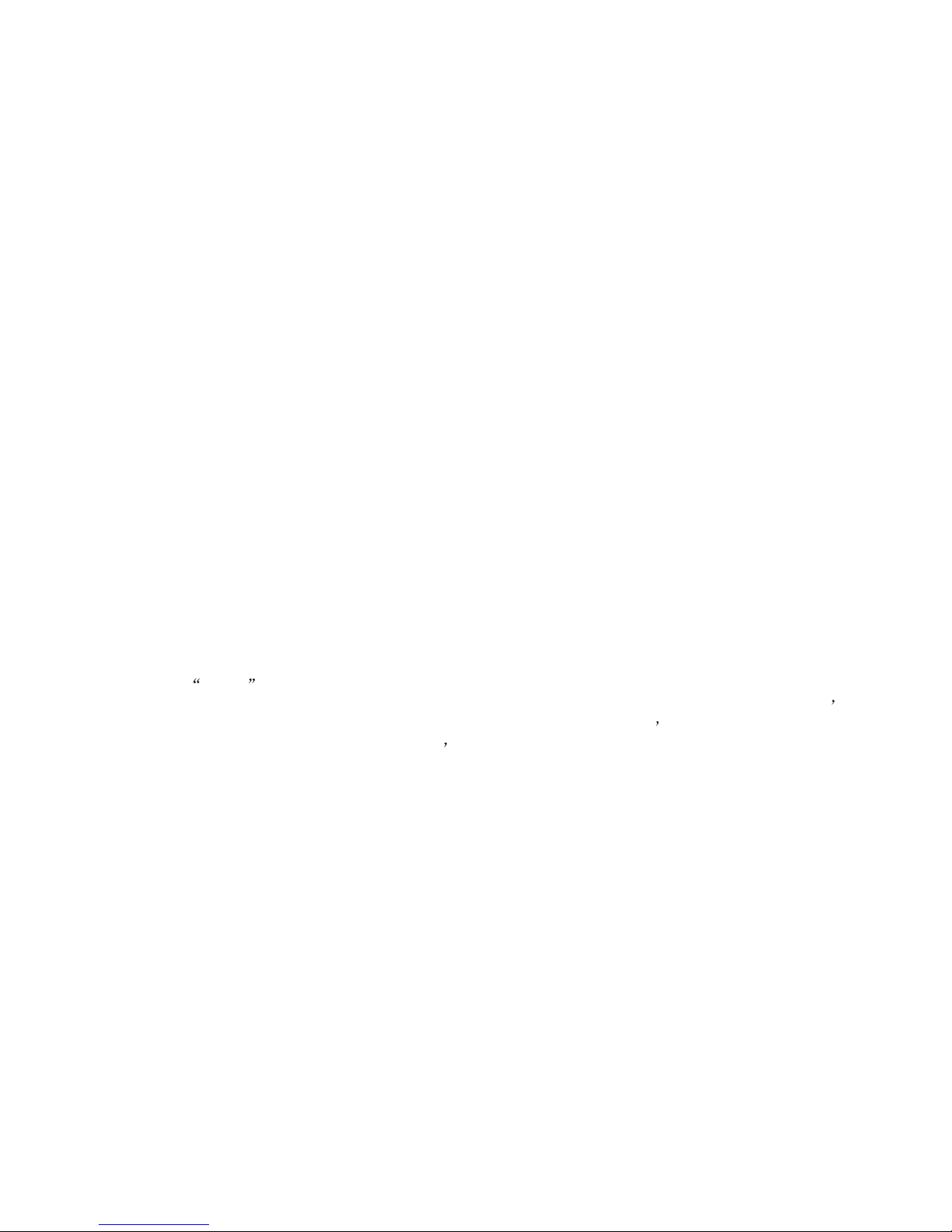

4.8.The unit hot water side circle outlet connect to tank circle inlet, and the host hot water side

circle inlet connect to tank circle outlet,tank hot water supply connect to hot water pipe.

4.9.Air-conditioning side buffer tank in series installed on the outlet of the main pipe.

4.10. After hot water side and air-conditioning side water system pipes, circulated pipes, hot water

supply pipes connected, it must be pipe connection rigorous testing , plus 0.7Mpa pressure

testing 24 hours, system pipes connector no leakage and clean and sewage pipes, to ensure

that the system clean, no debris. No leakage after the test, then pack the pipe and valve with

insulation (including the replenishment pipes and valves).

4.11.In order to discharge the water system air clean, avoid air trapping in the pipeline, the water

supply return pipe highest point should be set up a automatically exhaust valve.

4.12.The water system expansion tank, automatic water valve and stop valve should be installed

indoors, to prevent water pipes and valves crack when not use in the winter.

4.13.The metal pipe must be used above 50mm thickness of glass fiber or high-density fire

retardant PE for thermal insulation and moisture, PPR water pipe can be used 30mm

thickness of glass fiber or high-density fire retardant PE for thermal insulation and moisture to

prevent cold, heat loss and condensation.

4.14.The unit water inlet and outlet must install a thermometer, water pressure gage, to facilitate

inspection when operate.

3. Installation of terminal equipment

3.1.Indoor terminal equipment installation (such as: fan coil, radiator heater or floor heating), the

equipment should be installed in accordance with relevant regulatory requirements.

3.2.In accordance with the requirements of engineering design drawings, installation and

construction.

3.3.Use a soft connector to connect the unit and fan coil inlet and outlet pipes; install fan coil

condensate drain pipe, connect the condensate drain interface, and to ensure smooth drainage

of condensate water.

4. Pipe connection

4.1.Pipe material selection, can be stainless steel pipe, copper pipe, aluminum water pipe, hot

water PPR pipes and so on, according with national health and safety standards, heat-

resistant, rust-proof, no scaling pipe.

4.2.The choice of pipe sizes can be used the one which is matches the heat pump inlet and outlet

main pipe, and, respectively connect to heat pump inlet and outlet, and follow the proper

construction of plumbing standards.

4.3.Water tank outlet pipe and overflow pipe installed in the gutter or outlet position as far as

possible, where convenient to drainage.

4.4.The unit and the junction to the tank must be installed valve or demolition loose joint, for

maintenance use.

4.5.Water pipes are arranged reasonably to minimize bending and reduce the pressure loss of

water system

4.6.The unit air-conditioning side and the hot water side circle inlet must be installed a above 50

mesh water filter to reduce the water system resistance loss.